Conveyor for sheet-shaped thin plate and method of conveying same

a technology of conveying device and sheet-shaped thin plate, which is applied in the direction of manufacturing tools, soldering devices,auxillary welding devices, etc., can solve the problems of high labor intensity, high time and labor intensity, and inability to achieve good welding conditions, etc., and achieves easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]Hereunder, a preferred embodiment of the present invention will be explained with reference to the accompanying drawings. Further, it is to be noted that terms “upper”, “lower”, “right”, “left” and the like terns are used herein with reference to the illustrated state on the drawings or in a usually operative state of the apparatus.

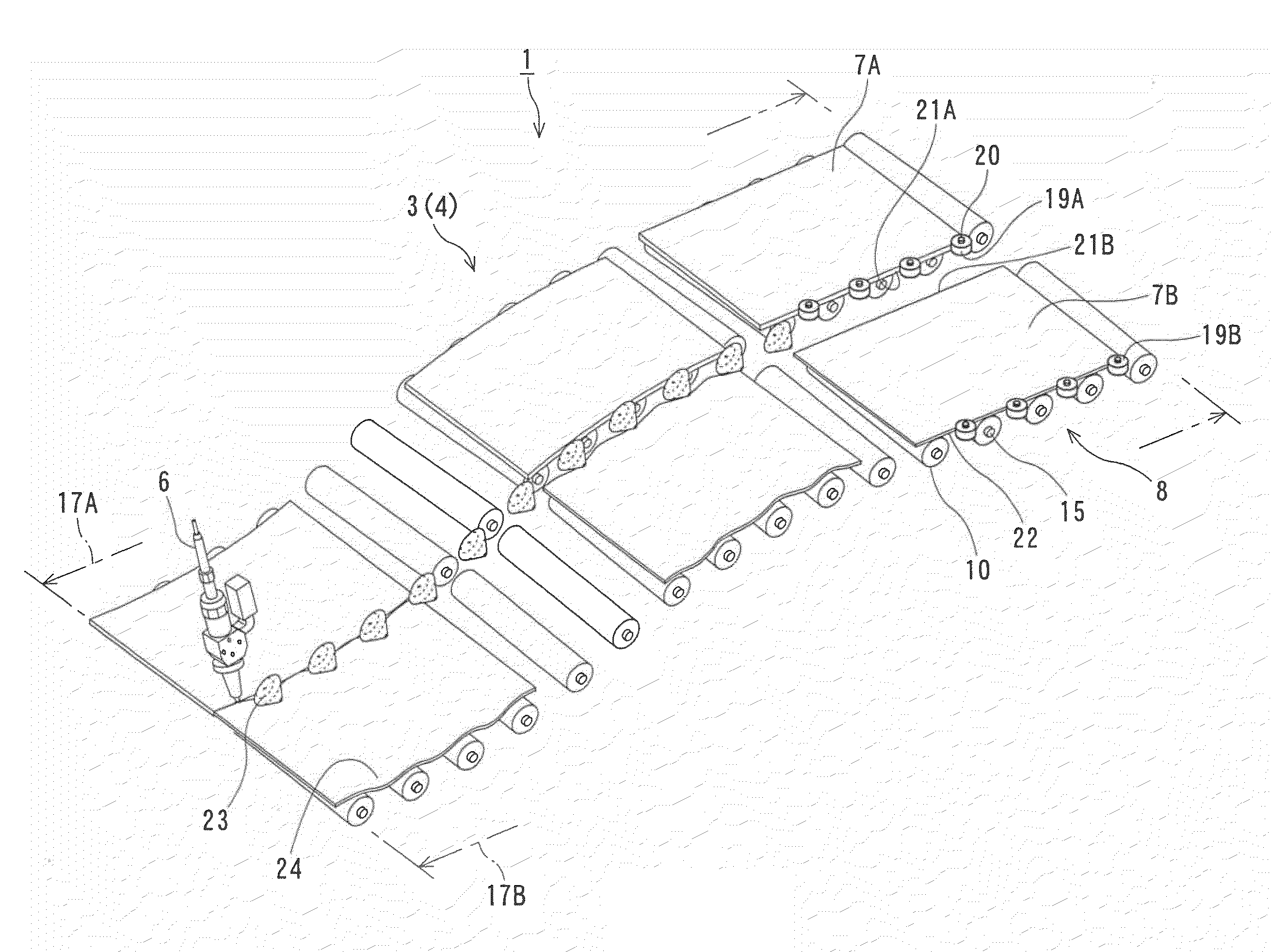

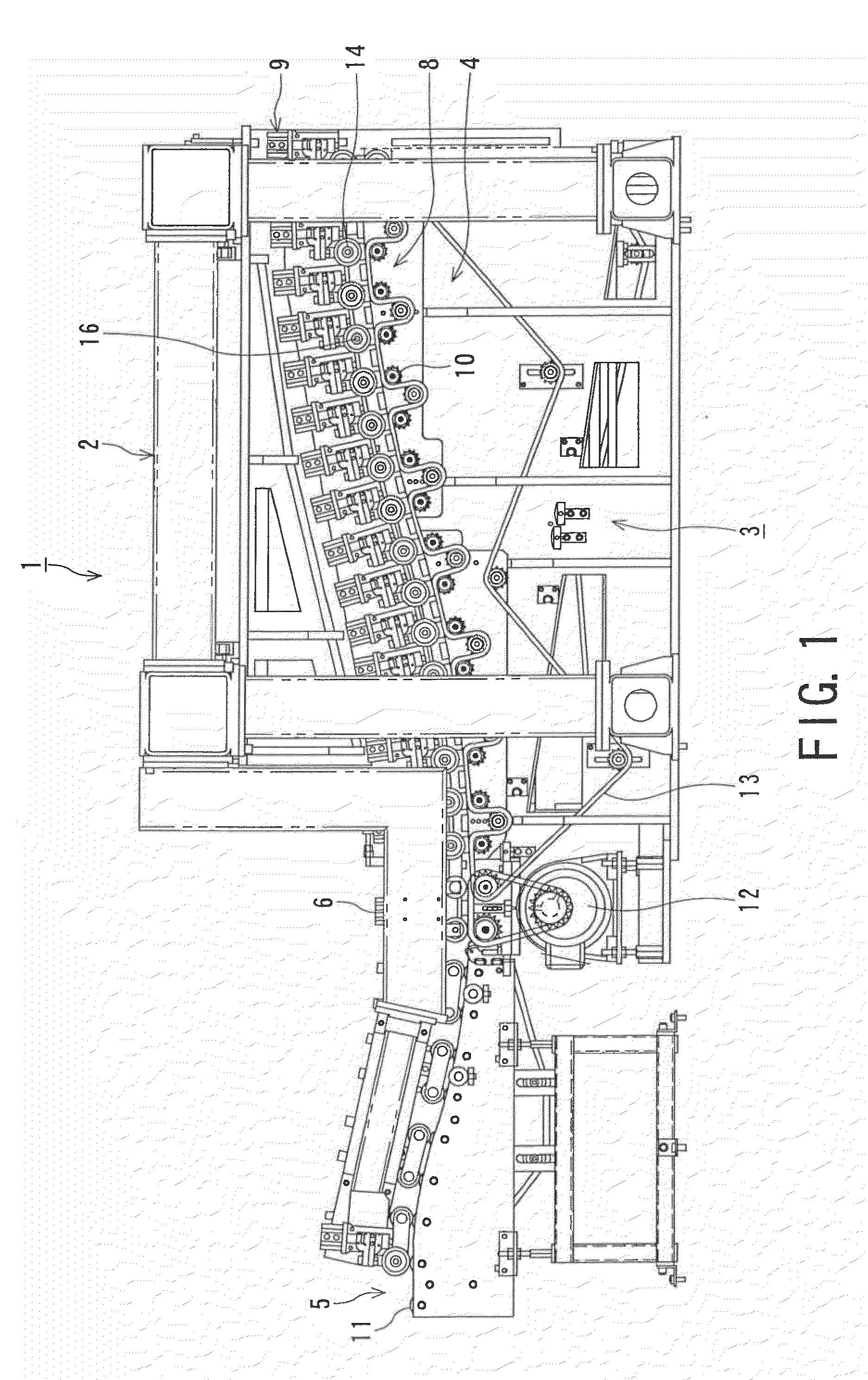

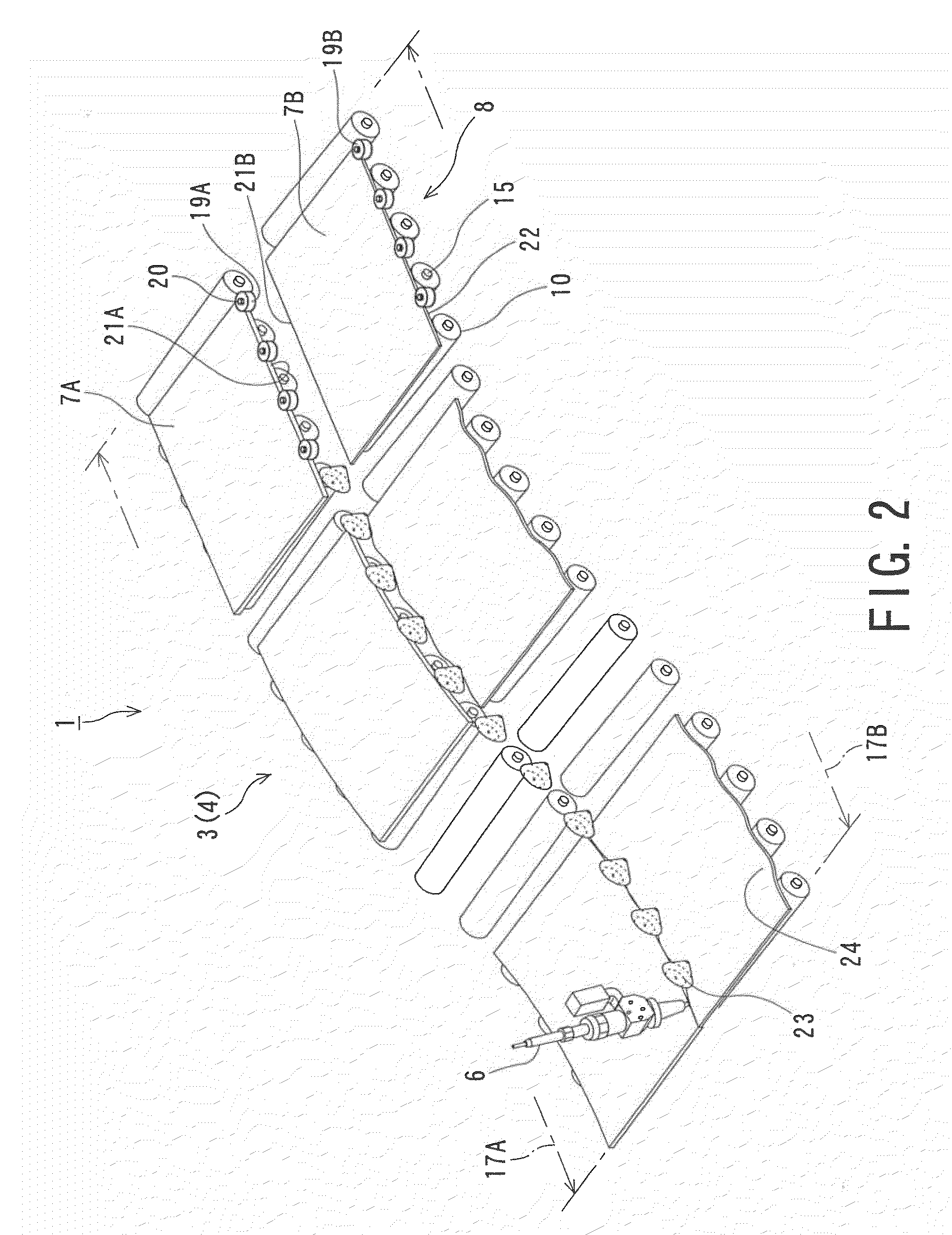

[0052]FIG. 1 shows a continuous welding apparatus to which a conveyor for a sheet-shaped thin plate of the present invention is applicable (which may be called hereinafter “sheet-shaped thin plate conveyor” or merely “conveyor”).

[0053]As shown in FIG. 1, the continuous welding apparatus or machine 1 includes a sheet-shaped thin plate conveyor 3 assembled to a framework 2. The conveyor 3 mainly includes a carry-in unit 4 and a carry-out unit 5 for the sheet-shaped thin plates.

[0054]In this embodiment, a fixed laser welding machine 6 is used as welding means. The laser welding machine 6 is disposed above and between the carry-in unit 4 and the carry-o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thicknesses | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com