Stationary seat for fixing upper lid of rotary drum washing machine

A technology for fixing the drum and the fixing seat, which is applied in the field of washing machines, can solve the problems of long assembly time and achieve the effect of improving the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

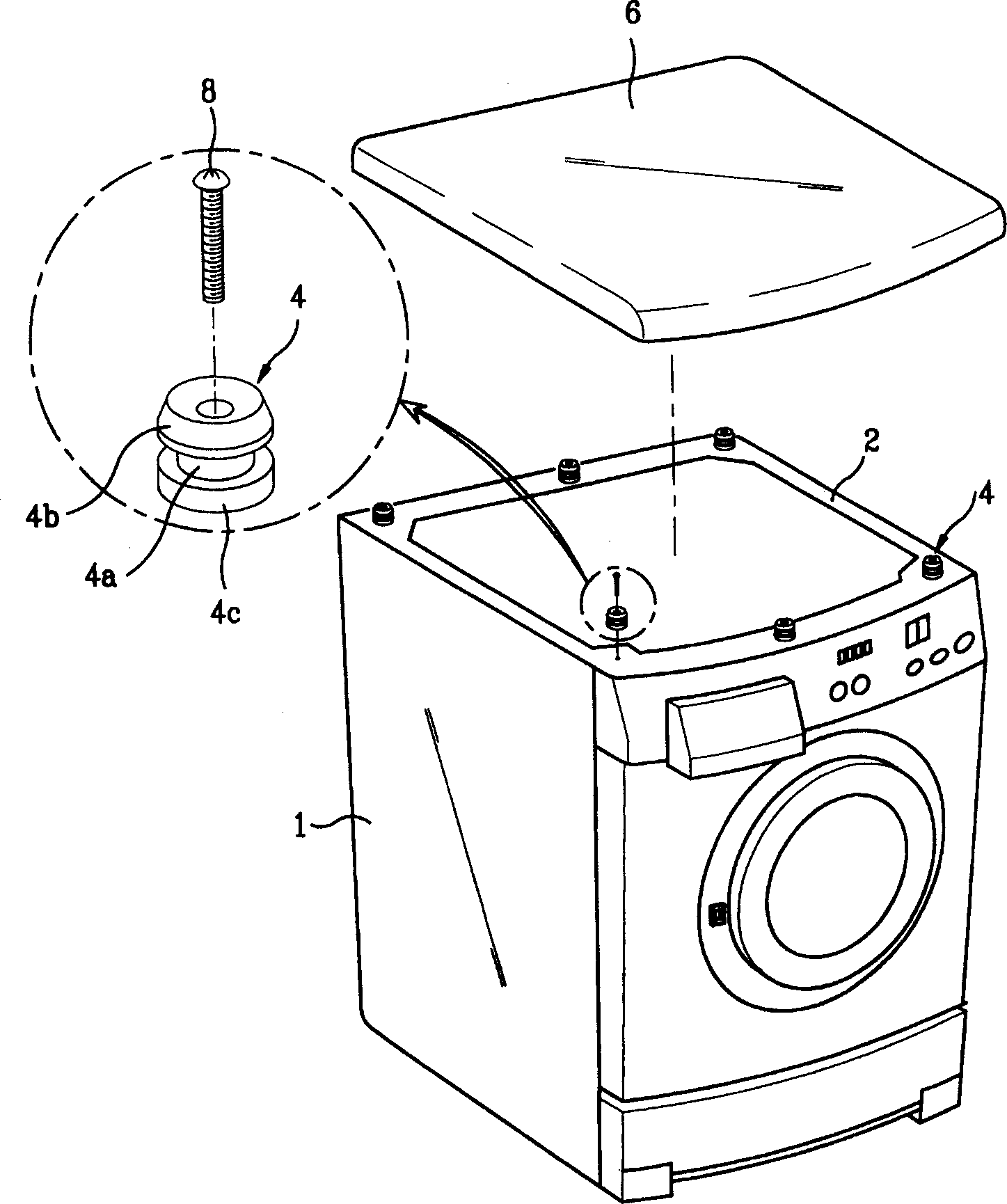

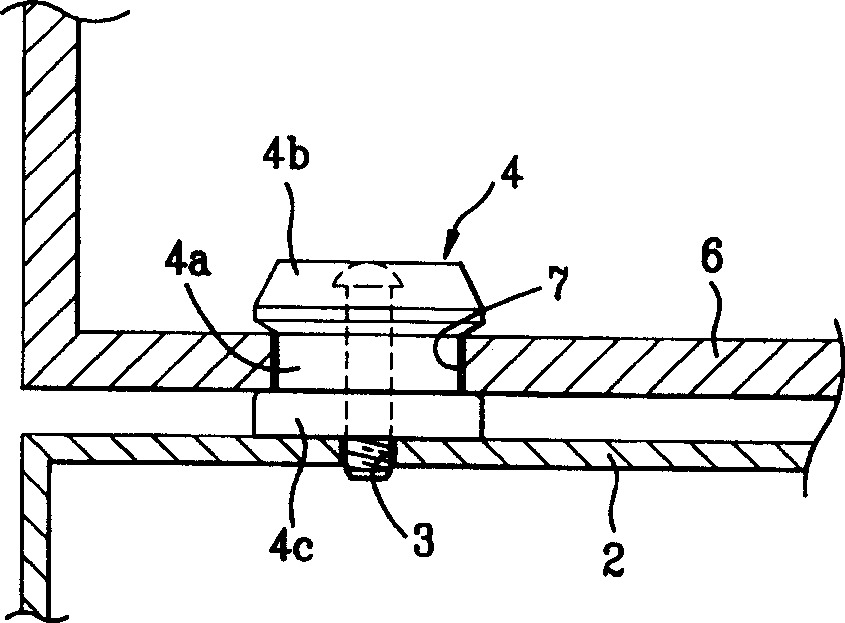

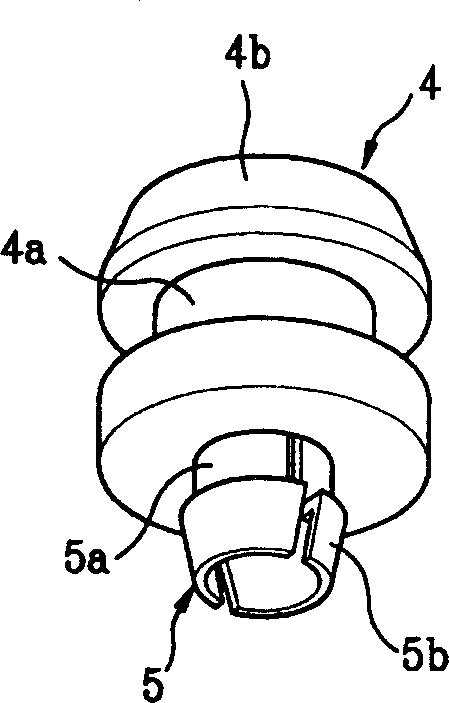

[0026] Refer to the following image 3 and Figure 4 The fixing structure of the upper cover (6) of the present invention will be described.

[0027] image 3 For showing the side view of the structure of the fixing seat of the present invention, Figure 4 It is a cross-sectional view showing the connection state of the fixing seat for fixing the upper bracket and the upper cover of the present invention.

[0028] Such as Figure 4 As shown, the upper cover fixing structure of the present invention is a hook-shaped card (5) that is fixed by several fixing holes (3) that are inserted into the upper bracket (2) and is fixed at the upper end of the hook-shaped card (5). Form the fixed seat (4) of the connecting groove (4a) of depression, correspond to above-mentioned each fixed seat (4), there is the loam cake (6) composition of the coupling groove (7) that can make fixed seat snap in below.

[0029] From image 3 and Figure 4 It can be seen from the figure that the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com