Photonic crystal fiber with electrical conductivity and its preparation method

A technology of photonic crystal fiber and conductive performance, which is applied in the field of optical communication materials to reduce splicing loss and facilitate alignment and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

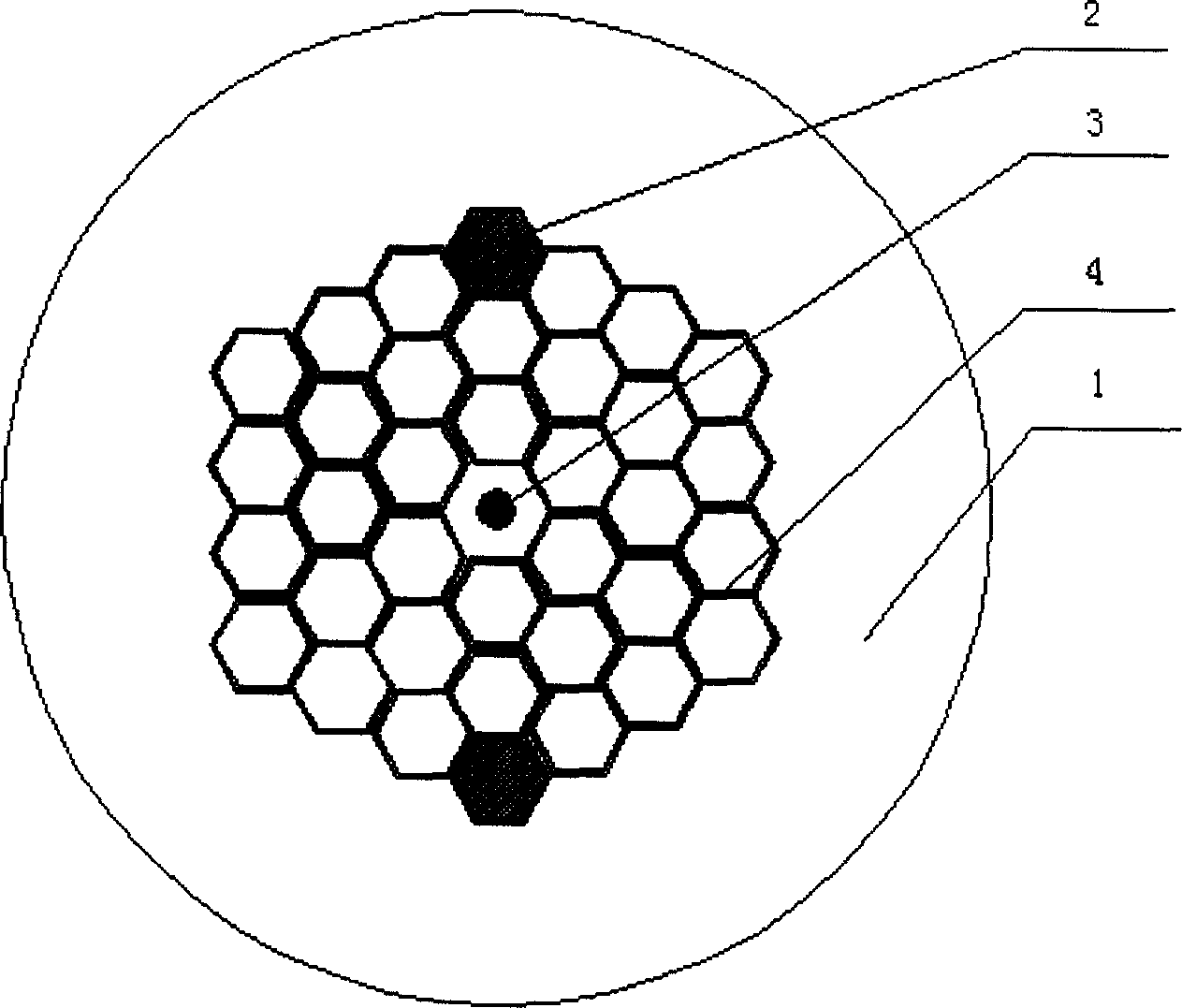

[0061] 34 capillary tubes of φ370mm*35mm are used, a solid rod of φ150mm is sandwiched in the center, and two conductive glass rods of φ370mm are positioned in the diameter direction of the outermost circumference. After the position is fixed, it is fixed with low-melting glass filaments, and then sleeved to form a photonic crystal structure.

[0062] The completed preform rod is drawn with a power of 4KW, and the diameter is controlled to be 125 microns, and then coated on the outside of the glass, and the diameter of the coated optical fiber reaches 245-250 microns.

[0063] To use this kind of fiber for fusion splicing experiments, first strip off the coating layer at one end of the fiber, and then install the fiber on the clamp of the fusion splicer; connect the other end of the fiber to the DC electrode. Set the fusion splicer to manual, align first, then approach, and observe the position of the two photonic crystal fibers under the lens to ensure that the error in the X...

example 2

[0065] A modified PMMA rod with a specification of φ450mm is used, and the prefabricated rod is processed according to the designed microholes, and two polyacetylene conductive polymer rods matching the diameter of the micropores are placed inside the microholes in the direction of the diameter of the outermost circumference. . After the position is fixed, the photonic crystal crystal prefabricated rod is made by thermal welding, and then drawn to form a photonic crystal structure. Control the diameter to meet the requirements.

[0066] To use this fiber for fusion splicing experiments, first install the fiber on the clip of the fusion splicer; connect the other end of the fiber to the DC electrode. Set the fusion splicer to manual, align first, then approach, and observe the position of the two photonic crystal fibers under the lens to ensure that the error in the X and Y directions is less than 0.3 microns, and the angle error of the end face is less than 10 degrees, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap