Three-phase nanometer composite polymer/inorganic nanometer particle/graphite material and its prepn

An inorganic nanoparticle and nanocomposite material technology, which is applied in the field of composite materials composed of graphite, polymer and inorganic nanoparticle and its preparation, can solve the problem of reducing the dispersibility of graphite, uneven dispersion of graphite, affecting the friction reduction performance of composite materials and Mechanical properties and other issues, to achieve the effect of improving thermal stability, solving agglomeration, and eliminating the mismatch of thermal expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

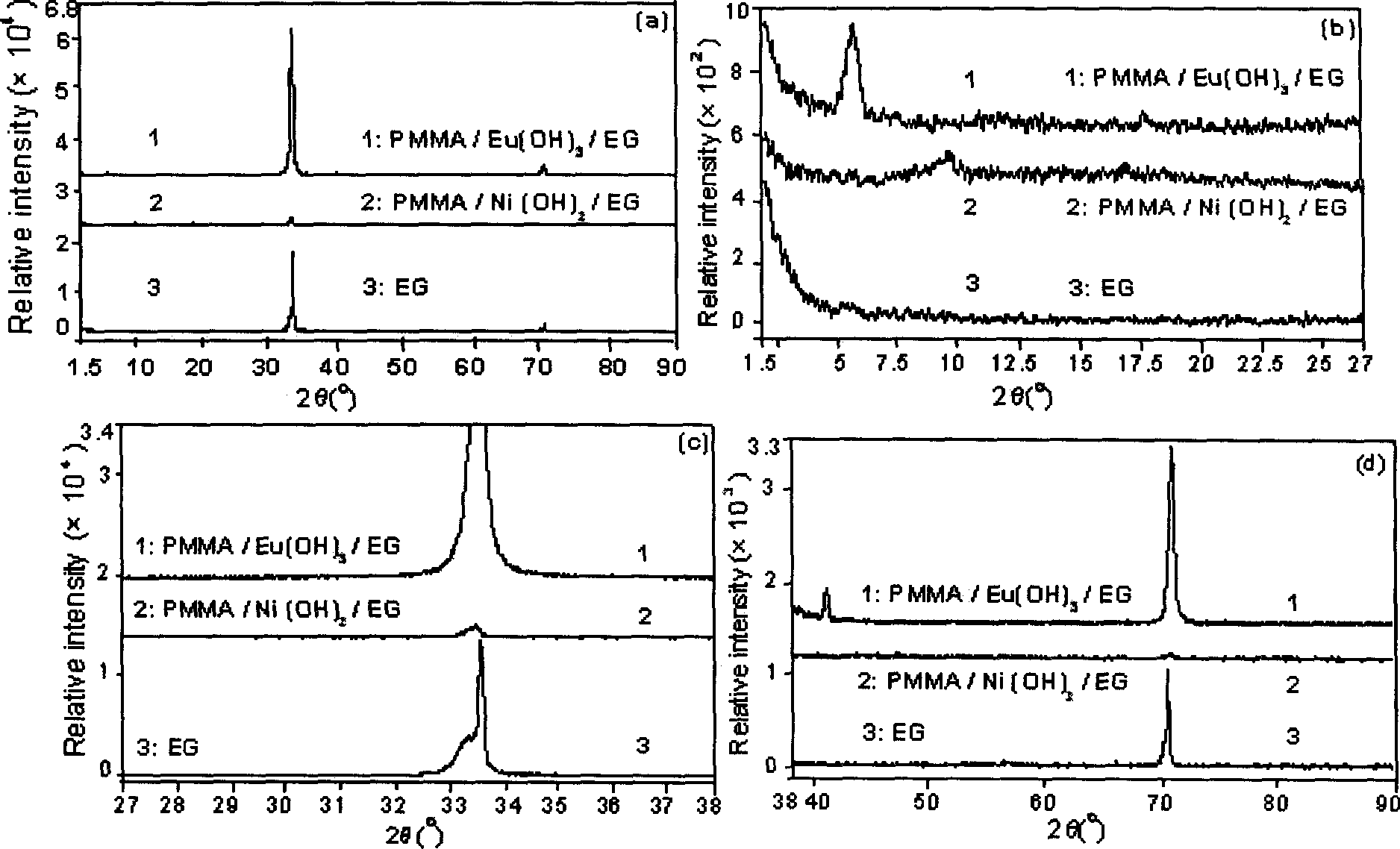

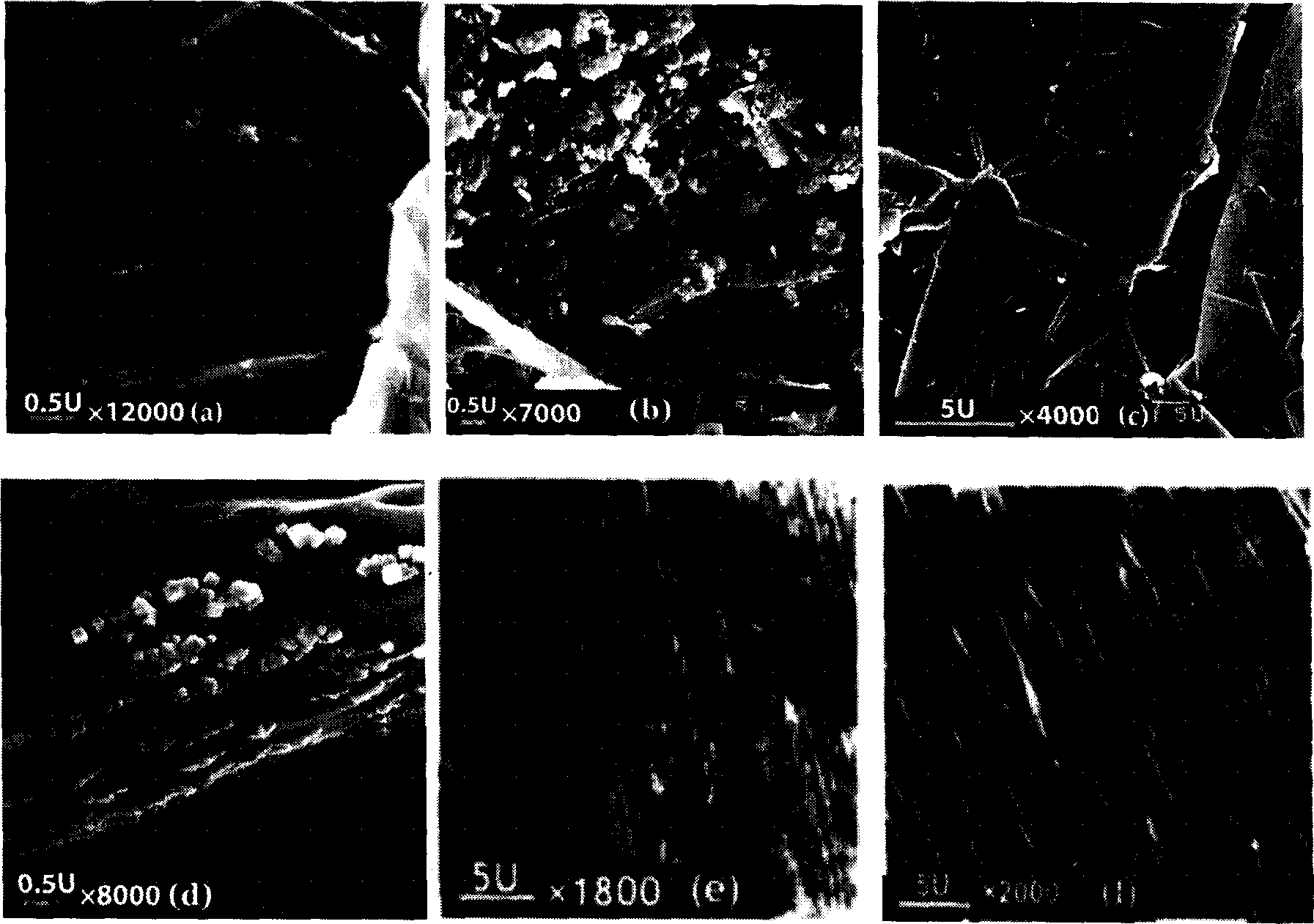

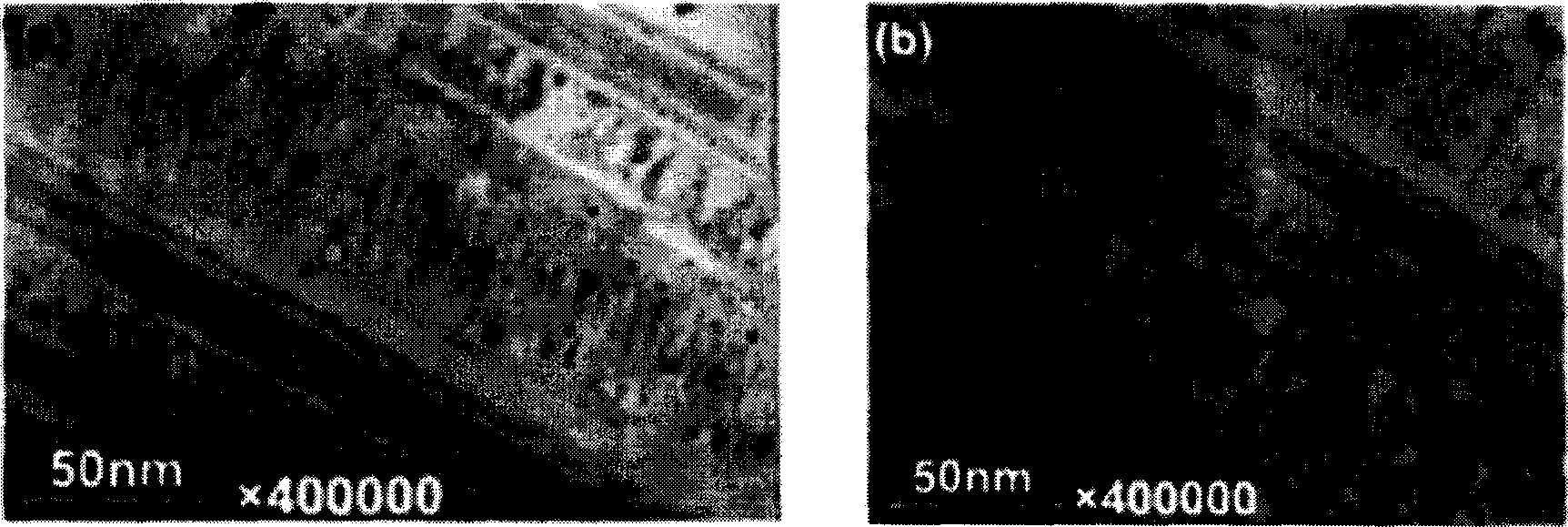

[0036] Example 1: 100 parts of methyl methacrylate (MMA) and 0.01 part of cetyltrimethylammonium bromide were dissolved in 100 parts of chloroform (CHCl) 3 ), and then add 400 parts of Ni(NO 3 ) 2 aqueous solution, ultrasonically dispersed for 13 minutes at room temperature; then 0.05 part of expanded graphite (EG) was added, and the 2 Ultrasonic for 13 minutes under the protection, then add 480 parts of 0.2mol / L NaOH solution as a precipitant, and in N 2 Ultrasonic treatment was carried out for 30 minutes under protection; 5 parts of azobisisobutyronitrile (AIBN) was added as an initiator, reacted at 60° C. for 3 hours, filtered and washed to obtain polymethyl methacrylate / Ni(OH) 2 / Expanded graphite three-phase nanocomposites. The X-ray powder diffraction XRD pattern of the composite material is shown in figure 1 , its SEM photo, TEM photo and TG curve refer to figure 2 , image 3 , Figure 4 .

[0037] The interlayer spacing of graphite and the particle size of ino...

Example Embodiment

[0038] Embodiment 2, dissolve 100 parts of methyl acrylate and 0.05 part of sodium lauryl sulfate in 110 parts of N, N-dimethylformamide, then add 600 parts of 0.1mol / L EuCl to it 3 aqueous solution, and ultrasonically dispersed for 14 minutes at room temperature; then 0.1 part of expanded graphite (EG) was added, under N 2 Under the protection of ultrasonic for 14 minutes, then add 480 parts of 0.2mol / L NaOH solution, and under N 2 Ultrasonic treatment under protection for 32 minutes; finally adding 5.5 parts of azobisisobutyronitrile (AIBN) as an initiator, reacting at 65 ° C for 4 hours, filtering and washing to obtain polymethyl acrylate / Eu(OH) 3 / Expanded graphite three-phase nanocomposites. The X-ray powder diffraction (XRD) pattern, SEM photo, TEM photo, TG curve and TG curve of the composite material

[0039] Example 1 is basically the same.

Example Embodiment

[0040] Embodiment 3, dissolve 100 parts of aniline and 0.1 part of sodium stearate in 110 parts of N-dimethylacetamide, then add 800 parts of 0.1mol / L EuCl to it 3 aqueous solution, and ultrasonically dispersed for 15 minutes at room temperature; then 0.5 part of expanded graphite (EG) was added, under N 2 Under the protection of ultrasonic for 15 minutes, then add 500 parts of 0.2mol / L NaOH solution, and in N 2 Under the protection of ultrasonic treatment for 35 minutes; finally add 6 parts of ammonium persulfate as an initiator, react at 20 ° C for 5 hours, filter and wash to obtain polyaniline / Eu(OH) 3 / Expanded graphite three-phase nanocomposites. The X-ray powder diffraction (XRD) pattern, SEM photograph, and TG curve of the TEM photograph of the composite material are basically the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap