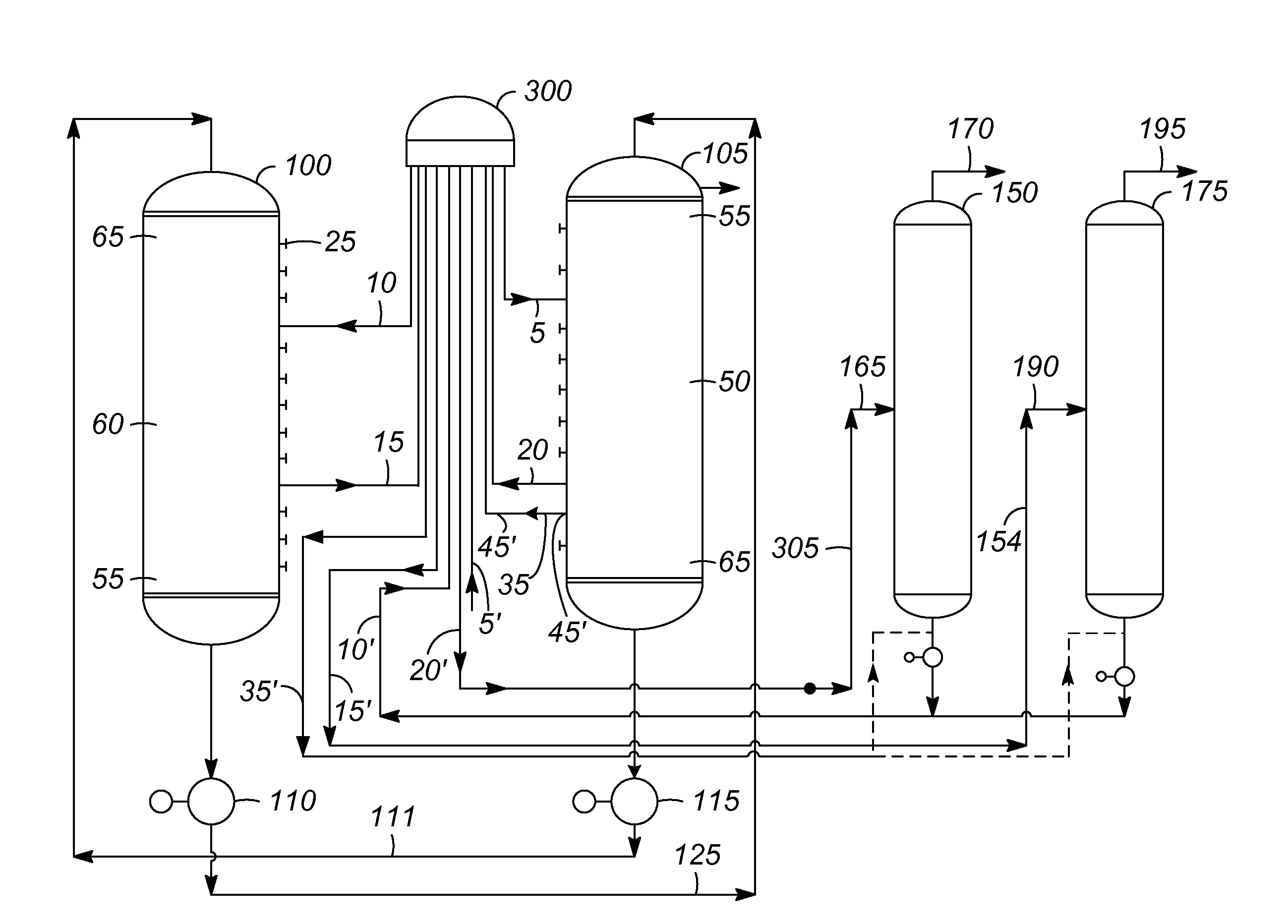

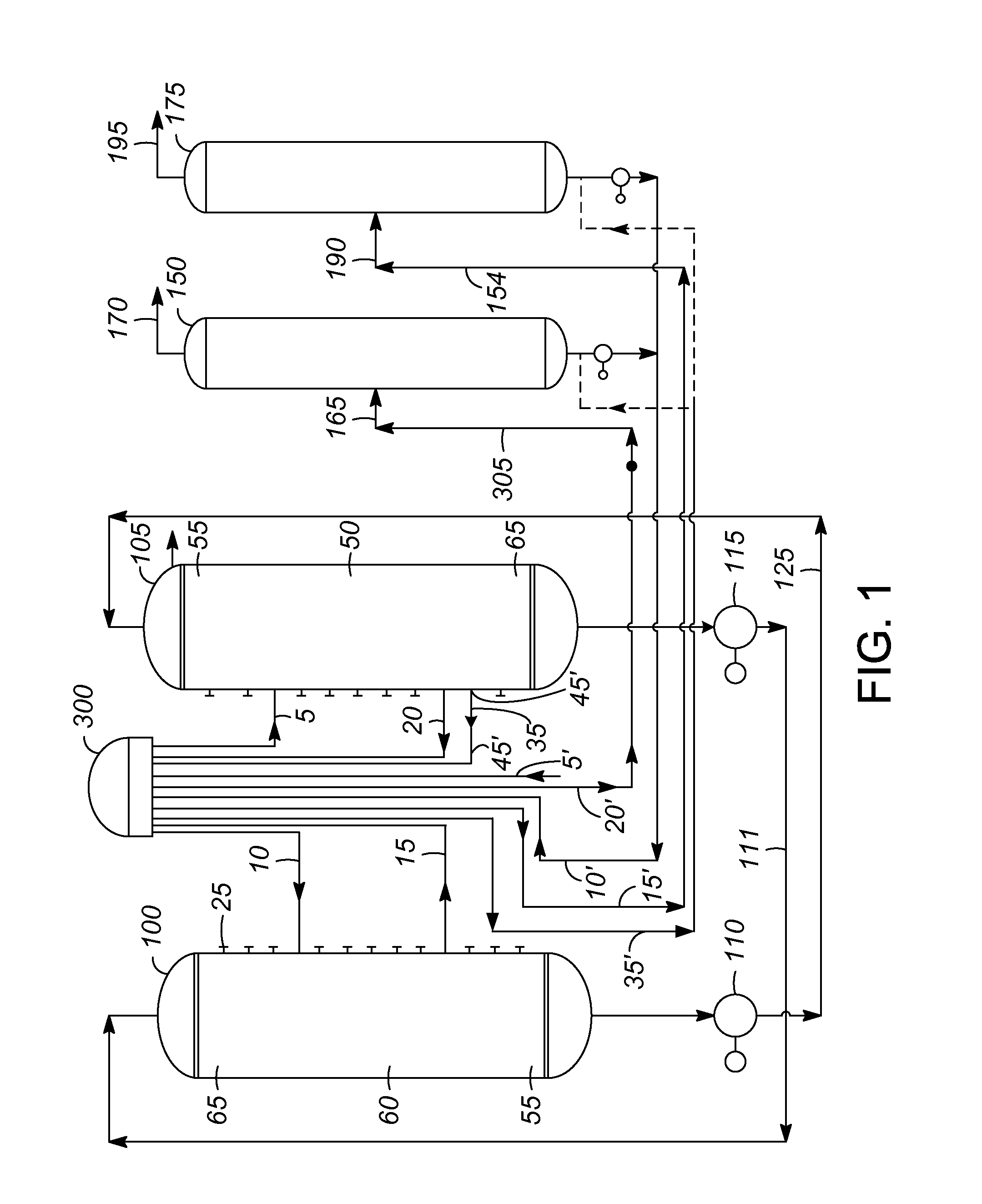

System and process for flushing residual fluid from transfer lines in simulated moving bed adsorption

a technology of residual fluid and transfer line, which is applied in the direction of hydrocarbon purification/separation, chemistry apparatus and processes, organic chemistry, etc., can solve the problems of detrimental effects of residual compounds in the transfer line, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

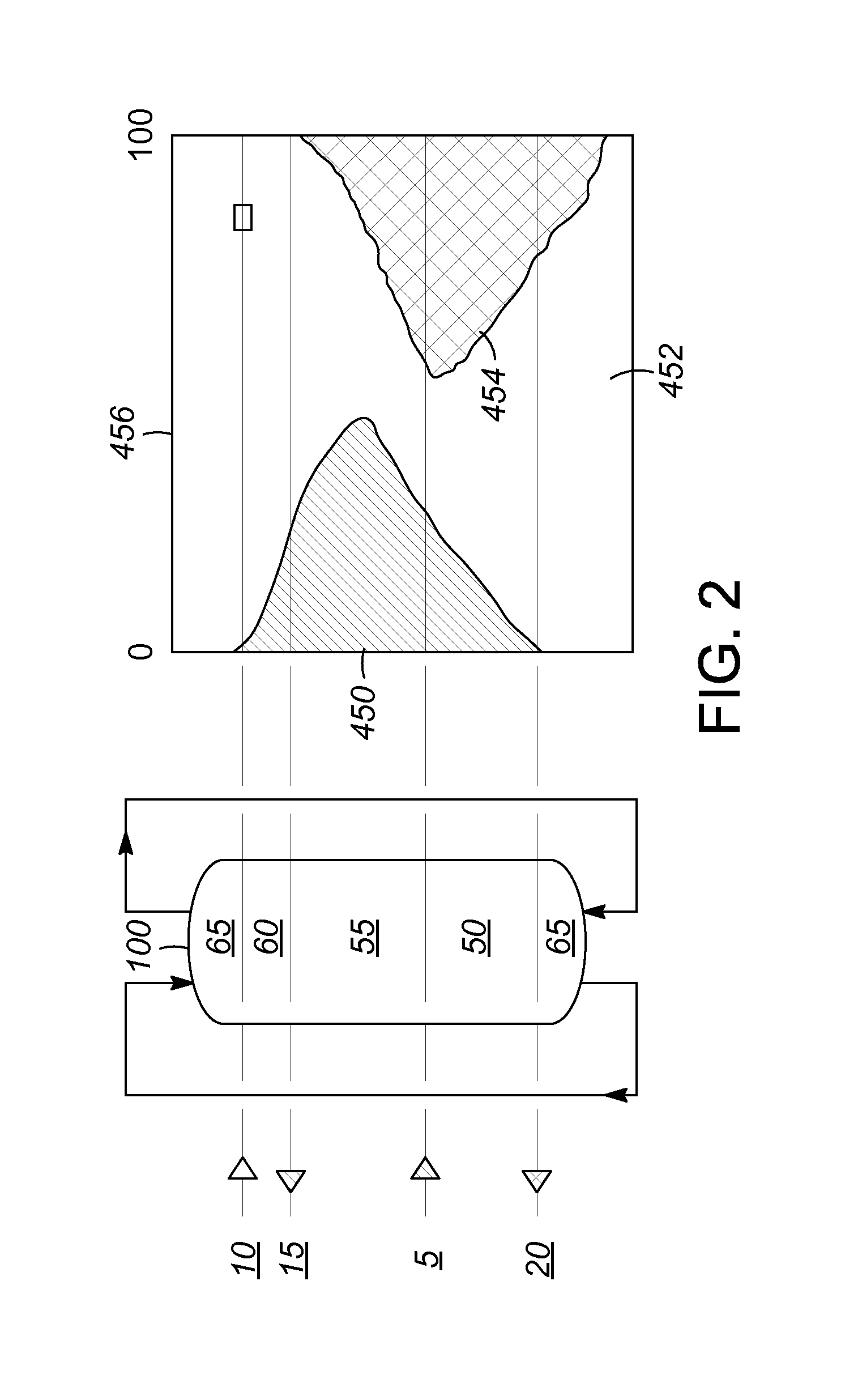

[0019]Co-pending unpublished U.S. patent application Ser. No. 13 / 630,461 describes a process wherein a first portion of the raffinate stream is directed to a recycle line and a second portion is directed to the raffinate column. As the transfer line used for withdrawing the raffinate stream was previously occupied by the desorbent stream, residual desorbent remains in the transfer line. By directing this first portion of the raffinate stream away from the raffinate column, separation of this residual desorbent in the raffinate column and the associated energy penalty could be avoided. It has been identified, however, that in some systems, when no surge capacity in the feed to the raffinate column is available, the feed to the column may be discontinuous and compromise steady column control.

[0020]Adsorptive separation is applied to the recovery of a variety of hydrocarbon and other chemical products. Chemical separations using this approach which have been disclosed include the separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com