Comprehensive treating method for industrial waste water and sludge using coke powder

A technology for comprehensive treatment of industrial wastewater, applied in water/sludge/sewage treatment, sludge treatment, water/sewage treatment, etc. Only input and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

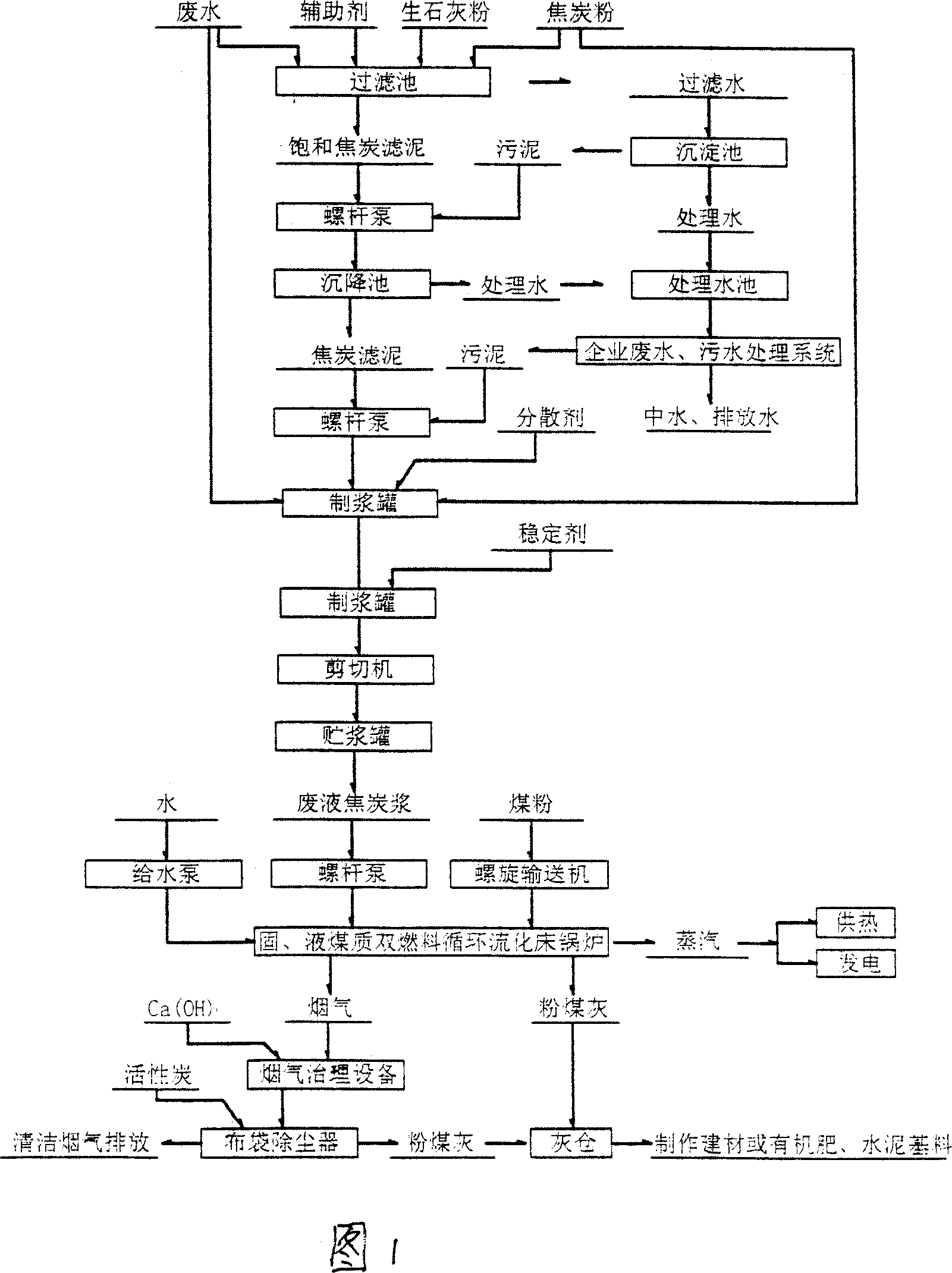

Image

Examples

Embodiment 1

[0043] Coke powder is used to treat industrial wastewater to generate coke filter sludge, and the coke filter sludge and coke powder are combined to make waste liquid coke slurry. The wastewater composition of a paper mill is: COD value 3,000mg / L, suspended solids: 800mg / L, chroma 430 times. Add coke powder with a particle size of 0.2-1mm and no less than 40% of >0.5mm in the filter tank as filter and adsorption materials. The thickness of the material bed is 0.5-2m, the filtration speed is 0.16-0.4m / min, and the contact time is 10 -20min. When the wastewater flows through the coke powder in the filter tank, it removes the suspended solids and colloidal substances in the wastewater, absorbs organic matter and harmful microorganisms, and plays the role of deodorization and decolorization. The coke powder in the filter tank becomes saturated coke filter sludge after a period of use, and the saturated coke filter sludge in the filter tank is discharged regularly and transported ...

Embodiment 2

[0052] The waste liquid coke slurry is prepared by combining the concentrated waste water from the paper mill-cooking liquid with coke powder. A small test is required before each batch of pulp is made. The particle size of coke powder is as mentioned above. When pulping, add 30% cooking liquid and 70% coke powder to the pulping tank, and then add 0.3-0.6% of the pulping amount to disperse agent, start the agitator on the top of the pulping tank, the agitation time is 30-40min, and the agitation intensity is 90-98r / min. Then add 0.3-0.8% stabilizer with slurrying amount to carry out stirring and ripening, the stirring intensity is 90-98r / min, and the stirring time after adding the stabilizer shall not exceed 40min. After being sheared by a high-speed shearing machine, it is transported to a storage tank for storage. The waste liquid coke slurry in the storage tank needs to be stirred for 20 minutes every 4 hours according to the situation, and at least every 12 hours should b...

Embodiment 3

[0055] The sludge produced in the process of industrial wastewater treatment is combined with coke powder to make waste liquid coke slurry. Sludge, coke powder, dispersant, and stabilizer are added in proportion to the slurry tank and mixed to make boiler fuel-waste liquid coke slurry. Before pulping, the sludge should be tested to check the moisture content and composition, and a small test should be carried out before each batch of pulp is made. According to the moisture content of the sludge during pulping, sludge and coke fine powder are added to the slurry tank according to the following ratio:

[0056] Sludge moisture content

40%

45%

50%

55%

60%

65%

70%

75%

80%

Sludge ratio

75%

67%

60%

55%

50%

46%

43%

40%

38%

Ratio of coke powder

25%

33%

40%

45%

50%

44%

57%

60%

6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com