A LED display device

A technology for display devices and LED arrays, applied in identification devices, static indicators, instruments, etc., can solve problems such as reverse current increase, and achieve the effect of eliminating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] Example one

[0036] Provide alternating high and low pulse voltages at the P pole of the LED that needs to emit light, and provide a low level at its N pole. In order to prevent other LEDs from emitting light, a P pole that is connected to the light emitting LED must be provided at the N pole of the LED that does not need to emit light. Pulse voltages with the same pulse phase and pulse width are provided with a low level on its P pole.

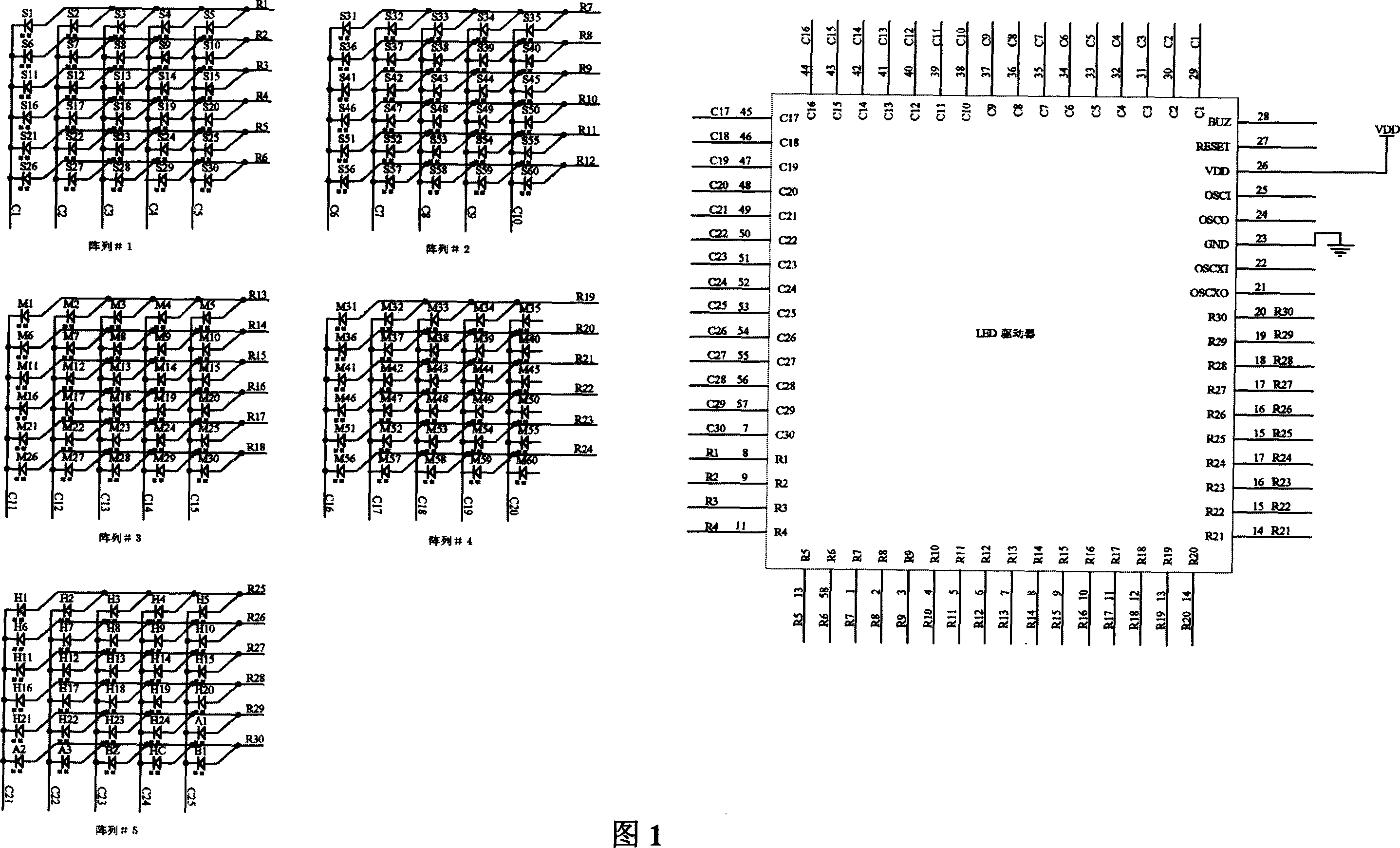

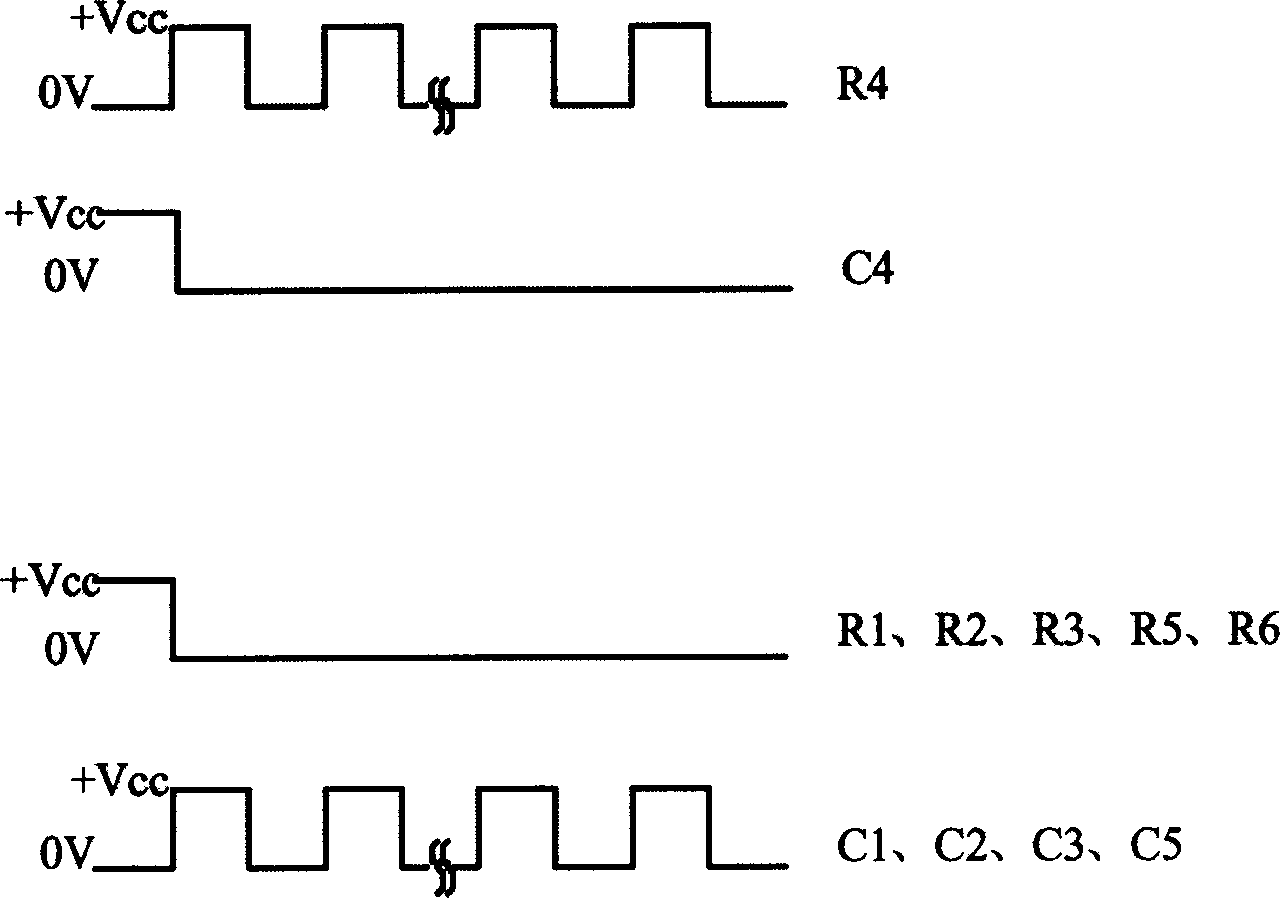

[0037] Such as figure 2 As shown, in the array #1, when the LED with the current number S19 emits light, the microprocessor outputs a pulse signal with adjustable pulse width to the row drive line R4 connected to its port, that is, a pulse signal with adjustable pulse width is applied to the P pole of S19. Adjust the pulse voltage of the pulse width, and at the same time the microprocessor outputs a low level to the column drive line C4 connected to the N pole of S19, so that the LED codenamed S19 is turned on and illuminated; at this ti...

Example Embodiment

[0066] Example two

[0067] Provide a high level at the P pole of the LED that needs to emit light, and at the same time provide an alternating high and low pulse width pulse voltage at the N pole of the LED. In order to prevent other LEDs from emitting light, one must be applied to the N pole of the LED that does not need to emit light. High level, and at the same time provide a pulse voltage with the same phase and pulse width as the N-pole pulse of the light-emitting LED at its P pole.

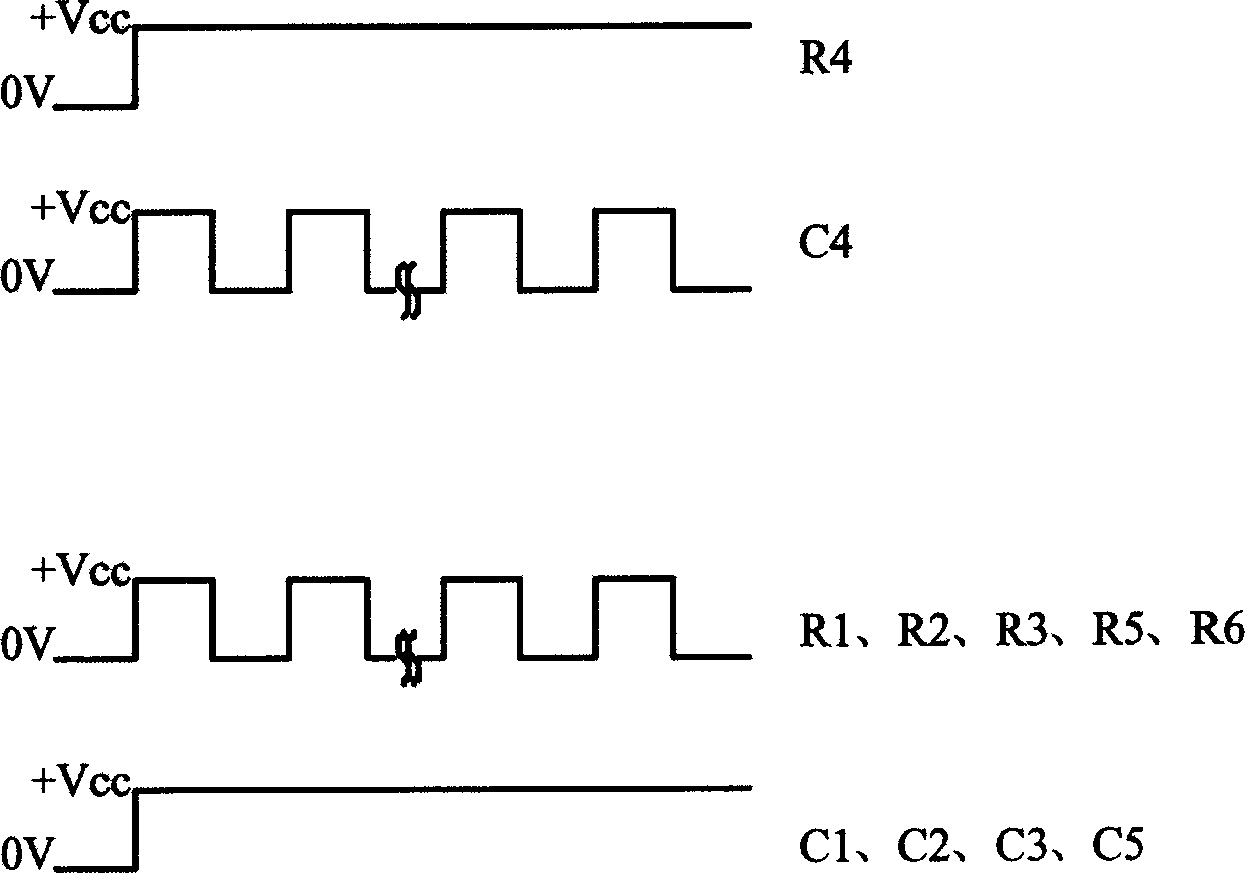

[0068] Such as image 3 As shown, in array #1, when the LED with the current number S19 emits light, the microprocessor outputs a high level to the row drive line R4 connected to its port, that is, applies a high level to the P pole of S19, and at the same time The microprocessor outputs a pulse voltage signal with adjustable pulse width to the column drive line C4 connected to the N pole of S19, so that the LED codenamed S19 is turned on and displays light; at this time, in order to prevent oth...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap