Method for testing external permeability of fibre fabre surface

A technology of fiber fabrics and test methods, applied in the fields of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc., can solve the problems of no experimental method, difficult to achieve, etc., and achieve easy handling, thickness direction increase, easy Effects of Image Analysis and Calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example 1

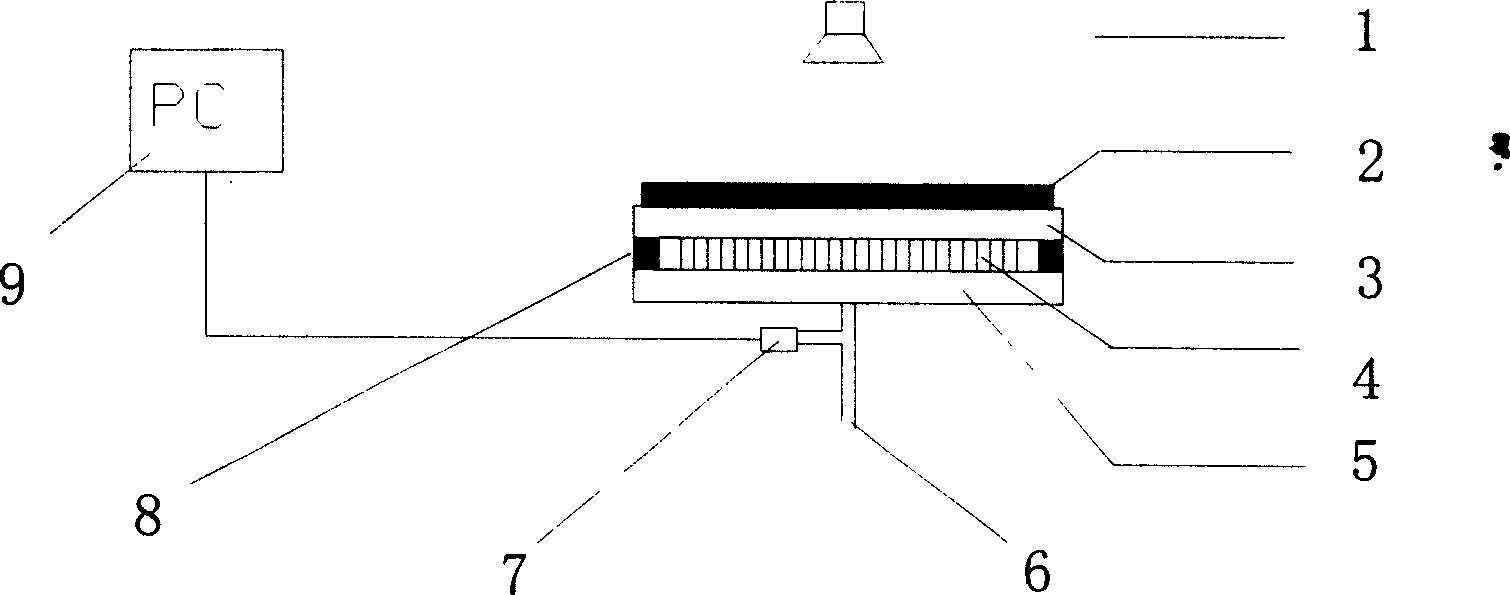

[0024] Disc-shaped sample 4 was prepared by domestic glass fiber tape. Its specifications and performance parameters are listed in Table 1. The fiber porosity ε is calculated according to the formula (2) to be 71.5% (the density of the fiber is calculated as 2.54), the sample is put into the test device, and the center of the sample 4 is required to be consistent with the center of the injection hole, and the gaskets are placed in turn 8. The upper mold 3 and the pressure transmission frame 2 make the upper and lower molds 3 and 5 clamp the sample 4; then turn on the fluid injection switch, the digital camera 1 switch and the computer acquisition system 9; the out-of-plane permeability can be determined according to the Darcy's law formula (1) to calculate, the calculation results are shown in Table 2. In the embodiment, the thickness h of the gasket is 9.83 mm, and the numerical value of the injected constant pressure is 58675 Pa obtained by collecting th...

Example Embodiment

[0030] Example 2

[0031] The same domestic glass fiber tape as in Example 1 was used to prepare the sample, and its specifications and performance parameters are as described in Table 3. Fiber porosity ε calculates 68.7% (the density of fiber is calculated with 2.54) by formula (2), injects constant pressure, obtains 65532Pa through the data of computer collection pressure sensor; Conditions such as gasket thickness, fluid viscosity are identical with embodiment 1. The radius of the flow front is obtained by image analysis based on the data recorded by the digital camera 1, as shown in Table 4, and the out-of-plane permeability parameters can be calculated by substituting the obtained parameters into formula (1).

[0032] Table 3. Parameters of glass fiber tapes used in the samples

[0033] Thickness Width Density Weave Weight Diameter

[0034] (mm) (mm) (root / cm) (gram) (mm)

[0035] 0.1±0.01 10±1 longitude 10 weft 8 plain weave 552.1 300

[0036] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap