Engine control device

A control device, engine technology, applied in the direction of engine control, machine/engine, electrical control, etc., to prevent discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

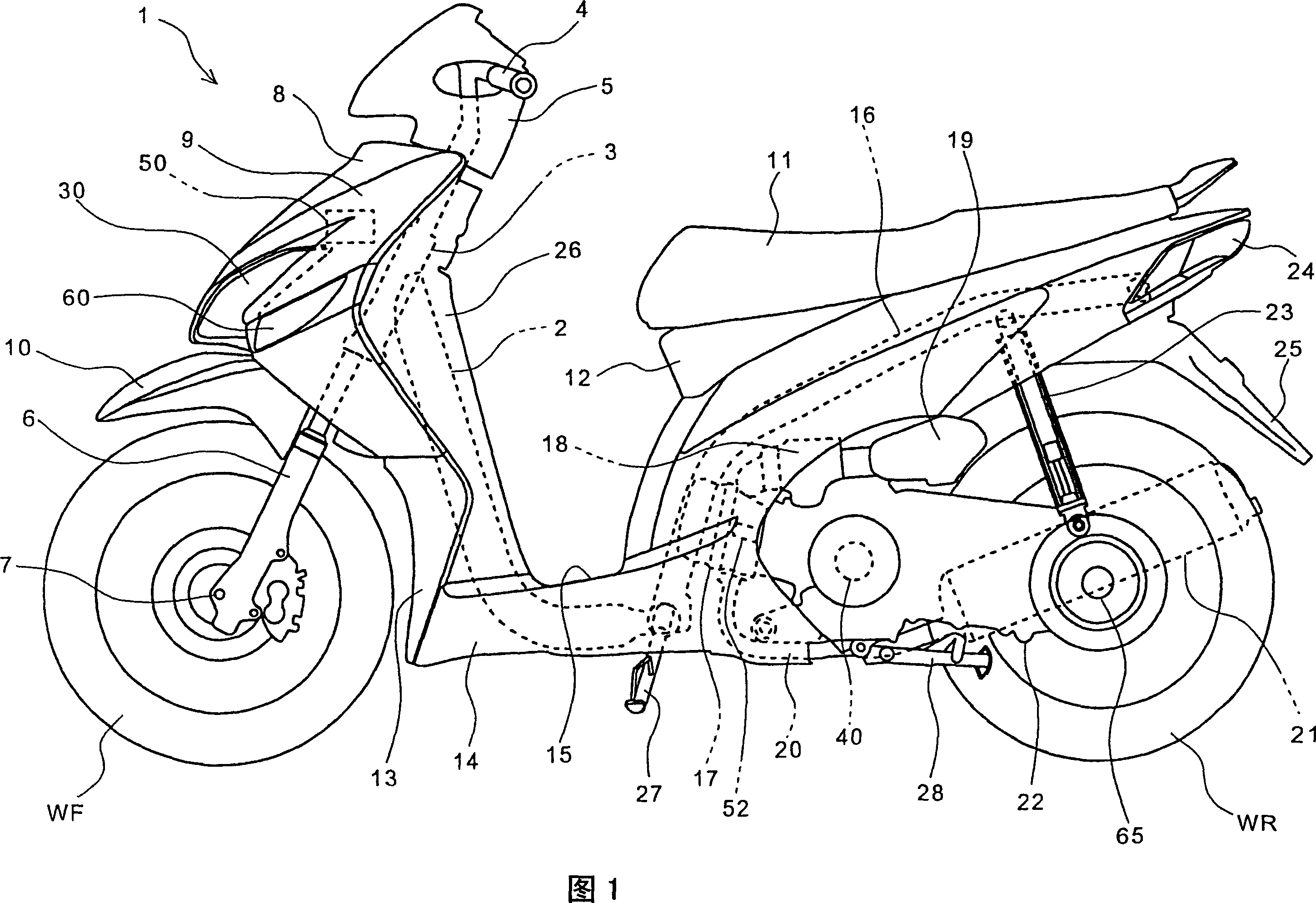

[0020] Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Fig. 1 is a side view of an embodiment of a motorcycle to which the present invention is applied. The motorcycle 1 is a scooter equipped with a vibration-proof power unit incorporating a continuously variable transmission. A pair of left and right front forks 6 are pivotally supported on a head pipe 3 fixedly connected to a main frame 2 serving as a vehicle frame, and a front wheel WF is pivotally supported on an axle 7 at the lower end thereof. The front fork 6 can be steered by the handlebar 4 protruding from the handlebar cover 5 to the left and right in the vehicle width direction, and the front fender 10 covering the top of the front wheel WF is steered integrally with the front fork 6 . On the front cover 9 serving as a vehicle body cover disposed above the front fender 10 , a left and right double lamp type headlamp unit 60 and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap