Slidable boring tool with fine adjustment

A boring and boring machine technology, applied in the direction of boring/drilling, boring head, tool holder accessories, etc., can solve the problems of detrimental CNC boring machine speed and economic benefits, inflexible labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

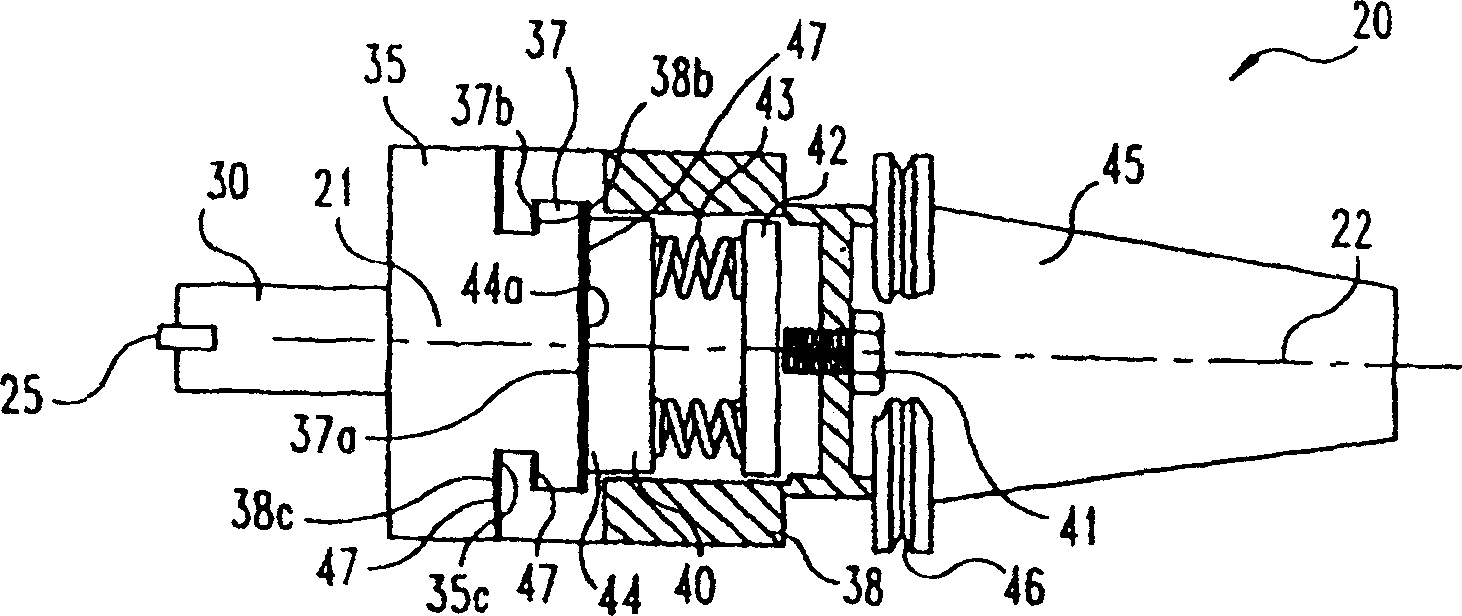

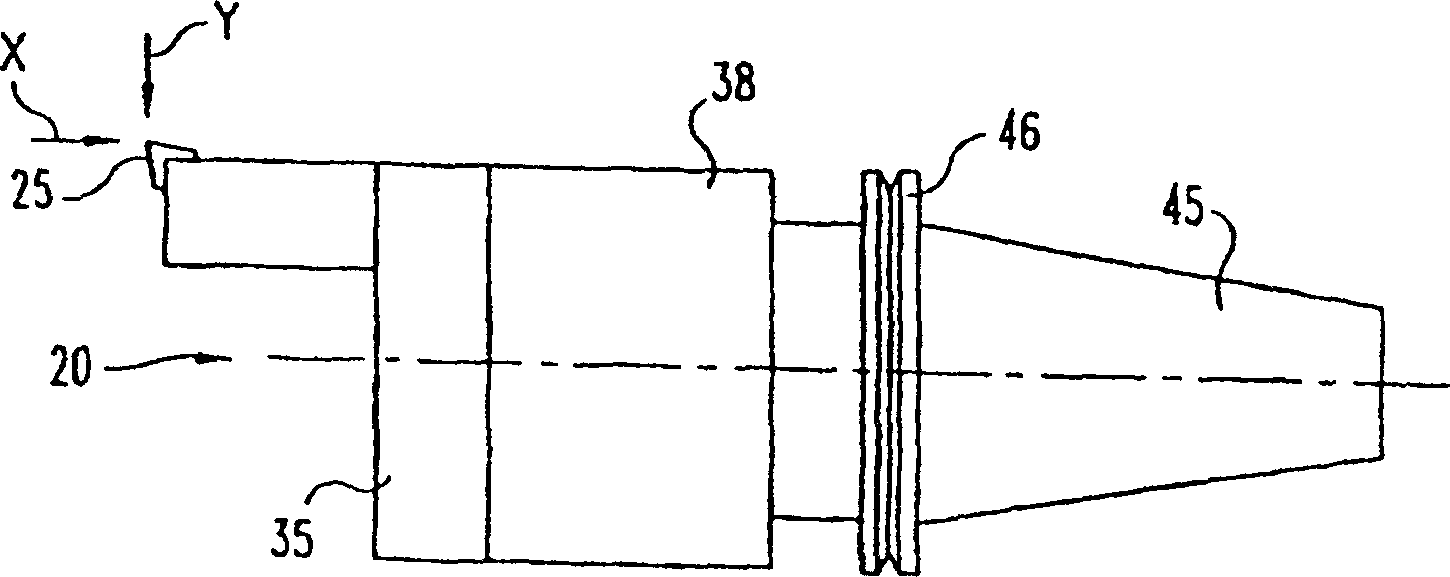

[0173] In order to facilitate understanding of the principles of the present invention, the following describes the embodiments shown in the drawings and specific language is used to explain these embodiments. It should be understood, however, that these examples do not limit the scope of the invention, and such changes and other modifications in the exemplary apparatus, as well as other applications of the principles of the invention, are also contemplated as would normally occur to those skilled in the invention. .

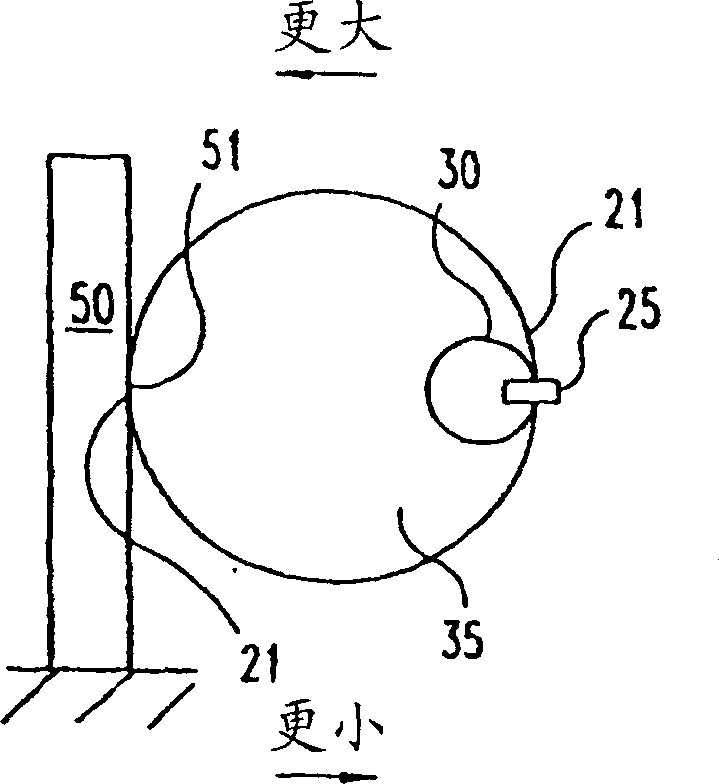

[0174] The present invention relates both to an apparatus and a method for an operator to adjust the lateral position of a cutting tool during a machining operation, such as adjusting a cutting tool for boring a hole with a CNC boring machine. According to one embodiment of the invention, the cutting tool or the cutting tool holder is connected to a connection part of the machine and is movable relative to the connection part. In yet another embodiment, the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com