Process of preparing high purity chlorogenic acid and flavonid with eucommia leaf

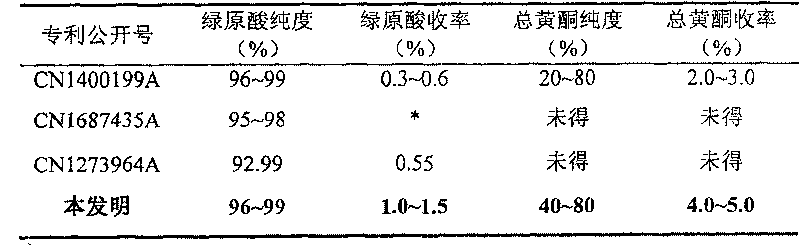

A technology of chlorogenic acid and eucommia leaves, which is applied in the field of preparing high-purity chlorogenic acid and total flavonoids, can solve the problems of many types of reagents, large solvent consumption, cumbersome process, etc., and achieve high target component content and product quality The effect of stability and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The selection of embodiment 1 extraction process condition:

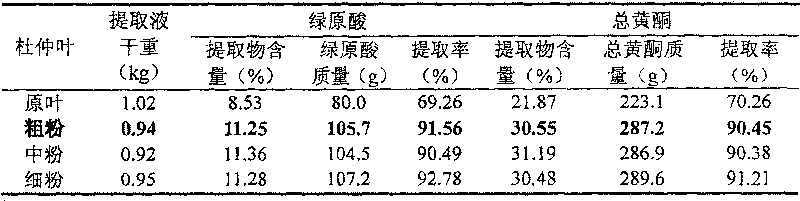

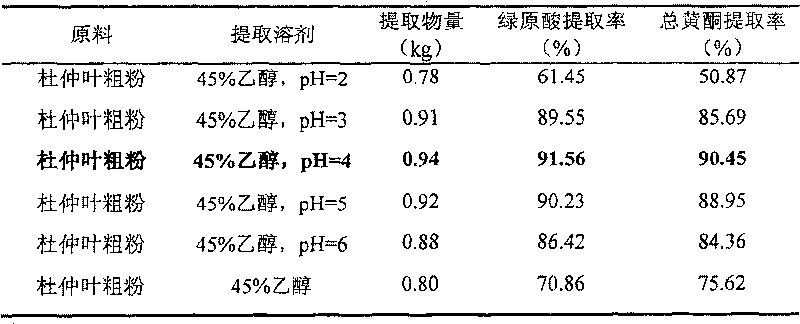

[0034] (1) Effect of pulverized Eucommia leaves on the extraction rate of chlorogenic acid and total flavonoids

[0035] Experimental method: 5.0kg of eucommia leaves were extracted with 40L of 45% ethanol solution with pH=4, stirred twice at 70°C, the first time was extracted with 25L solvent for 2 hours, and the second time was extracted with 15L solvent for 1 hour. After the solution was concentrated to 4L, it was left to stand for 1.0 hour and centrifuged, and the supernatant was taken to dry, and the extraction rates of chlorogenic acid and total flavonoids were calculated respectively. The results are shown in the table below

[0036]

[0037] It can be seen from the above table that pulverizing Eucommia leaves increases the contact area between the raw material and the extraction solvent, and improves the extraction rate of active ingredients. When Eucommia leaves were crushed into coarse powder, me...

Embodiment 2

[0051] The selection of embodiment 2 separation process

[0052] (1) The influence of the choice of macroporous resin type on the separation effect

[0053] Experimental method: Extract 5kg of eucommia leaf coarse powder with 45% ethanol solution with pH=4 at 70°C for 1.5 hours each time, concentrate the combined extracts to 4L and centrifuge, and take the supernatant as eucommia leaf The extract was determined to have a dry weight of 0.9kg, a mass content of chlorogenic acid of 11.3% and a mass content of total flavonoids of 30.5%. The extract was divided into 7 parts on average, and the macroporous resin was used for static saturated adsorption, and the adsorption capacity and desorption rate of different types of resins for chlorogenic acid and total flavonoids were calculated respectively. Macroporous resin mainly selects non-polar resin XDA-5, LSA-20, D140, polar resin NKA-II, HPD-400, HPD-400A and medium polar resin JD-1 in the method of the present invention.

[0054]...

Embodiment 3

[0059] The process selection of embodiment 3 chlorogenic acid refining process

[0060] (1) The effect of the amount of silica gel on the separation of chlorogenic acid silica gel column

[0061] Experimental method: Take 0.25kg of crude chlorogenic acid (content is 24.5%) and dissolve it with 100ml of methanol, mix the sample with 125g of silica gel and put it on a silica gel column. The amount of silica gel in the silica gel column is 6 to 15 times the dry weight of crude chlorogenic acid, and then Use ethyl acetate as the eluent for elution, collect in sections and then concentrate under reduced pressure. The fractions collected in sections are monitored by HPLC, and the fractions with a content higher than 90% are combined and concentrated to dryness. The result shows that when the amount of silica gel is less than 6 times of the dry weight of the crude product of chlorogenic acid, the crude product of chlorogenic acid is not separated well, and the yield of 90% chlorogeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com