Resistive primer coating for cathode-ray tube

A cathode ray tube and resistive technology, applied in the field of display devices, can solve problems such as poor bonding strength and high resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

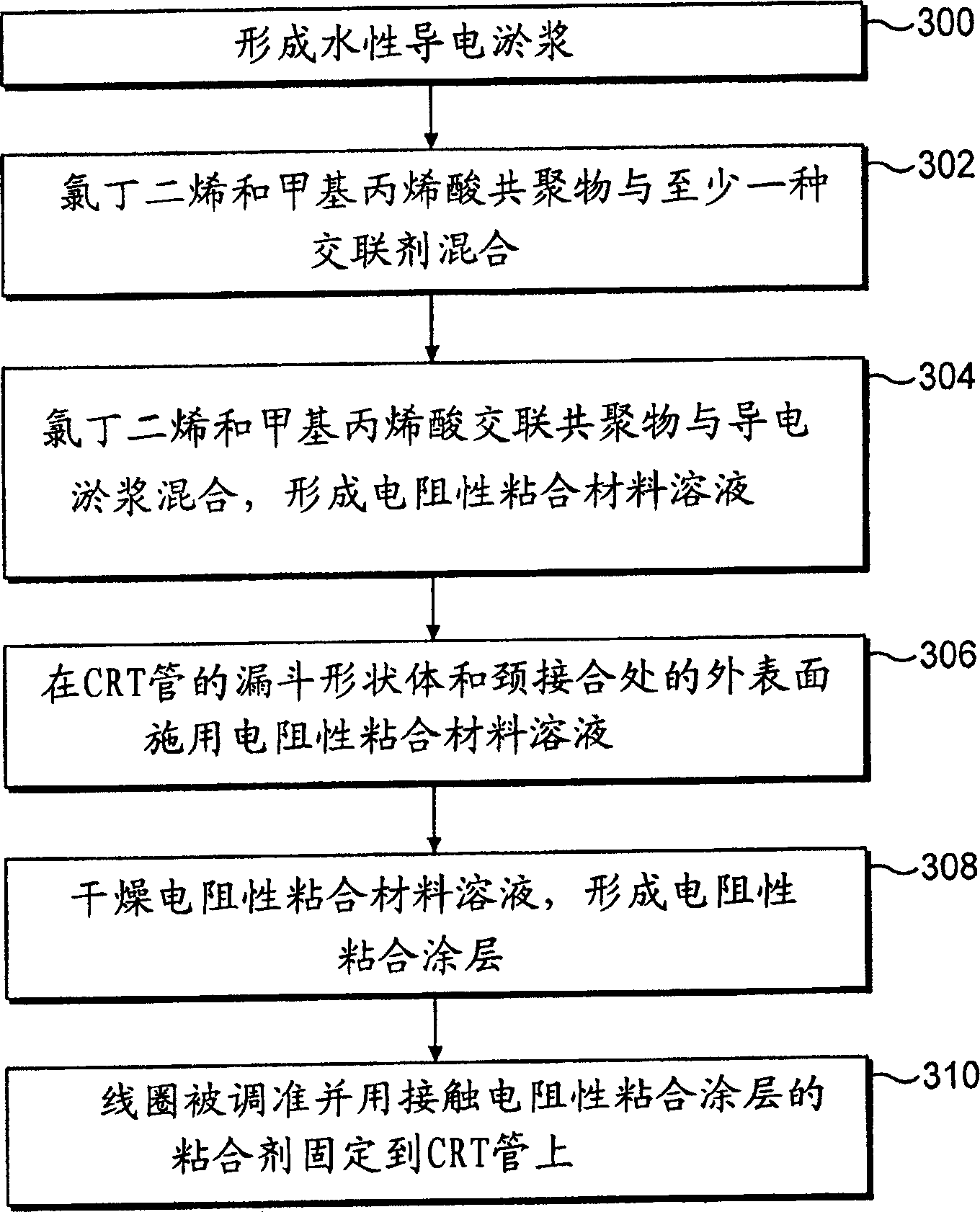

Method used

Image

Examples

Embodiment 1

[0034] The tensile strength of the hot melt adhesive of the present invention for resistive primers was compared with conventional resistive coatings comprising polychloroprene. From 3300 grams of Panel Master 40-803A (polychloroprene) (commercially available from National Starch and Chemical Co. Rothschild's Borregaard LignoTech USA), 710 grams of Vulcan XC-72R carbon (commercially available from Cabot Corporation, Boston, MA) and 2600 grams of deionized water heated to a temperature range of about 50°C to about 60°C A conventional polychloroprene resistive coating was prepared.

[0035] 30 grams of 1E in 300 grams of deionized water were used consisting of 3300 grams of NEOPRENE 115 (commercially available from DuPont Company of Wilmington, Delaware), 255 grams of 1D-229 zinc oxide dispersion (commercially available from R.T. Vanderbilt Company of Norwalk, Connecticut), -1233 butyl zimate powder (commercially available from Norwalk, the R.T.Vanderbilt company of Connecticut...

Embodiment 2

[0038] The resistive primers of the present invention were compared to the resistance of conventional resistive primers containing polychloroprene as a function of cure temperature. A conventional polychloroprene resistive coating consists of 3300 grams of PanelMaster 40-803A (polychloroprene) (commercially available from Bridgewater, NJ's National Starch and Chemical Company), 500 grams of conductive carbon mud (110 grams of MARASPERSE CBOS- 4, commercially available from Rothschild, Wisconsin's Borregaard Ligno Tech USA), 710 grams of Vulcan XC-72R carbon (commercially available from the Cabot Corporation of Boston, Massachusetts) and 2600 grams of carbon heated to a temperature range of about 50°C to about 60°C. Preparation of formulations blended with deionized water.

[0039] The resistive primer of the present invention is to use 3300 grams of NEOPRENE 115 (commercially available from Wilmington, the DuPont company of Delaware, 255 grams of 1D-229 zinc oxide dispersion (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com