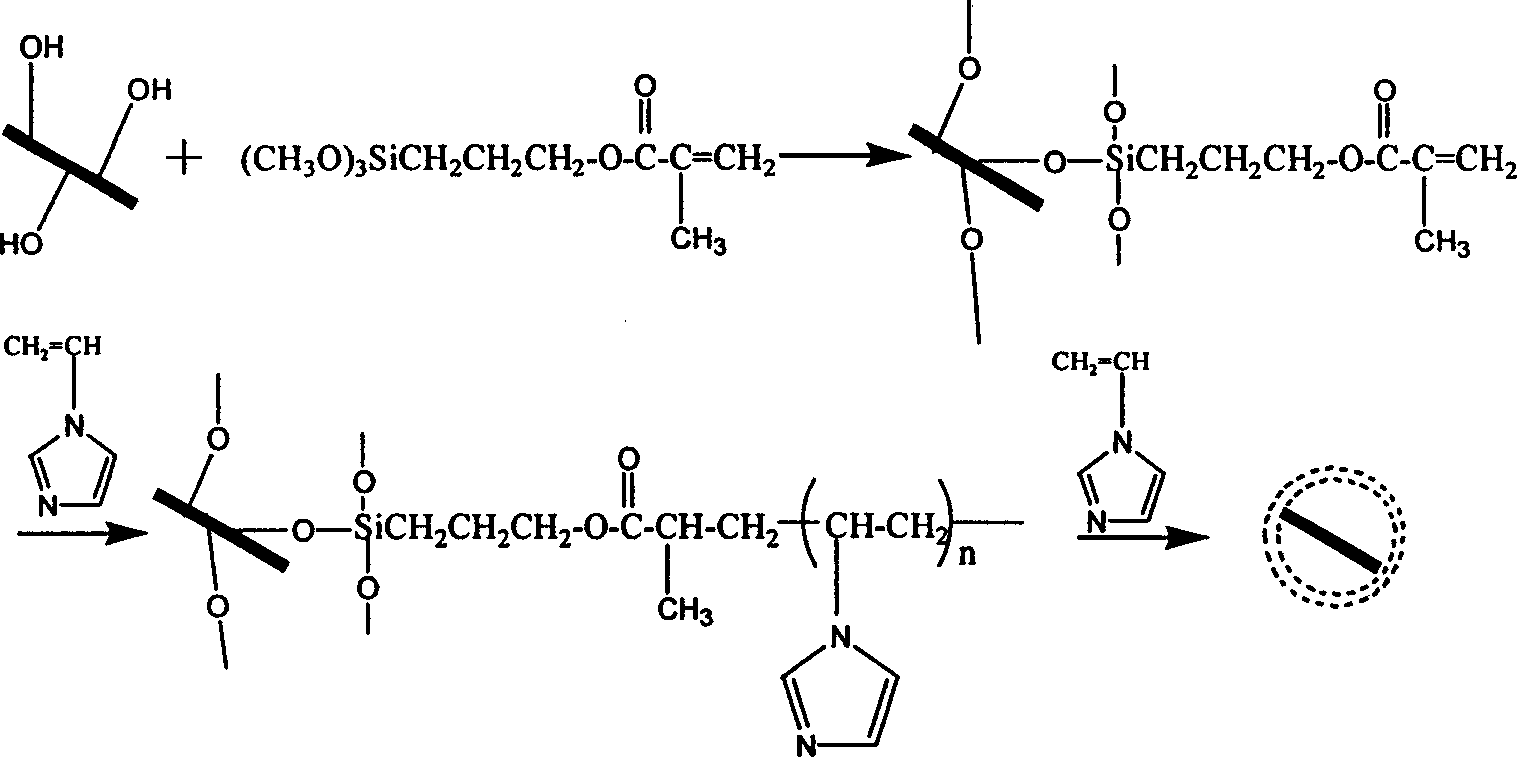

Carbon nano-pipel poly vinyl imidazole nano-composite material and its preparation method

A carbon nanotube composite and nanocomposite material technology, which is applied in the field of carbon nanotube/polyvinylimidazole nanocomposite materials and their preparation, can solve the problems of poor thermal stability, poor mechanical properties, and complicated processes of composite materials, and achieves excellent The effect of high solubility, thermal and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 1 g of multi-walled carbon nanotubes into a mixed strong acid solution consisting of 100 ml of concentrated sulfuric acid and concentrated nitric acid (volume ratio of 3:1), and after 6 hours of ultrasonic vibration treatment, slowly pour 500 ml of deionized water (with stirring), and let it stand After overnight, it was filtered and washed with deionized water until it became neutral, and dried in an oven. Repeat 3 times to obtain the carbon nanotube material after chemical etching. Weigh 100 mg of chemically etched carbon nanotubes and disperse them in absolute ethanol, and add 30 ml of KH-570 ethanol solution (concentration: 0.067 g / ml) dropwise in a water bath at 35°C. Keep the temperature and stirring speed constant, after continuous reaction for 40 hours, centrifuge and filter at 3400 rpm, re-disperse with absolute ethanol, repeat 5 times, vacuum dry at 40°C overnight to obtain coupling agent treatment carbon nanotubes containing double bonds. Add 50 mg of c...

Embodiment 2

[0030] Same as Example 1, but KH-570 changed to Wolan.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap