Burner for regeneration of diesel particulate filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Other objects and aspects of the invention will become apparent from the following description of the embodiments with reference to the accompanying drawings, which is set forth hereinafter.

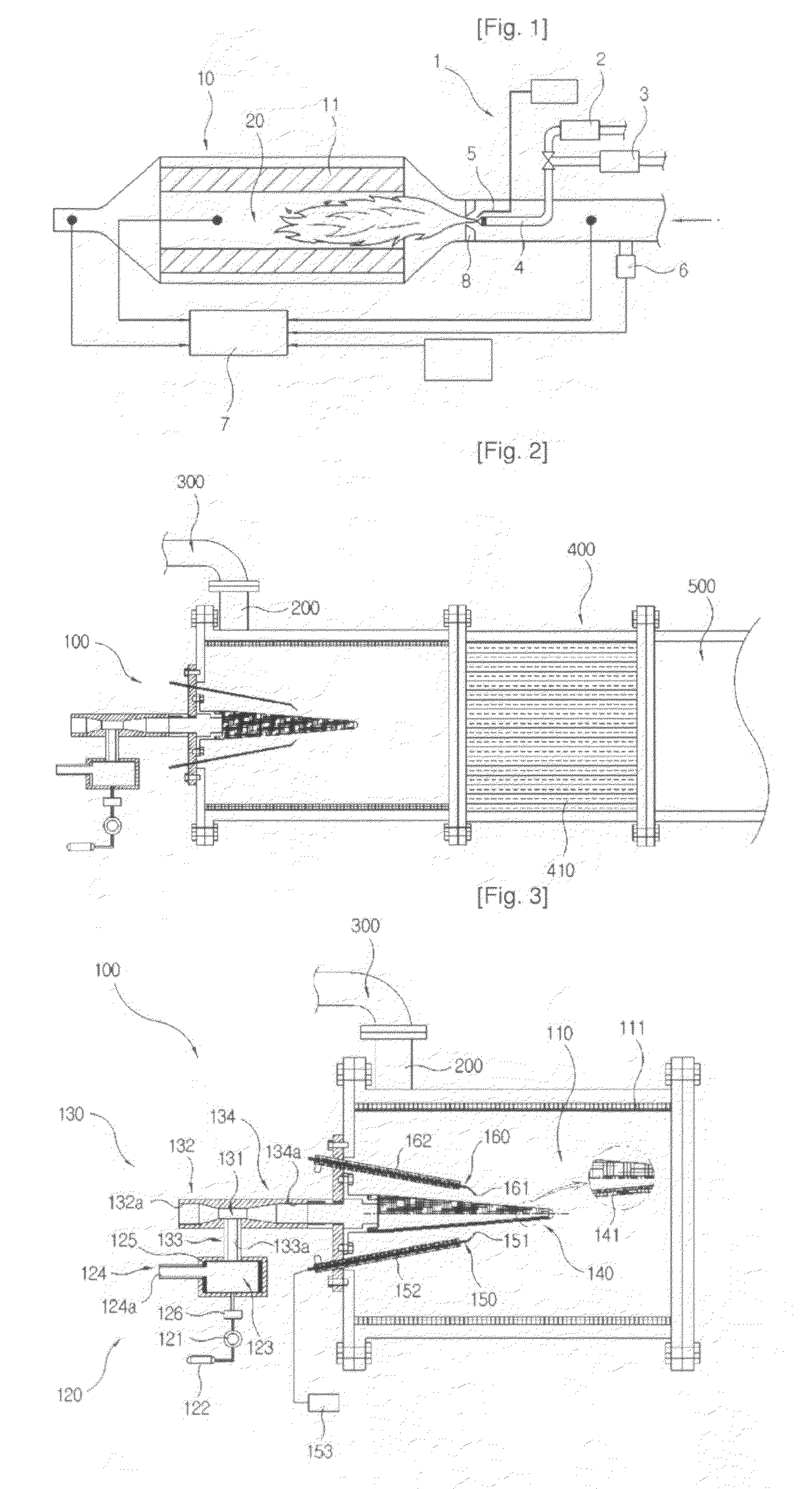

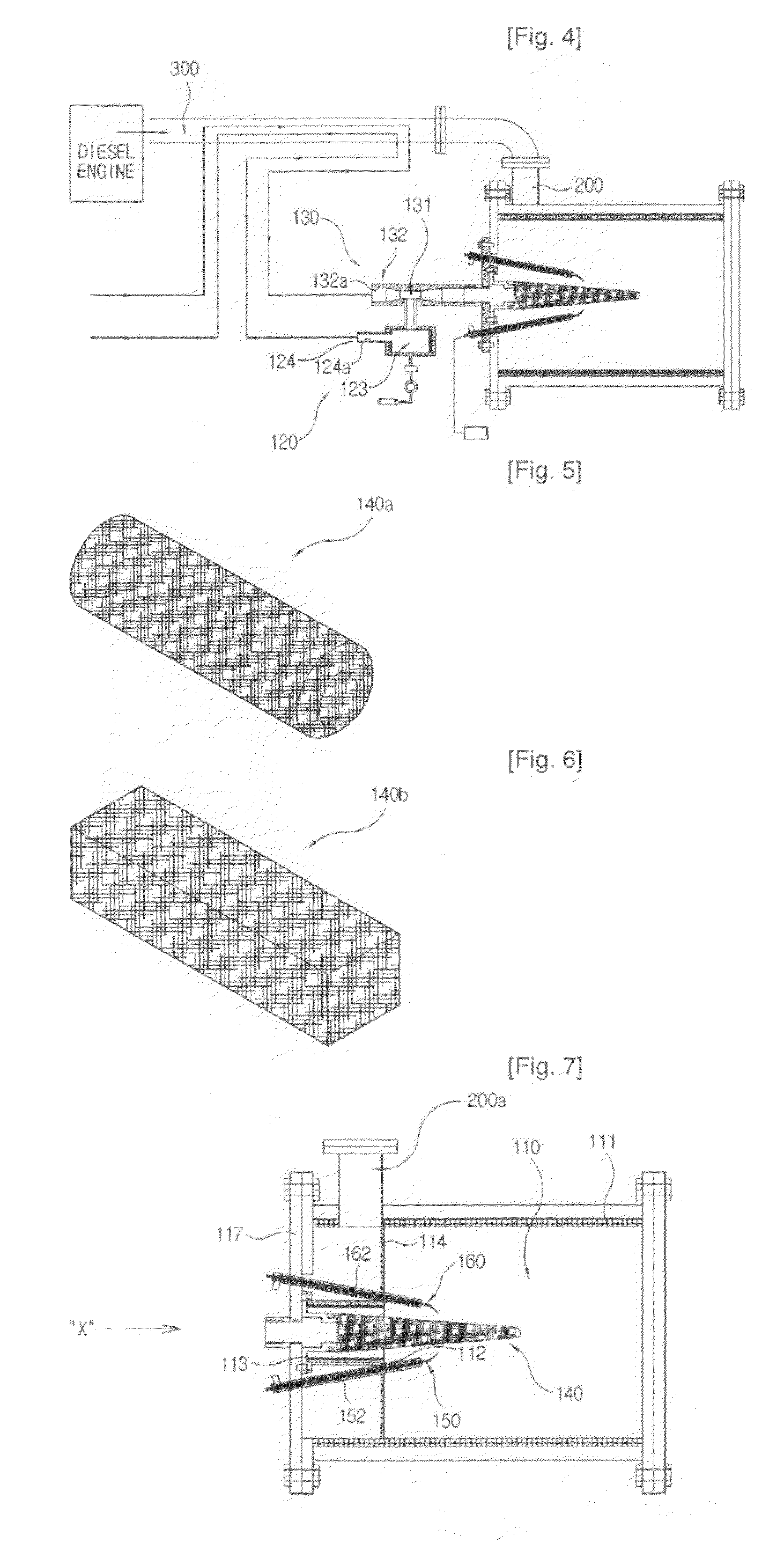

[0037]FIG. 2 is a diagram illustrating a diesel particulate filter having a burner for regenerating the diesel particulate filter according to an embodiment of the present invention, and FIG. 3 is a diagram illustrating a burner for regenerating the diesel particulate filter shown in FIG. 2 according to an embodiment of the present invention.

[0038]Referring to FIG. 2, the burner 100 according to the present embodiment includes one side connected to an exhaust gas channel 300 through a connecting pipe 200 and other side connected to a particulate filtering unit 400 having a filter 410 for collecting soot particles.

[0039]As shown in FIG. 3, the burner 100 includes a combustion chamber 110 for receiving an exhaust gas from an engine, a carburetor 120 for gasifying a liquid fuel such as diesel,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap