Light mould member for cast-in-situ concrete

A technology of cast-in-place concrete and components, which is applied to building components, building structures, floor slabs, etc., can solve the problems of affecting the appearance quality of the floor and ceiling, the bottom surface is prone to breakage and cracking, and the damage rate of lightweight tire mold components is high. To achieve the effect of convenient handling and construction, high strength and rigidity, and excellent anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

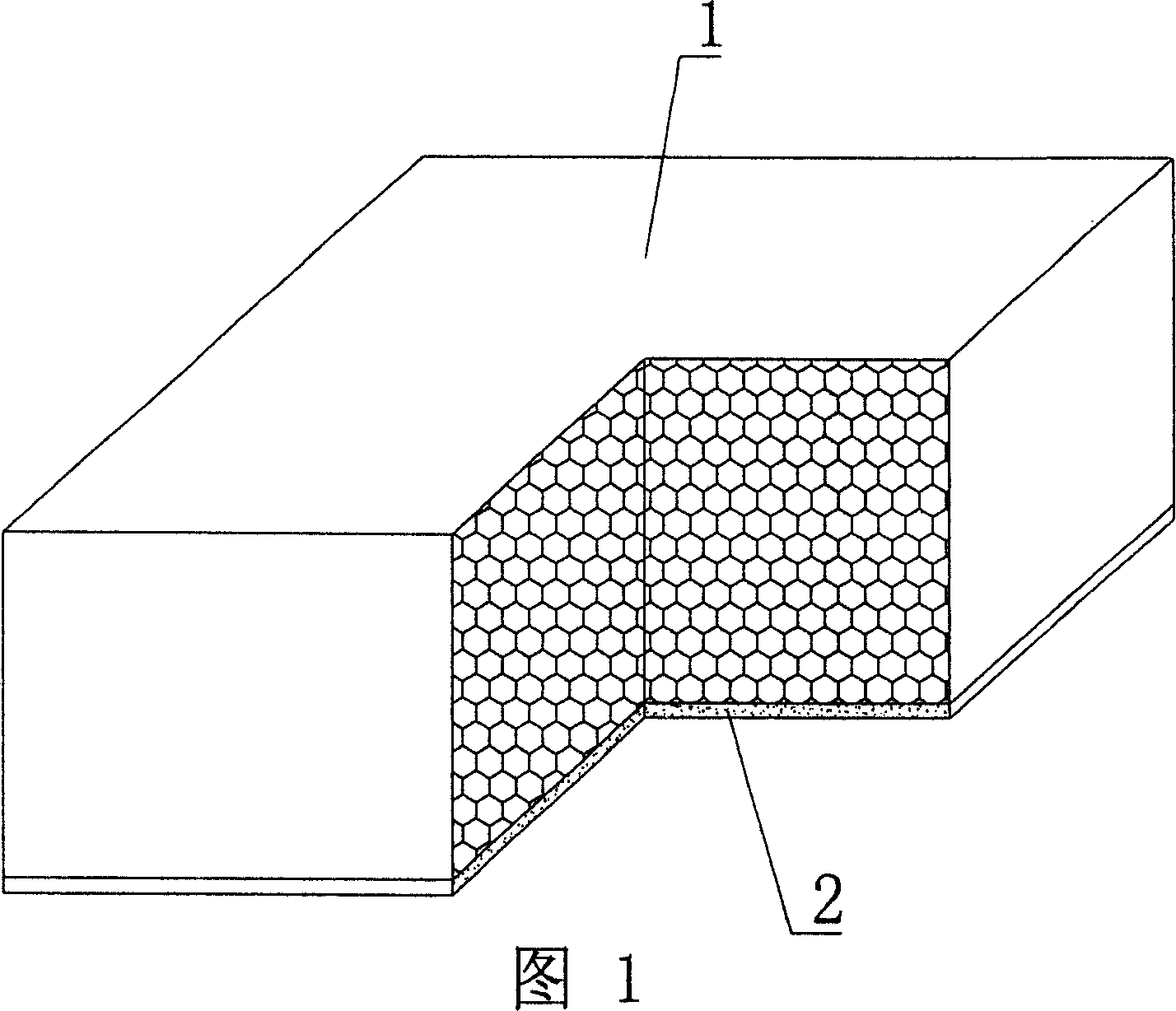

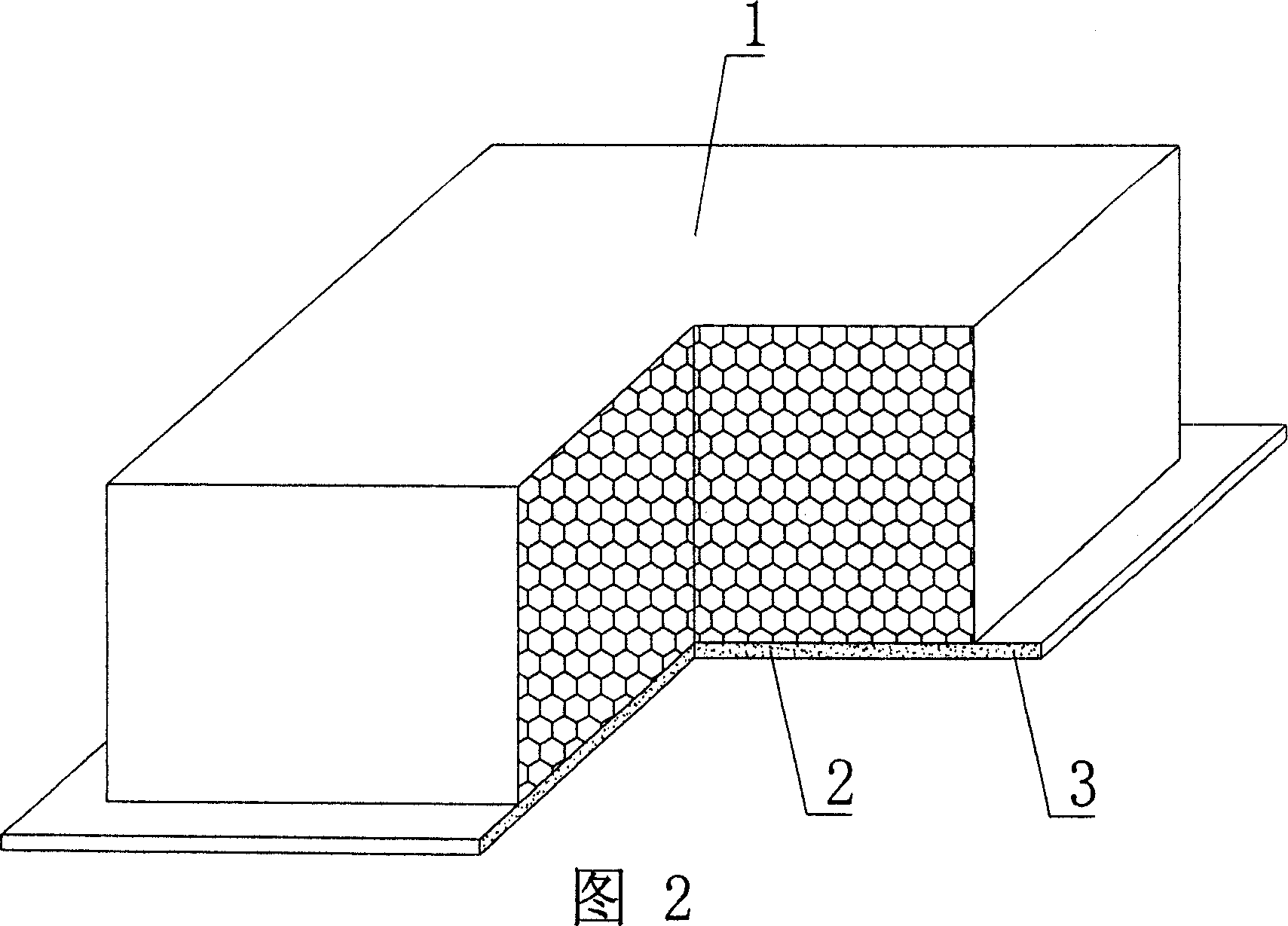

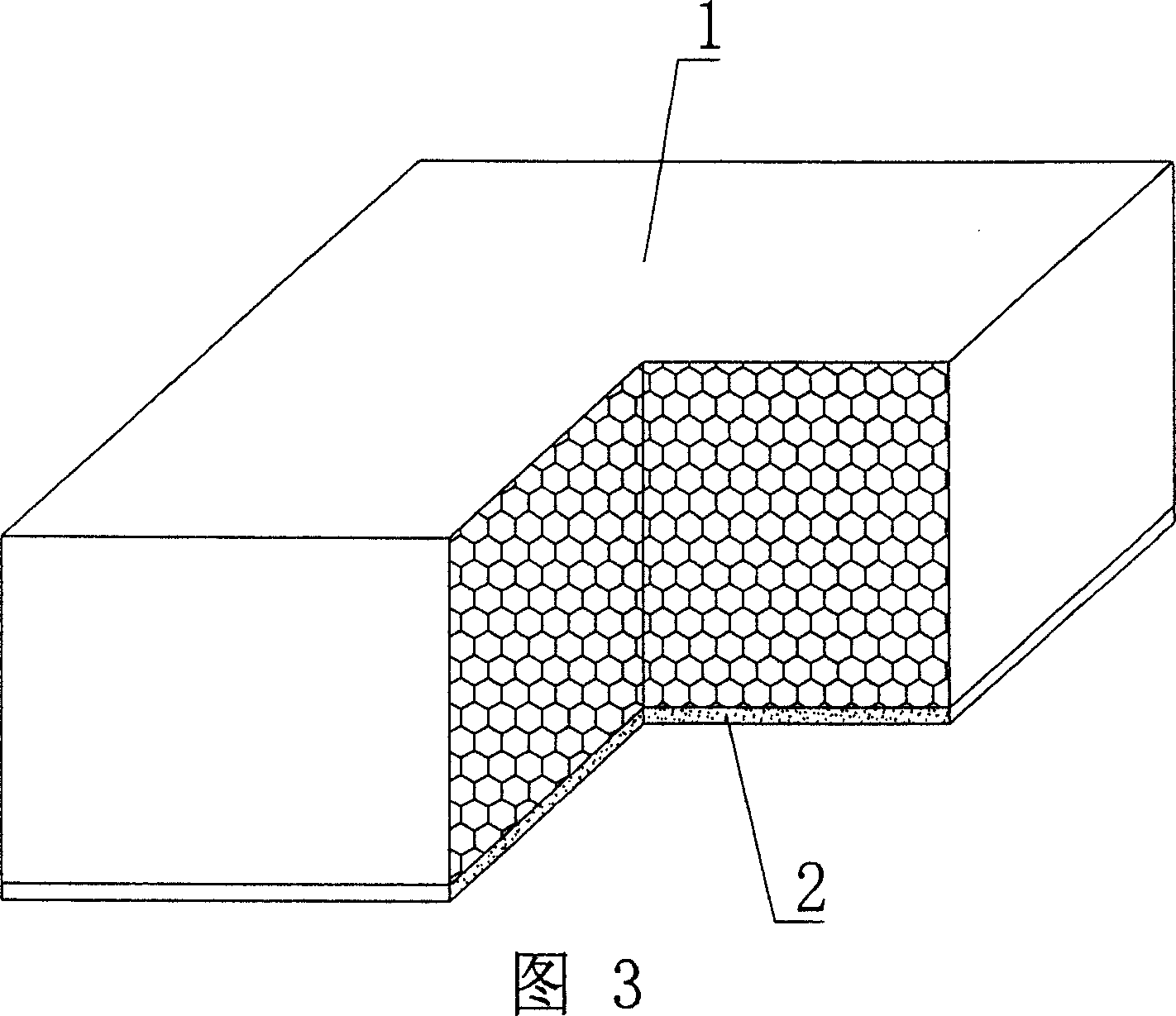

[0045] As shown in the accompanying drawings, the present invention includes a polyhedral solid lightweight material component 1, which is characterized in that it also includes a bottom plate 2, the polyhedral solid lightweight material component 1 is connected to the bottom plate 2 to form a whole, and the bottom plate 2 is a straight strip-shaped bottom plate, At least two polyhedron solid lightweight material members 1 are arranged in parallel and spaced apart in a line on the elongated longitudinal bottom plate 2 , supported by braces 21 at intervals. Fig. 1 is a schematic structural diagram of Embodiment 1 of the present invention. In the accompanying drawings, 1 is a polyhedral solid lightweight material member, and 2 is a base plate. In the following drawings, those with the same number have the same description. As shown in Fig. 1, the polyhed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com