Method of producing silicon carbide

a technology of silicon carbide and carbide, which is applied in the field of silicon carbide production, can solve the problems of vapor phase, low purity, contamination of wafers, etc., and achieve the effect of high productivity and comparative ease of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

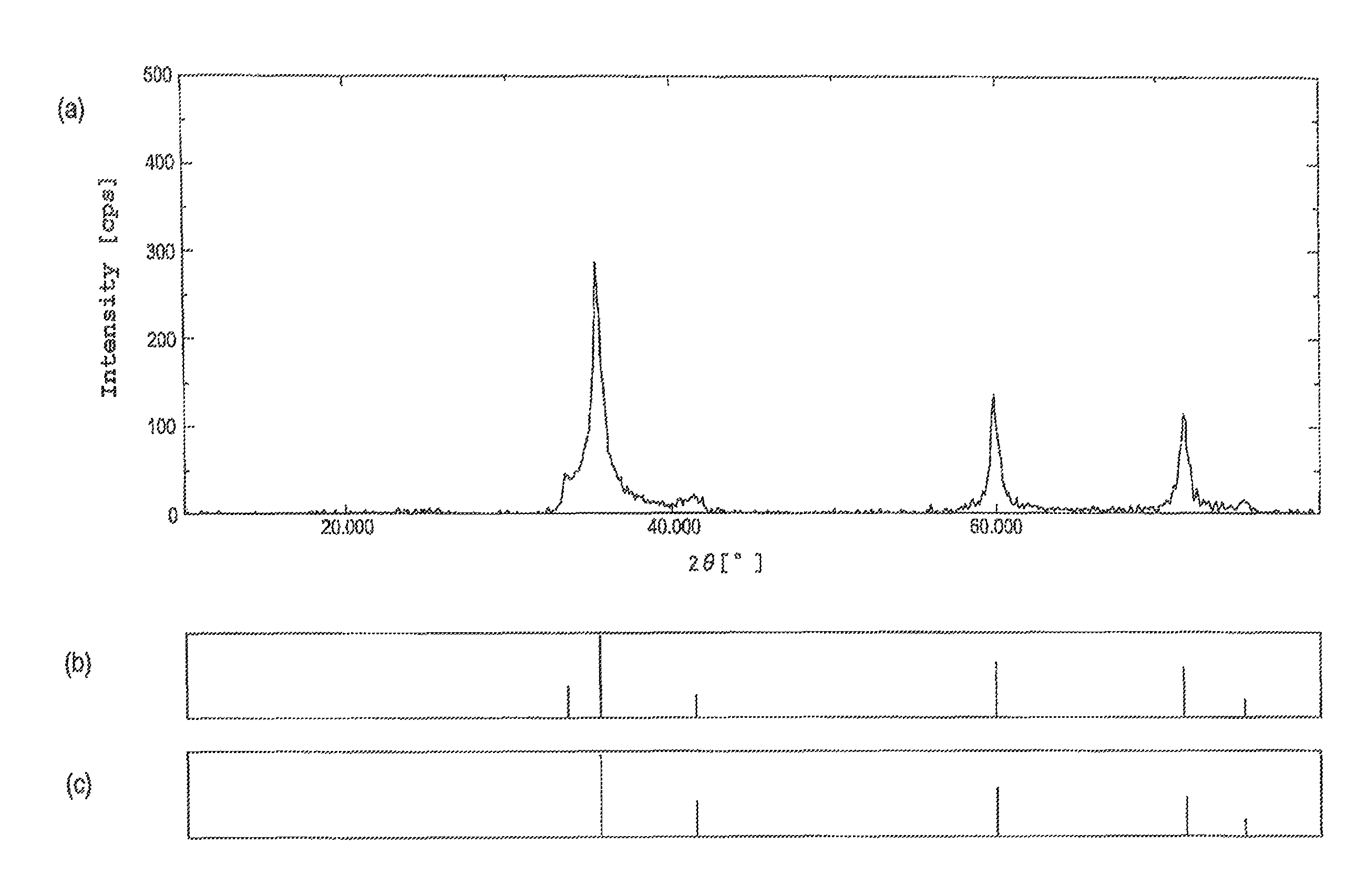

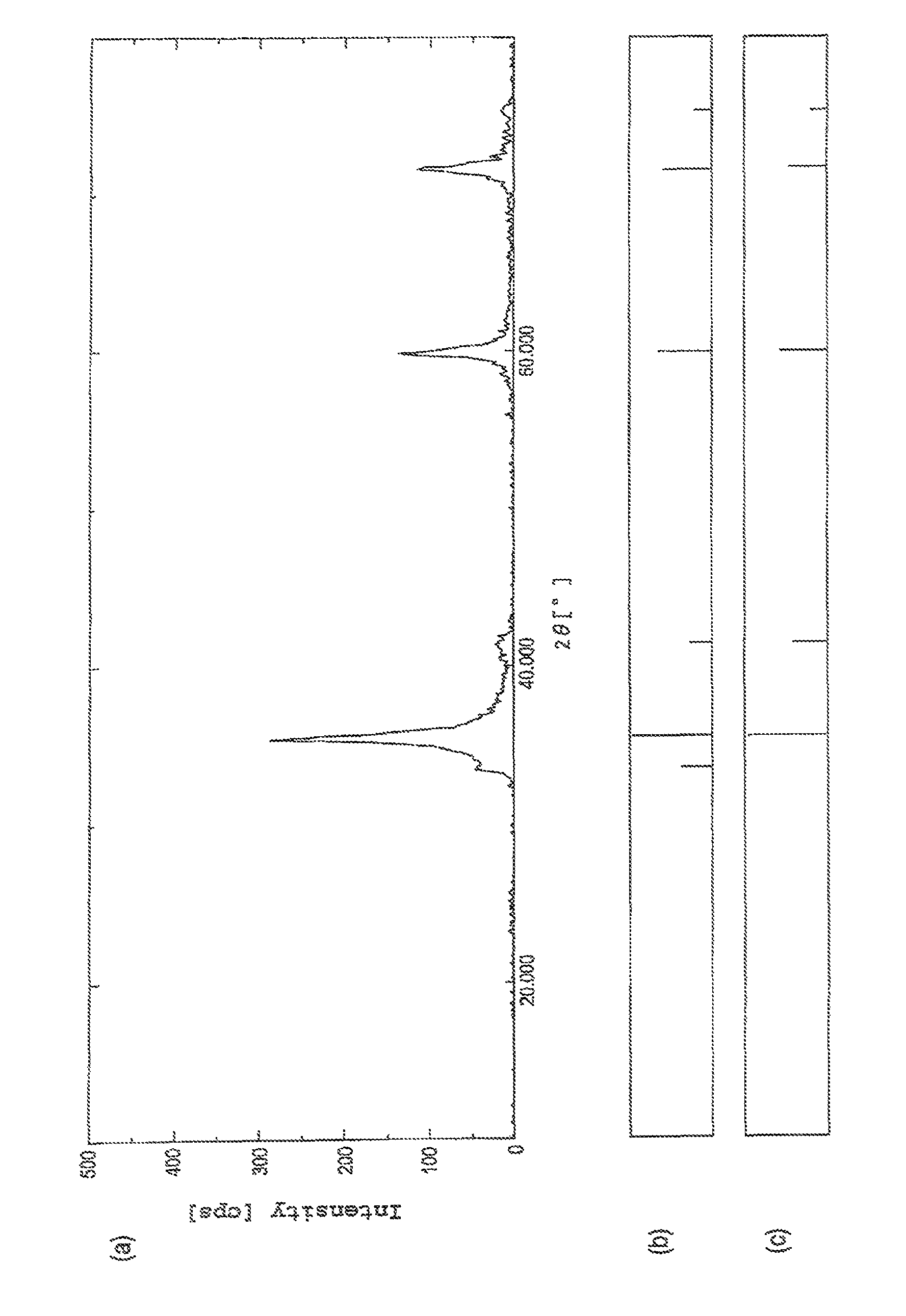

Image

Examples

example 1

[0090]The components (A) and (B) described below were used as silicone components, and the component (C) described below was used as a platinum group metal-based catalyst. The quantity of each component is also shown below.

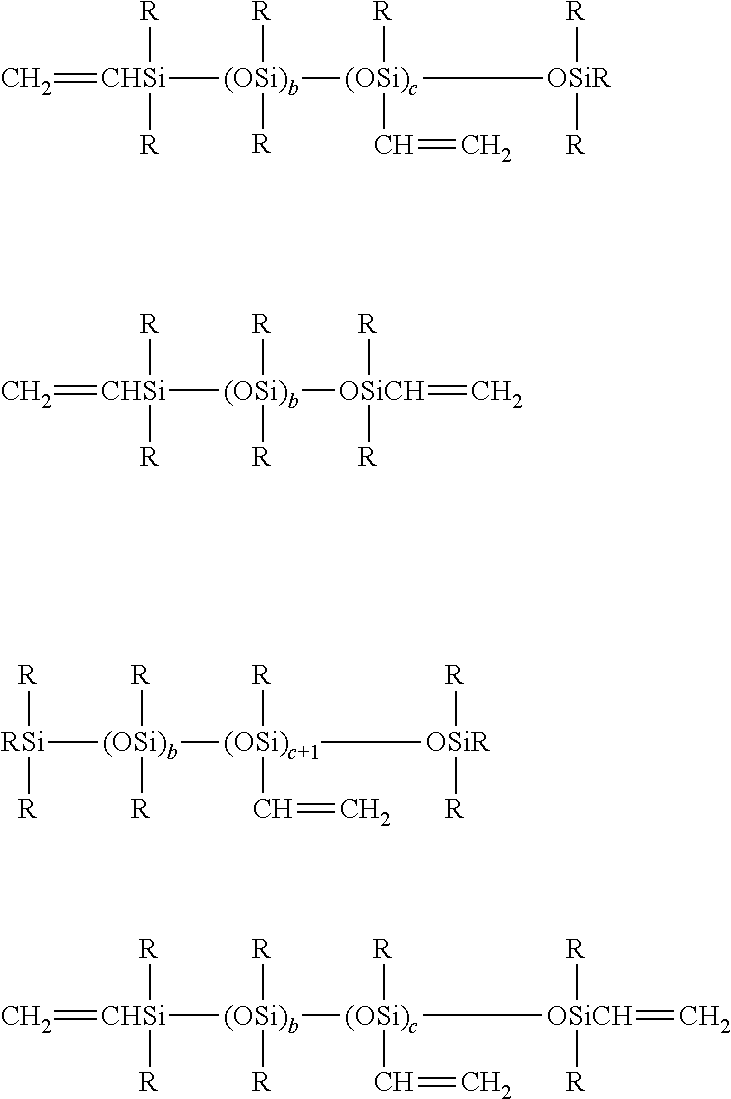

(A) 55 parts by mass of a diorganopolysiloxane containing alkenyl groups bonded to silicon atoms, represented by an average composition formula (5) shown below.

[0091]

(B) 45 parts by mass of a diorganopolysiloxane containing hydrogen atoms bonded to silicon atoms, represented by an average composition formula (6) shown below (wherein, the quantity of SiH groups within the component (B) per 1.0 mols of silicon atom-bonded alkenyl groups within the component (A) is 1.0 mols).

[0092]

(wherein, the molar ratio of SiH groups relative to all the silicon atoms within the molecule is 0.625).

(C) a toluene solution of a platinum-divinyltetramethyldisiloxane complex (platinum element content: 0.5% by mass), in a quantity equivalent to 50 ppm of the platinum element relative to ...

example 2

[0095]100 parts by mass of a silicone resin containing only MeSiO3 / 2 units as the siloxane units and also containing 5% by mass of hydroxyl groups (molecular weight: 1,000, average composition formula: Me(OH)0.2SiO1.3, softening point: 65° C.) was placed in an aluminum Petri dish and cured by heating at 200° C. for one hour. The resulting silicone cured product was subjected to a heat treatment in the same manner as Example 1, yielding a yellow-green solid. Analysis of this yellow-green solid in the same manner as that described in Example 1 revealed a carbon mass ratio of 30.4% by mass, an oxygen mass ratio of not more than 0.2% by mass, and an elemental ratio of SiC1.02.

example 3

[0096]The components (A) to (C) used in Example 1 and a component (D) described below as a silicon carbide powder were used in the respective quantities listed below.

(A) 55 parts by mass of the diorganopolysiloxane containing alkenyl groups bonded to silicon atoms and represented by the average composition formula (5) shown above.

(B) 45 parts by mass of the diorganopolysiloxane containing hydrogen atoms bonded to silicon atoms and represented by the average composition formula (6) shown above.

(C) a toluene solution of a platinum-divinyltetramethyldisiloxane complex (platinum element content: 0.5% by mass), in a quantity equivalent to 0.15% by mass relative to the combined mass of the component (A) and the component (B).

[0097](D) 327 parts by mass of a silicon carbide powder (volume average particle size: 10 μm) obtained by pulverizing the yellow-green solid of Example 1 using a ball mill (this quantity is equivalent to the quantity required to ensure that the silicon carbide powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ambient temperature | aaaaa | aaaaa |

| average particle size | aaaaa | aaaaa |

| average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com