Method of fabricating a commutator for a motor

A commutator and engine technology, which is applied in the direction of commutator manufacturing, stator/rotor body manufacturing, electromechanical devices, etc., can solve problems such as short service life of commutators, and achieve the effect of increasing service life and preventing carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

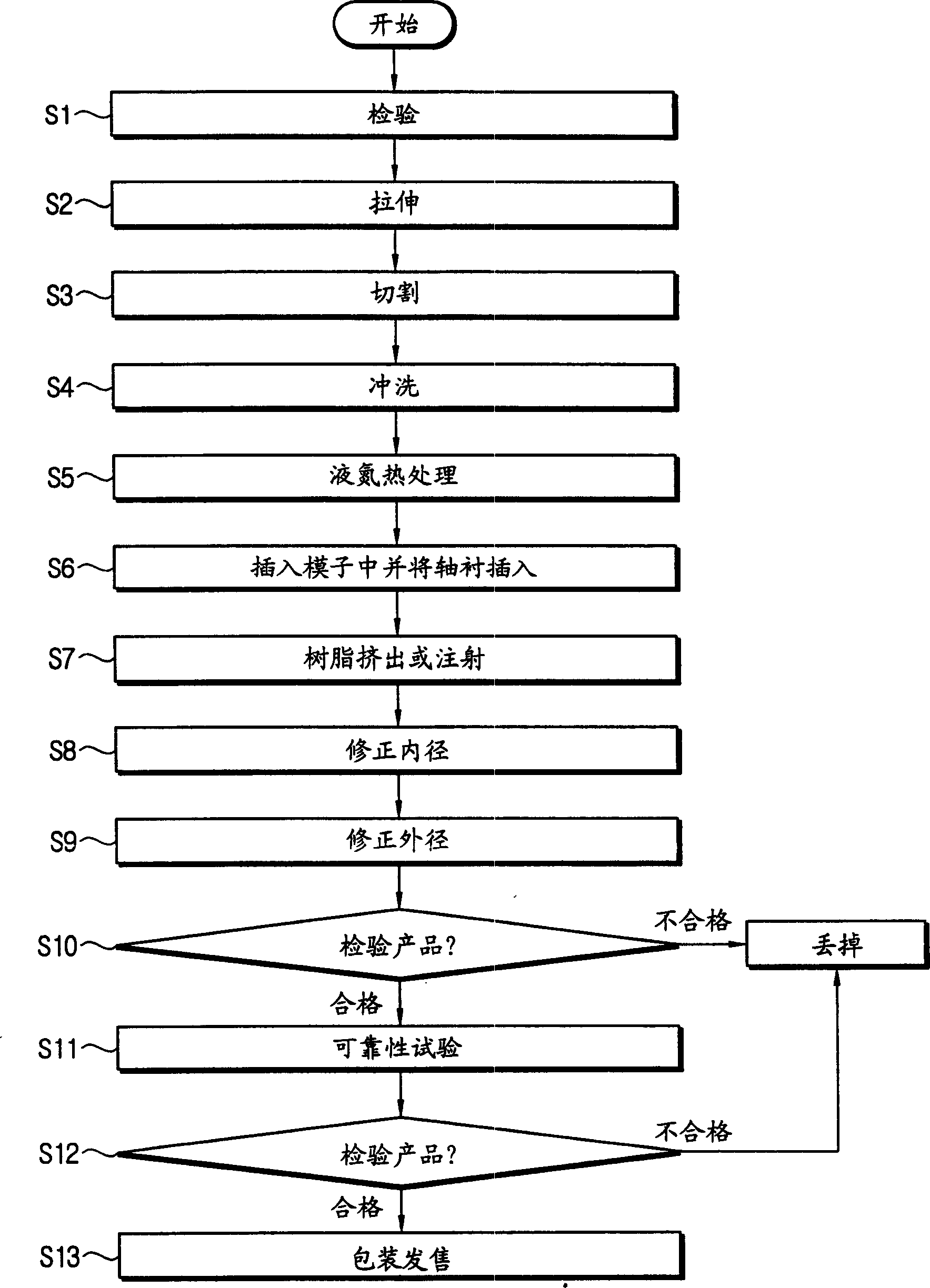

[0027] image 3 is a step-by-step flow diagram illustrating a method of manufacturing an engine commutator according to an embodiment of the present invention. Such as image 3 As shown, the inspection step S1 is carried out on the round copper rod. Pure copper wire may be used for the rod and, perhaps more preferably, an alloy containing a silver (Ag) additive ranging from at least 0.01% by weight to a maximum of 2% by weight may be used.

[0028] Then, the round rod is subjected to a stretching step S2 to form a sheet with a desired thickness.

[0029] The sheet formed by the stretching step is cut into a predetermined size to form a commutator segment (step S3).

[0030] The commutator segments are then rinsed by using a mixed solution consisting of detergent, water and lactic acid (step S4).

[0031] After rinsing, the commutator segments are immersed in liquid nitrogen for 15 to 25 minutes (step S5). In one embodiment, the temperature of the liquid nitrogen may be, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com