Gauge based on metric system and Morse standard taper and its manufacture

A Morse taper and benchmark technology, applied in the field of measuring tools, can solve the problems of quantity transfer and unification, and achieve the effect of quantity unification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

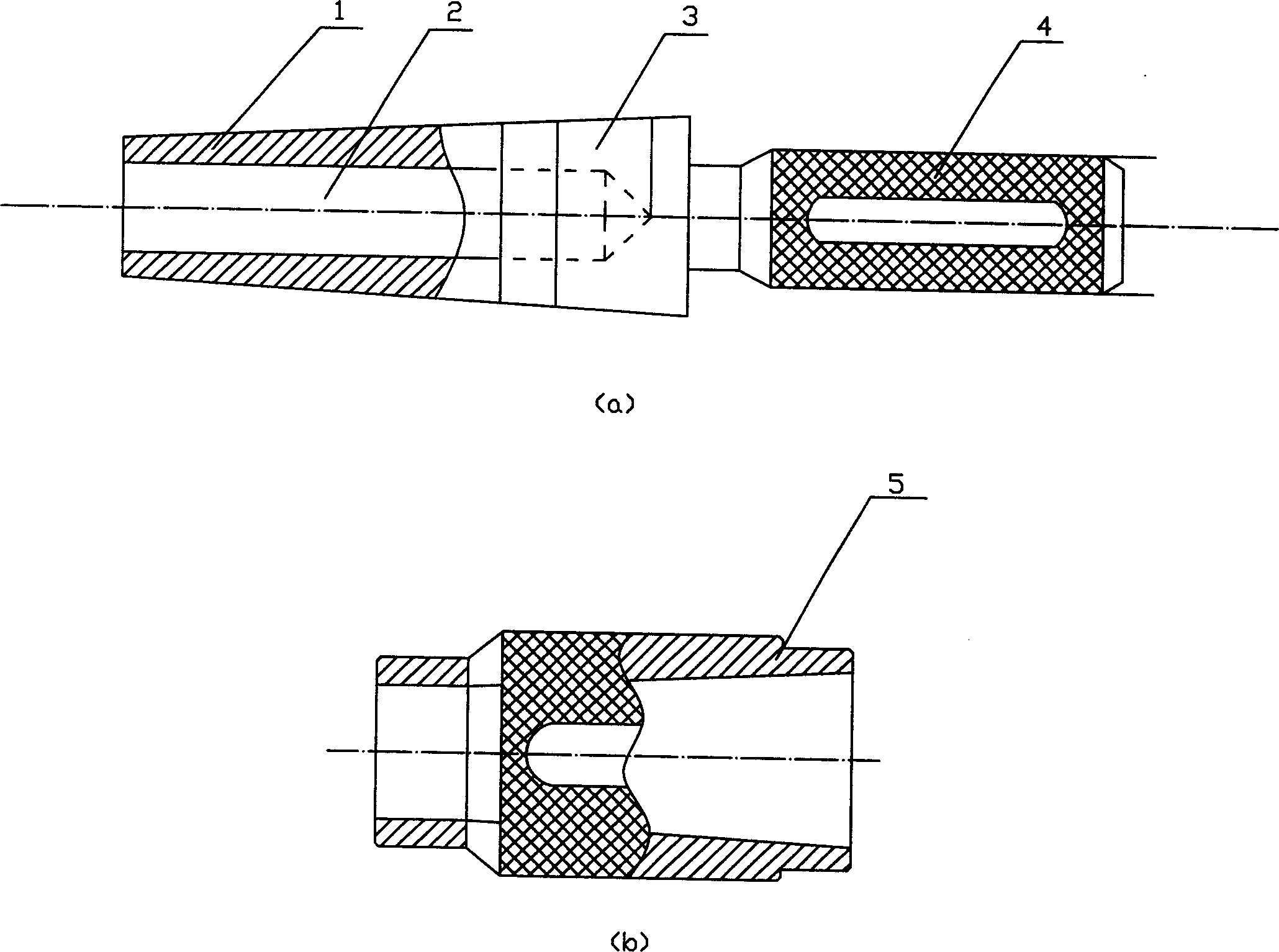

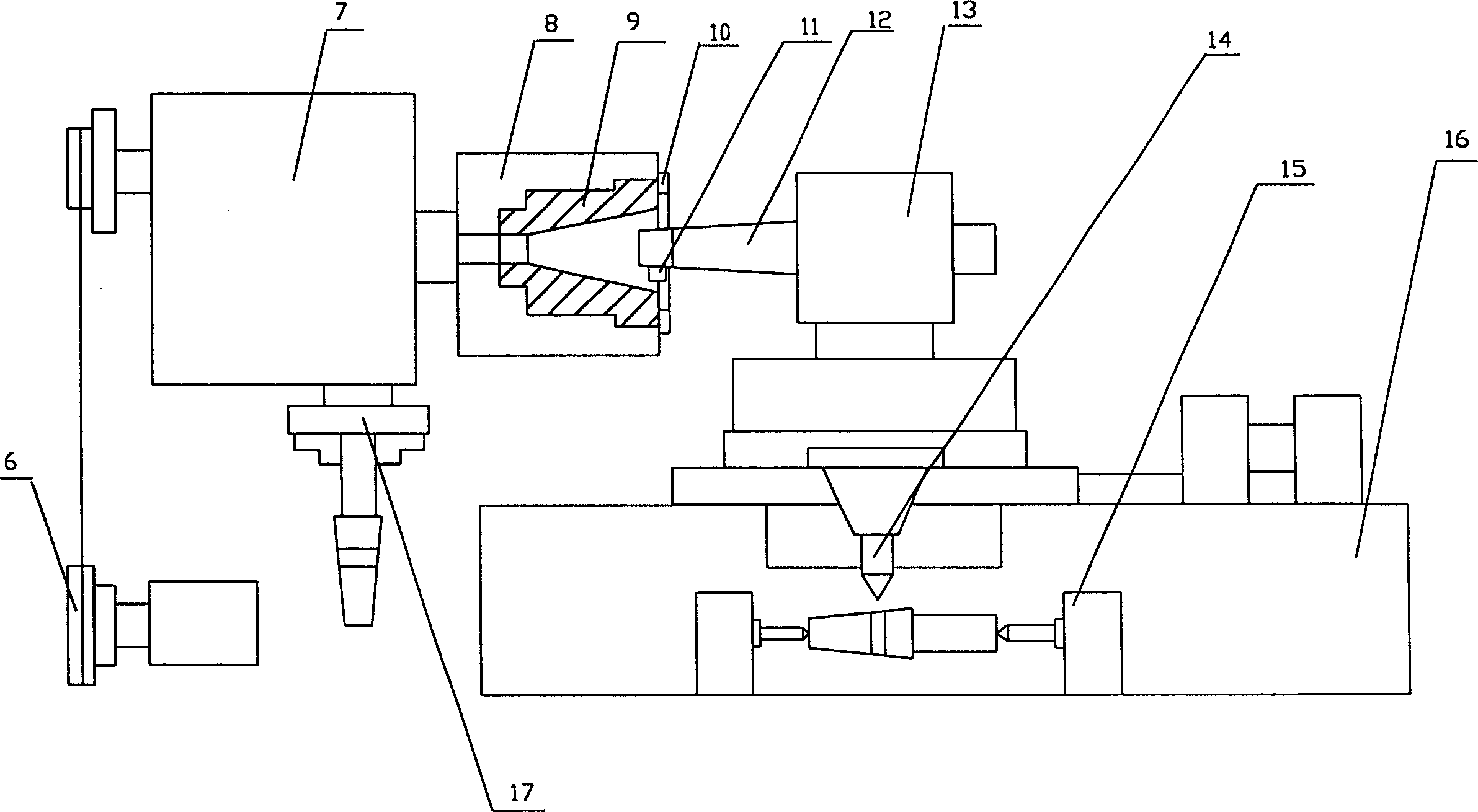

[0019] A metric and Morse cone reference gauge and its method of manufacture as shown. The reference gauge is composed of three sets of interchangeable ring gauges and plug gauges. The big end dimensions of the three sets of plug gauges are all ±0.001mm, and the degree of bonding with the three sets of ring gauges is 100%. The manufacturing method mainly includes rough machining and semi-finishing process, which is characterized in that the key step of the manufacturing process begins with developing the ovality of the plug gauge and ring gauge in advance, so that all 6 lead powder lines are bonded, and at the same time, the big end of the plug gauge is guaranteed The size tolerance is ±0.001mm. The first set of plug gauges should be manually ground bit by bit until the 0 position is checked with a sine ruler and a standard gauge block. The subsequent grinding process starts with the first set of plug gauges paired with the first set of ring gauges, the first set of ring gauge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com