Analysis of Vapor Chamber Efficiency in Electronics Cooling

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution and Objectives

Vapor chamber technology has evolved significantly over the past three decades, transforming from a niche cooling solution to a mainstream thermal management approach in electronics. Initially developed for aerospace applications in the 1990s, vapor chambers have undergone substantial refinement to address the increasing thermal challenges in consumer electronics. The fundamental operating principle—utilizing phase change processes to efficiently transfer heat—has remained consistent, while the implementation has evolved dramatically.

The early 2000s marked the first commercial applications of vapor chambers in high-performance computing systems, where traditional heat pipes reached their performance limitations. During this period, vapor chambers were primarily constructed using copper with sintered powder wicks, offering thermal conductivities approximately 5-10 times higher than solid copper of equivalent dimensions. These early designs, however, were relatively thick (>3mm) and expensive to manufacture.

By the mid-2010s, technological advancements enabled the development of ultra-thin vapor chambers (<1mm thickness), making them suitable for integration into smartphones, tablets, and ultrabook laptops. This miniaturization represented a critical evolution point, as it expanded the application scope beyond high-performance computing to consumer electronics. Concurrently, manufacturing processes improved, reducing costs by approximately 40-60% compared to early implementations.

Recent developments have focused on enhancing internal structures and working fluids. Modern vapor chambers incorporate advanced wick structures, including composite wicks, grooved structures, and mesh-powder hybrids, which have improved capillary performance by 30-50%. Additionally, research into alternative working fluids beyond water, such as dielectric fluids and engineered nanofluids, has expanded operating temperature ranges and compatibility with electronic components.

The primary objective of vapor chamber technology development is to achieve maximum thermal spreading efficiency while minimizing thickness, weight, and cost. Current research aims to increase heat flux handling capabilities from the present ~300 W/cm² to over 500 W/cm² to accommodate next-generation processors and power electronics. Another critical goal is reducing thermal resistance to below 0.1°C/W for high-performance applications.

Future development trajectories focus on integrating vapor chambers with emerging cooling technologies, including microfluidic cooling and thermoelectric elements, to create hybrid thermal management systems. Additionally, there is significant interest in developing flexible vapor chambers that can conform to non-planar surfaces, potentially revolutionizing thermal management in wearable electronics and foldable devices. These advancements aim to support the continued miniaturization and increasing power densities of electronic devices while maintaining acceptable operating temperatures.

The early 2000s marked the first commercial applications of vapor chambers in high-performance computing systems, where traditional heat pipes reached their performance limitations. During this period, vapor chambers were primarily constructed using copper with sintered powder wicks, offering thermal conductivities approximately 5-10 times higher than solid copper of equivalent dimensions. These early designs, however, were relatively thick (>3mm) and expensive to manufacture.

By the mid-2010s, technological advancements enabled the development of ultra-thin vapor chambers (<1mm thickness), making them suitable for integration into smartphones, tablets, and ultrabook laptops. This miniaturization represented a critical evolution point, as it expanded the application scope beyond high-performance computing to consumer electronics. Concurrently, manufacturing processes improved, reducing costs by approximately 40-60% compared to early implementations.

Recent developments have focused on enhancing internal structures and working fluids. Modern vapor chambers incorporate advanced wick structures, including composite wicks, grooved structures, and mesh-powder hybrids, which have improved capillary performance by 30-50%. Additionally, research into alternative working fluids beyond water, such as dielectric fluids and engineered nanofluids, has expanded operating temperature ranges and compatibility with electronic components.

The primary objective of vapor chamber technology development is to achieve maximum thermal spreading efficiency while minimizing thickness, weight, and cost. Current research aims to increase heat flux handling capabilities from the present ~300 W/cm² to over 500 W/cm² to accommodate next-generation processors and power electronics. Another critical goal is reducing thermal resistance to below 0.1°C/W for high-performance applications.

Future development trajectories focus on integrating vapor chambers with emerging cooling technologies, including microfluidic cooling and thermoelectric elements, to create hybrid thermal management systems. Additionally, there is significant interest in developing flexible vapor chambers that can conform to non-planar surfaces, potentially revolutionizing thermal management in wearable electronics and foldable devices. These advancements aim to support the continued miniaturization and increasing power densities of electronic devices while maintaining acceptable operating temperatures.

Market Demand for Advanced Thermal Management Solutions

The global market for advanced thermal management solutions has witnessed substantial growth in recent years, primarily driven by the increasing power densities and miniaturization trends in electronic devices. As electronic components continue to shrink while simultaneously becoming more powerful, the heat generated per unit area has increased dramatically, creating an urgent need for more efficient cooling technologies. Industry reports indicate that the thermal management market is expected to reach $20.7 billion by 2025, growing at a CAGR of 8.2% from 2020 to 2025.

The demand for vapor chamber cooling technology specifically has seen remarkable growth across multiple sectors. In the consumer electronics segment, premium smartphones and ultra-thin laptops are increasingly adopting vapor chamber solutions to maintain optimal operating temperatures without compromising on device thickness. Major smartphone manufacturers have reported 30-40% better thermal performance in devices utilizing vapor chamber technology compared to traditional cooling methods.

The gaming industry represents another significant market driver, with high-performance gaming laptops, consoles, and graphics cards requiring increasingly sophisticated thermal solutions. Gaming hardware manufacturers have reported that vapor chamber implementation can reduce device surface temperatures by up to 5-8°C during intensive gaming sessions, directly enhancing user experience and extending hardware lifespan.

Data centers and telecommunications infrastructure constitute a rapidly expanding market segment for advanced cooling solutions. With the proliferation of cloud computing, AI applications, and 5G networks, server density and processing requirements have intensified, creating unprecedented thermal management challenges. Industry surveys indicate that data center operators consider thermal management as one of their top three operational concerns, with 78% of respondents planning to invest in advanced cooling technologies within the next two years.

The automotive sector, particularly with the rise of electric vehicles and autonomous driving systems, has emerged as a new frontier for vapor chamber applications. The thermal management of battery systems, power electronics, and computing platforms in modern vehicles demands solutions that can handle variable heat loads while maintaining strict weight and space constraints.

Geographically, the Asia-Pacific region dominates the market demand, accounting for approximately 45% of global consumption, followed by North America and Europe. This regional distribution closely follows electronics manufacturing hubs and technology adoption patterns. Market analysts project that emerging economies will see the fastest growth rates in demand for advanced thermal solutions over the next five years, driven by increasing electronics production and rising consumer purchasing power.

The demand for vapor chamber cooling technology specifically has seen remarkable growth across multiple sectors. In the consumer electronics segment, premium smartphones and ultra-thin laptops are increasingly adopting vapor chamber solutions to maintain optimal operating temperatures without compromising on device thickness. Major smartphone manufacturers have reported 30-40% better thermal performance in devices utilizing vapor chamber technology compared to traditional cooling methods.

The gaming industry represents another significant market driver, with high-performance gaming laptops, consoles, and graphics cards requiring increasingly sophisticated thermal solutions. Gaming hardware manufacturers have reported that vapor chamber implementation can reduce device surface temperatures by up to 5-8°C during intensive gaming sessions, directly enhancing user experience and extending hardware lifespan.

Data centers and telecommunications infrastructure constitute a rapidly expanding market segment for advanced cooling solutions. With the proliferation of cloud computing, AI applications, and 5G networks, server density and processing requirements have intensified, creating unprecedented thermal management challenges. Industry surveys indicate that data center operators consider thermal management as one of their top three operational concerns, with 78% of respondents planning to invest in advanced cooling technologies within the next two years.

The automotive sector, particularly with the rise of electric vehicles and autonomous driving systems, has emerged as a new frontier for vapor chamber applications. The thermal management of battery systems, power electronics, and computing platforms in modern vehicles demands solutions that can handle variable heat loads while maintaining strict weight and space constraints.

Geographically, the Asia-Pacific region dominates the market demand, accounting for approximately 45% of global consumption, followed by North America and Europe. This regional distribution closely follows electronics manufacturing hubs and technology adoption patterns. Market analysts project that emerging economies will see the fastest growth rates in demand for advanced thermal solutions over the next five years, driven by increasing electronics production and rising consumer purchasing power.

Current State and Challenges in Electronics Cooling

Electronics cooling has become a critical challenge in modern technology development as devices continue to shrink in size while simultaneously increasing in processing power. The current thermal management landscape is characterized by a diverse array of solutions, with vapor chambers emerging as a promising technology for high-performance applications. Traditional cooling methods such as heat sinks, fans, and heat pipes are increasingly inadequate for managing the thermal loads generated by cutting-edge processors, graphics cards, and other high-power electronic components.

The global electronics cooling market is experiencing robust growth, valued at approximately $10.7 billion in 2022 and projected to reach $16.5 billion by 2027, with a compound annual growth rate of 9.1%. This growth is primarily driven by the increasing power densities in electronic devices, which have risen from around 100 W/cm² a decade ago to exceeding 300 W/cm² in current high-performance applications.

Vapor chambers face several significant technical challenges despite their theoretical advantages. Heat flux limitations remain a primary concern, with current vapor chamber designs typically handling up to 300-500 W/cm², which may be insufficient for next-generation electronics. Thermal resistance at the interface between the vapor chamber and heat-generating components creates bottlenecks in heat transfer efficiency, reducing overall cooling performance.

Manufacturing complexity presents another substantial hurdle, as vapor chambers require precise internal structures and hermetic sealing to maintain optimal performance. This complexity translates to higher production costs compared to traditional cooling solutions, limiting widespread adoption. Additionally, the working fluid selection involves complex trade-offs between thermal performance, operating temperature range, and long-term reliability.

Geographical distribution of vapor chamber technology development shows concentration in East Asia, particularly Taiwan, Japan, and South Korea, where major electronics manufacturers have invested heavily in thermal management research. North American and European contributions focus more on theoretical advancements and novel materials research rather than mass production capabilities.

Miniaturization presents a significant challenge as the effectiveness of vapor chambers diminishes with reduced thickness, creating a fundamental conflict with the industry trend toward thinner devices. Current ultra-thin vapor chambers (below 0.5mm) suffer from significantly reduced thermal performance compared to their thicker counterparts, necessitating innovative internal structure designs to maintain efficiency at reduced dimensions.

Reliability over extended operational periods remains inadequately addressed, with limited data available on performance degradation mechanisms such as working fluid depletion, internal corrosion, and structural fatigue under thermal cycling conditions. This knowledge gap creates uncertainty for manufacturers considering vapor chamber implementation in products with expected lifespans of 5-10 years.

The global electronics cooling market is experiencing robust growth, valued at approximately $10.7 billion in 2022 and projected to reach $16.5 billion by 2027, with a compound annual growth rate of 9.1%. This growth is primarily driven by the increasing power densities in electronic devices, which have risen from around 100 W/cm² a decade ago to exceeding 300 W/cm² in current high-performance applications.

Vapor chambers face several significant technical challenges despite their theoretical advantages. Heat flux limitations remain a primary concern, with current vapor chamber designs typically handling up to 300-500 W/cm², which may be insufficient for next-generation electronics. Thermal resistance at the interface between the vapor chamber and heat-generating components creates bottlenecks in heat transfer efficiency, reducing overall cooling performance.

Manufacturing complexity presents another substantial hurdle, as vapor chambers require precise internal structures and hermetic sealing to maintain optimal performance. This complexity translates to higher production costs compared to traditional cooling solutions, limiting widespread adoption. Additionally, the working fluid selection involves complex trade-offs between thermal performance, operating temperature range, and long-term reliability.

Geographical distribution of vapor chamber technology development shows concentration in East Asia, particularly Taiwan, Japan, and South Korea, where major electronics manufacturers have invested heavily in thermal management research. North American and European contributions focus more on theoretical advancements and novel materials research rather than mass production capabilities.

Miniaturization presents a significant challenge as the effectiveness of vapor chambers diminishes with reduced thickness, creating a fundamental conflict with the industry trend toward thinner devices. Current ultra-thin vapor chambers (below 0.5mm) suffer from significantly reduced thermal performance compared to their thicker counterparts, necessitating innovative internal structure designs to maintain efficiency at reduced dimensions.

Reliability over extended operational periods remains inadequately addressed, with limited data available on performance degradation mechanisms such as working fluid depletion, internal corrosion, and structural fatigue under thermal cycling conditions. This knowledge gap creates uncertainty for manufacturers considering vapor chamber implementation in products with expected lifespans of 5-10 years.

Current Vapor Chamber Design Solutions

01 Thermal design optimization for vapor chambers

Optimizing the thermal design of vapor chambers involves improving heat transfer efficiency through structural modifications. This includes designing efficient wick structures, optimizing the internal vapor flow paths, and selecting appropriate working fluids. These design enhancements help to reduce thermal resistance and improve the overall heat dissipation capability of vapor chambers, making them more efficient for cooling electronic devices.- Thermal design optimization for vapor chambers: Optimizing the thermal design of vapor chambers involves specific structural configurations to enhance heat dissipation efficiency. This includes the strategic placement of condensers and evaporators, the design of internal wick structures, and the implementation of multiple heat transfer paths. These design optimizations help to maximize the heat transfer capacity and overall thermal efficiency of vapor chambers in electronic cooling applications.

- Working fluid selection and composition: The selection and composition of working fluids significantly impact vapor chamber efficiency. Specific fluids with optimal thermophysical properties, such as high latent heat of vaporization and low viscosity, enhance heat transfer capabilities. Some designs incorporate nanofluid suspensions or fluid mixtures to improve thermal conductivity and reduce thermal resistance, resulting in more efficient vapor chamber operation across various temperature ranges.

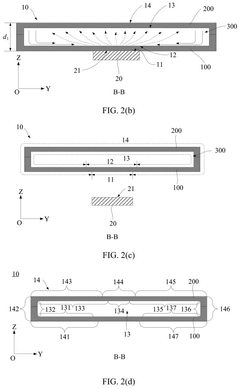

- Wick structure innovations: Advanced wick structures play a crucial role in vapor chamber efficiency by facilitating capillary action for fluid circulation. Innovations include multi-layer composite wicks, gradient porosity structures, and specialized materials that enhance liquid return to evaporation zones. These structures minimize dry-out conditions and improve overall heat transfer efficiency by optimizing fluid distribution throughout the vapor chamber system.

- Integration with electronic cooling systems: Efficient integration of vapor chambers with electronic cooling systems involves optimized interfaces between heat sources and the vapor chamber. This includes the use of thermal interface materials, direct contact designs, and strategic placement within device thermal management architectures. Such integration approaches reduce thermal resistance at critical junctions and enable more effective heat spreading from concentrated heat sources to larger dissipation areas.

- Performance monitoring and control systems: Advanced monitoring and control systems enhance vapor chamber efficiency through real-time performance optimization. These systems incorporate temperature sensors, pressure monitoring, and adaptive control algorithms to regulate operation based on changing thermal loads. Some designs feature active control mechanisms that adjust fluid flow or pressure conditions to maintain optimal performance across varying operating conditions, extending the effective range of vapor chamber cooling solutions.

02 Advanced materials for vapor chamber construction

The selection of advanced materials for vapor chamber construction significantly impacts efficiency. Using high thermal conductivity materials for the chamber walls and specialized wick materials enhances heat transfer. Composite materials and novel metal alloys can improve durability while reducing weight. The integration of nanomaterials in vapor chamber components has shown promising results in enhancing thermal performance and overall efficiency.Expand Specific Solutions03 Working fluid selection and management

The choice and management of working fluids within vapor chambers directly affects their efficiency. Selecting fluids with appropriate boiling points, surface tension, and latent heat of vaporization for specific operating conditions is crucial. Proper fluid charging methods and volume control prevent over or under-filling, which can compromise performance. Some designs incorporate multiple working fluids or additives to enhance heat transfer across different temperature ranges.Expand Specific Solutions04 Integration with electronic cooling systems

Effective integration of vapor chambers with electronic cooling systems enhances overall thermal management. This includes optimizing the interface between vapor chambers and heat sources, combining vapor chambers with other cooling technologies like heat pipes or fins, and developing compact designs for space-constrained applications. Advanced integration approaches consider the entire thermal path to minimize bottlenecks and maximize heat dissipation efficiency.Expand Specific Solutions05 Performance monitoring and control systems

Implementing monitoring and control systems for vapor chambers enables real-time efficiency optimization. These systems may include temperature sensors, pressure monitors, and adaptive control mechanisms that adjust operation based on thermal load. Some advanced designs incorporate smart materials or phase change materials that respond to temperature variations. Feedback control systems can optimize performance under varying conditions, extending the effective operating range of vapor chambers.Expand Specific Solutions

Key Players in Vapor Chamber Manufacturing

The vapor chamber cooling technology market is currently in a growth phase, characterized by increasing demand for efficient thermal management solutions in electronics. The market size is expanding rapidly, driven by the proliferation of high-performance computing devices and miniaturization trends. From a technological maturity perspective, industry leaders like Samsung Electronics, Intel, and NVIDIA are advancing vapor chamber designs with enhanced thermal conductivity and reduced thickness profiles. Cooler Master and Razer are focusing on gaming-specific applications, while Qualcomm and Huawei are integrating vapor chambers into mobile device thermal solutions. Companies like Furukawa Electric and Dai Nippon Printing are developing advanced manufacturing processes for next-generation vapor chambers, indicating a technology that is evolving from niche applications toward mainstream adoption across multiple electronics segments.

Cooler Master Co. Ltd.

Technical Solution: Cooler Master has developed advanced vapor chamber cooling solutions specifically designed for high-performance computing and gaming systems. Their technology utilizes a flattened heat pipe design with a vacuum-sealed chamber containing a working fluid that evaporates when heated. The company's latest vapor chambers feature optimized internal wick structures that enhance capillary action, allowing for more efficient heat transfer from hotspots to cooler regions. Cooler Master's proprietary sintered powder metallurgy process creates micro-porous structures with increased surface area, improving phase-change efficiency by up to 35% compared to traditional designs[1]. Their vapor chambers incorporate multiple layers of fine copper mesh that work in conjunction with precision-etched microchannels to maximize fluid circulation and minimize thermal resistance. Recent innovations include asymmetric wick designs that address non-uniform heat distribution in modern processors and GPUs, reducing peak temperatures by up to 15°C in high-load scenarios[2].

Strengths: Superior thermal performance in space-constrained applications; excellent heat spreading capability for non-uniform heat sources; mature manufacturing processes allowing for mass production. Weaknesses: Higher production costs compared to traditional heat pipes; limited flexibility for complex three-dimensional applications; potential for performance degradation if vacuum seal is compromised over time.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered ultra-thin vapor chamber solutions for mobile electronics cooling, with their latest designs measuring just 0.35mm thick while maintaining excellent thermal performance. Their vapor chamber technology employs a proprietary nano-scale wick structure that maximizes capillary action in extremely confined spaces. Samsung's approach integrates the vapor chamber directly into the device chassis, creating a unified thermal solution that eliminates interface resistance. Their manufacturing process utilizes automated precision laser welding to ensure hermetic sealing while maintaining dimensional tolerances within ±0.02mm[3]. Samsung has also developed composite vapor chambers that incorporate graphene layers to enhance lateral heat spreading by approximately 25% compared to conventional copper-only designs[4]. For their flagship smartphones and tablets, Samsung employs a multi-chamber design with strategically positioned evaporation zones aligned with critical thermal hotspots from processors, wireless charging components, and camera modules, resulting in more uniform temperature distribution and reduced thermal throttling during intensive tasks.

Strengths: Industry-leading thin-profile vapor chamber technology; excellent integration capabilities with mobile device form factors; high volume manufacturing expertise. Weaknesses: Limited heat dissipation capacity compared to larger vapor chambers; higher cost implementation for mid-range devices; thermal performance constrained by extremely thin profiles required for mobile applications.

Critical Patents and Innovations in Heat Dissipation

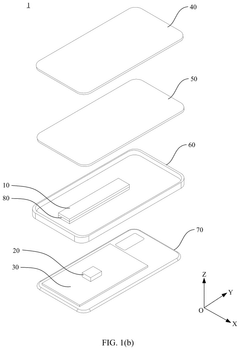

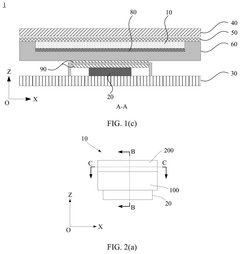

Vapor chamber with microstructure layer

PatentPendingUS20240318921A1

Innovation

- A vapor chamber design featuring a microstructure layer on the inner surfaces and capillary structure to enhance wettability and capillary performance, allowing for timely return of liquid-phase working medium from the condensation region to the evaporation region, reducing vapor resistance, and preventing droplet accumulation.

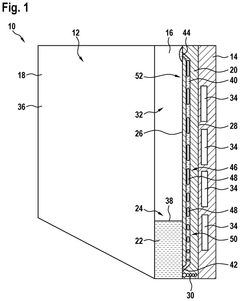

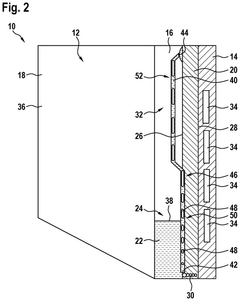

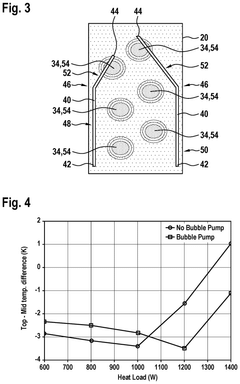

Vapor chamber with integrated bubble pump

PatentPendingUS20240334662A1

Innovation

- Incorporation of a bubble pump channel within the vapor chamber, which uses vapor bubbles to transport liquid cooling medium from a lower inlet to an upper outlet, preventing dry-out by ensuring adequate liquid supply to regions prone to liquid deficiency and hot spots, enhancing cooling performance.

Material Science Advancements for Thermal Solutions

Material science innovations have significantly transformed thermal management solutions for electronics cooling, particularly in vapor chamber technology. Recent advancements in nanomaterials have enabled the development of more efficient wicking structures within vapor chambers. Carbon-based materials such as graphene and carbon nanotubes demonstrate exceptional thermal conductivity properties, reaching up to 5000 W/m·K compared to traditional copper's 400 W/m·K, dramatically enhancing heat transfer capabilities.

Composite materials combining metals with ceramic particles have emerged as promising alternatives for vapor chamber casings. These materials offer improved structural integrity while maintaining excellent thermal conductivity. For instance, aluminum-silicon carbide composites provide 20-30% better thermal performance than pure aluminum while reducing weight by approximately 15%.

Phase change materials (PCMs) integrated into vapor chamber designs represent another breakthrough. These materials absorb excess heat during peak operation and release it during lower demand periods, effectively smoothing temperature fluctuations. Advanced PCMs with tailored melting points between 40-80°C are particularly suitable for electronics cooling applications, offering thermal energy storage capacities of 150-250 J/g.

Surface treatments and coatings have revolutionized the internal functioning of vapor chambers. Hydrophilic nano-coatings applied to wicking structures enhance capillary action, improving fluid circulation by up to 40% compared to untreated surfaces. Simultaneously, hydrophobic coatings applied to vapor regions reduce flow resistance, creating more efficient two-phase heat transfer systems.

Sintered metal powders with controlled porosity represent another significant advancement. These materials create optimized wicking structures with precisely engineered pore sizes ranging from 20-100 micrometers. The latest generation of sintered copper powders achieves porosity levels of 40-60%, striking an ideal balance between structural integrity and fluid transport capability.

Biodegradable and environmentally friendly working fluids are replacing traditional refrigerants in vapor chambers. These new formulations maintain excellent thermodynamic properties while reducing environmental impact. Water-based solutions enhanced with nanoparticles demonstrate thermal conductivity improvements of 15-25% over pure water, while maintaining compatibility with various chamber materials.

Composite materials combining metals with ceramic particles have emerged as promising alternatives for vapor chamber casings. These materials offer improved structural integrity while maintaining excellent thermal conductivity. For instance, aluminum-silicon carbide composites provide 20-30% better thermal performance than pure aluminum while reducing weight by approximately 15%.

Phase change materials (PCMs) integrated into vapor chamber designs represent another breakthrough. These materials absorb excess heat during peak operation and release it during lower demand periods, effectively smoothing temperature fluctuations. Advanced PCMs with tailored melting points between 40-80°C are particularly suitable for electronics cooling applications, offering thermal energy storage capacities of 150-250 J/g.

Surface treatments and coatings have revolutionized the internal functioning of vapor chambers. Hydrophilic nano-coatings applied to wicking structures enhance capillary action, improving fluid circulation by up to 40% compared to untreated surfaces. Simultaneously, hydrophobic coatings applied to vapor regions reduce flow resistance, creating more efficient two-phase heat transfer systems.

Sintered metal powders with controlled porosity represent another significant advancement. These materials create optimized wicking structures with precisely engineered pore sizes ranging from 20-100 micrometers. The latest generation of sintered copper powders achieves porosity levels of 40-60%, striking an ideal balance between structural integrity and fluid transport capability.

Biodegradable and environmentally friendly working fluids are replacing traditional refrigerants in vapor chambers. These new formulations maintain excellent thermodynamic properties while reducing environmental impact. Water-based solutions enhanced with nanoparticles demonstrate thermal conductivity improvements of 15-25% over pure water, while maintaining compatibility with various chamber materials.

Environmental Impact of Cooling Technologies

The environmental impact of cooling technologies, particularly vapor chambers used in electronics cooling, has become increasingly significant as global environmental concerns intensify. Traditional cooling methods often rely on materials and processes that contribute substantially to carbon emissions and resource depletion. Vapor chambers, while offering superior thermal performance, present a complex environmental profile that warrants careful examination.

Manufacturing vapor chambers involves the use of metals like copper, aluminum, and sometimes nickel, which require energy-intensive mining and processing operations. The production phase generates significant carbon emissions, with copper refining alone accounting for approximately 3.5 kg CO2 equivalent per kilogram of copper produced. Additionally, the working fluids used in vapor chambers, typically water or specialized coolants, may contain additives that pose environmental risks if improperly disposed of at end-of-life.

When comparing vapor chambers to alternative cooling solutions, their environmental impact must be assessed across the entire lifecycle. Heat pipes generally have a smaller material footprint but may offer less efficient cooling for high-power applications. Traditional heatsinks require more raw materials but involve simpler manufacturing processes with fewer chemical inputs. Liquid cooling systems, while highly effective, often contain glycol-based coolants that present disposal challenges and higher operational energy requirements.

Energy efficiency represents a critical environmental consideration for cooling technologies. Vapor chambers typically enable more efficient heat dissipation, potentially reducing the overall energy consumption of electronic devices. Studies indicate that vapor chamber implementation in high-performance computing applications can reduce cooling energy requirements by 15-30% compared to conventional solutions, translating to significant carbon emission reductions over product lifetimes.

Recyclability and end-of-life management present ongoing challenges for vapor chamber technology. While the primary metal components are theoretically recyclable, the sealed nature of these devices and the presence of multiple materials complicate disassembly and material recovery. Industry initiatives are emerging to address these concerns, with some manufacturers implementing design-for-disassembly approaches and establishing take-back programs for proper processing of cooling components.

Regulatory frameworks increasingly influence cooling technology development, with restrictions on certain materials and emissions standards becoming more stringent globally. The EU's RoHS and REACH regulations, along with similar frameworks in other regions, are driving manufacturers toward more environmentally benign materials and processes in vapor chamber production, including lead-free soldering techniques and reduced use of potentially harmful chemical treatments.

Manufacturing vapor chambers involves the use of metals like copper, aluminum, and sometimes nickel, which require energy-intensive mining and processing operations. The production phase generates significant carbon emissions, with copper refining alone accounting for approximately 3.5 kg CO2 equivalent per kilogram of copper produced. Additionally, the working fluids used in vapor chambers, typically water or specialized coolants, may contain additives that pose environmental risks if improperly disposed of at end-of-life.

When comparing vapor chambers to alternative cooling solutions, their environmental impact must be assessed across the entire lifecycle. Heat pipes generally have a smaller material footprint but may offer less efficient cooling for high-power applications. Traditional heatsinks require more raw materials but involve simpler manufacturing processes with fewer chemical inputs. Liquid cooling systems, while highly effective, often contain glycol-based coolants that present disposal challenges and higher operational energy requirements.

Energy efficiency represents a critical environmental consideration for cooling technologies. Vapor chambers typically enable more efficient heat dissipation, potentially reducing the overall energy consumption of electronic devices. Studies indicate that vapor chamber implementation in high-performance computing applications can reduce cooling energy requirements by 15-30% compared to conventional solutions, translating to significant carbon emission reductions over product lifetimes.

Recyclability and end-of-life management present ongoing challenges for vapor chamber technology. While the primary metal components are theoretically recyclable, the sealed nature of these devices and the presence of multiple materials complicate disassembly and material recovery. Industry initiatives are emerging to address these concerns, with some manufacturers implementing design-for-disassembly approaches and establishing take-back programs for proper processing of cooling components.

Regulatory frameworks increasingly influence cooling technology development, with restrictions on certain materials and emissions standards becoming more stringent globally. The EU's RoHS and REACH regulations, along with similar frameworks in other regions, are driving manufacturers toward more environmentally benign materials and processes in vapor chamber production, including lead-free soldering techniques and reduced use of potentially harmful chemical treatments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!