Vertical unipolar component

a technology of vertical unipolar components and components, applied in the manufacturing of semiconductor devices, semiconductor/solid-state devices, electric devices, etc., can solve the problems of complex structure and achieve the effect of high breakdown voltage and simple manufacturing structure of figs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] For clarity, the same elements have been referred to with the same reference numerals in the different drawings. Further, as usual in semiconductor component representation, the drawings are not to scale.

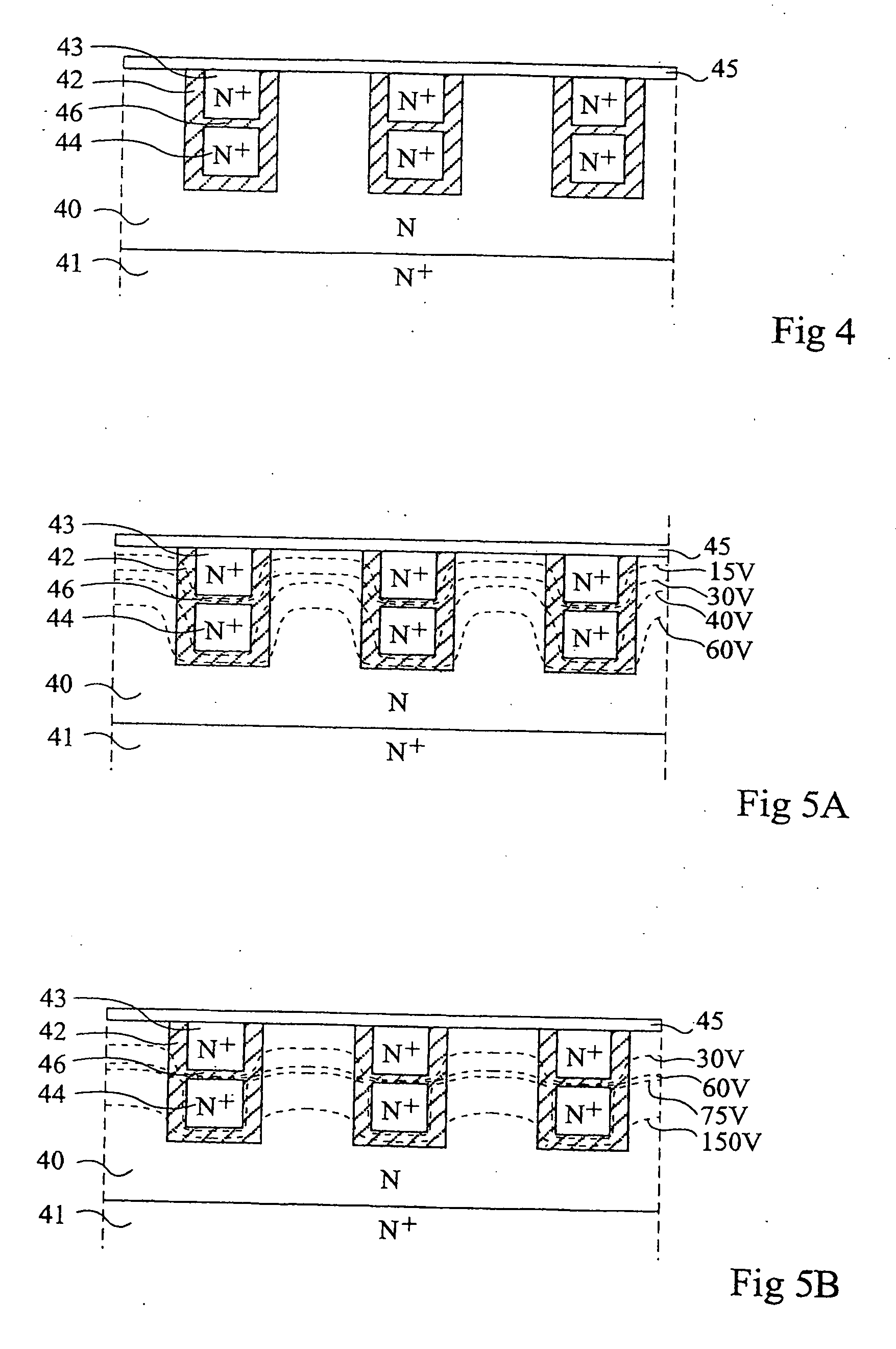

[0040]FIG. 4 is a partial simplified cross-section view of an embodiment of a Schottky diode according to the present invention. The cathode of the diode is an upper portion (N) 40 of a semiconductor substrate, for example made of single-crystal silicon. A lower portion (N+) 41 of the substrate forms a contact area of the cathode. Cathode 40 is more lightly doped than portion 41.

[0041] In cathode 40 are formed trenches coated with an insulator 42 and filled with a conductor divided in two conductive elements, a high element 43 and a low element 44 separated by an insulating layer 46. It will be said hereafter that insulated conductor elements 43-44 form a multiple-layer. The upper surface of high element 43 is coplanar with the upper surface of peripheral cathode 40 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com