Gasification furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

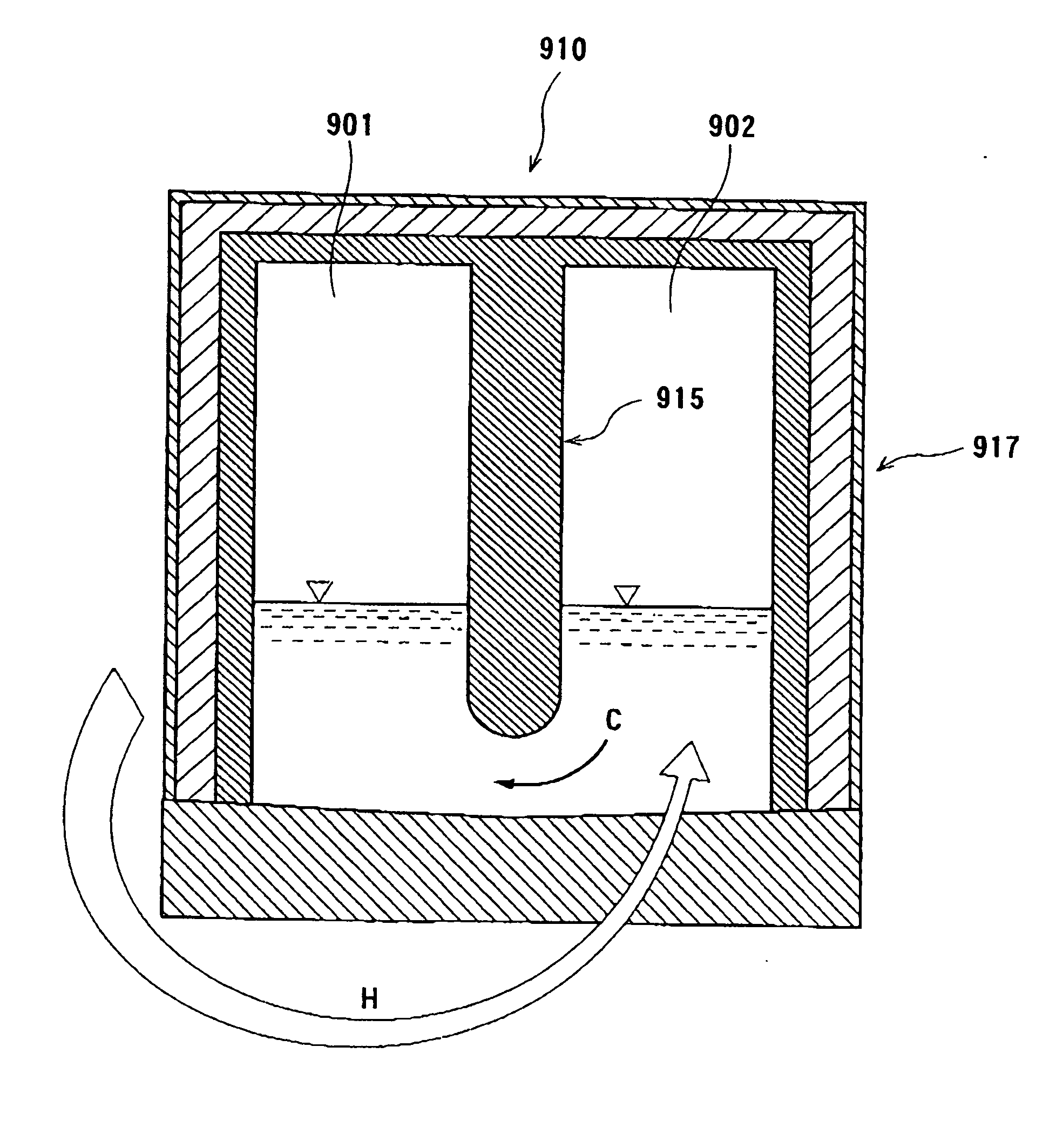

[0036]FIG. 2A is a cross-sectional plan view showing an integrated gasification furnace 100 as a fluidized-bed gasification furnace according to the present invention. As shown in FIG. 2A, the integrated gasification furnace 100 has a gasification chamber 1 for pyrolyzing a raw material such as various wastes or solid fuel and a char combustion chamber 2 for combusting char to heat a fluidized medium therein. The gasification chamber 1 and the char combustion chamber 2 are separated from each other by a partition wall 15. Dense beds including a fluidized medium are formed on furnace bottoms of the gasification chamber 1 and the char combustion chamber 2, respectively. The fluidized beds are fluidized by a diffuser (not shown).

[0037] As shown in FIG. 2A, the combustion chamber 2 is separated from the exterior of the furnace by a circumferential furnace wall 17. The circumferential furnace wall 17 includes an inner wall 17a made of a refractory material which is exposed to the interio...

second embodiment

[0057]FIG. 5 is a cross-sectional front view showing an integrated gasification furnace 101 as a fluidized-bed gasification furnace according to the present invention. The integrated gasification furnace 101 includes a gasification chamber 1 for pyrolysis (i.e., gasification), a char combustion chamber 2 for char combustion, and a heat recovery chamber 3 for heat recovery. The integrated gasification furnace 101 has a furnace body in the form of a cylinder or a parallelepiped. The gasification chamber 1, the char combustion chamber 2, and the heat recovery chamber 3 are housed in the furnace body and separated from each other by partition walls 11, 12, 13, and 15. Dense beds including a fluidized medium are formed on bottoms of the gasification chamber 1, the char combustion chamber 2, and the heat recovery chamber 3, respectively. Diffusers are provided on furnace bottoms of the respective chambers 1, 2, and 3 to eject fluidizing gases into the fluidized medium. The fluidized mediu...

third embodiment

[0095]FIG. 7 is a cross-sectional front view showing a gasification furnace 102 according to the present invention. FIG. 7 shows a structure of a gasification chamber 1 and a char combustion chamber 2 and movement of a fluidized medium.

[0096] The gasification furnace 102 in the present embodiment has substantially the same structure as the gasification furnace in the second embodiment. In addition to the structure of the second embodiment, the gasification furnace 102 includes a steam supply port 35a for supplying steam from a furnace bottom near a communication hole 25, through which the fluidized medium flows from the char combustion chamber 2 into the gasification chamber 1. The steam supply port 35a is located downstream of the communication hole 25 (in the gasification chamber 1). Similarly, the gasification furnace 102 includes a steam supply port 35b for supplying steam from a furnace bottom near a communication hole 21, through which the fluidized medium flows from the gasif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com