Method for directly treating high temperature and high turbidity PVC mother liquor by using biologic filter

The technology of biological filter and aerated biological filter is applied in the field of direct treatment of aerated biological filter of high temperature and high turbidity PVC mother liquor, which can solve the problems that have not yet been found, and achieves easy operation, large specific surface area and adhesion. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described with reference to the drawings and embodiments.

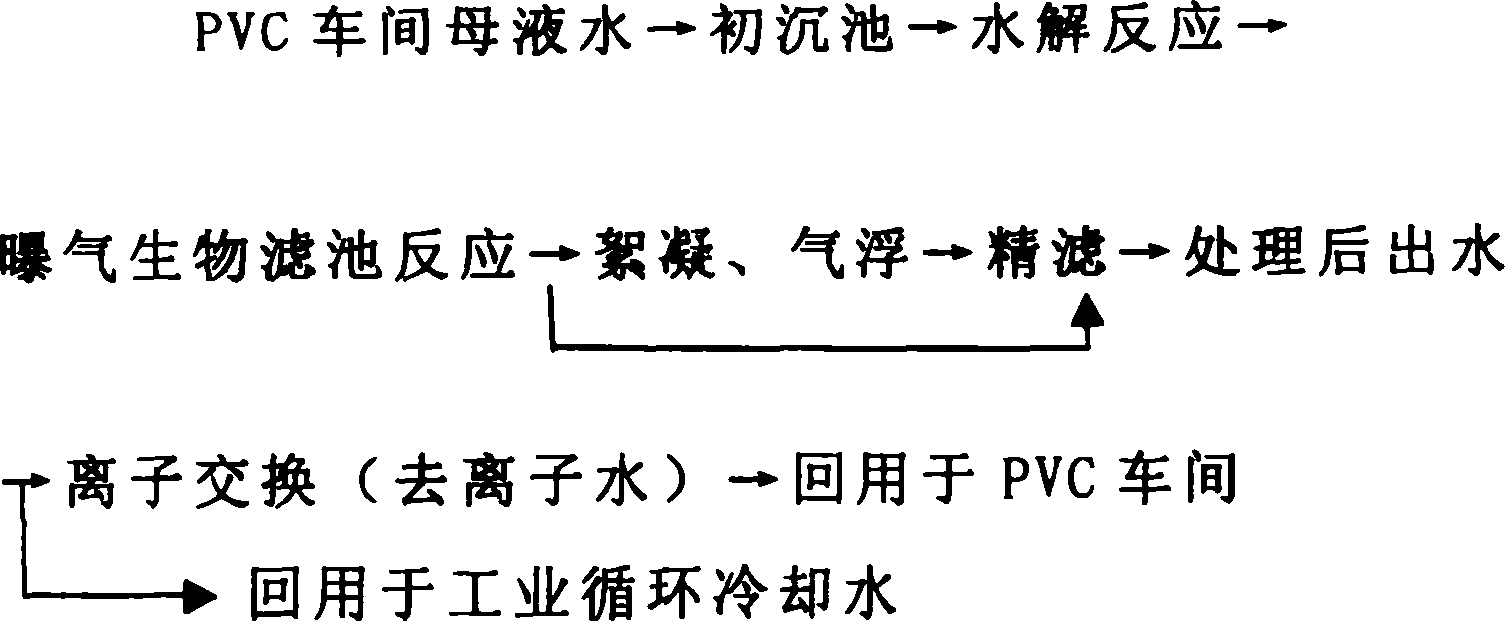

[0018] As shown in Figure 1, the technical difficulty of the method for directly treating high-temperature and high-turbidity PVC mother liquor water by the biological filter of the present invention is to solve the problem of removing extremely fine PVC particles (membrane investment is large, and the operating cost is high), repeated recycling and solution Remove various soluble impurities that affect the degree of polymerization. The industrial wastewater discharged from the production of polyvinyl chloride by the suspension method contains high-turbidity PVC particles and polyvinyl alcohol as the main component of the dispersant, as well as various additives, initiators, dispersants, chain transfer agents, matting agents, and defoamers. agent, heat stabilizer, terminator, coating liquid and acetylene high boiler, etc., a total of more than fifteen kinds of substances, the water temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com