Cope holder device

A clamping device, the technology of the upper type, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problem of the upper type falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

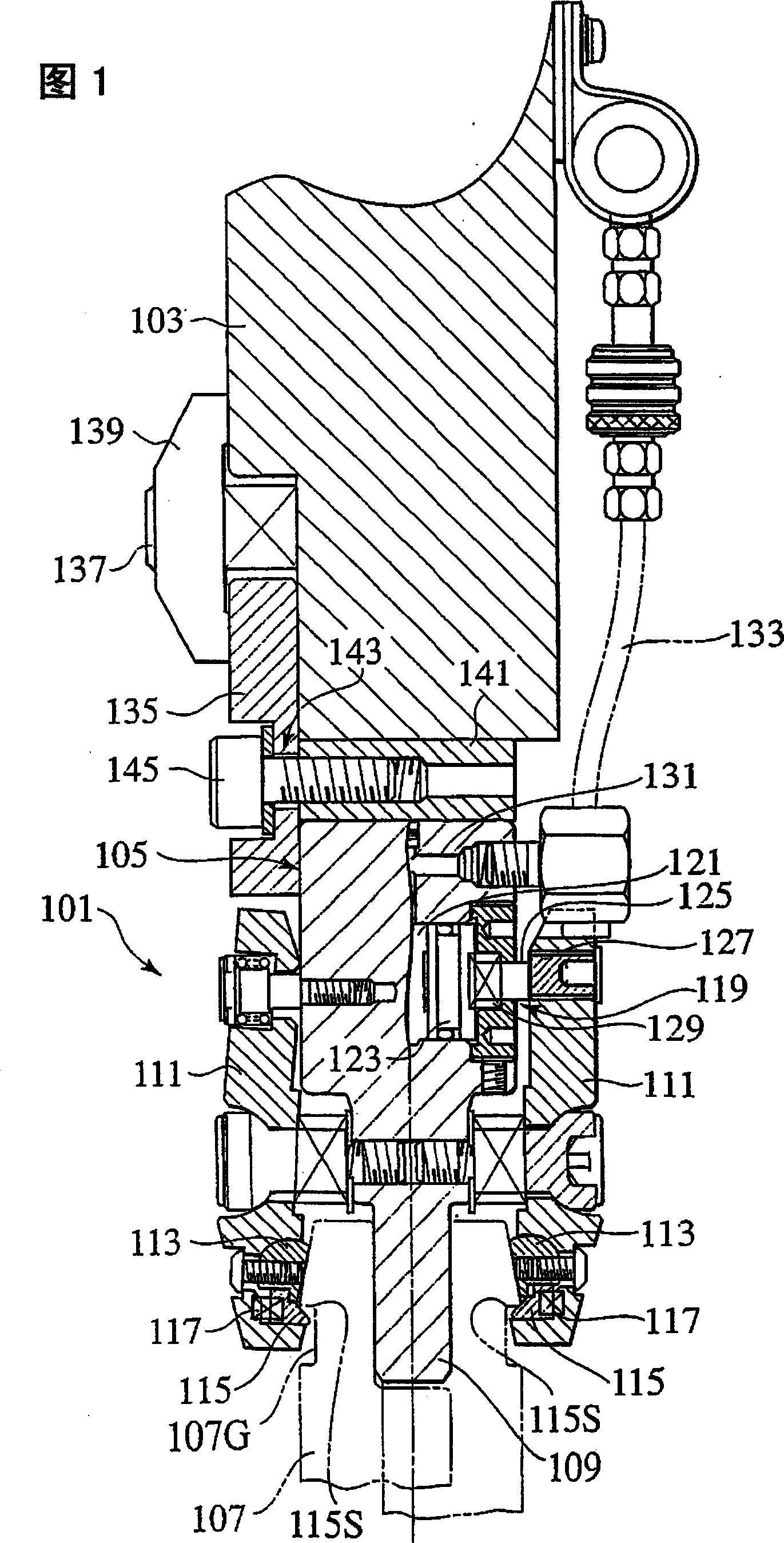

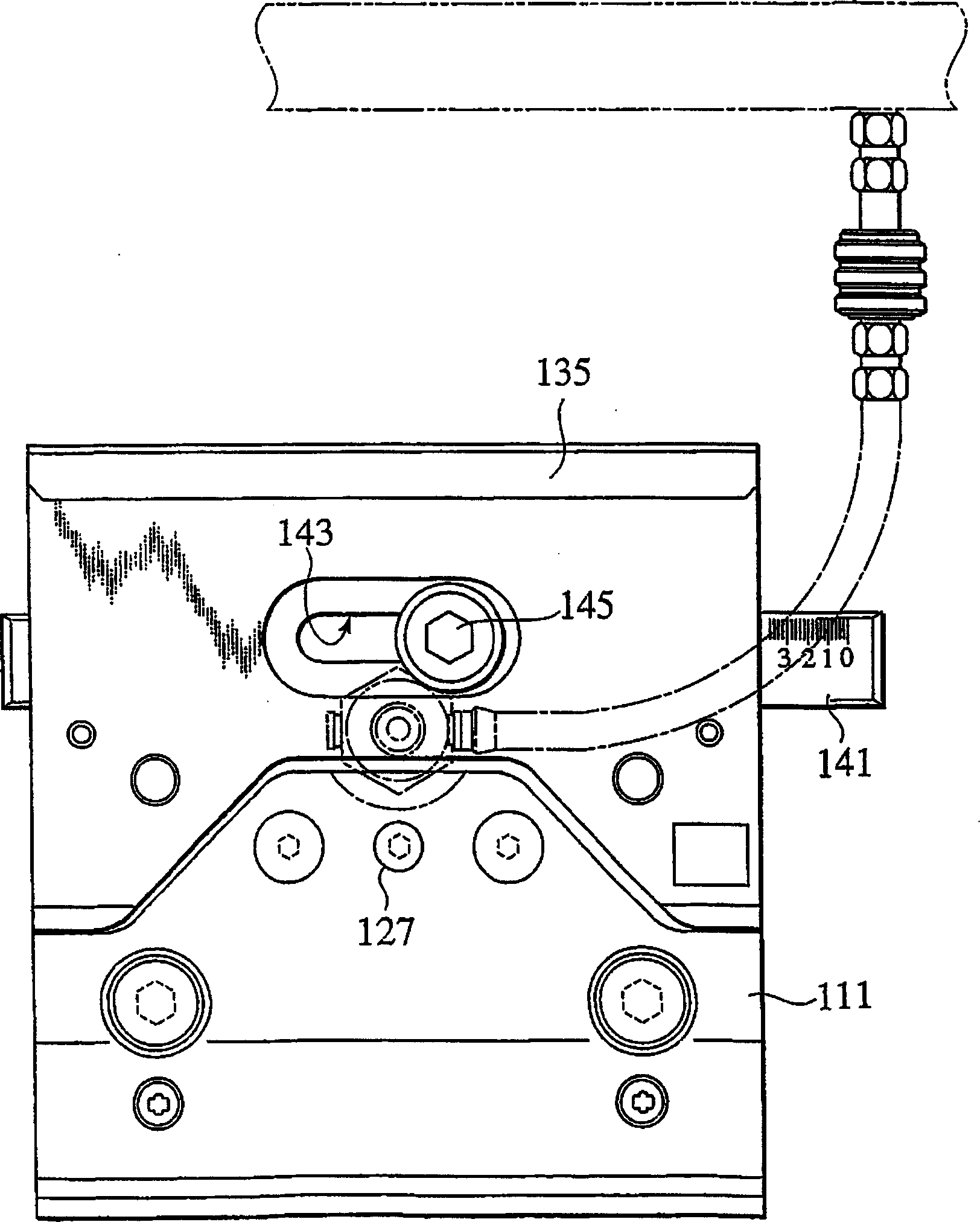

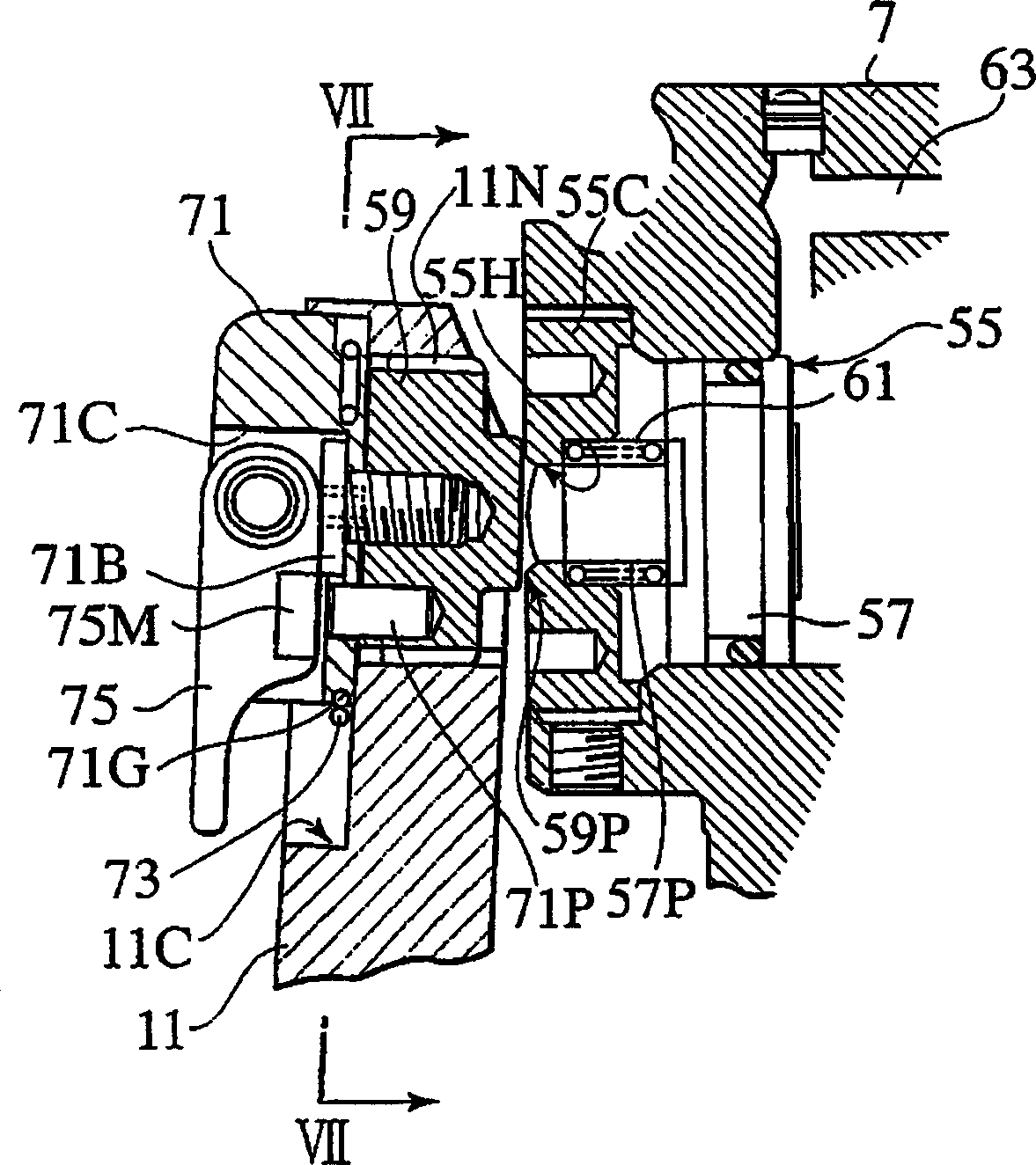

[0040] Hereinafter, the upper type clamping device and the method of removing the upper type clamping device from the upper type clamping device according to the present invention will be described with reference to the drawings.

[0041] As shown in Figure 5, Figure 6As shown, the upper type clamping device 1 of the present embodiment is detachably mounted on the lower part of the upper workbench 3 of the bending machine (not showing its overall composition in the figure). A plurality of the upper clamping devices 1 are installed at appropriate intervals in the left-right direction on the lower portion of the upper table 3 and used.

[0042] That is, the upper type 5 of the bending machine is along the left-right direction (in Fig. 5, the direction perpendicular to the plane of paper, Figure 6 The middle is the left and right direction) and its total length is integrated, and it is also used in combination of several split types of different sizes. Since the upper type cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com