Ink-jet recording head

An inkjet recording and discharge port technology, applied in printing and other directions, can solve the problems of increased fluid resistance at the discharge port, reduced ink droplet ejection speed, ink droplet ejection characteristics and image quality effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

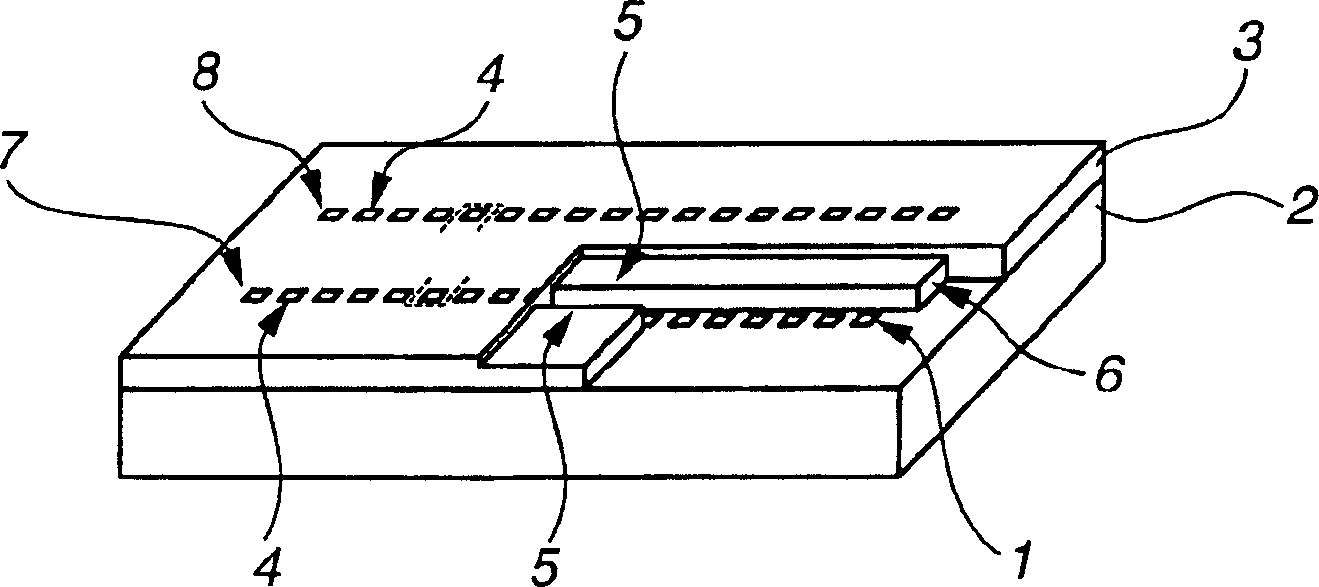

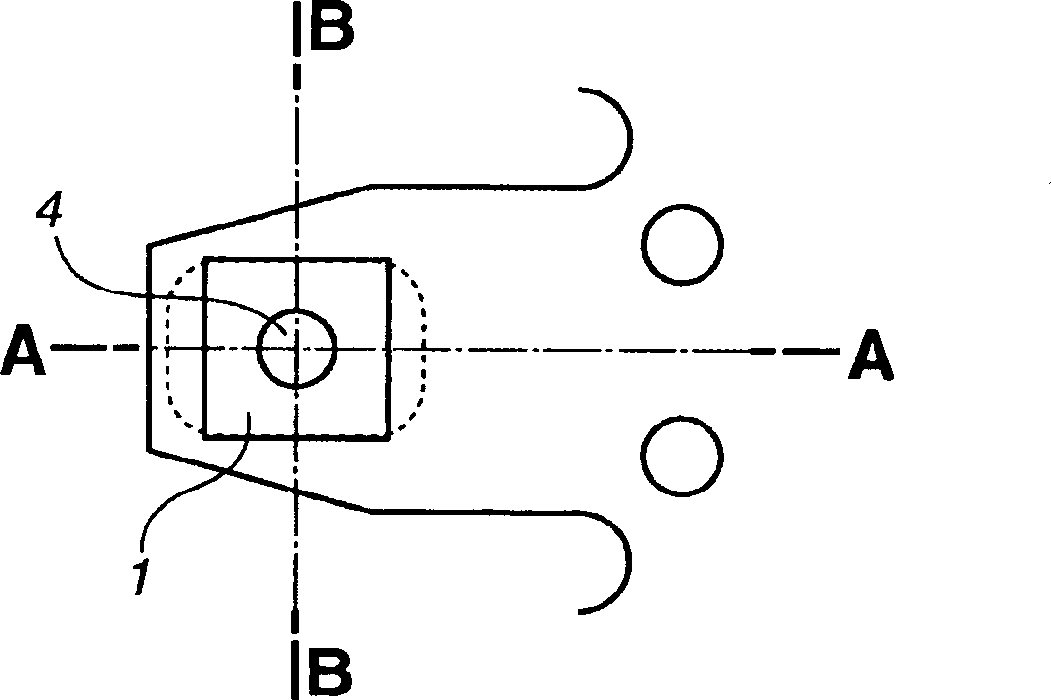

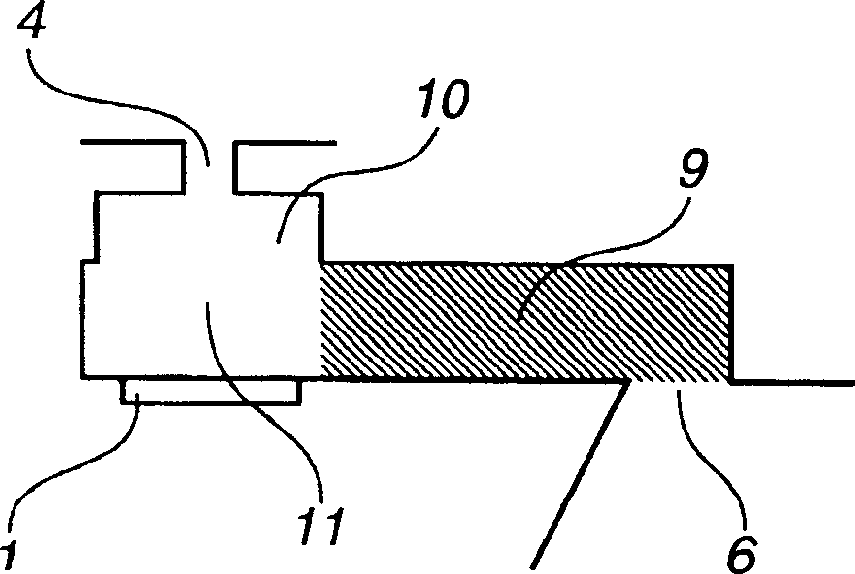

[0041] Figures 2A-2C The structure of the nozzles of the ink jet recording head according to the first embodiment of the present invention is shown. Figure 2A It is a plan perspective view in which, when viewed from a direction perpendicular to the main surface of the element substrate 2 (that is, the surface at the groove-shaped substrate to which the element substrate 2 is attached), a plurality of inkjet recording heads can be seen. one of the nozzles; Figure 2B for along Figure 2A The sectional view made by the section line A-A in ; Figure 2C for along Figure 2A Sectional view taken along section line B-B in .

[0042] like figure 1 As shown, the recording head having the nozzle structure described in the first embodiment includes an element substrate 2, on which a plurality of heaters 1 and a groove substrate 3 are arranged, wherein each heater is used as an electrothermal transducer device, and the groove-shaped substrate constitutes a plurality of ink channe...

no. 2 example

[0052] In the second embodiment of the present invention, a nozzle having a structure in which the second discharge port portion is tapered in order to reduce stagnation of ink at the second discharge port portion is employed. The following will refer to Figures 3A-3C Parts different from the first embodiment will be mainly described.

[0053] Figures 3A-3C The nozzle structure of the inkjet recording head according to the second embodiment is shown. Figure 3A is a plan perspective view in which one of the plurality of nozzles of the inkjet recording head can be seen from a direction perpendicular to the main surface of the element substrate 2; Figure 3B for along Figure 3A Sectional view of section line A-A in; Figure 3C for along Figure 3A Sectional view of the middle section line B-B.

[0054] like Figures 3A to 3C As shown, as in the first embodiment, in the second embodiment of the ink jet recording head, the second discharge port portion 10 is provided wit...

no. 3 example

[0057] The object of the third embodiment of the present invention is to reduce the stagnation area of the ink to reduce the variation of the discharge volume. In the second embodiment, the cross-section of the second discharge port portion is substantially rectangular. In this third embodiment, however, the cross-section of the second discharge port portion is elliptical.

[0058] The following will refer to Figures 4A to 4C , mainly explaining the parts of the third embodiment that are different from the first embodiment.

[0059] Figures 4A-4C The nozzle structure of the inkjet recording head according to the third embodiment is shown. Figure 4A is a plan perspective view in which one of the plurality of nozzles of the inkjet recording head can be seen from a direction perpendicular to the main surface of the element substrate 2; Figure 4B for along Figure 4A Sectional view of section line A-A in; Figure 4C for along Figure 4A Sectional view of the middle se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com