Thin wall metal casing plastic composite pipe and its producing method

A metal shell, plastic parts technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, pipes, etc., can solve the problems of unfavorable mass production, unstable quality, low efficiency, etc. Low, high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention is described in further detail in conjunction with accompanying drawing and specific embodiment:

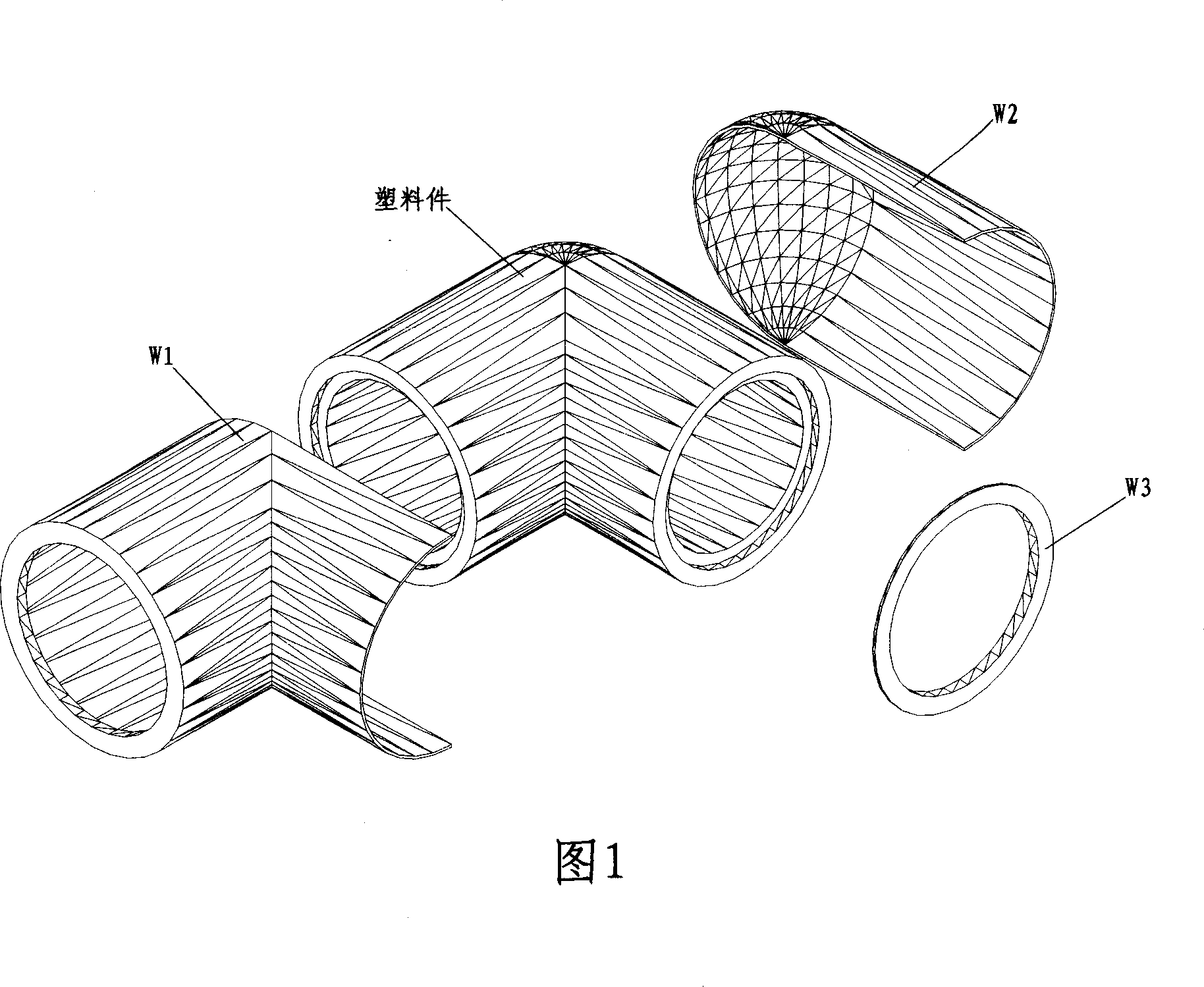

[0021] Figure 1: The elbow is composed of plastic parts and a metal shell, and the elbow shell is composed of three parts with different shapes - W1, W2, and W3. W1 is composed of a tube with one end turned inward twice and a half tube cut along the axis; W2 is composed of a half tube cut along the axis and a 1 / 4 spherical shell; W3 is a circle Disk, the hole in the middle of the disk has a flange.

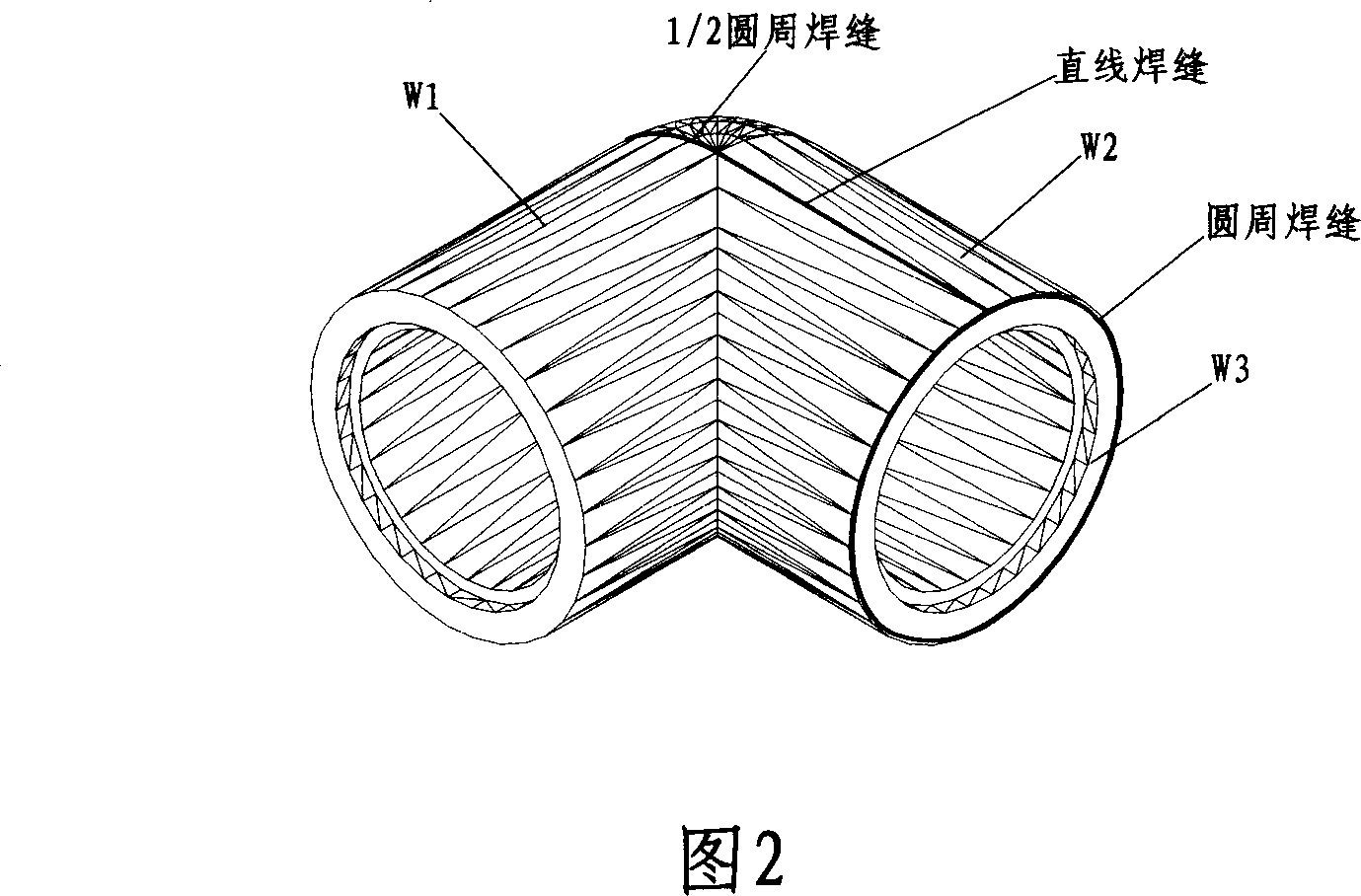

[0022] Figure 2: When W1, W2, and W3 are welded as a whole, there are two straight-line welds and a 1 / 2 circular weld between W1 and W2, and a circular weld between W3 and W1W2.

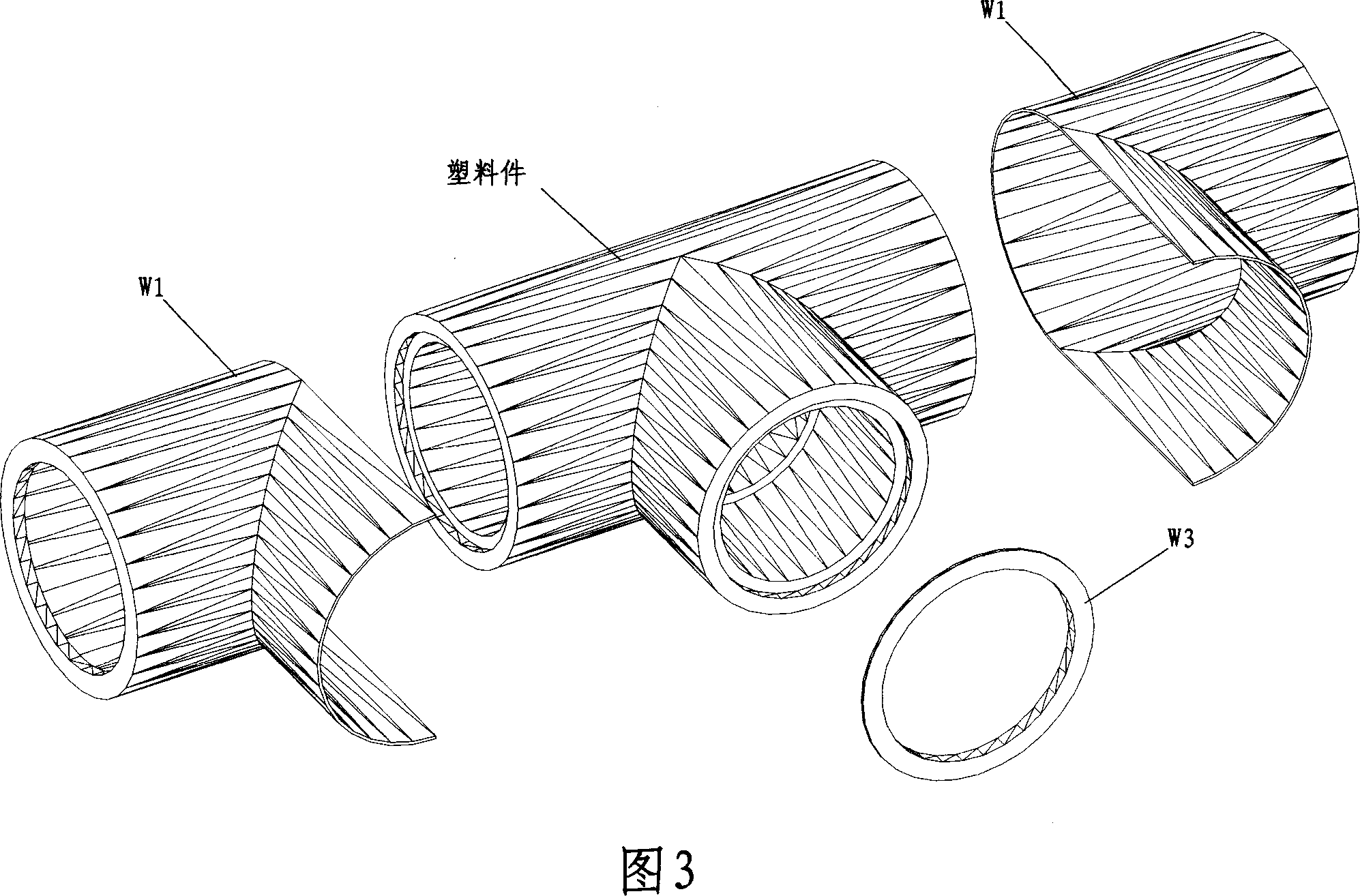

[0023] Figure 3: The tee is composed of plastic parts and a metal shell, and the tee shell is composed of three parts - two W1s and one W3.

[0024] Figure 4: When two W1s and one W3 are welded into a whole, there are two sections of straight line welds and 1 / 2 circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com