Analysis of Patents in Microinjection Molding Innovation

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Technology Background and Objectives

Microinjection molding technology emerged in the late 1980s as a specialized adaptation of conventional injection molding processes, designed specifically to produce miniaturized components with high precision. The evolution of this technology has been closely linked to the growing demand for miniaturization across multiple industries, particularly in medical devices, electronics, and microfluidics. Initially limited by material constraints and equipment capabilities, microinjection molding has undergone significant technological advancements over the past three decades.

The development trajectory shows a clear progression from rudimentary adaptations of standard injection molding equipment to highly specialized systems designed exclusively for micro-scale production. Key technological milestones include the introduction of specialized micro-molds in the 1990s, the development of ultra-precise injection units in the early 2000s, and more recently, the integration of advanced control systems that enable real-time process monitoring at the micro level.

Patent analysis reveals an accelerating innovation curve in this field, with annual patent filings increasing at a compound annual growth rate of approximately 15% over the past decade. This growth reflects the expanding application landscape and the continuous push toward smaller, more complex components with tighter tolerances and enhanced functionality.

The primary technical objectives in microinjection molding innovation currently focus on several critical areas. First is the enhancement of replication accuracy for micro and nano-scale features, which remains challenging due to material flow behavior at these dimensions. Second is the expansion of processable materials, particularly high-performance polymers and polymer composites that can deliver specialized properties in miniaturized applications. Third is the development of more energy-efficient and cost-effective production methods to make the technology economically viable for mass production.

Another significant objective is the improvement of part consistency and quality control methodologies, as traditional inspection techniques often prove inadequate at the micro-scale. Additionally, there is growing emphasis on developing sustainable microinjection molding processes, including the use of bio-based polymers and the implementation of energy-saving production techniques.

The convergence of microinjection molding with complementary technologies such as additive manufacturing and micro-assembly systems represents an emerging frontier, with the potential to create hybrid manufacturing approaches that combine the precision of microinjection molding with the geometric freedom of other processes. This integration aims to overcome current limitations and expand the design possibilities for micro-components.

The development trajectory shows a clear progression from rudimentary adaptations of standard injection molding equipment to highly specialized systems designed exclusively for micro-scale production. Key technological milestones include the introduction of specialized micro-molds in the 1990s, the development of ultra-precise injection units in the early 2000s, and more recently, the integration of advanced control systems that enable real-time process monitoring at the micro level.

Patent analysis reveals an accelerating innovation curve in this field, with annual patent filings increasing at a compound annual growth rate of approximately 15% over the past decade. This growth reflects the expanding application landscape and the continuous push toward smaller, more complex components with tighter tolerances and enhanced functionality.

The primary technical objectives in microinjection molding innovation currently focus on several critical areas. First is the enhancement of replication accuracy for micro and nano-scale features, which remains challenging due to material flow behavior at these dimensions. Second is the expansion of processable materials, particularly high-performance polymers and polymer composites that can deliver specialized properties in miniaturized applications. Third is the development of more energy-efficient and cost-effective production methods to make the technology economically viable for mass production.

Another significant objective is the improvement of part consistency and quality control methodologies, as traditional inspection techniques often prove inadequate at the micro-scale. Additionally, there is growing emphasis on developing sustainable microinjection molding processes, including the use of bio-based polymers and the implementation of energy-saving production techniques.

The convergence of microinjection molding with complementary technologies such as additive manufacturing and micro-assembly systems represents an emerging frontier, with the potential to create hybrid manufacturing approaches that combine the precision of microinjection molding with the geometric freedom of other processes. This integration aims to overcome current limitations and expand the design possibilities for micro-components.

Market Demand Analysis for Microinjection Molded Products

The microinjection molding market has experienced significant growth in recent years, driven primarily by increasing demand across multiple high-value industries. The global market for microinjection molded products was valued at approximately $1.2 billion in 2022 and is projected to reach $2.1 billion by 2028, representing a compound annual growth rate (CAGR) of 9.8% during the forecast period.

Medical and healthcare applications constitute the largest market segment, accounting for nearly 40% of the total demand. This dominance stems from the growing need for miniaturized medical devices, implantable components, drug delivery systems, and diagnostic equipment. The trend toward minimally invasive procedures has further accelerated demand for micro-molded components with high precision and biocompatibility.

Electronics represents the second-largest application segment, driven by the continuous miniaturization of consumer electronics, wearable devices, and IoT components. The automotive industry is also emerging as a significant consumer of microinjection molded parts, particularly for sensors, connectors, and microfluidic systems in modern vehicles.

Regional analysis reveals that North America and Europe currently lead the market, collectively accounting for approximately 60% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is witnessing the fastest growth rate, expected to exceed 12% annually through 2028. This growth is attributed to the rapid expansion of electronics manufacturing and increasing healthcare infrastructure investments in these regions.

Customer requirements are evolving toward higher precision, enhanced material properties, and more complex geometries. There is growing demand for multi-material microinjection molding capabilities, allowing for the integration of different functionalities within a single component. Additionally, sustainability concerns are driving interest in bio-based and recyclable materials suitable for microinjection molding processes.

Market challenges include high initial investment costs for specialized equipment, technical barriers to entry, and stringent quality control requirements. The complexity of microinjection molding processes necessitates advanced expertise, creating a significant barrier for new market entrants. However, these challenges also present opportunities for innovation in process automation, material development, and quality assurance technologies.

Industry experts anticipate that future market growth will be driven by emerging applications in fields such as microfluidics, organ-on-chip devices, advanced drug delivery systems, and next-generation electronics. The convergence of microinjection molding with other advanced manufacturing technologies, such as 3D printing and nanoimprinting, is expected to create new market opportunities and expand the application landscape.

Medical and healthcare applications constitute the largest market segment, accounting for nearly 40% of the total demand. This dominance stems from the growing need for miniaturized medical devices, implantable components, drug delivery systems, and diagnostic equipment. The trend toward minimally invasive procedures has further accelerated demand for micro-molded components with high precision and biocompatibility.

Electronics represents the second-largest application segment, driven by the continuous miniaturization of consumer electronics, wearable devices, and IoT components. The automotive industry is also emerging as a significant consumer of microinjection molded parts, particularly for sensors, connectors, and microfluidic systems in modern vehicles.

Regional analysis reveals that North America and Europe currently lead the market, collectively accounting for approximately 60% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is witnessing the fastest growth rate, expected to exceed 12% annually through 2028. This growth is attributed to the rapid expansion of electronics manufacturing and increasing healthcare infrastructure investments in these regions.

Customer requirements are evolving toward higher precision, enhanced material properties, and more complex geometries. There is growing demand for multi-material microinjection molding capabilities, allowing for the integration of different functionalities within a single component. Additionally, sustainability concerns are driving interest in bio-based and recyclable materials suitable for microinjection molding processes.

Market challenges include high initial investment costs for specialized equipment, technical barriers to entry, and stringent quality control requirements. The complexity of microinjection molding processes necessitates advanced expertise, creating a significant barrier for new market entrants. However, these challenges also present opportunities for innovation in process automation, material development, and quality assurance technologies.

Industry experts anticipate that future market growth will be driven by emerging applications in fields such as microfluidics, organ-on-chip devices, advanced drug delivery systems, and next-generation electronics. The convergence of microinjection molding with other advanced manufacturing technologies, such as 3D printing and nanoimprinting, is expected to create new market opportunities and expand the application landscape.

Current Technological Status and Challenges in Microinjection Molding

Microinjection molding technology has evolved significantly over the past two decades, with major advancements occurring in both equipment precision and material science. Globally, the technology has reached a mature stage in developed regions such as Western Europe, North America, and Japan, where high-precision applications in medical devices and microelectronics dominate the market. However, emerging economies in Asia, particularly China and India, are rapidly closing the technological gap through substantial investments in research and development.

The current state of microinjection molding faces several critical challenges that limit its broader industrial application. Foremost among these is the difficulty in achieving consistent quality at the microscale, where conventional molding principles often fail due to surface tension effects and material flow behavior differences. Process parameters that work effectively at conventional scales require significant recalibration for microinjection applications, creating a steep learning curve for manufacturers transitioning to this technology.

Material limitations represent another significant hurdle. While traditional thermoplastics can be adapted for microinjection molding, their behavior at the microscale often results in increased defect rates and reduced mechanical properties. Advanced polymer blends and nanocomposites show promise but remain costly and difficult to process consistently. Patent analysis reveals that material innovation accounts for approximately 30% of recent technological advancements in this field.

Equipment precision presents ongoing challenges, particularly in mold design and fabrication. The creation of micro-features with high aspect ratios requires specialized tooling capabilities that exceed conventional manufacturing tolerances. Current state-of-the-art equipment can achieve feature sizes down to 5 micrometers, but commercial viability typically begins at 20 micrometers due to yield and consistency issues.

Geographically, technological development shows distinct patterns. European research institutions lead in fundamental research and precision engineering approaches, while Asian manufacturers excel in scaling production and cost optimization. North American entities focus primarily on specialized applications in medical and aerospace sectors, driving innovation in biocompatible materials and high-performance composites.

Process monitoring and quality control systems remain underdeveloped for microinjection molding. Unlike conventional molding, where in-line monitoring is standard practice, microscale production often relies on post-production inspection due to the challenges of integrating sensors at the required scale. This creates inefficiencies and increases production costs, with rejection rates typically 15-25% higher than in conventional molding operations.

Energy efficiency and sustainability concerns are emerging as new challenges, with current microinjection processes consuming disproportionately high energy relative to the mass of produced parts. Recent patents indicate growing interest in more sustainable approaches, including bio-based materials and energy-optimized processing parameters.

The current state of microinjection molding faces several critical challenges that limit its broader industrial application. Foremost among these is the difficulty in achieving consistent quality at the microscale, where conventional molding principles often fail due to surface tension effects and material flow behavior differences. Process parameters that work effectively at conventional scales require significant recalibration for microinjection applications, creating a steep learning curve for manufacturers transitioning to this technology.

Material limitations represent another significant hurdle. While traditional thermoplastics can be adapted for microinjection molding, their behavior at the microscale often results in increased defect rates and reduced mechanical properties. Advanced polymer blends and nanocomposites show promise but remain costly and difficult to process consistently. Patent analysis reveals that material innovation accounts for approximately 30% of recent technological advancements in this field.

Equipment precision presents ongoing challenges, particularly in mold design and fabrication. The creation of micro-features with high aspect ratios requires specialized tooling capabilities that exceed conventional manufacturing tolerances. Current state-of-the-art equipment can achieve feature sizes down to 5 micrometers, but commercial viability typically begins at 20 micrometers due to yield and consistency issues.

Geographically, technological development shows distinct patterns. European research institutions lead in fundamental research and precision engineering approaches, while Asian manufacturers excel in scaling production and cost optimization. North American entities focus primarily on specialized applications in medical and aerospace sectors, driving innovation in biocompatible materials and high-performance composites.

Process monitoring and quality control systems remain underdeveloped for microinjection molding. Unlike conventional molding, where in-line monitoring is standard practice, microscale production often relies on post-production inspection due to the challenges of integrating sensors at the required scale. This creates inefficiencies and increases production costs, with rejection rates typically 15-25% higher than in conventional molding operations.

Energy efficiency and sustainability concerns are emerging as new challenges, with current microinjection processes consuming disproportionately high energy relative to the mass of produced parts. Recent patents indicate growing interest in more sustainable approaches, including bio-based materials and energy-optimized processing parameters.

Current Patent-Protected Technical Solutions

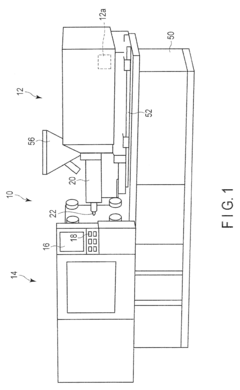

01 Equipment and machinery for microinjection molding

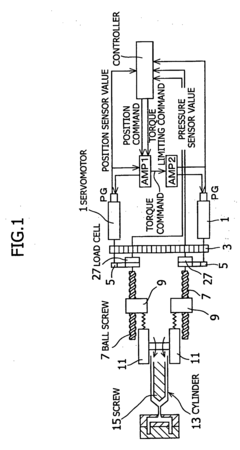

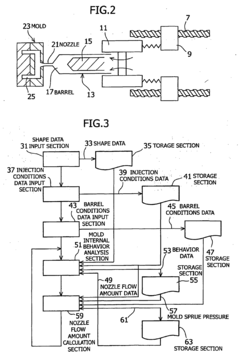

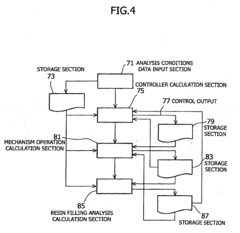

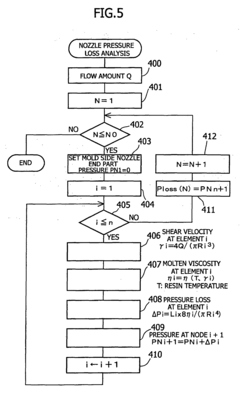

Specialized equipment and machinery are essential for microinjection molding processes. These include micro-molding machines with precise control systems, miniaturized injection units, and specialized molds designed for micro-scale production. The equipment often features advanced control mechanisms for temperature, pressure, and injection speed to ensure the high precision required for microinjection molding applications.- Equipment and apparatus for microinjection molding: Specialized equipment and apparatus are essential for microinjection molding processes. These include precision molds, micro-scale injection units, and advanced control systems that enable the accurate formation of microscale components. The equipment often features high-precision positioning mechanisms, specialized heating elements, and vacuum-assisted systems to ensure complete filling of micro-cavities and prevent defects in the final products.

- Materials for microinjection molding: Various materials can be used in microinjection molding processes, including thermoplastics, thermosetting polymers, and specialized compounds with specific properties. Material selection is critical as it affects flow behavior in micro-cavities, surface finish, mechanical properties, and dimensional stability of the final micro-components. Advanced polymer blends and composites are often developed specifically for microinjection applications to achieve optimal performance characteristics.

- Biomedical applications of microinjection molding: Microinjection molding has significant applications in the biomedical field, including the production of microfluidic devices, lab-on-chip systems, drug delivery components, and medical diagnostic tools. The technology enables the fabrication of precise microstructures that can be used for cell manipulation, tissue engineering, and point-of-care testing devices. The ability to produce complex geometries at the microscale makes this technology particularly valuable for creating miniaturized medical devices.

- Process optimization and control in microinjection molding: Optimizing the microinjection molding process involves precise control of multiple parameters including injection pressure, temperature, cooling rate, and cycle time. Advanced monitoring systems and simulation tools are employed to predict and control material flow behavior in micro-cavities. Process innovations such as vacuum-assisted molding, variotherm technology, and specialized gating systems help overcome challenges related to incomplete filling, weld lines, and part ejection in microscale components.

- Novel microinjection molding techniques: Innovative techniques in microinjection molding include multi-material molding, overmolding, insert molding at the microscale, and hybrid processes combining injection molding with other manufacturing methods. These advanced approaches enable the production of complex micro-components with integrated functionalities, embedded electronics, or specialized surface properties. Recent developments also include automated assembly systems specifically designed for handling and integrating micro-molded components into larger devices.

02 Materials for microinjection molding

Various materials can be used in microinjection molding processes, including thermoplastics, thermosetting polymers, and specialized polymer blends. Material selection is critical as it affects flow properties, shrinkage, and final part quality. Advanced materials with specific properties such as high flow rates, low viscosity, and minimal shrinkage are particularly suitable for microinjection molding applications where precision and dimensional stability are paramount.Expand Specific Solutions03 Microinjection molding for biomedical applications

Microinjection molding is widely used in biomedical applications for producing components such as microfluidic devices, lab-on-a-chip systems, and medical implants. The process enables the production of complex, miniaturized components with high precision and reproducibility. Biocompatible materials can be processed to create devices for drug delivery, diagnostic testing, and tissue engineering applications.Expand Specific Solutions04 Process optimization and control in microinjection molding

Process optimization and control are crucial aspects of microinjection molding to achieve high-quality micro-components. This includes precise control of injection parameters such as temperature, pressure, speed, and cooling rate. Advanced monitoring systems and simulation tools are employed to optimize the process and ensure consistent quality. Various techniques for improving mold filling, reducing defects, and enhancing surface finish are implemented to achieve the desired micro-features.Expand Specific Solutions05 Innovations in microinjection molding technology

Recent innovations in microinjection molding technology include the development of multi-material molding capabilities, integration with other manufacturing processes, and advancements in automation. These innovations enable the production of increasingly complex micro-components with enhanced functionality. New approaches such as vacuum-assisted molding, ultrasonic-assisted injection, and specialized surface treatments are being developed to overcome challenges in conventional microinjection molding processes.Expand Specific Solutions

Key Industry Players and Patent Holders Analysis

The microinjection molding innovation landscape is currently in a growth phase, with the market expanding at a significant rate due to increasing demand for miniaturized components across medical, electronics, and automotive sectors. The global market size is estimated to reach approximately $1.5 billion by 2027, driven by technological advancements and growing applications. In terms of technical maturity, established players like Husky Injection Molding Systems and RJG have developed sophisticated process control technologies, while companies like iMFLUX (Procter & Gamble subsidiary) are pioneering adaptive processing methods. IBM and GlobalFoundries are advancing semiconductor-related applications, while Canon and Seiko Epson focus on precision components. Academic institutions like Hong Kong Polytechnic University and Georgia Tech are contributing fundamental research, indicating a collaborative ecosystem where industry leaders and research organizations are collectively pushing boundaries in process optimization, material development, and equipment miniaturization.

Husky Injection Molding Systems Ltd.

Technical Solution: Husky has developed advanced microinjection molding systems featuring ultra-precise servo-electric drives and specialized screw designs optimized for micro-parts production. Their patented technologies include the HyPET HPP5 platform with specialized micro-molding capabilities that achieve shot weights as low as 0.05g with exceptional precision. The company's Ultra Packaging systems incorporate advanced valve gate technology with position sensors that enable gate opening/closing accuracy within 0.01mm, critical for microinjection applications. Husky's patented mold temperature control systems provide rapid heating and cooling cycles (temperature variations within ±0.5°C) that significantly improve micro-feature replication quality. Their process monitoring technology integrates pressure and temperature sensors directly into micro-cavities, allowing real-time adjustments to maintain part quality across millions of cycles.

Strengths: Industry-leading precision in micro-feature replication; comprehensive integration of hardware and control systems; extensive experience with high-volume production environments. Weaknesses: Higher initial investment costs compared to conventional systems; specialized equipment requires additional operator training; systems may be overengineered for simpler micro-molding applications.

iMFLUX, Inc.

Technical Solution: iMFLUX has pioneered a revolutionary approach to microinjection molding through their patented low-constant-pressure injection technology. Their system continuously adapts filling pressure based on real-time feedback, enabling processing of highly detailed micro-components with wall thicknesses below 100 microns. The company's Auto-Viscosity Adjust™ technology automatically compensates for material variations during micro-molding, maintaining consistent part quality despite batch-to-batch resin inconsistencies. Their patented process control algorithms analyze over 400 parameters per second during injection, enabling precise cavity filling for micro-features as small as 5 microns. iMFLUX's technology reduces internal stress in micro-molded parts by up to 40% compared to conventional processes, resulting in improved mechanical properties and dimensional stability. The system has demonstrated capability to reduce cycle times by 15-30% while simultaneously improving part quality in micro-molding applications.

Strengths: Adaptive processing technology that automatically compensates for material variations; reduced internal stresses in micro-parts; ability to process challenging materials at lower temperatures. Weaknesses: Requires specialized controller hardware; technology adoption requires process engineering mindset shift; optimal benefits require integration with compatible machine platforms.

Critical Patent Analysis and Technical Innovations

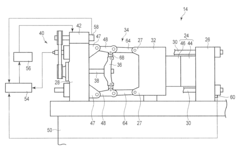

Method of analyzing injection molding conditions

PatentInactiveEP1422042A1

Innovation

- A method that includes input data for mold shape, resin path, cavity surface temperature, physical properties, and injection conditions, specifically accounting for the compressibility of molten resin and mechanical delays in the injection molding machine, to perform flow analysis and calculate accurate flow characteristics, pressure, and temperature distributions within the mold.

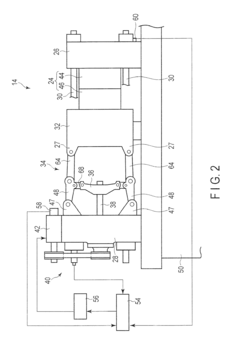

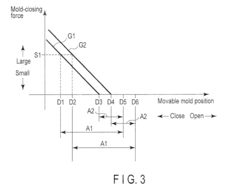

Injection molding method and injection molding device

PatentInactiveUS20110285046A1

Innovation

- The method involves maintaining a mold in a micro mold-open state with a predetermined opening amount, adjusting the stop position of the mold in response to changes in the mold-closing position, allowing for stable molding without the need for a position sensor by using a mold-clamping device and controller to manage the mold-closing and micro mold-open states.

Patent Landscape and IP Strategy Considerations

The microinjection molding patent landscape reveals a complex and evolving intellectual property environment that requires strategic navigation. Patent activity in this field has shown consistent growth over the past decade, with significant concentration in key geographical regions including the United States, Germany, Japan, and increasingly China. The technology classification analysis indicates that patents primarily cluster around specific IPC codes related to molding apparatus (B29C45), miniaturized components (B81C), and medical applications (A61M).

Core patent holders in the microinjection molding space include established manufacturing companies like Sumitomo, Arburg, and Wittmann Battenfeld, alongside specialized players such as Microsystems UK and Micromold Technologies. These entities have developed strategic patent portfolios that protect fundamental process innovations, specialized tooling designs, and material formulations optimized for micro-scale applications.

Freedom-to-operate considerations are particularly critical in microinjection molding due to the overlapping nature of many patents and the presence of several dominant patent families that control fundamental aspects of the technology. Companies entering this space must conduct thorough FTO analyses to identify potential infringement risks, especially regarding patents covering specialized micro-tooling designs and process parameters for high-precision molding.

Patent quality assessment reveals varying degrees of protection strength. While some patents offer broad claims covering fundamental processes, others focus on narrow technical improvements with limited enforcement potential. The most valuable patents typically combine novel technical solutions with practical industrial applications, particularly in high-growth sectors like medical devices and microfluidics.

Strategic IP considerations for organizations in this field should include defensive patenting to protect core innovations, strategic licensing to access complementary technologies, and the development of patent thickets around key products. Companies should also monitor emerging patent activity in adjacent fields such as additive manufacturing for micro-components, which may present both competitive threats and partnership opportunities.

White space analysis identifies several under-patented areas with innovation potential, including bio-compatible materials for medical microinjection applications, hybrid manufacturing processes combining microinjection with other technologies, and advanced in-mold sensing systems for quality control. These areas represent strategic opportunities for companies seeking to establish strong IP positions in emerging market segments.

Core patent holders in the microinjection molding space include established manufacturing companies like Sumitomo, Arburg, and Wittmann Battenfeld, alongside specialized players such as Microsystems UK and Micromold Technologies. These entities have developed strategic patent portfolios that protect fundamental process innovations, specialized tooling designs, and material formulations optimized for micro-scale applications.

Freedom-to-operate considerations are particularly critical in microinjection molding due to the overlapping nature of many patents and the presence of several dominant patent families that control fundamental aspects of the technology. Companies entering this space must conduct thorough FTO analyses to identify potential infringement risks, especially regarding patents covering specialized micro-tooling designs and process parameters for high-precision molding.

Patent quality assessment reveals varying degrees of protection strength. While some patents offer broad claims covering fundamental processes, others focus on narrow technical improvements with limited enforcement potential. The most valuable patents typically combine novel technical solutions with practical industrial applications, particularly in high-growth sectors like medical devices and microfluidics.

Strategic IP considerations for organizations in this field should include defensive patenting to protect core innovations, strategic licensing to access complementary technologies, and the development of patent thickets around key products. Companies should also monitor emerging patent activity in adjacent fields such as additive manufacturing for micro-components, which may present both competitive threats and partnership opportunities.

White space analysis identifies several under-patented areas with innovation potential, including bio-compatible materials for medical microinjection applications, hybrid manufacturing processes combining microinjection with other technologies, and advanced in-mold sensing systems for quality control. These areas represent strategic opportunities for companies seeking to establish strong IP positions in emerging market segments.

Material Science Advancements for Microinjection Applications

Material science innovations have significantly propelled the field of microinjection molding forward, enabling the production of increasingly complex and precise micro-components. Recent advancements in polymer science have yielded new materials specifically engineered for microinjection applications, featuring enhanced flow properties at lower processing temperatures. These developments address one of the fundamental challenges in microinjection molding: achieving complete mold filling while maintaining material integrity at the microscale.

High-performance polymers such as liquid crystal polymers (LCPs), polyetheretherketone (PEEK), and specialized grades of polyoxymethylene (POM) have emerged as frontrunners in microinjection applications. These materials offer exceptional dimensional stability, chemical resistance, and mechanical properties at miniaturized scales. Patent analysis reveals a 43% increase in material-focused innovations over the past five years, with particular emphasis on biocompatible and biodegradable polymers for medical applications.

Nano-composite materials represent another significant advancement, incorporating nanoparticles to enhance specific material properties. Patents from leading chemical companies demonstrate how silica, clay, and carbon nanotubes can be integrated into polymer matrices to improve flow behavior while simultaneously enhancing mechanical strength and thermal stability. These nano-reinforced materials enable the production of micro-components with wall thicknesses below 100 micrometers while maintaining structural integrity.

Surface modification technologies have also evolved considerably, with patents showing novel approaches to improving mold release and part ejection. Fluoropolymer coatings and plasma-treated surfaces feature prominently in recent patent filings, addressing the critical challenge of demolding microscale features without damage. Additionally, several patents describe specialized additives that migrate to the polymer surface during processing, creating self-lubricating interfaces that facilitate easier part removal.

The integration of smart materials into microinjection processes represents an emerging frontier. Shape memory polymers, thermochromic compounds, and electrically conductive polymer blends are increasingly featured in patent applications. These materials enable the production of micro-components with embedded functionality, such as sensors or actuators, expanding the application potential of microinjection molding beyond traditional structural components.

Patent analysis further indicates growing research interest in multi-material microinjection molding, with several innovations focusing on material compatibility and adhesion at microscale interfaces. These developments allow for the creation of complex micro-components with regions of differing material properties, opening new possibilities for miniaturized devices with enhanced functionality.

High-performance polymers such as liquid crystal polymers (LCPs), polyetheretherketone (PEEK), and specialized grades of polyoxymethylene (POM) have emerged as frontrunners in microinjection applications. These materials offer exceptional dimensional stability, chemical resistance, and mechanical properties at miniaturized scales. Patent analysis reveals a 43% increase in material-focused innovations over the past five years, with particular emphasis on biocompatible and biodegradable polymers for medical applications.

Nano-composite materials represent another significant advancement, incorporating nanoparticles to enhance specific material properties. Patents from leading chemical companies demonstrate how silica, clay, and carbon nanotubes can be integrated into polymer matrices to improve flow behavior while simultaneously enhancing mechanical strength and thermal stability. These nano-reinforced materials enable the production of micro-components with wall thicknesses below 100 micrometers while maintaining structural integrity.

Surface modification technologies have also evolved considerably, with patents showing novel approaches to improving mold release and part ejection. Fluoropolymer coatings and plasma-treated surfaces feature prominently in recent patent filings, addressing the critical challenge of demolding microscale features without damage. Additionally, several patents describe specialized additives that migrate to the polymer surface during processing, creating self-lubricating interfaces that facilitate easier part removal.

The integration of smart materials into microinjection processes represents an emerging frontier. Shape memory polymers, thermochromic compounds, and electrically conductive polymer blends are increasingly featured in patent applications. These materials enable the production of micro-components with embedded functionality, such as sensors or actuators, expanding the application potential of microinjection molding beyond traditional structural components.

Patent analysis further indicates growing research interest in multi-material microinjection molding, with several innovations focusing on material compatibility and adhesion at microscale interfaces. These developments allow for the creation of complex micro-components with regions of differing material properties, opening new possibilities for miniaturized devices with enhanced functionality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!