Composite differential device for four-drive transmission system

A technology of drive train and differential, applied in the direction of transmission, differential transmission, belt/chain/gear, etc., can solve the problems of large space occupation, loss of steering function, causing accidents, etc. The effect of off-road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

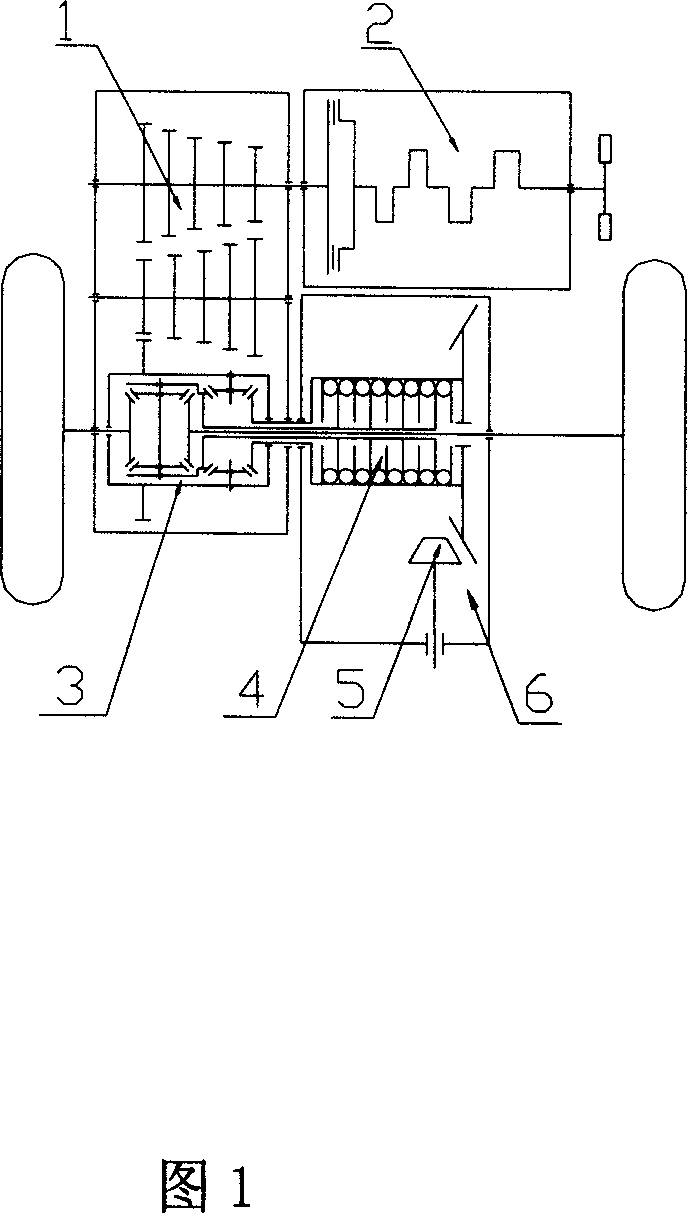

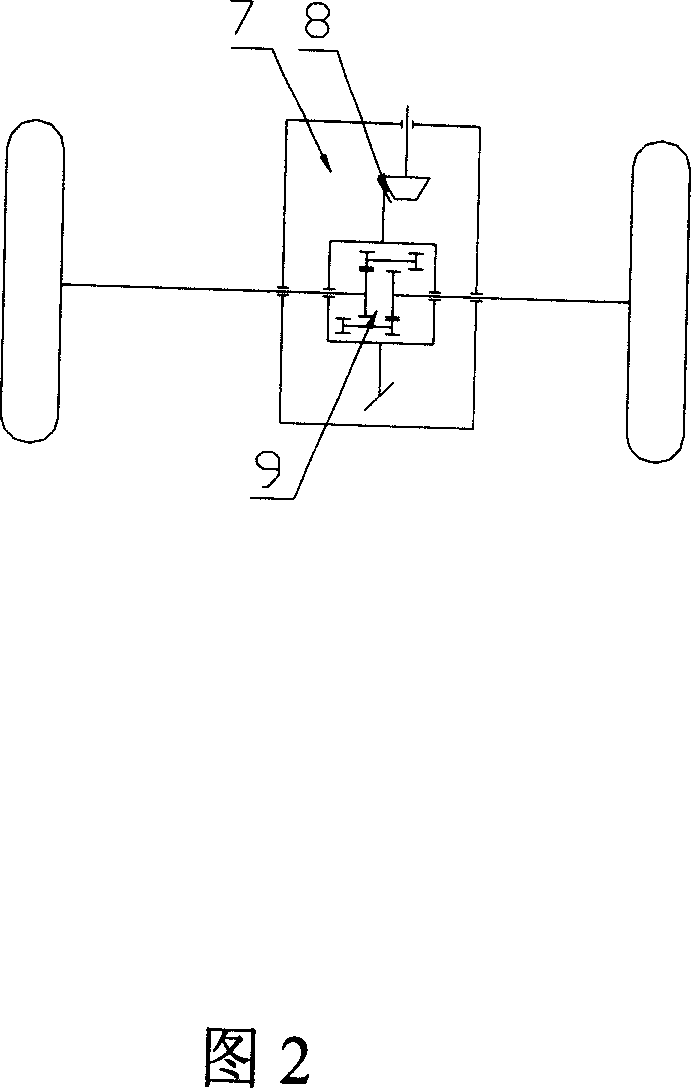

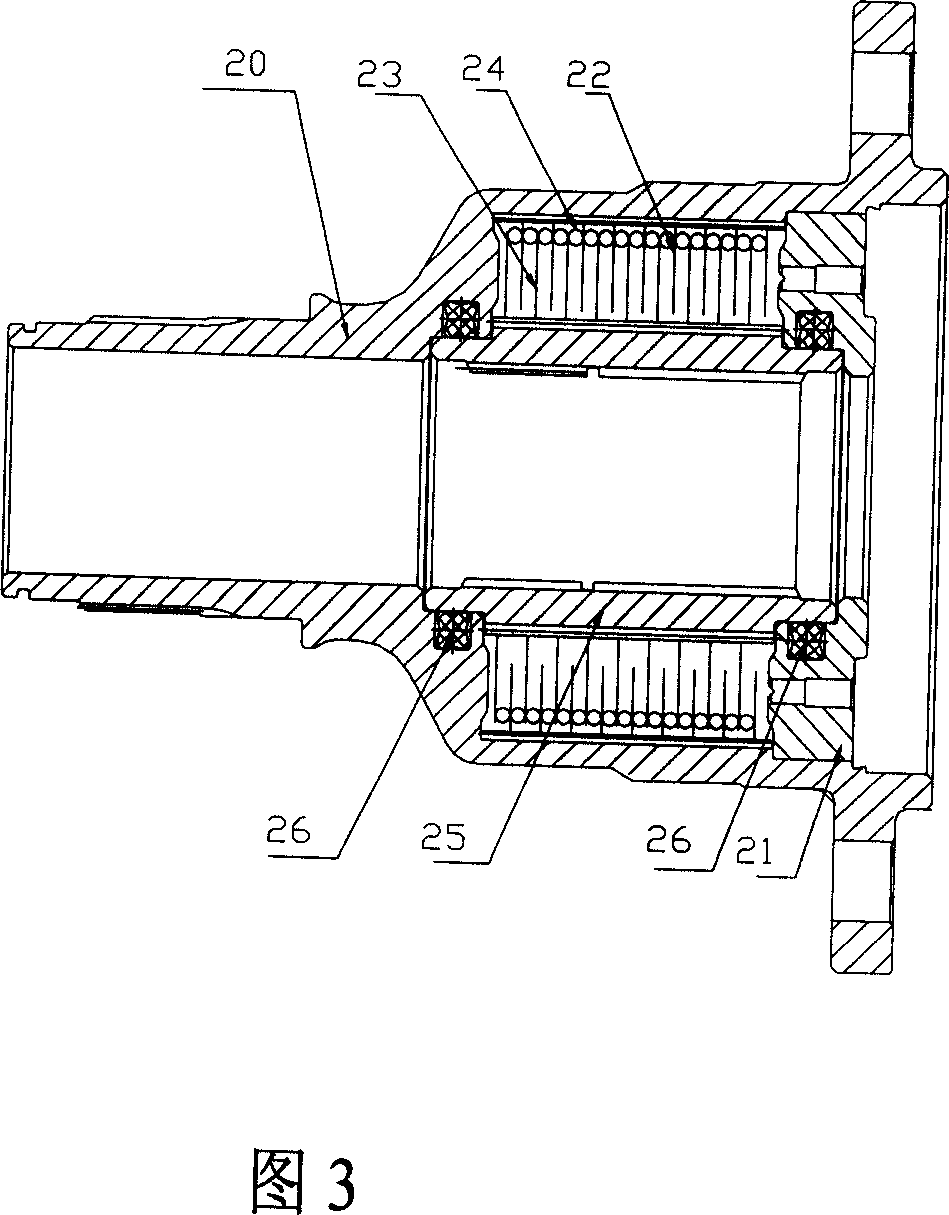

[0015] In the embodiment, a composite differential device used in a four-drive transmission system includes a composite differential 3 and a rear axle differential 9, and the rear axle differential adopts a non-slip differential. The quasi-hyposide gear 5 and the viscous coupling 4 are put together in the transfer case 6 , and the compound differential 3 is arranged in the gearbox 1 .

[0016] The transmission of engine 2 is connected to gearbox 1, the transmission of gearbox 1 is connected to compound differential 3, and the transmission of compound differential 3 is connected to viscous coupling 4, the inner hub of viscous coupling 4 is connected to the front axle difference in compound differential 3 The transmission casing is connected, and the casing of the viscous coupling 4 is connected with the hypoid gear, thereby connecting the rear axle differential 9, and the rear axle differential 9 is transmission-connected to the rear driving wheel. The viscous coupling 4 cooper...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap