Method for quick degrading pollutant in water

A rapid degradation and pollutant technology, applied in chemical instruments and methods, oxidized water/sewage treatment, chemical/physical processes, etc., can solve the problems of limited reaction speed, low catalytic performance, and limited effective working area of photocatalytic materials, etc. To achieve the effect of fast degradation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

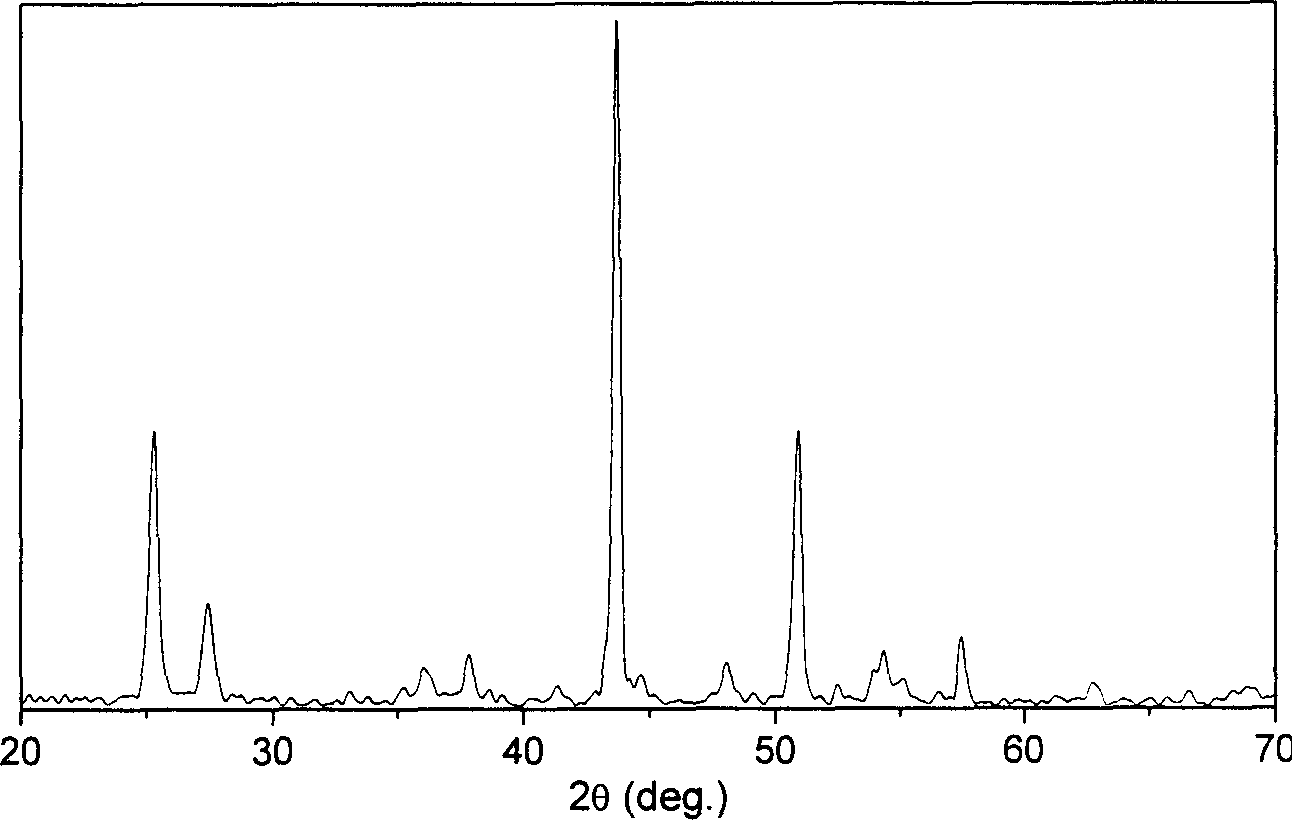

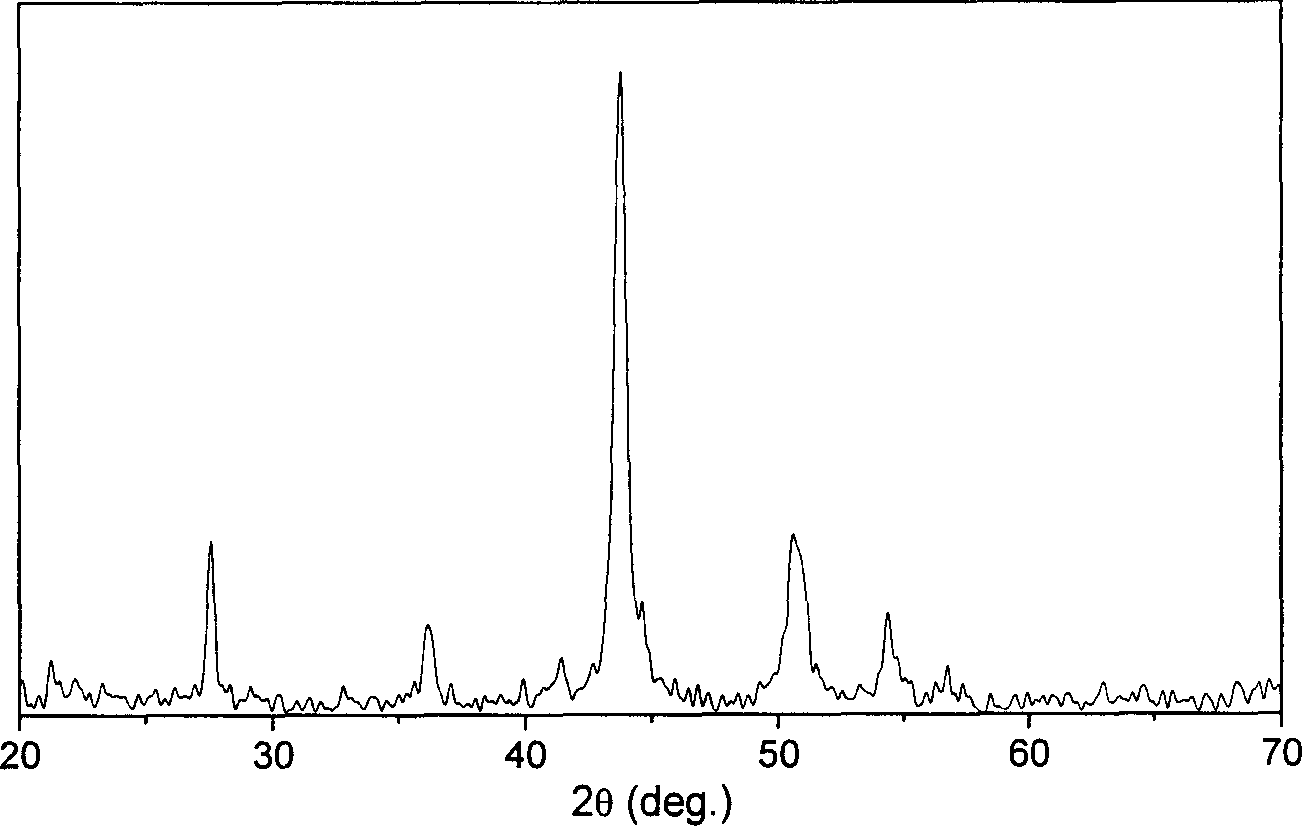

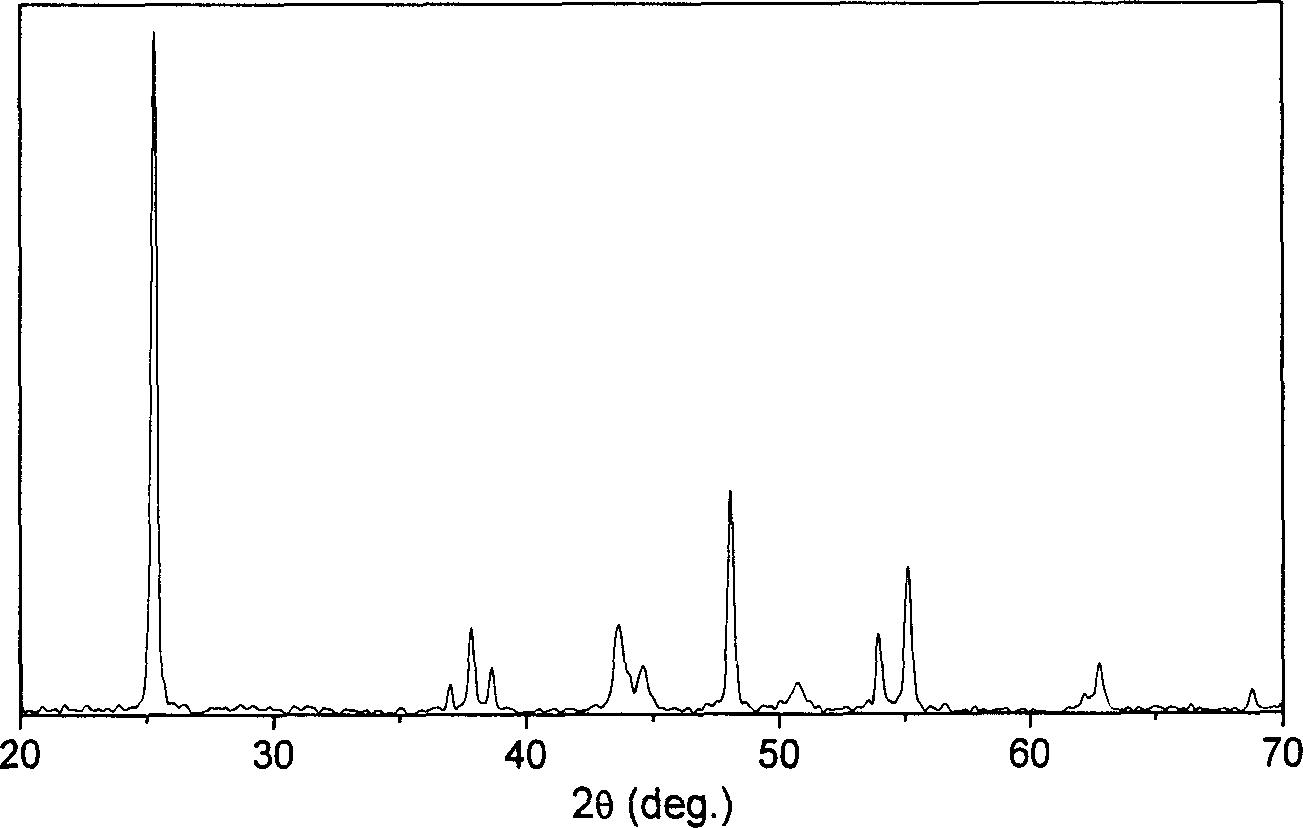

[0033] Example 1: see figure 1 , 2 , 3, 4, 5. figure 1 , 2 , 3, 4, and 5 are the X-ray diffraction patterns of titanium oxide prepared by different methods in the present invention. It can be seen from the figure that the coating is mainly composed of anatase phase and rutile phase. According to the spraying method The content of anatase phase is different. According to the implementation of the present invention, such as figure 1 The content of the titanium oxide anatase phase of the liquid thermal spraying shown can be varied within the range of 0-100%; figure 2 , 3 The titanium oxide prepared by cold spraying can basically maintain the crystal structure of the original powder; cold spraying is also regarded as the newly developed thermal spraying technology, which is considered to be one of the latest developments in thermal spraying technology; Figure 4 , 5 In the titanium oxide prepared by supersonic flame spraying and plasma spraying, the adjustability of the anatase ph...

Example Embodiment

[0034] Example 2: see Figure 6 , 7 ,8. Figure 6 , 7 And 8 are respectively the surface morphology of the titanium oxide coating prepared in the practice of the present invention. A titanium oxide coating prepared by cold spraying with rutile titanium oxide powder, the titanium oxide particles are fixed on the substrate in an embedded form to form the coating of the present invention, such as Figure 6 The part with sharp edges and corners represented by the similar sign "1" is titanium oxide, and the part represented by the sign "2" with similar appearance is the matrix. Such as Figure 7 The surface morphology of the titanium oxide coating prepared by liquid spraying shows the morphology of agglomeration and accumulation. XRD and TEM confirm that the coating is a nanostructured coating formed by the accumulation of nanoparticles. Such as Figure 8 The titanium oxide coating prepared by supersonic flame spraying of anatase-type titanium oxide powder shown has a relatively large ...

Example Embodiment

[0035]Example 3: See Picture 9 . Picture 9 According to the idea of the present invention, several titanium oxide coatings prepared by the present invention are combined with hydrogen peroxide to degrade the performance of phenol in water under the condition of no light. The test condition is room temperature, the titanium oxide used is titanium oxide coating, the surface area is 25cm 2 (Note: Considering the actual total surface area of the coating surface roughness is 2 to 5 times this value), the phenol concentration is 50ppm, the volume is 100ml, and the hydrogen peroxide concentration when liquid spraying, cold spraying, and plasma spraying of titanium oxide coating are used is Respectively 100, 50 and 25ppm, which means that the relative molar ratio of hydrogen peroxide oxidant to phenol is 6:1 to 1.5:1, and the solution is stirred and oxygenated by airing 100ml / min. It can be found from the figure that without a coating, phenol does not degrade, and various coatings c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap