High open rate organic electroluminescence device and mfg. method thereof

A technology of electroluminescence and aperture ratio, which is applied in the direction of circuits, electrical components, and electrical solid devices, and can solve the problems of difficult control of the inverted trapezoidal angle, high cost, and difficulty in improving the resolution of the cathode partition wall 3, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

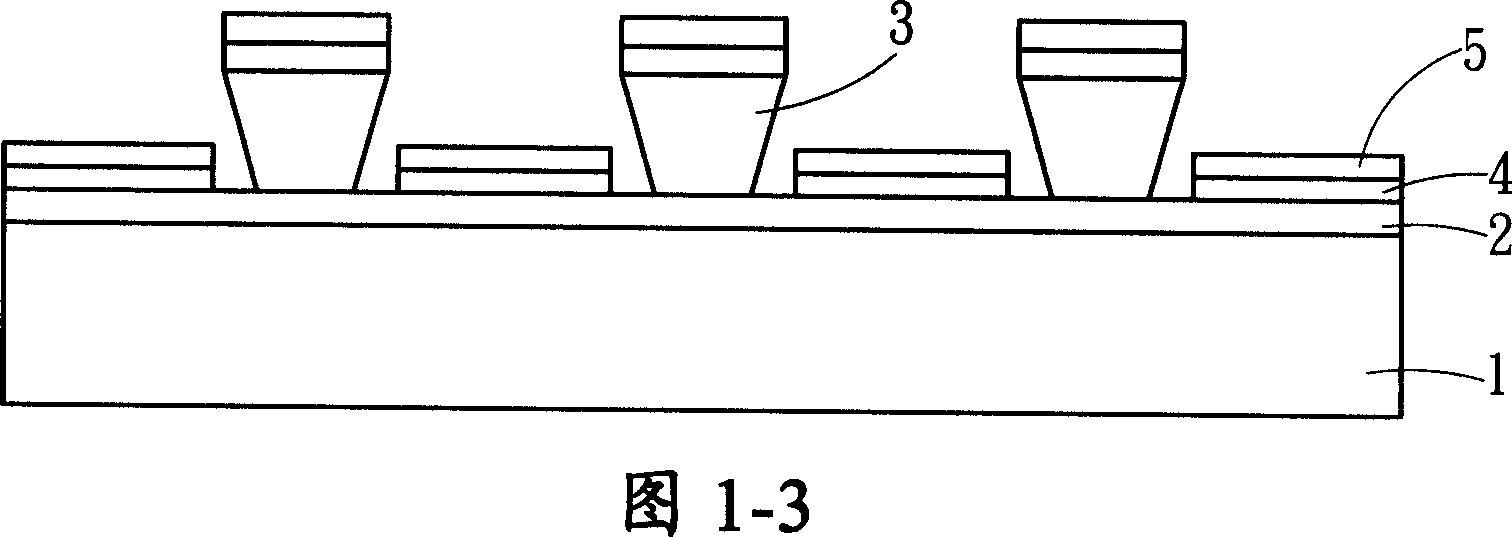

[0024] In order to have a deeper understanding and recognition of the features, purposes, and effects of the present invention, the preferred embodiments are now listed and described in conjunction with the accompanying drawings as follows:

[0025] Please refer to Fig. 4, which is a schematic view of the appearance of the strip-shaped convex body 30 of the present invention, which is elongated and can be arranged on a substrate 15. The strip-shaped convex body 30 is respectively provided with two opposite A first side 301 and a second side 302 , and the angle between the first side 301 and the substrate 15 forms an obtuse angle, and the angle between the second side 302 and the substrate 15 forms an acute angle.

[0026] If the strip-shaped convex body 30 is made of organic material, it can be manufactured by oblique exposure. The manufacturing method includes procedures such as organic material coating, pre-baking, oblique exposure, development, and curing. The material of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com