Packing material for wafer

A technology for packaging and wafers, which is applied in the directions of packaging, transportation and packaging, and containers to prevent mechanical damage, etc., can solve the problems of low cost of unfavorable optical components, large mold cost burden, and large wafer transportation costs, etc., to achieve improved Reliability, reduced shipping cost, stable cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Hereinafter, the present invention will be described in detail based on illustrated embodiments.

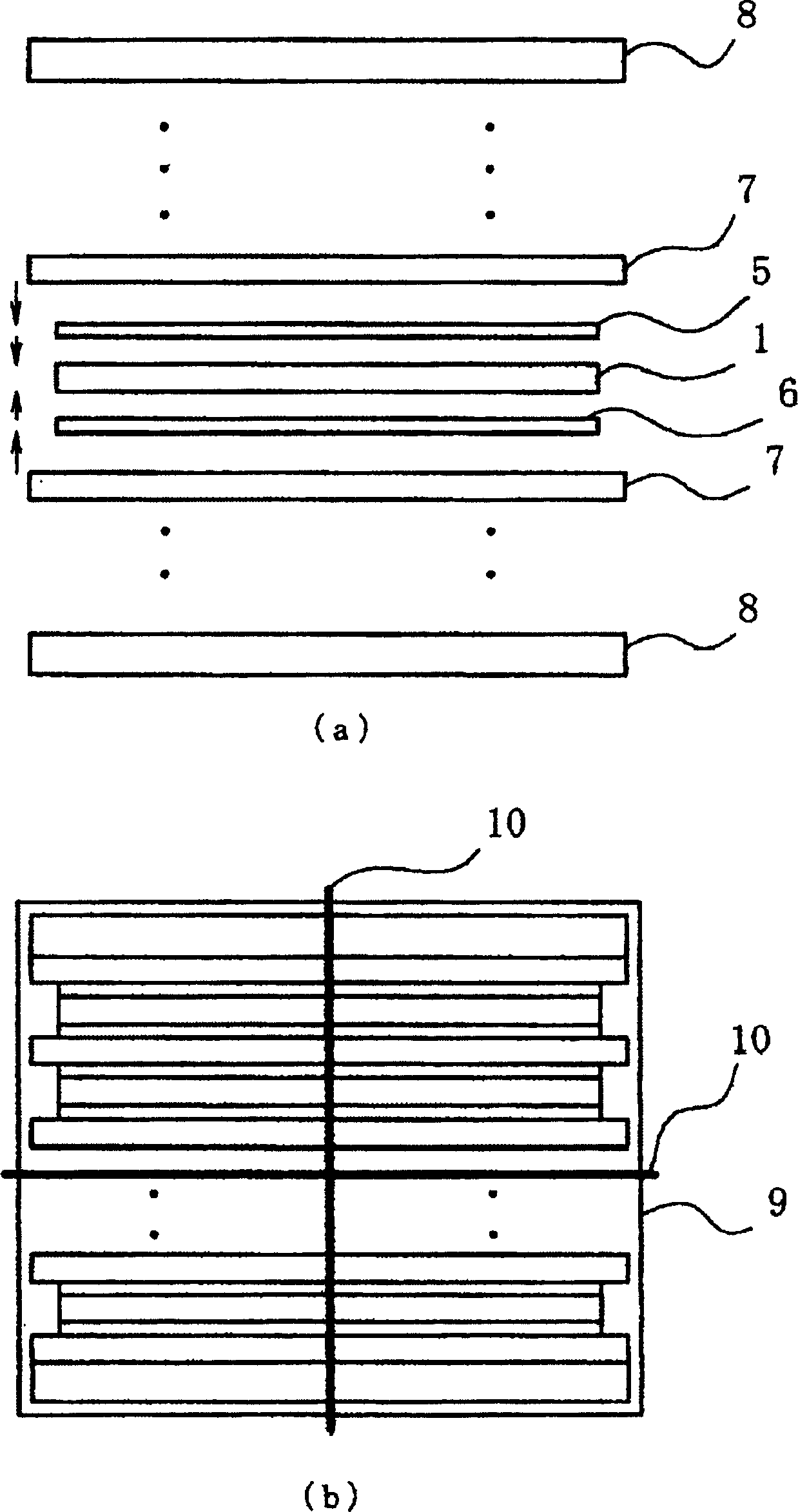

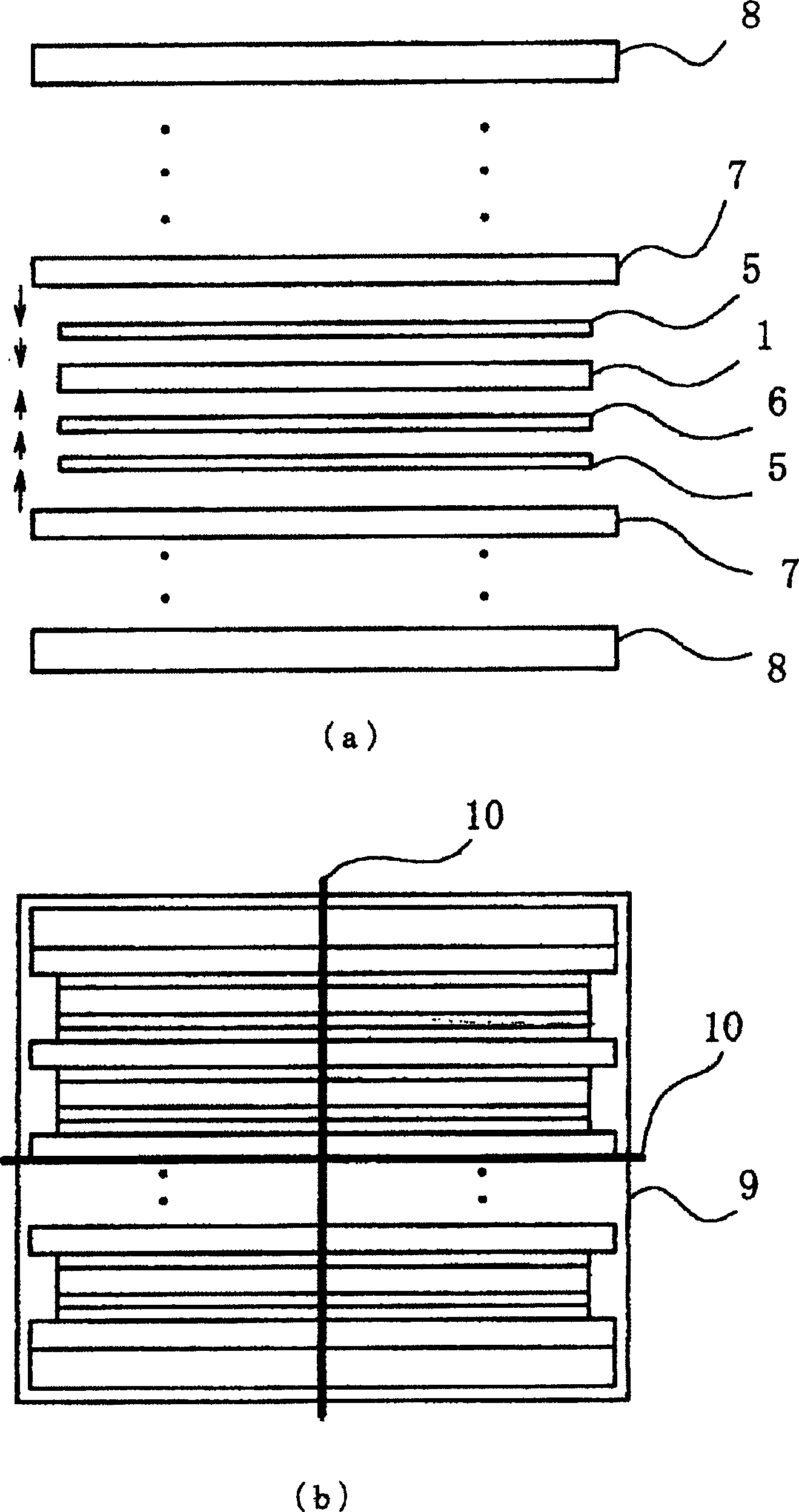

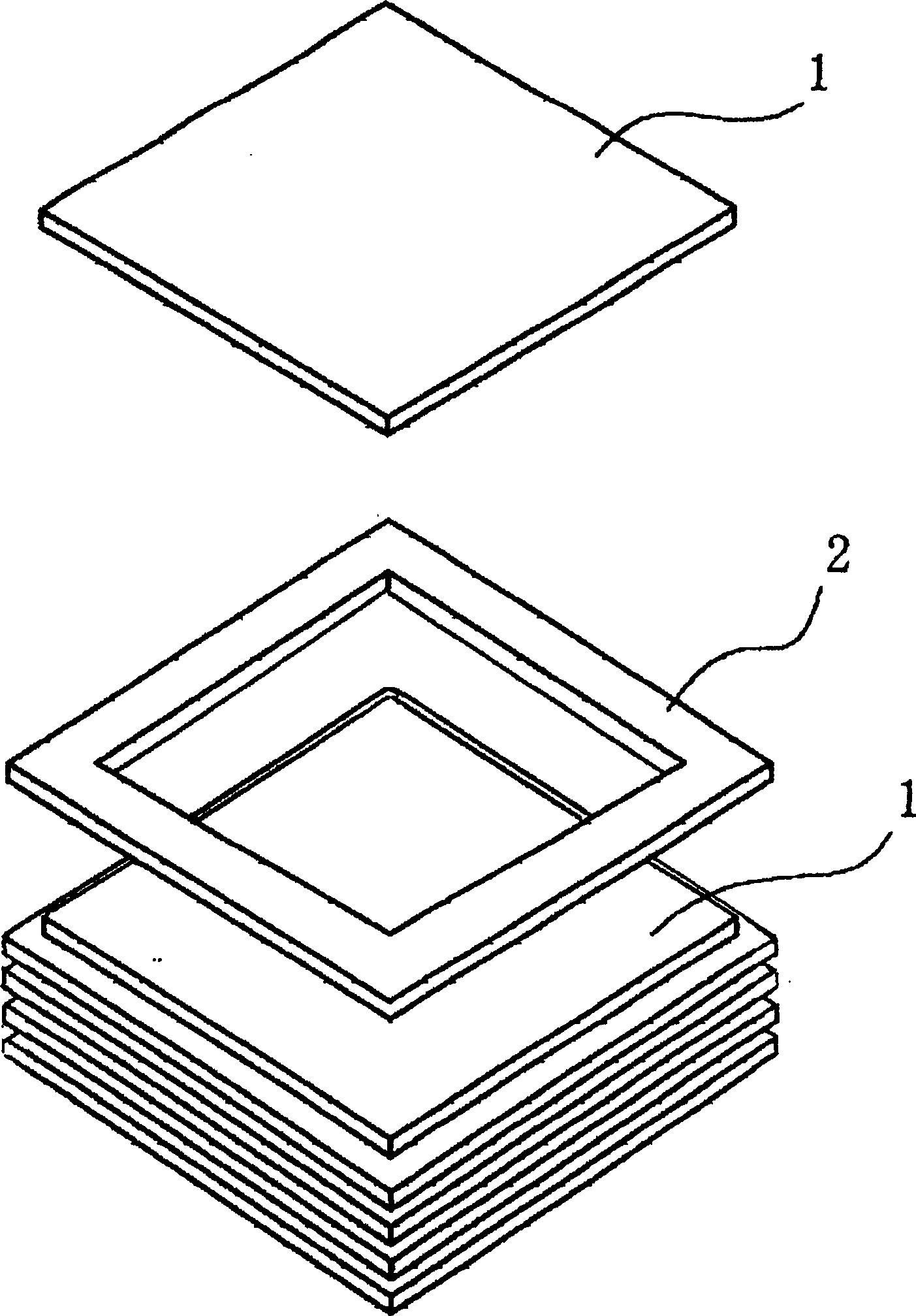

[0027] In the present invention, when the wafer is transported, a protective sheet for protecting the optical surface is attached to the entire upper surface of the wafer, a dicing tape is attached to the entire lower surface of the crystal, and a plurality of wafers are stacked and packaged with a buffer material in between. The subsequent process after the wafer is transported is to cut, clean, visually inspect, package, and ship the optical components obtained by dicing the wafer. Therefore, a dicing tape is attached to the lower surface of the wafer in advance to protect the lower surface of the wafer. In this state, the wafer is transported, and the wafer can be diced in this state directly after the transport. Therefore, the surface of the wafer is not in direct contact with the cushioning material, so damage or breakage due to vibration or impact during transportati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap