Automatic testing system for light transient

An automatic test system, transient technology, applied in optical testing flaws/defects, single semiconductor device testing, measuring devices, etc., can solve the problems of complicated data processing, difficult to determine the peak value of equipment spectrum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

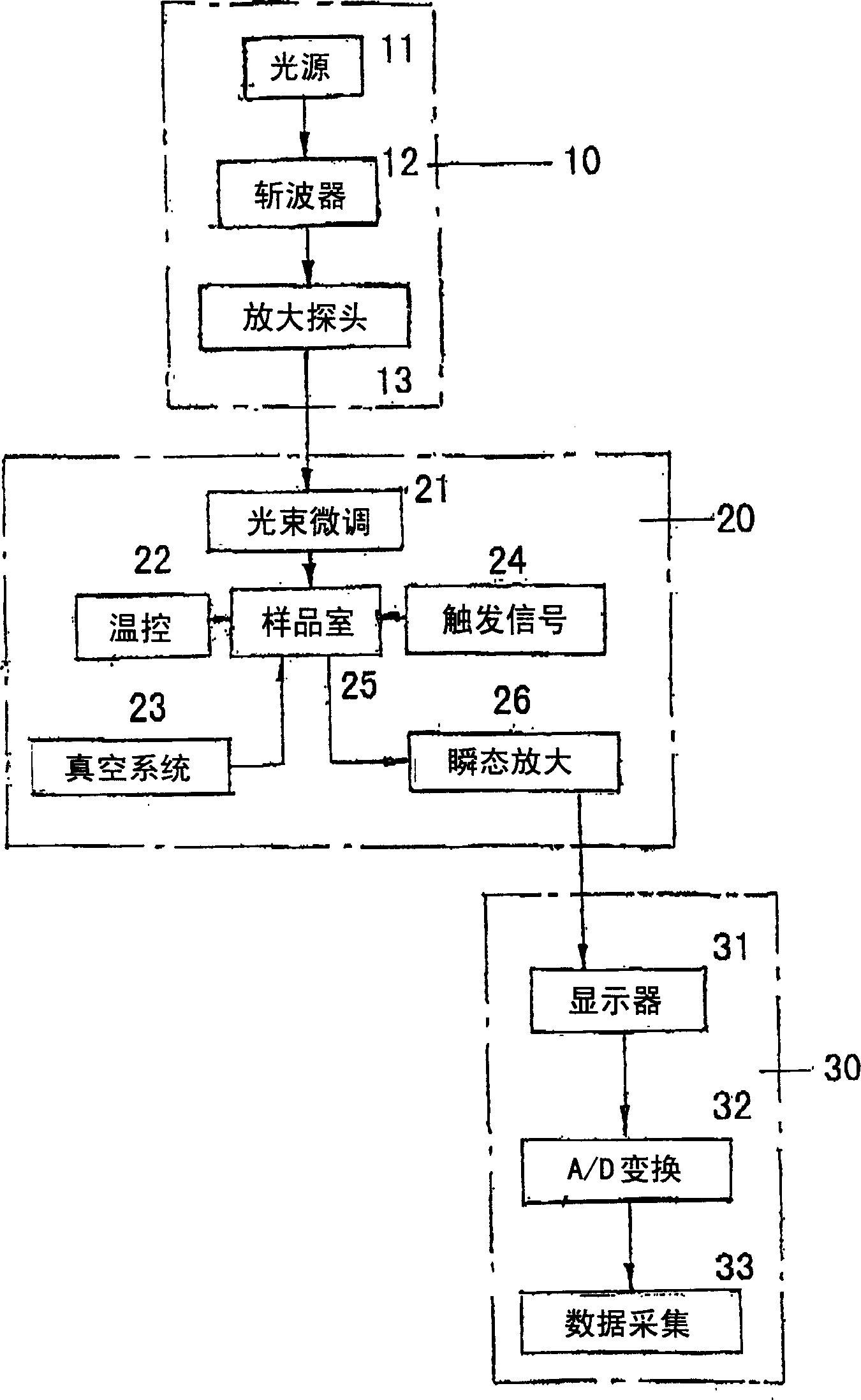

[0031] Attached below Figure 1 A further detailed description is made on the optically excited transient automatic test system.

[0032] figure 1 Among them, it is divided into three parts:

[0033] The first part is a diagram of the light injection device of the present invention.

[0034] The second part is the diagram of the sample chamber device of the present invention.

[0035] The third part is a diagram of the information collection and processing device of the present invention.

[0036] figure 1 Among them, the light injection device 10; is fixed on a movable track by the white light source 11, after the light passes through the chopper 12 fixed on the same track, the required wavelength can be obtained, and then through the amplifying probe 13, and The quartz optical fiber is transmitted to the micro-motion frame fixed on the light port of the upper cover of the sample chamber.

[0037] Sample chamber device 20: a three-dimensional micro-motion adjustment fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com