Delayed coking waste water filtering technique and equipment thereof

A technology of delayed coking and process, applied in the direction of filtration separation, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, complicated operation, small scale, etc., and achieve the prevention of filter material pollution, enhanced filtration accuracy, continuous The effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Instance

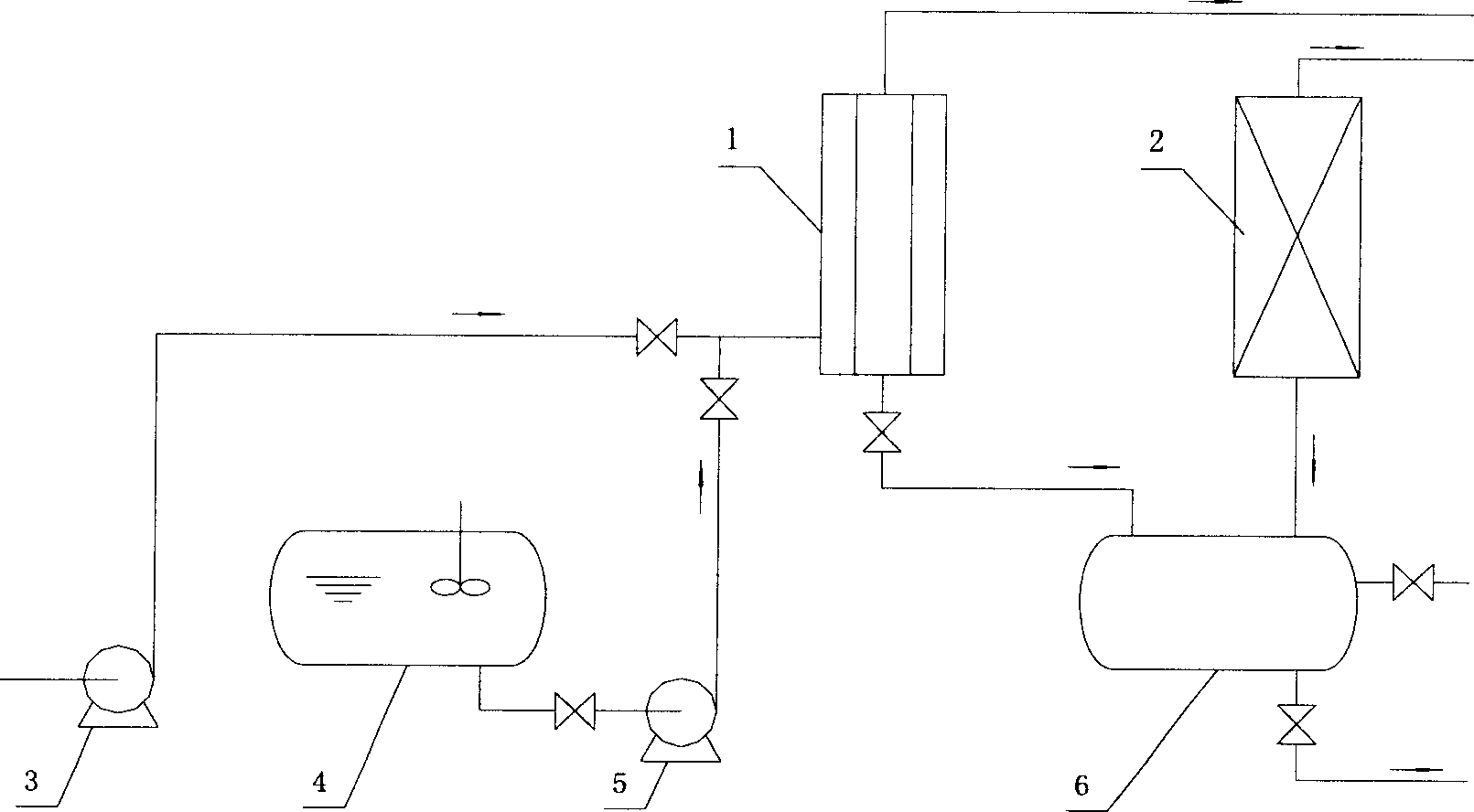

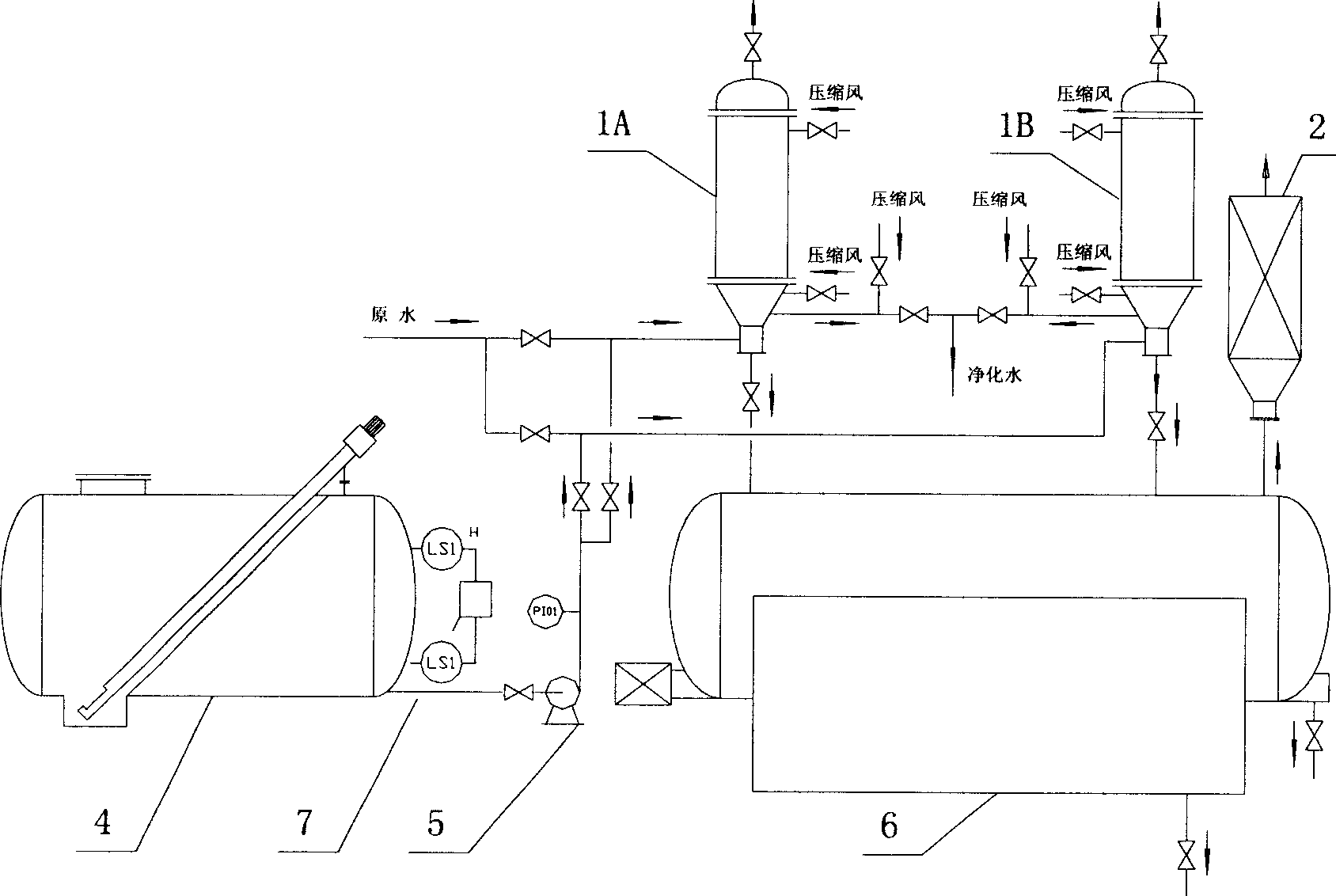

[0032] A specific example of the process of the present invention will be described in further detail below with reference to the accompanying drawings. The filtering process of the present invention is composed of four main processes: adding auxiliary agent-filtering-stripping filter cake-gas, solid and liquid separation. Such as figure 1 with figure 2 As shown, the present invention mainly consists of a solid-liquid mixer 4, two multi-tube filters 1A and 1B, a three-phase separator 6, a tail gas absorption tank 2, a raw water pump 3, a mud pump 5, a regulating valve, and multiple pipelines Connection composition.

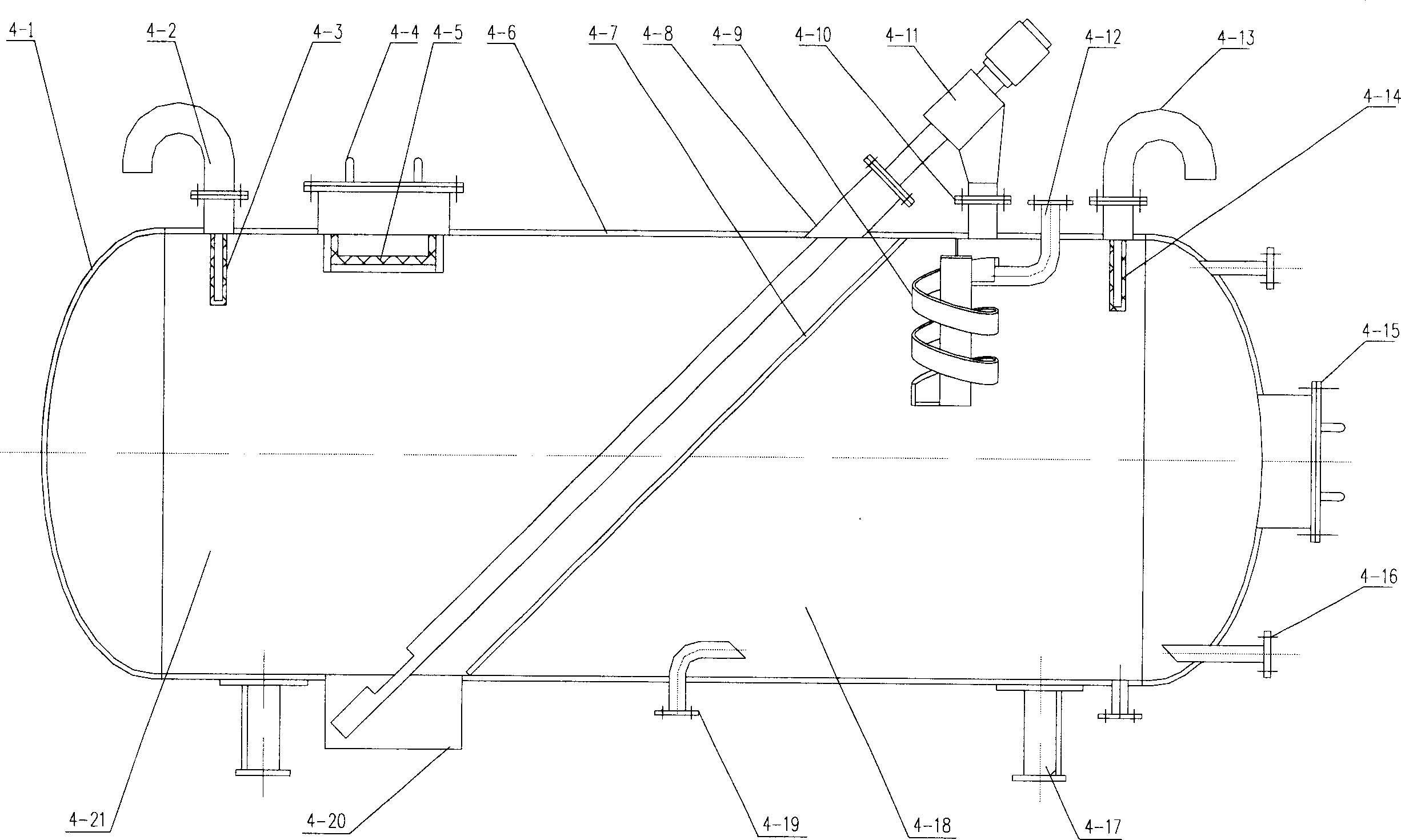

[0033] The specific structure of the solid-liquid mixer 4 is as follows image 3 , 4 , As shown in 5.

[0034] The integrated solid-liquid mixing equipment consists of four parts: powder bin 4-21, powder conveying meter 4-11, dispersing assembly 4-9 and mud bin 4-18. The powder bin consists of cylinder 4-6, head 4-1, manhole 4-4, fence 4-5, vent 4-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap