Integral rail

An integral track technology, applied in tracks, roads, buildings, etc., can solve problems such as long construction period, insufficient serialization and standardization of track components, unfavorable mechanized production and automatic laying, etc., to achieve shortened construction period, replacement and maintenance Convenience and the effect of reducing the weight of the base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

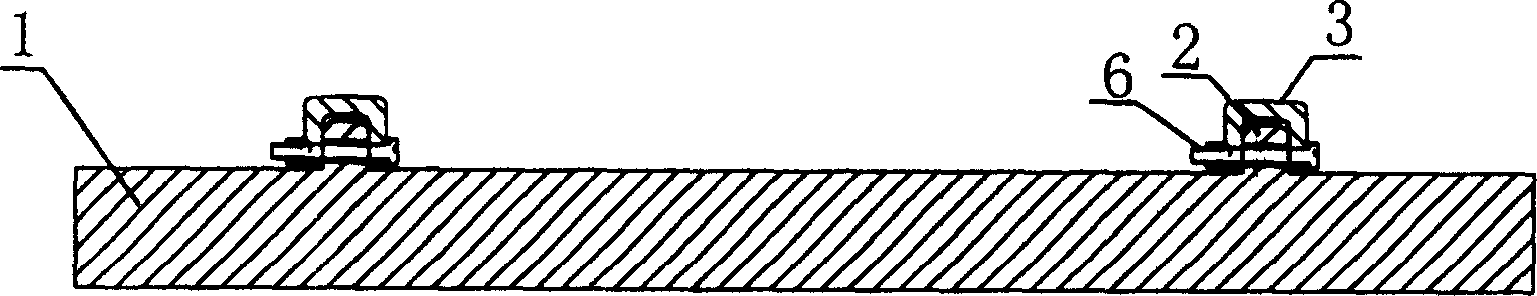

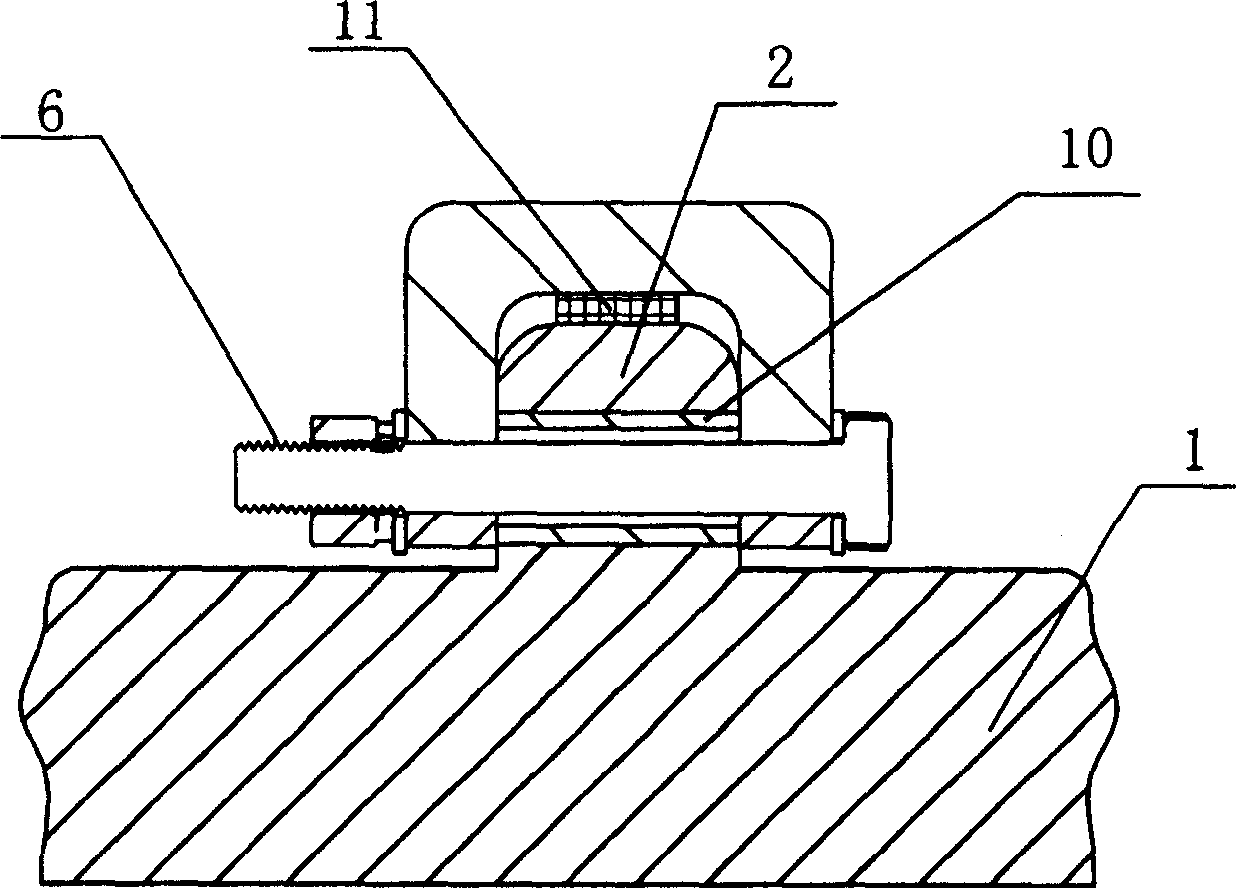

[0018] Figure 1-Figure 2 It is shown that a specific embodiment of the present invention is: an integral track, the base 1 is a long strip integral structure, the upper part of the base 1 is symmetrically distributed with two protrusions 2 along the length direction, and the protrusions 2 The upper part is installed and covered with an inverted concave hat rail 3 adapted to form a railway track.

[0019] figure 1 It is shown that one end of the base 1 has an outward protrusion 7 , and the other end has a groove 8 matching the protrusion 7 . A plurality of drainage holes 9 are opened between the two protrusions 2 on the base 1 . Figure 1-3 As shown, the middle or lower part of the protrusion 2 is provided with a plurality of lateral mounting holes, and the cap rail 3 has a cap rail hole corresponding to the position of the mounting hole, and the bolt assembly 6 passes through the mounting hole and the cap rail hole to connect the cap rail 3 and the base 1 are installed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com