Sheet separating system, sheet handling system, method for the frictional separation and feeding of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

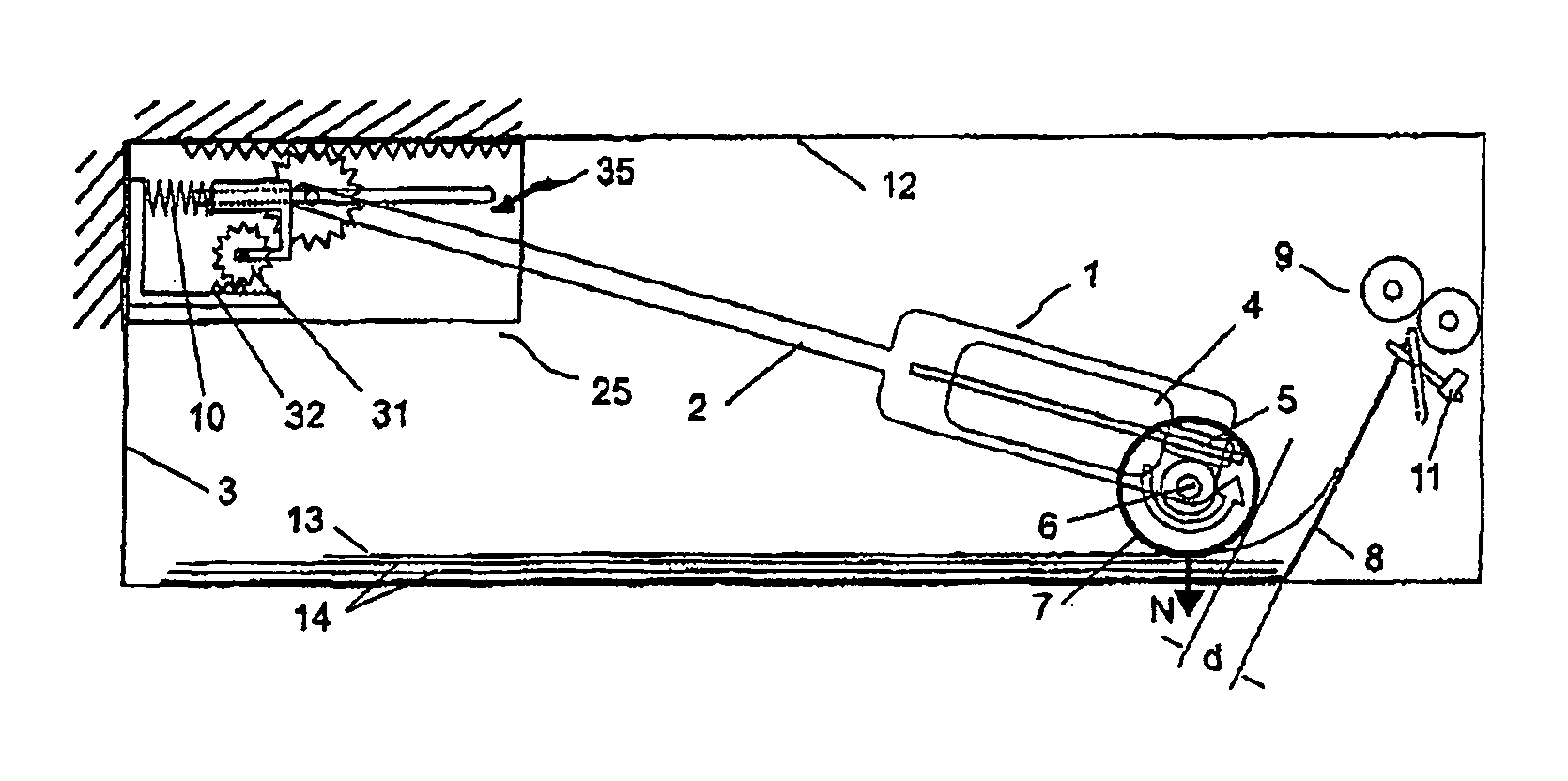

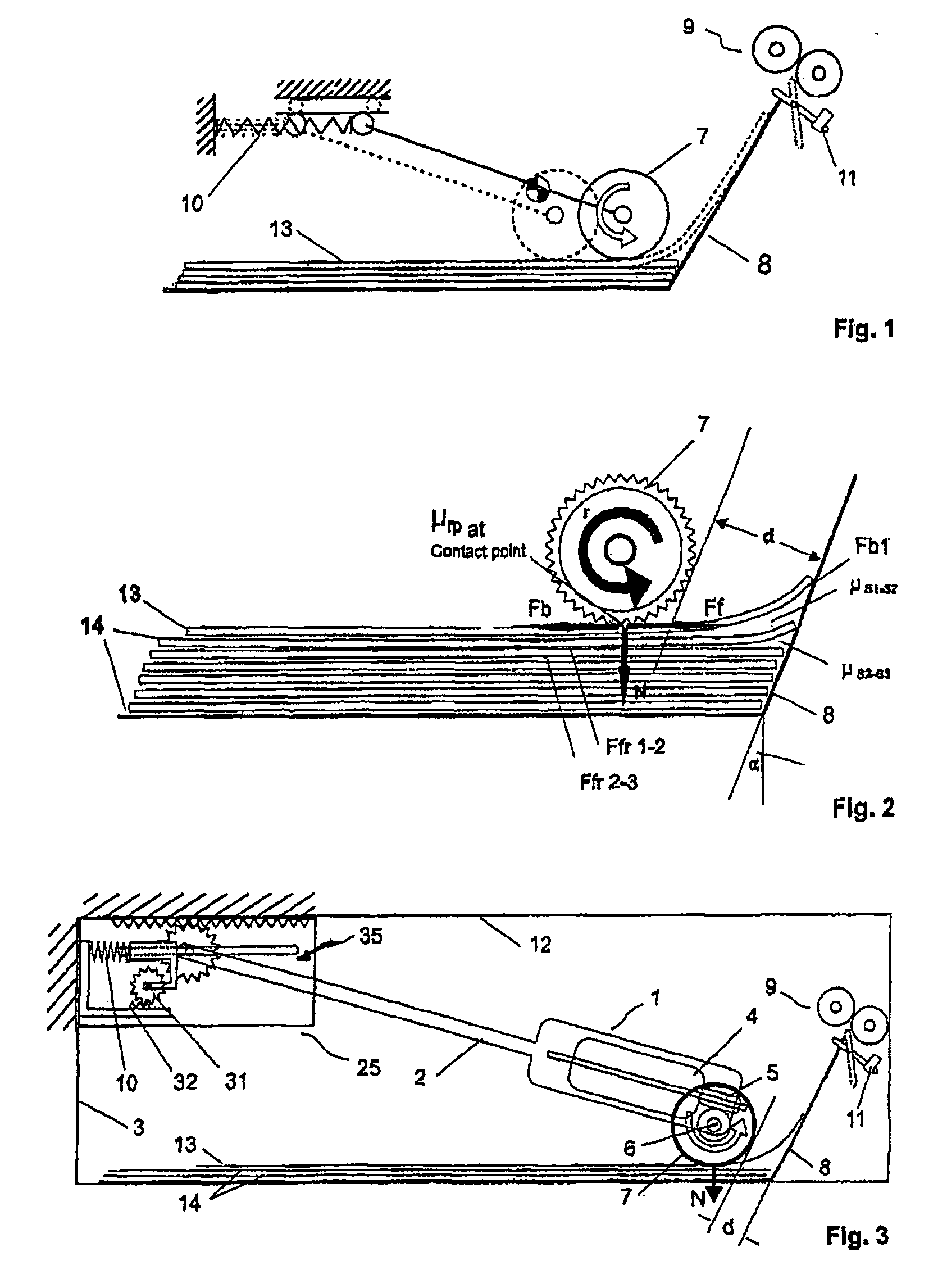

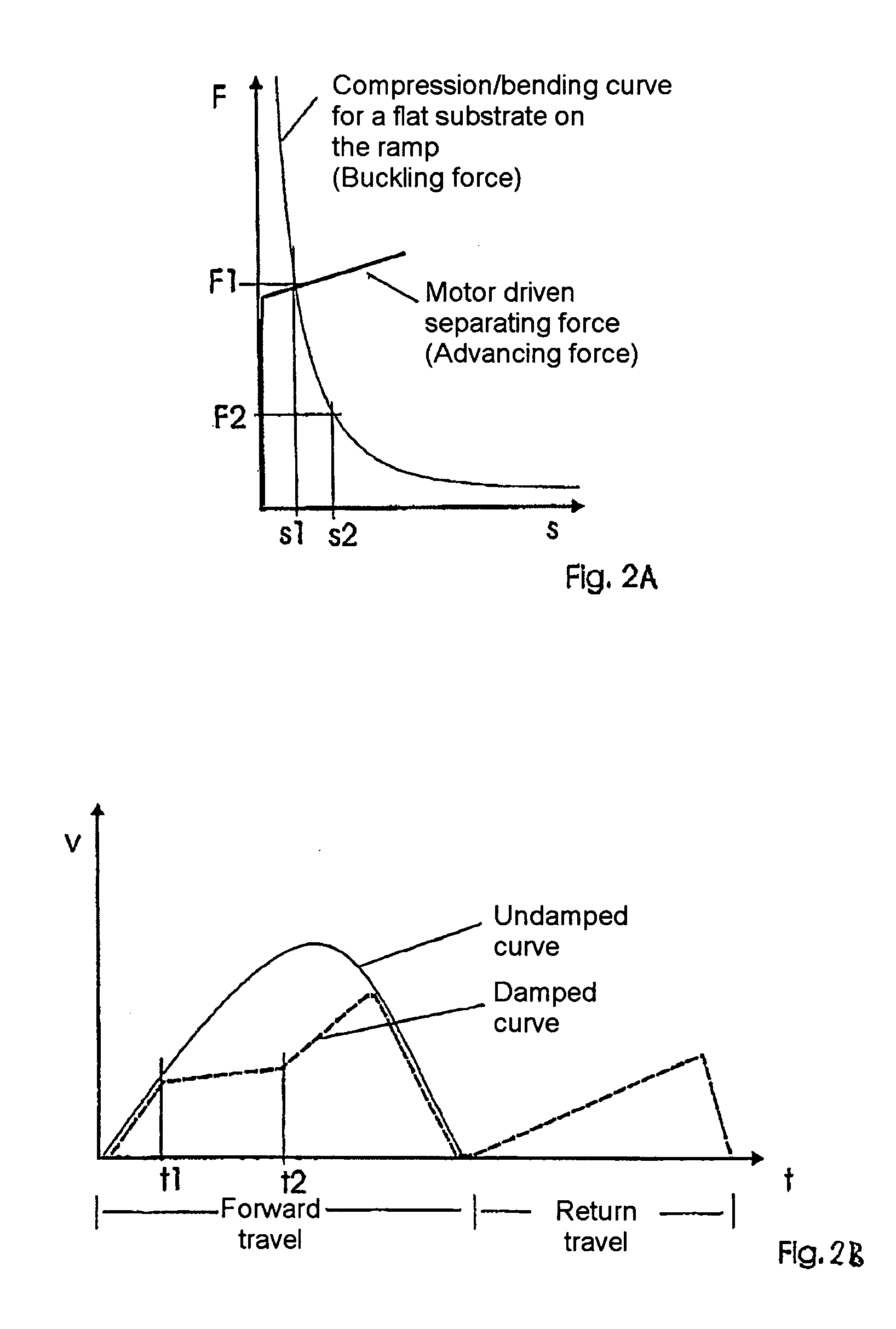

[0039] The embodiments of the apparatus and of the method explained here are used, according to the concept of the invention, to optimize the reliability when separating stores of sheets in the form of stacks which are separated using a separating system. Identical reference symbols have been used for corresponding parts. The separating system according to the embodiment comprises essentially a frictional roller 7 which is shown in FIG. 1 and is driven by an (electric) motor and frictionally separates the uppermost sheet 13 of a stack of sheets of paper or substrates from the rest of this stack and feeds it to a pair of rollers via a mechanical ramp 8, 12 (which in addition to applying friction to the stack functions as a second hurdle).

[0040] The paper stack is usually stored in a shaft or a cartridge.

[0041] The single sheet can be drawn from the cartridge using the separating device (also referred to as feeder).

[0042] The pair 9 of rollers at the end of the ramp 8, which are al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Speed | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap