Cylinder lubricating oil composition for crosshead diesel engine equipped with scrubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0138]Hereinafter, the present invention will be explained further in detail based on Examples and Comparative Examples. However, the present invention is not limited to these Examples.

examples 1 to 11

, Comparative Examples 1 to 7

[0139]Regarding the first embodiment of the lubricating oil composition, lubricating oil compositions of compounding formulations shown in Tables 1 and 2 were prepared and a high-speed emulsification test was carried out thereon. The results are shown in Tables 1 and 2. In Tables 1 and 2, the amounts of the base oils are the contents on the basis of the total amount of the base oils, and the amounts of additives are the contents on the basis of the total amount of the composition.

[0140](Commercially Available Cylinder Oil)

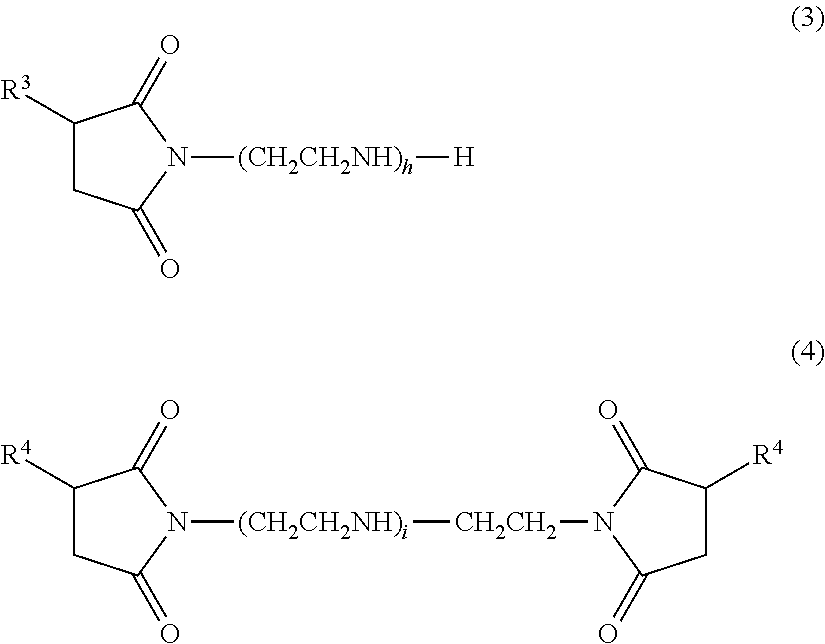

[0141]A commercially available cylinder oil containing: mineral base oil in an amount of 81 mass %; a Ca phenate detergent of the above formula (1) wherein R1 is a C12 alkyl or alkenyl group; a carbonic Ca sulfonate detergent (C20, C22 and C24 hydrocarbon groups are bonded to an aromatic six-membered ring); a polybutenyl succinimide of the above formula (4) wherein R4 is a polybutenyl group; alkyldiphenylamine (carbon numbers of the alk...

examples 12 to 26

, Comparative Examples 8 to 13

[0150]Regarding the second embodiment of the lubricating oil composition of the present invention, lubricating oil compositions of the compounding formulations shown in Tables 3 to 5 were prepared, and a high-speed emulsification test was carried out in the same way as above. The results are shown in Tales 3 to 5. In Tables 3 to 5, the amounts of the base oils are the contents on the basis of the total amount of the base oils, and the amounts of additives are the contents on the basis of the total amount of the composition.

[0151](Base Oil)

Base oil 1: solvent refining base oil, 500 N, kinematic viscosity at 100° C. 10.8 mm2 / s, content of saturated component 62 mass %

Base oil 2: solvent refining base oil, Bright Stock, kinematic viscosity at 100° C. 31.8 mm2 / s, content of saturated component 46 mass %

[0152](Component (A1))

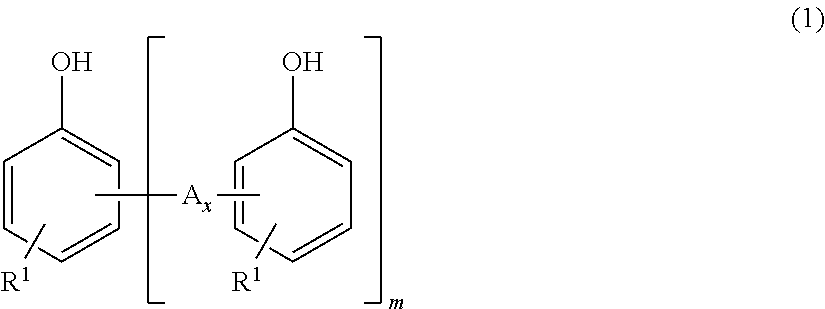

(A1)-1: a Ca phenate of the above formula (1) wherein A is a sulfide group, x=1 to 2, and m=1 to 2, base number 250 mgKOH / g, Ca content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com