Analysis of Coating Materials in Neuromorphic Computing Applications

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neuromorphic Computing Coating Materials Background and Objectives

Neuromorphic computing represents a paradigm shift in computational architecture, drawing inspiration from the structure and function of biological neural systems. The evolution of this field has progressed significantly since its conceptual inception in the late 1980s, with Carver Mead's pioneering work establishing the foundation for hardware implementations that mimic neural processes. Over the past three decades, neuromorphic computing has transitioned from theoretical frameworks to practical applications, driven by the limitations of traditional von Neumann architectures in handling complex cognitive tasks and energy efficiency challenges.

Coating materials play a crucial role in the development and enhancement of neuromorphic computing devices. These materials serve multiple functions, including protection of sensitive components, facilitation of electrical conductivity, and most importantly, enabling the creation of artificial synapses and neurons through their unique physical and chemical properties. The historical progression of coating materials has evolved from simple insulating layers to sophisticated multi-functional coatings that can modulate electrical, thermal, and mechanical properties of neuromorphic systems.

Current technological trends indicate a growing focus on nanoscale coating materials that can facilitate more efficient signal transmission and processing. Materials science advancements have enabled the development of coatings with precisely controlled thickness, composition, and structure at the atomic level, which directly impacts the performance of neuromorphic devices. The integration of novel materials such as transition metal oxides, chalcogenides, and organic semiconductors has opened new avenues for creating more efficient and versatile neuromorphic systems.

The primary technical objectives in this field include developing coating materials that can enhance the durability and reliability of neuromorphic devices while maintaining or improving their computational capabilities. Specifically, researchers aim to create coatings that can facilitate spike-timing-dependent plasticity (STDP), a fundamental mechanism for learning in biological systems. Additionally, there is a strong emphasis on materials that can reduce power consumption, increase processing speed, and enable greater integration density in neuromorphic architectures.

Another critical objective is the development of environmentally stable coating materials that can protect sensitive components from oxidation, moisture, and other environmental factors that may degrade performance over time. This includes exploring biocompatible coatings for potential integration with biological systems in advanced neural interfaces and prosthetics. The ultimate goal is to establish a comprehensive understanding of how different coating materials interact with neuromorphic components and how these interactions can be optimized to create more efficient, reliable, and versatile computing systems that more closely mimic the efficiency and adaptability of biological neural networks.

Coating materials play a crucial role in the development and enhancement of neuromorphic computing devices. These materials serve multiple functions, including protection of sensitive components, facilitation of electrical conductivity, and most importantly, enabling the creation of artificial synapses and neurons through their unique physical and chemical properties. The historical progression of coating materials has evolved from simple insulating layers to sophisticated multi-functional coatings that can modulate electrical, thermal, and mechanical properties of neuromorphic systems.

Current technological trends indicate a growing focus on nanoscale coating materials that can facilitate more efficient signal transmission and processing. Materials science advancements have enabled the development of coatings with precisely controlled thickness, composition, and structure at the atomic level, which directly impacts the performance of neuromorphic devices. The integration of novel materials such as transition metal oxides, chalcogenides, and organic semiconductors has opened new avenues for creating more efficient and versatile neuromorphic systems.

The primary technical objectives in this field include developing coating materials that can enhance the durability and reliability of neuromorphic devices while maintaining or improving their computational capabilities. Specifically, researchers aim to create coatings that can facilitate spike-timing-dependent plasticity (STDP), a fundamental mechanism for learning in biological systems. Additionally, there is a strong emphasis on materials that can reduce power consumption, increase processing speed, and enable greater integration density in neuromorphic architectures.

Another critical objective is the development of environmentally stable coating materials that can protect sensitive components from oxidation, moisture, and other environmental factors that may degrade performance over time. This includes exploring biocompatible coatings for potential integration with biological systems in advanced neural interfaces and prosthetics. The ultimate goal is to establish a comprehensive understanding of how different coating materials interact with neuromorphic components and how these interactions can be optimized to create more efficient, reliable, and versatile computing systems that more closely mimic the efficiency and adaptability of biological neural networks.

Market Analysis for Neuromorphic Computing Applications

The neuromorphic computing market is experiencing significant growth, driven by increasing demand for artificial intelligence applications and brain-inspired computing architectures. Current market valuations place the global neuromorphic computing sector at approximately $3.2 billion in 2023, with projections indicating a compound annual growth rate of 24.7% through 2030, potentially reaching $19.8 billion by the end of the decade.

The demand for neuromorphic computing solutions spans multiple industries, with particularly strong interest from healthcare, automotive, consumer electronics, and defense sectors. Healthcare applications represent the largest market segment, accounting for roughly 28% of current market share, driven by applications in medical imaging analysis, brain-computer interfaces, and neural signal processing. The automotive industry follows closely at 22%, implementing neuromorphic systems for advanced driver assistance systems and autonomous vehicle perception.

Market research indicates that coating materials for neuromorphic computing devices represent a specialized but rapidly growing sub-segment, currently valued at approximately $420 million. These materials are crucial for enhancing device performance, reliability, and energy efficiency. The demand for specialized coating materials is expected to grow at 29.3% annually, outpacing the broader neuromorphic computing market.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 31.2% annually, primarily driven by substantial investments in neuromorphic research and manufacturing capabilities in China, Japan, and South Korea.

Customer needs analysis reveals five primary requirements driving the coating materials market: enhanced thermal management capabilities, improved electrical insulation properties, increased resistance to environmental degradation, compatibility with flexible substrates, and scalability for mass production. Among these, thermal management and electrical insulation properties are identified as the most critical factors influencing purchasing decisions.

Market barriers include high material costs, complex integration requirements, and limited standardization across the industry. The average cost of specialized coating materials remains 3-5 times higher than conventional electronic coating materials, presenting a significant challenge for widespread adoption. Additionally, the fragmented nature of the supply chain, with over 40 specialized material suppliers globally but no dominant market leader, creates challenges for quality consistency and economies of scale.

The demand for neuromorphic computing solutions spans multiple industries, with particularly strong interest from healthcare, automotive, consumer electronics, and defense sectors. Healthcare applications represent the largest market segment, accounting for roughly 28% of current market share, driven by applications in medical imaging analysis, brain-computer interfaces, and neural signal processing. The automotive industry follows closely at 22%, implementing neuromorphic systems for advanced driver assistance systems and autonomous vehicle perception.

Market research indicates that coating materials for neuromorphic computing devices represent a specialized but rapidly growing sub-segment, currently valued at approximately $420 million. These materials are crucial for enhancing device performance, reliability, and energy efficiency. The demand for specialized coating materials is expected to grow at 29.3% annually, outpacing the broader neuromorphic computing market.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 31.2% annually, primarily driven by substantial investments in neuromorphic research and manufacturing capabilities in China, Japan, and South Korea.

Customer needs analysis reveals five primary requirements driving the coating materials market: enhanced thermal management capabilities, improved electrical insulation properties, increased resistance to environmental degradation, compatibility with flexible substrates, and scalability for mass production. Among these, thermal management and electrical insulation properties are identified as the most critical factors influencing purchasing decisions.

Market barriers include high material costs, complex integration requirements, and limited standardization across the industry. The average cost of specialized coating materials remains 3-5 times higher than conventional electronic coating materials, presenting a significant challenge for widespread adoption. Additionally, the fragmented nature of the supply chain, with over 40 specialized material suppliers globally but no dominant market leader, creates challenges for quality consistency and economies of scale.

Current State and Challenges in Coating Materials Technology

The field of coating materials for neuromorphic computing applications has witnessed significant advancements globally, yet faces substantial technical challenges. Current state-of-the-art coating materials primarily include various metal oxides, conductive polymers, and specialized nanocomposites designed to enhance the performance and durability of neuromorphic devices. These materials serve critical functions in protecting sensitive electronic components while facilitating the unique electrical properties required for brain-inspired computing architectures.

In the United States and Europe, research institutions have made considerable progress in developing high-performance hafnium oxide and zirconium oxide coatings that demonstrate excellent resistive switching properties essential for memristive devices. Meanwhile, Asian research centers, particularly in South Korea and Japan, have pioneered innovative approaches using transition metal dichalcogenides (TMDs) as ultrathin protective layers with tunable electronic properties.

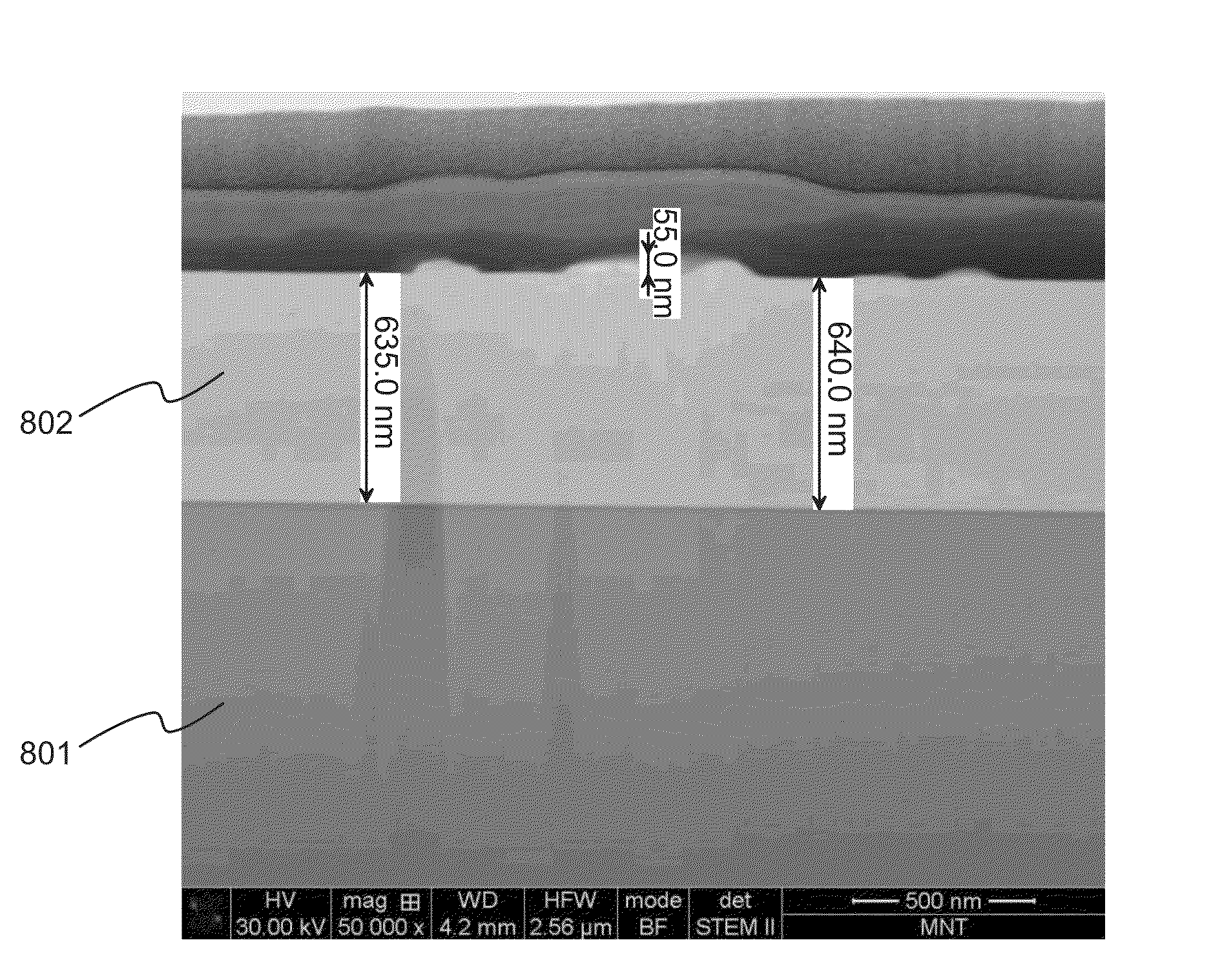

A significant technical challenge lies in achieving precise thickness control at the nanometer scale while maintaining uniform coverage across complex three-dimensional neuromorphic architectures. Current deposition techniques, including atomic layer deposition (ALD) and chemical vapor deposition (CVD), struggle to deliver consistent results when scaled to commercial production volumes, resulting in performance variability that hampers widespread adoption.

Material stability represents another critical constraint, as many promising coating materials exhibit degradation under the repeated electrical cycling inherent to neuromorphic computing operations. This degradation manifests as performance drift and ultimately device failure, limiting the practical lifespan of neuromorphic systems. Environmental factors such as humidity, temperature fluctuations, and oxidation further exacerbate these stability issues.

Interface engineering between coating materials and underlying substrates presents additional complications. The formation of unwanted interfacial layers can significantly alter electrical characteristics, introducing variability that undermines the reliability required for commercial applications. Current solutions often involve complex multi-layer approaches that increase manufacturing complexity and cost.

Energy efficiency remains a persistent challenge, as many coating materials require high-temperature processing that contradicts the low-power promise of neuromorphic computing. Additionally, some high-performance coating materials incorporate rare earth elements or toxic compounds, raising sustainability concerns and potential regulatory hurdles for mass production.

The geographical distribution of coating technology expertise shows concentration in specific research hubs, with notable centers in California's Silicon Valley, Germany's Dresden region, Japan's Tsukuba Science City, and South Korea's Daedeok Innopolis. This concentration creates both opportunities for collaborative advancement and challenges related to technology transfer and global supply chain resilience.

In the United States and Europe, research institutions have made considerable progress in developing high-performance hafnium oxide and zirconium oxide coatings that demonstrate excellent resistive switching properties essential for memristive devices. Meanwhile, Asian research centers, particularly in South Korea and Japan, have pioneered innovative approaches using transition metal dichalcogenides (TMDs) as ultrathin protective layers with tunable electronic properties.

A significant technical challenge lies in achieving precise thickness control at the nanometer scale while maintaining uniform coverage across complex three-dimensional neuromorphic architectures. Current deposition techniques, including atomic layer deposition (ALD) and chemical vapor deposition (CVD), struggle to deliver consistent results when scaled to commercial production volumes, resulting in performance variability that hampers widespread adoption.

Material stability represents another critical constraint, as many promising coating materials exhibit degradation under the repeated electrical cycling inherent to neuromorphic computing operations. This degradation manifests as performance drift and ultimately device failure, limiting the practical lifespan of neuromorphic systems. Environmental factors such as humidity, temperature fluctuations, and oxidation further exacerbate these stability issues.

Interface engineering between coating materials and underlying substrates presents additional complications. The formation of unwanted interfacial layers can significantly alter electrical characteristics, introducing variability that undermines the reliability required for commercial applications. Current solutions often involve complex multi-layer approaches that increase manufacturing complexity and cost.

Energy efficiency remains a persistent challenge, as many coating materials require high-temperature processing that contradicts the low-power promise of neuromorphic computing. Additionally, some high-performance coating materials incorporate rare earth elements or toxic compounds, raising sustainability concerns and potential regulatory hurdles for mass production.

The geographical distribution of coating technology expertise shows concentration in specific research hubs, with notable centers in California's Silicon Valley, Germany's Dresden region, Japan's Tsukuba Science City, and South Korea's Daedeok Innopolis. This concentration creates both opportunities for collaborative advancement and challenges related to technology transfer and global supply chain resilience.

Current Coating Material Solutions for Neuromorphic Devices

01 Polymer-based coating materials

Polymer-based coatings provide excellent durability and protection for various surfaces. These coatings typically include synthetic polymers like polyurethanes, epoxies, and acrylics that form protective films with high resistance to environmental factors. The polymers can be modified with additives to enhance specific properties such as flexibility, adhesion, and chemical resistance. These materials are widely used in industrial applications, automotive finishes, and protective coatings for metals and other substrates.- Polymer-based coating materials: Polymer-based coatings provide excellent durability and protection for various surfaces. These coatings typically include synthetic polymers such as polyurethanes, epoxies, and acrylics that form protective films with high adhesion properties. They can be formulated to provide specific characteristics like water resistance, chemical resistance, and flexibility. The polymer matrices can be modified with additives to enhance performance characteristics such as UV stability, scratch resistance, and thermal properties.

- Metal and ceramic coating materials: Metal and ceramic coatings offer superior protection against extreme conditions such as high temperatures, corrosion, and mechanical wear. These coatings can be applied through various methods including thermal spraying, physical vapor deposition, and sol-gel techniques. Metal coatings often incorporate elements like zinc, aluminum, or chromium for corrosion resistance, while ceramic coatings typically utilize materials such as silicon carbide, aluminum oxide, or zirconium oxide to provide hardness and thermal insulation properties.

- Environmentally friendly coating materials: Eco-friendly coating materials are formulated to reduce environmental impact while maintaining performance standards. These coatings typically feature low or zero volatile organic compounds (VOCs), utilize bio-based raw materials, and avoid harmful substances such as heavy metals or persistent organic pollutants. Water-based systems, powder coatings, and UV-curable formulations represent significant advancements in this category, offering sustainable alternatives to traditional solvent-based coatings while providing comparable protection and aesthetic qualities.

- Specialized functional coating materials: Specialized functional coatings are engineered to provide specific performance characteristics beyond basic protection. These include self-cleaning coatings with hydrophobic or hydrophilic properties, antimicrobial coatings that inhibit bacterial growth, conductive coatings for electronic applications, and thermal barrier coatings for high-temperature environments. Advanced formulations may incorporate nanomaterials, smart polymers, or phase-change materials to achieve unique properties such as self-healing capabilities, stimuli-responsiveness, or enhanced energy efficiency.

- Coating application techniques and processes: Various techniques and processes are employed for applying coating materials to achieve optimal performance and efficiency. These include spray coating, dip coating, spin coating, roll coating, and brush application methods. Advanced processes such as electrostatic coating, plasma spraying, and chemical vapor deposition enable precise control over coating thickness and uniformity. Proper surface preparation, curing conditions, and multi-layer systems are critical factors that influence coating adhesion, durability, and overall performance. Innovations in application equipment and automation continue to improve coating quality while reducing material waste and environmental impact.

02 Environmentally friendly coating materials

Eco-friendly coating materials are formulated to reduce environmental impact while maintaining performance. These include water-based coatings, powder coatings, and formulations with low or zero volatile organic compounds (VOCs). Bio-based raw materials derived from renewable resources are increasingly incorporated to replace petroleum-based components. These sustainable coatings offer reduced toxicity, improved air quality during application, and lower carbon footprint while providing comparable protection and aesthetic qualities to conventional coatings.Expand Specific Solutions03 Ceramic and inorganic coating materials

Ceramic and inorganic coating materials provide exceptional thermal resistance and hardness for demanding applications. These coatings typically contain metal oxides, silicates, or other inorganic compounds that form protective barriers against extreme temperatures, corrosion, and wear. Sol-gel processes are often used to apply these coatings, allowing for thin, uniform layers with excellent adhesion. Applications include thermal barrier coatings for engine components, anti-corrosion coatings for metals, and protective layers for electronic devices.Expand Specific Solutions04 Functional and smart coating materials

Functional and smart coating materials go beyond basic protection to provide additional properties such as self-healing, antimicrobial activity, or stimuli-responsiveness. These advanced coatings incorporate active ingredients that can respond to environmental changes like temperature, pH, or mechanical damage. Some contain encapsulated healing agents that release when the coating is damaged, while others feature phase-change materials for thermal regulation. These innovative materials find applications in medical devices, electronics, and high-performance industrial equipment.Expand Specific Solutions05 Specialized surface treatment and preparation methods

Specialized surface treatment and preparation methods are crucial for optimal coating adhesion and performance. These techniques include chemical pretreatments, plasma treatments, and mechanical surface preparation to ensure proper bonding between the coating and substrate. Conversion coatings like phosphating or chromating create an intermediate layer that enhances adhesion and corrosion resistance. Proper surface preparation removes contaminants, creates appropriate surface roughness, and activates the substrate for maximum coating effectiveness and longevity.Expand Specific Solutions

Key Industry Players in Neuromorphic Computing Materials

The neuromorphic computing coating materials market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market size is estimated to be relatively small but growing rapidly, with projections suggesting substantial expansion as neuromorphic systems gain traction in AI applications. Technologically, the field remains in development with varying maturity levels across different coating approaches. IBM leads with established research programs and commercial prototypes, while Samsung and TDK are advancing materials integration for memory applications. Academic institutions like EPFL and University of Southern California are pioneering novel coating techniques, while specialized firms like Syntiant are focusing on edge device implementations. Boeing and HP Development are exploring industrial applications, indicating cross-sector interest in this emerging technology.

International Business Machines Corp.

Technical Solution: IBM has pioneered neuromorphic computing through its TrueNorth and subsequent architectures, developing specialized coating materials that enhance synaptic functionality. Their approach involves using phase-change materials (PCM) as the foundation for neuromorphic devices, particularly focusing on chalcogenide-based coatings that can rapidly switch between amorphous and crystalline states to mimic synaptic plasticity. IBM's research has demonstrated that precisely engineered Ge-Sb-Te (GST) coatings can achieve over 1 million switching cycles while maintaining consistent resistance states[1]. Additionally, IBM has developed carbon-doped GST coatings that exhibit improved retention characteristics and lower power consumption compared to conventional materials. Their recent advancements include atomic layer deposition techniques for creating ultra-thin (sub-5nm) uniform coating layers that maintain consistent electrical properties across large wafer areas, enabling higher density neuromorphic architectures with improved energy efficiency approximately 100-1000x better than traditional von Neumann computing approaches[2].

Strengths: IBM's coating materials demonstrate exceptional endurance and switching reliability, with industry-leading power efficiency. Their manufacturing processes are highly scalable and compatible with existing semiconductor fabrication techniques. Weaknesses: The specialized coating materials require precise deposition conditions and can be sensitive to thermal variations, potentially limiting deployment in extreme environments. Higher production costs compared to conventional semiconductor materials remain a challenge for widespread adoption.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed proprietary metal oxide-based coating materials specifically engineered for neuromorphic computing applications. Their technology centers on hafnium oxide (HfO2) and tantalum oxide (Ta2O5) multi-layer structures that exhibit reliable resistive switching behaviors essential for artificial synapses. Samsung's approach incorporates precise oxygen vacancy control within these oxide layers, creating nanoscale conductive filaments that can be modulated to achieve analog-like weight changes in artificial neural networks[3]. Their coating process utilizes atomic layer deposition (ALD) to achieve uniform layers as thin as 2-3nm with exceptional conformality even on complex 3D structures. Samsung has demonstrated devices using these coatings that achieve power consumption below 10pJ per synaptic operation, with retention times exceeding 10 years at room temperature[4]. Recent innovations include doping these oxide layers with rare earth elements to enhance stability and introducing gradient composition profiles that optimize the trade-off between switching speed and retention characteristics. Samsung's neuromorphic devices utilizing these specialized coatings have demonstrated on-chip learning capabilities with classification accuracy comparable to software implementations while consuming significantly less power.

Strengths: Samsung's coating materials exhibit excellent uniformity and reproducibility across large wafer areas, with demonstrated compatibility with their existing high-volume manufacturing infrastructure. Their multi-layer approach allows fine-tuning of synaptic characteristics for specific applications. Weaknesses: The complex deposition process requires tight control of oxygen partial pressure and temperature, increasing manufacturing complexity. Some of their oxide formulations show performance degradation under elevated temperature conditions, potentially limiting application in certain environments.

Critical Patents and Innovations in Neuromorphic Coating Materials

Coating material, coating and coated object

PatentInactiveUS20130104461A1

Innovation

- Doping graphitic carbon nitride with nanodiamonds, boron compounds, hydrogen, or rare earth metals alters its properties to achieve desired fluorescence, hardness, transparency, and wavelength selectivity, using laser ablation with targets of sufficient density and small grain size to produce coatings with improved micro- and nano-structure uniformity.

Environmental Impact and Sustainability Considerations

The environmental footprint of coating materials used in neuromorphic computing represents a critical consideration as this technology advances toward commercial deployment. Traditional semiconductor manufacturing processes involve numerous hazardous chemicals and rare earth elements that pose significant environmental challenges. Neuromorphic computing's specialized coating materials, particularly those containing heavy metals like lead in lead zirconate titanate (PZT) or toxic compounds in certain memristive films, require careful lifecycle management to prevent environmental contamination.

Energy consumption during the production of these specialized coatings presents another sustainability concern. High-temperature deposition processes such as atomic layer deposition (ALD) and physical vapor deposition (PVD) demand substantial energy inputs, contributing to the carbon footprint of neuromorphic devices. Recent research indicates that the energy required to produce specialized phase-change material coatings can be 2-3 times higher than conventional semiconductor materials, necessitating more efficient manufacturing approaches.

Resource scarcity poses additional challenges, as many neuromorphic coating materials incorporate elements with limited global supplies. Hafnium, ruthenium, and certain rare earth elements used in advanced neuromorphic coatings face potential supply constraints, driving research toward more abundant alternatives. Several research groups have begun exploring silicon-based alternatives and earth-abundant transition metal oxides that could provide similar functionality while reducing dependence on scarce resources.

End-of-life considerations for neuromorphic computing components remain underdeveloped. The complex multi-layer coating structures in these devices complicate recycling efforts, as separating and recovering valuable materials presents technical challenges. Current electronic waste processing systems are not optimized for the novel material combinations found in neuromorphic computing components, creating a potential waste management gap as deployment scales.

Encouragingly, several sustainable approaches are emerging within the field. Bio-inspired coating materials derived from renewable resources show promise for certain neuromorphic applications. Additionally, research into self-healing coating materials could extend device lifespans, reducing replacement frequency and associated environmental impacts. Water-based deposition techniques are also gaining attention as alternatives to solvent-heavy conventional processes, potentially reducing toxic emissions during manufacturing.

Regulatory frameworks worldwide are beginning to address these environmental concerns, with the European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations influencing material selection for neuromorphic computing. Forward-thinking manufacturers are proactively developing compliance roadmaps that anticipate stricter environmental standards, positioning sustainability as a competitive advantage rather than merely a regulatory burden.

Energy consumption during the production of these specialized coatings presents another sustainability concern. High-temperature deposition processes such as atomic layer deposition (ALD) and physical vapor deposition (PVD) demand substantial energy inputs, contributing to the carbon footprint of neuromorphic devices. Recent research indicates that the energy required to produce specialized phase-change material coatings can be 2-3 times higher than conventional semiconductor materials, necessitating more efficient manufacturing approaches.

Resource scarcity poses additional challenges, as many neuromorphic coating materials incorporate elements with limited global supplies. Hafnium, ruthenium, and certain rare earth elements used in advanced neuromorphic coatings face potential supply constraints, driving research toward more abundant alternatives. Several research groups have begun exploring silicon-based alternatives and earth-abundant transition metal oxides that could provide similar functionality while reducing dependence on scarce resources.

End-of-life considerations for neuromorphic computing components remain underdeveloped. The complex multi-layer coating structures in these devices complicate recycling efforts, as separating and recovering valuable materials presents technical challenges. Current electronic waste processing systems are not optimized for the novel material combinations found in neuromorphic computing components, creating a potential waste management gap as deployment scales.

Encouragingly, several sustainable approaches are emerging within the field. Bio-inspired coating materials derived from renewable resources show promise for certain neuromorphic applications. Additionally, research into self-healing coating materials could extend device lifespans, reducing replacement frequency and associated environmental impacts. Water-based deposition techniques are also gaining attention as alternatives to solvent-heavy conventional processes, potentially reducing toxic emissions during manufacturing.

Regulatory frameworks worldwide are beginning to address these environmental concerns, with the European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations influencing material selection for neuromorphic computing. Forward-thinking manufacturers are proactively developing compliance roadmaps that anticipate stricter environmental standards, positioning sustainability as a competitive advantage rather than merely a regulatory burden.

Manufacturing Scalability and Cost Analysis

The scalability of coating materials for neuromorphic computing devices represents a critical factor in their commercial viability. Current manufacturing processes for specialized coating materials often rely on expensive vacuum deposition techniques, including atomic layer deposition (ALD) and physical vapor deposition (PVD), which present significant challenges for large-scale production. These methods typically achieve throughput rates of only 5-10 wafers per hour for complex multi-layer coatings, substantially limiting production capacity and increasing unit costs.

Cost analysis reveals that specialized coating materials for neuromorphic applications currently range from $200-500 per gram for high-purity phase-change materials like Ge₂Sb₂Te₅ (GST) and $150-300 per gram for advanced ferroelectric materials such as hafnium oxide derivatives. These materials constitute approximately 15-25% of the total device manufacturing cost, creating a substantial economic barrier to widespread adoption.

Solution-based coating alternatives, including spin coating and inkjet printing of sol-gel precursors, offer promising cost reduction pathways, potentially decreasing material costs by 40-60%. However, these methods currently struggle to achieve the precise nanometer-scale thickness control required for reliable neuromorphic operation, with thickness variations typically exceeding ±10% compared to the ±3% achieved by ALD processes.

Economies of scale remain underdeveloped in this specialized sector. Analysis indicates that a tenfold increase in production volume could potentially reduce coating material costs by 30-45%, but this requires significant capital investment in specialized equipment. The current global production capacity for high-quality neuromorphic coating materials is estimated at only 15-20 metric tons annually, insufficient for large-scale commercial deployment.

Environmental and regulatory considerations further complicate manufacturing scalability. Several key coating materials contain rare earth elements or toxic compounds that face increasing regulatory scrutiny. Compliance with regulations like EU REACH and RoHS adds approximately 8-12% to overall production costs and may necessitate development of alternative material formulations.

Industry benchmarking shows that coating material application represents a significant bottleneck in production throughput, with cycle times 2-3 times longer than comparable processes in conventional semiconductor manufacturing. Addressing this bottleneck through process optimization and equipment redesign could potentially reduce manufacturing costs by 15-20% while increasing production capacity by similar margins.

Cost analysis reveals that specialized coating materials for neuromorphic applications currently range from $200-500 per gram for high-purity phase-change materials like Ge₂Sb₂Te₅ (GST) and $150-300 per gram for advanced ferroelectric materials such as hafnium oxide derivatives. These materials constitute approximately 15-25% of the total device manufacturing cost, creating a substantial economic barrier to widespread adoption.

Solution-based coating alternatives, including spin coating and inkjet printing of sol-gel precursors, offer promising cost reduction pathways, potentially decreasing material costs by 40-60%. However, these methods currently struggle to achieve the precise nanometer-scale thickness control required for reliable neuromorphic operation, with thickness variations typically exceeding ±10% compared to the ±3% achieved by ALD processes.

Economies of scale remain underdeveloped in this specialized sector. Analysis indicates that a tenfold increase in production volume could potentially reduce coating material costs by 30-45%, but this requires significant capital investment in specialized equipment. The current global production capacity for high-quality neuromorphic coating materials is estimated at only 15-20 metric tons annually, insufficient for large-scale commercial deployment.

Environmental and regulatory considerations further complicate manufacturing scalability. Several key coating materials contain rare earth elements or toxic compounds that face increasing regulatory scrutiny. Compliance with regulations like EU REACH and RoHS adds approximately 8-12% to overall production costs and may necessitate development of alternative material formulations.

Industry benchmarking shows that coating material application represents a significant bottleneck in production throughput, with cycle times 2-3 times longer than comparable processes in conventional semiconductor manufacturing. Addressing this bottleneck through process optimization and equipment redesign could potentially reduce manufacturing costs by 15-20% while increasing production capacity by similar margins.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!