Optical sensor and high-frequency laminating module

An optical sensor, high-frequency technology, used in lasers, optical recording heads, laser parts, etc., can solve the problems of complex optical sensor configuration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

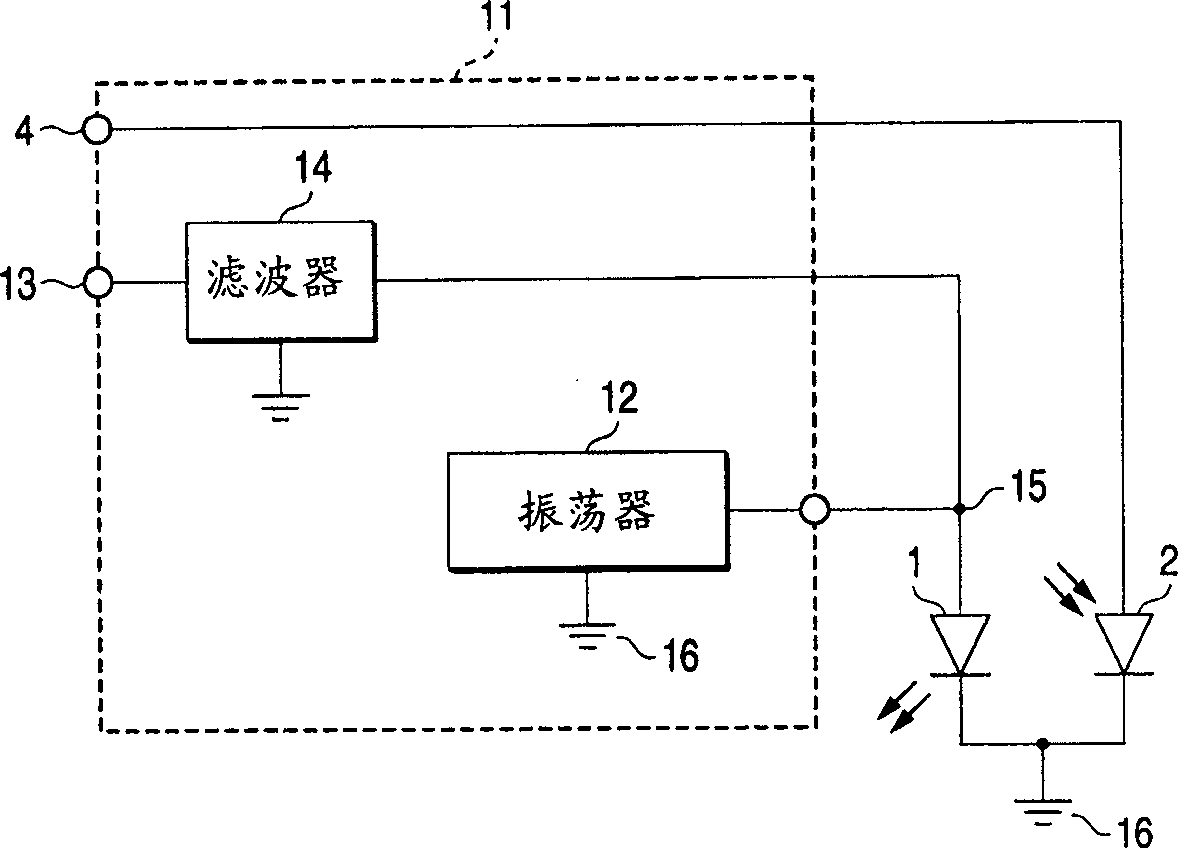

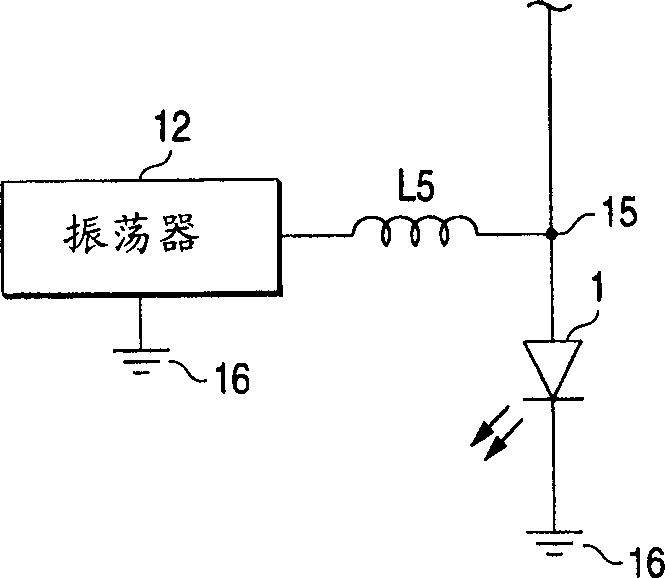

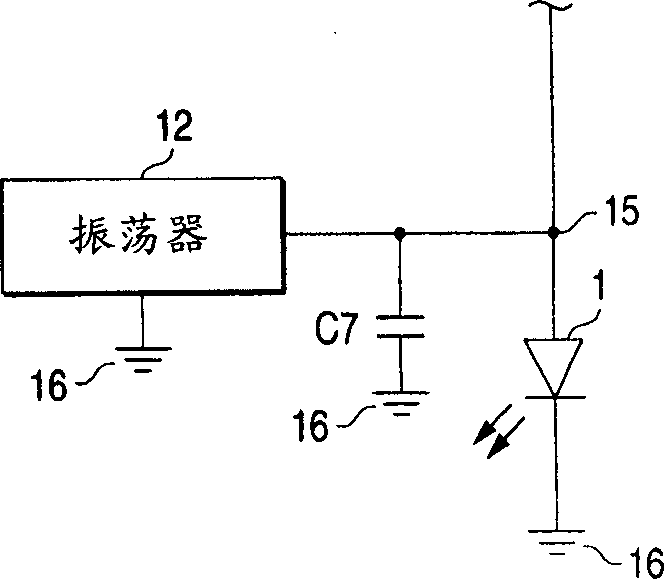

[0028] Figure 1A is a block diagram of an embodiment of a high frequency superposition module for an optical sensor according to the present invention. figure 2 yes Figure 1A circuit diagram. exist Figure 1A and figure 2 Among them, number 1 represents the laser diode used in the optical sensor, number 2 represents the photodetector diode, and number 11 represents the high-frequency superposition module. The number 4 represents the power supply terminal for the photodetector diode, the number 12 represents the oscillation circuit, the number 13 represents the power supply terminal for feeding direct current to the laser diode 1 and the power supply to the oscillation circuit 12, and the number 14 represents the power supply terminal used to prevent the oscillation circuit from 12 The high frequency generated is fed to the filter of the power supply.

[0029] The oscillation circuit 12 is connected between the junction 15 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com