Analyzing Ethylene Vinyl Acetate for Advanced Applications

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile polymer with a rich history spanning several decades. Initially developed in the 1950s, EVA has continuously evolved to meet the changing demands of various industries. This copolymer, composed of ethylene and vinyl acetate, offers a unique combination of properties that have made it increasingly valuable in advanced applications.

The development of EVA technology has been driven by the need for materials that can bridge the gap between flexible plastics and elastomers. Over the years, researchers and manufacturers have fine-tuned the composition and processing techniques of EVA to enhance its performance characteristics. The ability to adjust the vinyl acetate content has allowed for the creation of EVA grades with tailored properties, ranging from flexible and rubber-like to rigid and transparent.

In recent years, the focus on sustainable and eco-friendly materials has further propelled EVA research. Efforts are being made to develop bio-based EVA alternatives and improve the recyclability of EVA products. This aligns with the global trend towards circular economy principles and reduced environmental impact.

The primary objective of analyzing EVA for advanced applications is to unlock its full potential across diverse sectors. This includes exploring novel formulations and processing methods to enhance EVA's mechanical, thermal, and chemical properties. Researchers aim to expand EVA's applicability in high-performance areas such as aerospace, renewable energy, and biomedical devices.

Another key goal is to investigate EVA's role in composite materials. By combining EVA with other polymers, nanoparticles, or reinforcing fibers, scientists seek to create advanced composites with superior characteristics. This could lead to breakthroughs in lightweight, durable materials for automotive and construction industries.

Furthermore, the analysis of EVA for advanced applications aims to address specific challenges in various fields. For instance, in the solar energy sector, researchers are working on improving EVA's long-term stability and UV resistance to enhance the durability of photovoltaic modules. In the medical field, the focus is on developing biocompatible EVA formulations for drug delivery systems and implantable devices.

As technology continues to advance, the objectives of EVA research extend to smart and responsive materials. This includes exploring ways to incorporate sensors or stimuli-responsive elements into EVA-based products, opening up possibilities for intelligent packaging, wearable technology, and adaptive structures.

The development of EVA technology has been driven by the need for materials that can bridge the gap between flexible plastics and elastomers. Over the years, researchers and manufacturers have fine-tuned the composition and processing techniques of EVA to enhance its performance characteristics. The ability to adjust the vinyl acetate content has allowed for the creation of EVA grades with tailored properties, ranging from flexible and rubber-like to rigid and transparent.

In recent years, the focus on sustainable and eco-friendly materials has further propelled EVA research. Efforts are being made to develop bio-based EVA alternatives and improve the recyclability of EVA products. This aligns with the global trend towards circular economy principles and reduced environmental impact.

The primary objective of analyzing EVA for advanced applications is to unlock its full potential across diverse sectors. This includes exploring novel formulations and processing methods to enhance EVA's mechanical, thermal, and chemical properties. Researchers aim to expand EVA's applicability in high-performance areas such as aerospace, renewable energy, and biomedical devices.

Another key goal is to investigate EVA's role in composite materials. By combining EVA with other polymers, nanoparticles, or reinforcing fibers, scientists seek to create advanced composites with superior characteristics. This could lead to breakthroughs in lightweight, durable materials for automotive and construction industries.

Furthermore, the analysis of EVA for advanced applications aims to address specific challenges in various fields. For instance, in the solar energy sector, researchers are working on improving EVA's long-term stability and UV resistance to enhance the durability of photovoltaic modules. In the medical field, the focus is on developing biocompatible EVA formulations for drug delivery systems and implantable devices.

As technology continues to advance, the objectives of EVA research extend to smart and responsive materials. This includes exploring ways to incorporate sensors or stimuli-responsive elements into EVA-based products, opening up possibilities for intelligent packaging, wearable technology, and adaptive structures.

Market Demand Analysis

The market demand for Ethylene Vinyl Acetate (EVA) in advanced applications has been experiencing significant growth in recent years. This versatile copolymer has found its way into various high-tech sectors due to its unique combination of properties, including flexibility, toughness, and excellent adhesion characteristics.

In the renewable energy sector, EVA has become a crucial component in the production of solar panels. The material is widely used as an encapsulant for photovoltaic cells, providing protection against environmental factors and enhancing the overall efficiency of solar modules. As the global push for clean energy continues, the demand for EVA in this application is expected to rise substantially.

The automotive industry has also recognized the potential of EVA for advanced applications. The material is increasingly being used in the manufacturing of lightweight components, contributing to improved fuel efficiency and reduced emissions. Additionally, EVA's shock-absorbing properties make it an ideal choice for safety-related applications in vehicles.

In the medical field, EVA has gained traction for its biocompatibility and flexibility. The material is being utilized in the production of advanced medical devices, drug delivery systems, and prosthetics. The growing emphasis on personalized medicine and minimally invasive treatments is likely to drive further demand for EVA in this sector.

The packaging industry represents another significant market for EVA, particularly in advanced food packaging applications. The material's barrier properties, combined with its flexibility and transparency, make it suitable for creating high-performance packaging solutions that extend shelf life and maintain product quality.

The sports and leisure sector has also embraced EVA for its cushioning and impact-resistant properties. The material is widely used in the production of high-performance athletic footwear, sports equipment, and protective gear, catering to the growing demand for advanced sports products.

As sustainability becomes an increasingly important factor in material selection, EVA's recyclability and potential for bio-based formulations are attracting attention. This aspect is likely to open up new market opportunities and drive demand in eco-conscious industries.

The global EVA market for advanced applications is projected to grow at a steady pace in the coming years, driven by technological advancements and expanding end-use industries. However, market growth may face challenges from fluctuating raw material prices and competition from alternative materials in certain applications.

In the renewable energy sector, EVA has become a crucial component in the production of solar panels. The material is widely used as an encapsulant for photovoltaic cells, providing protection against environmental factors and enhancing the overall efficiency of solar modules. As the global push for clean energy continues, the demand for EVA in this application is expected to rise substantially.

The automotive industry has also recognized the potential of EVA for advanced applications. The material is increasingly being used in the manufacturing of lightweight components, contributing to improved fuel efficiency and reduced emissions. Additionally, EVA's shock-absorbing properties make it an ideal choice for safety-related applications in vehicles.

In the medical field, EVA has gained traction for its biocompatibility and flexibility. The material is being utilized in the production of advanced medical devices, drug delivery systems, and prosthetics. The growing emphasis on personalized medicine and minimally invasive treatments is likely to drive further demand for EVA in this sector.

The packaging industry represents another significant market for EVA, particularly in advanced food packaging applications. The material's barrier properties, combined with its flexibility and transparency, make it suitable for creating high-performance packaging solutions that extend shelf life and maintain product quality.

The sports and leisure sector has also embraced EVA for its cushioning and impact-resistant properties. The material is widely used in the production of high-performance athletic footwear, sports equipment, and protective gear, catering to the growing demand for advanced sports products.

As sustainability becomes an increasingly important factor in material selection, EVA's recyclability and potential for bio-based formulations are attracting attention. This aspect is likely to open up new market opportunities and drive demand in eco-conscious industries.

The global EVA market for advanced applications is projected to grow at a steady pace in the coming years, driven by technological advancements and expanding end-use industries. However, market growth may face challenges from fluctuating raw material prices and competition from alternative materials in certain applications.

Technical Challenges

Ethylene Vinyl Acetate (EVA) has gained significant attention in advanced applications due to its unique properties. However, several technical challenges persist in its development and implementation. One of the primary obstacles is achieving consistent and uniform dispersion of vinyl acetate (VA) content throughout the polymer matrix. This non-uniformity can lead to variations in physical and chemical properties, affecting the overall performance of EVA-based products.

Another significant challenge lies in enhancing the thermal stability of EVA, particularly for high-temperature applications. As the VA content increases, the polymer's melting point decreases, limiting its use in environments that require heat resistance. Researchers are actively exploring methods to improve thermal stability without compromising the desirable properties of EVA, such as flexibility and impact resistance.

The adhesion properties of EVA, while generally good, present challenges in certain advanced applications. Improving the interfacial adhesion between EVA and other materials, especially in multi-layer structures or composites, remains an area of ongoing research. This is particularly crucial in fields such as photovoltaics, where EVA is used as an encapsulant for solar cells.

Weatherability and UV resistance pose another set of challenges for EVA in outdoor applications. The polymer tends to degrade under prolonged exposure to sunlight and environmental factors, leading to discoloration, loss of mechanical properties, and potential failure of the product. Developing effective UV stabilizers and antioxidants that can be seamlessly incorporated into EVA without affecting its other properties is a key focus area.

The processing of EVA for advanced applications also presents technical hurdles. Achieving optimal crosslinking density, especially in foam production, requires precise control over the curing process. Balancing the degree of crosslinking with the desired physical properties is a delicate process that demands sophisticated manufacturing techniques.

Furthermore, the environmental impact of EVA production and disposal is an emerging challenge. As sustainability becomes increasingly important, there is a growing need to develop eco-friendly production methods and improve the recyclability of EVA-based products. This includes finding alternatives to traditional crosslinking agents and developing efficient recycling processes for EVA waste.

Lastly, the customization of EVA for specific advanced applications often requires a fine balance between various properties. For instance, in the medical field, achieving biocompatibility while maintaining specific mechanical properties can be challenging. Similarly, in the electronics industry, balancing electrical insulation properties with thermal management capabilities presents ongoing technical difficulties.

Another significant challenge lies in enhancing the thermal stability of EVA, particularly for high-temperature applications. As the VA content increases, the polymer's melting point decreases, limiting its use in environments that require heat resistance. Researchers are actively exploring methods to improve thermal stability without compromising the desirable properties of EVA, such as flexibility and impact resistance.

The adhesion properties of EVA, while generally good, present challenges in certain advanced applications. Improving the interfacial adhesion between EVA and other materials, especially in multi-layer structures or composites, remains an area of ongoing research. This is particularly crucial in fields such as photovoltaics, where EVA is used as an encapsulant for solar cells.

Weatherability and UV resistance pose another set of challenges for EVA in outdoor applications. The polymer tends to degrade under prolonged exposure to sunlight and environmental factors, leading to discoloration, loss of mechanical properties, and potential failure of the product. Developing effective UV stabilizers and antioxidants that can be seamlessly incorporated into EVA without affecting its other properties is a key focus area.

The processing of EVA for advanced applications also presents technical hurdles. Achieving optimal crosslinking density, especially in foam production, requires precise control over the curing process. Balancing the degree of crosslinking with the desired physical properties is a delicate process that demands sophisticated manufacturing techniques.

Furthermore, the environmental impact of EVA production and disposal is an emerging challenge. As sustainability becomes increasingly important, there is a growing need to develop eco-friendly production methods and improve the recyclability of EVA-based products. This includes finding alternatives to traditional crosslinking agents and developing efficient recycling processes for EVA waste.

Lastly, the customization of EVA for specific advanced applications often requires a fine balance between various properties. For instance, in the medical field, achieving biocompatibility while maintaining specific mechanical properties can be challenging. Similarly, in the electronics industry, balancing electrical insulation properties with thermal management capabilities presents ongoing technical difficulties.

Current EVA Solutions

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to modify the properties of the resulting material, making it suitable for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used as a base polymer in hot melt adhesives, pressure-sensitive adhesives, and other bonding applications. The adhesive strength and performance can be tailored by adjusting the EVA composition and incorporating additives.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It can be processed into closed-cell foams for applications such as footwear, sports equipment, and building insulation. The foam density and properties can be controlled through formulation and processing techniques.

- EVA in solar panel encapsulation: EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and protection for solar cells. The material helps to enhance the durability and performance of solar panels by protecting the cells from moisture, UV radiation, and mechanical stress. Specialized EVA formulations are developed to optimize the encapsulation properties for solar applications.

- EVA in wire and cable insulation: EVA is employed in the production of wire and cable insulation due to its electrical insulation properties, flexibility, and resistance to environmental factors. It can be formulated with various additives to enhance flame retardancy, UV resistance, and other desired properties for specific cable applications. The material's processability allows for efficient extrusion and coating of wires and cables.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and performance can be tailored by adjusting the EVA composition and additives.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and ability to be crosslinked. It can be used in the manufacture of shoe soles, sports equipment padding, and building insulation. The foam structure and properties can be controlled through the EVA grade and foaming process.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a popular material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells. It helps to improve the durability and efficiency of photovoltaic modules by providing a protective barrier against moisture and environmental factors.Expand Specific Solutions05 Modifications and blends of EVA

EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes crosslinking, grafting, and the addition of fillers or compatibilizers. These modifications can improve mechanical properties, thermal stability, and compatibility with other materials in various industrial applications.Expand Specific Solutions

Key Industry Players

The market for Ethylene Vinyl Acetate (EVA) applications is in a mature growth stage, with a global market size expected to reach $9.7 billion by 2027. The technology's maturity is evident from the involvement of major petrochemical companies like China Petroleum & Chemical Corp., LyondellBasell, and DuPont de Nemours, Inc. These industry leaders are driving innovation in advanced EVA applications. Emerging players such as Celanese International Corp. and Borealis AG are also contributing to market expansion. The competitive landscape is characterized by ongoing research and development efforts, with academic institutions like Tianjin University and Queen's University of Belfast collaborating with industry to push the boundaries of EVA technology.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA production technologies, including a high-pressure tubular process and a solution polymerization process. Their tubular process achieves VA content up to 40% with improved product consistency[1]. They've also implemented a proprietary catalyst system that enhances copolymerization efficiency and allows for precise control of molecular weight distribution[2]. Sinopec's EVA products demonstrate excellent optical properties, with haze values as low as 0.5% for certain grades, making them suitable for high-transparency applications[3]. The company has also focused on developing specialty EVA grades for photovoltaic encapsulants, with improved crosslinking density and weatherability[4].

Strengths: Diverse production methods, high VA content capability, precise molecular weight control. Weaknesses: Potential higher production costs due to advanced technologies, may face competition in specialty markets.

Celanese International Corp.

Technical Solution: Celanese has developed a proprietary high-pressure autoclave process for EVA production, allowing for a wide range of VA content (3-40%) and melt index values[1]. Their technology incorporates advanced process control systems that enable rapid grade changes and consistent product quality[2]. Celanese has also introduced a novel crosslinking technology for their EVA products, enhancing thermal stability and mechanical properties for demanding applications such as wire and cable insulation[3]. The company's EVA grades exhibit improved adhesion characteristics, with peel strength values up to 30% higher than conventional grades in certain applications[4]. Additionally, Celanese has developed specialty EVA grades with enhanced oil resistance and low-temperature flexibility for automotive applications[5].

Strengths: Flexible production capabilities, advanced crosslinking technology, improved adhesion properties. Weaknesses: May have higher production costs, potential limitations in ultra-high VA content grades.

Core EVA Innovations

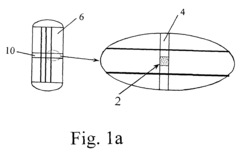

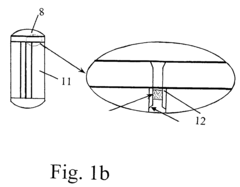

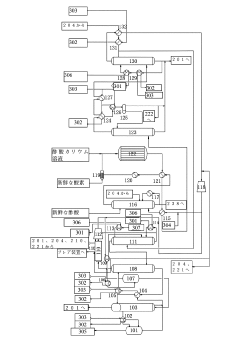

Process and apparatus for improved methods for making vinyl acetate monomer (VAM)

PatentInactiveUS7468455B2

Innovation

- A method involving a catalyst-containing reaction channel where ethylene, acetic acid, and dioxygen are passed through, with staged addition and optimized ratios, to achieve high conversion of ethylene to vinyl acetate or carbon dioxide, while maintaining low selectivity to carbon dioxide, utilizing microchannel reactors for improved heat and mass transfer and safety.

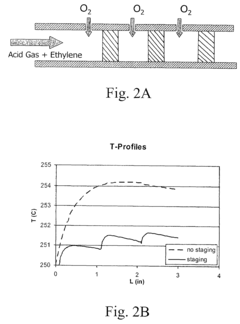

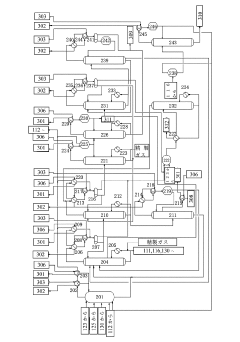

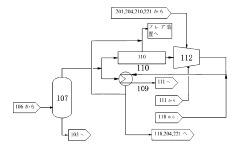

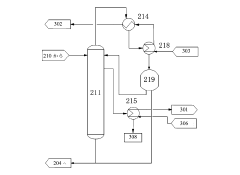

Production process of vinyl acetate due to ethylene method and apparatus

PatentActiveJP2024072774A

Innovation

- Incorporation of an ethylene recovery membrane assembly, series cooling with circulating water, and side cut stream in the purification VAC column, along with improved condensation and purification processes to enhance ethylene recovery and product purity.

Environmental Impact

The environmental impact of Ethylene Vinyl Acetate (EVA) is a critical consideration in its advanced applications. EVA production and usage have both positive and negative effects on the environment, necessitating a comprehensive analysis of its lifecycle.

EVA's production process involves the copolymerization of ethylene and vinyl acetate, which requires significant energy input and generates greenhouse gas emissions. However, compared to some alternative materials, EVA production can be less energy-intensive, potentially reducing its carbon footprint. The manufacturing process also produces waste products and emissions that need careful management to minimize environmental harm.

In terms of product use, EVA's durability and versatility contribute to its environmental profile. Its long lifespan in various applications, such as solar panel encapsulation, reduces the need for frequent replacements, thereby conserving resources and energy over time. Additionally, EVA's lightweight nature can lead to fuel savings when used in automotive applications, indirectly reducing carbon emissions.

Recycling and end-of-life management of EVA products present both challenges and opportunities. While EVA can be recycled, the process is not as straightforward as with some other polymers due to its cross-linked structure in certain applications. Improved recycling technologies and infrastructure are needed to enhance EVA's circularity and reduce its environmental impact at the end of its lifecycle.

EVA's role in renewable energy technologies, particularly in solar panels, contributes positively to environmental sustainability. By enhancing the efficiency and longevity of solar modules, EVA indirectly supports the transition to cleaner energy sources, potentially offsetting its production-related environmental costs.

Water pollution is another aspect to consider in EVA's environmental impact. The production process and potential leaching from EVA products can introduce pollutants into water systems. Proper waste management and treatment processes are essential to mitigate these risks.

Biodegradability is a concern with EVA, as it is not naturally biodegradable. This characteristic can lead to long-term environmental persistence if not properly managed at the end of its life cycle. Research into biodegradable alternatives or additives that enhance EVA's degradability without compromising its performance is an area of ongoing investigation.

In conclusion, the environmental impact of EVA in advanced applications is multifaceted. While it offers benefits in terms of durability, energy efficiency in certain applications, and support for renewable technologies, concerns remain regarding its production emissions, end-of-life management, and long-term environmental persistence. Balancing these factors is crucial for the sustainable use of EVA in advanced applications.

EVA's production process involves the copolymerization of ethylene and vinyl acetate, which requires significant energy input and generates greenhouse gas emissions. However, compared to some alternative materials, EVA production can be less energy-intensive, potentially reducing its carbon footprint. The manufacturing process also produces waste products and emissions that need careful management to minimize environmental harm.

In terms of product use, EVA's durability and versatility contribute to its environmental profile. Its long lifespan in various applications, such as solar panel encapsulation, reduces the need for frequent replacements, thereby conserving resources and energy over time. Additionally, EVA's lightweight nature can lead to fuel savings when used in automotive applications, indirectly reducing carbon emissions.

Recycling and end-of-life management of EVA products present both challenges and opportunities. While EVA can be recycled, the process is not as straightforward as with some other polymers due to its cross-linked structure in certain applications. Improved recycling technologies and infrastructure are needed to enhance EVA's circularity and reduce its environmental impact at the end of its lifecycle.

EVA's role in renewable energy technologies, particularly in solar panels, contributes positively to environmental sustainability. By enhancing the efficiency and longevity of solar modules, EVA indirectly supports the transition to cleaner energy sources, potentially offsetting its production-related environmental costs.

Water pollution is another aspect to consider in EVA's environmental impact. The production process and potential leaching from EVA products can introduce pollutants into water systems. Proper waste management and treatment processes are essential to mitigate these risks.

Biodegradability is a concern with EVA, as it is not naturally biodegradable. This characteristic can lead to long-term environmental persistence if not properly managed at the end of its life cycle. Research into biodegradable alternatives or additives that enhance EVA's degradability without compromising its performance is an area of ongoing investigation.

In conclusion, the environmental impact of EVA in advanced applications is multifaceted. While it offers benefits in terms of durability, energy efficiency in certain applications, and support for renewable technologies, concerns remain regarding its production emissions, end-of-life management, and long-term environmental persistence. Balancing these factors is crucial for the sustainable use of EVA in advanced applications.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of Ethylene Vinyl Acetate (EVA) for advanced applications. As the use of EVA expands into various industries, manufacturers and end-users must navigate a complex landscape of regulations to ensure product safety, environmental protection, and consumer well-being.

In the United States, the Food and Drug Administration (FDA) regulates the use of EVA in food contact applications. Manufacturers must comply with specific requirements outlined in the Code of Federal Regulations (CFR) Title 21, particularly in sections 175.105 and 177.1350. These regulations stipulate the permissible composition of EVA copolymers and their conditions of use in food packaging and processing equipment.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the production and import of EVA materials. Companies dealing with EVA must register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the EU's Restriction of Hazardous Substances (RoHS) directive impacts the use of EVA in electrical and electronic equipment, requiring manufacturers to ensure their products are free from restricted substances.

In the automotive industry, EVA materials used in vehicle components must comply with various safety standards set by organizations such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the United Nations Economic Commission for Europe (UNECE). These regulations often focus on flammability, emissions, and durability requirements for materials used in vehicle interiors and exteriors.

The construction sector faces stringent regulations regarding the use of EVA in building materials. In many countries, fire safety codes dictate the flame-retardant properties required for EVA-based products used in insulation, flooring, and roofing applications. Compliance with these standards often involves extensive testing and certification processes.

Environmental regulations also significantly impact EVA production and disposal. Many jurisdictions have implemented restrictions on volatile organic compound (VOC) emissions, affecting the manufacturing processes and formulations of EVA-based products. Furthermore, end-of-life considerations for EVA materials are becoming increasingly important, with regulations promoting recycling and proper disposal to minimize environmental impact.

As EVA finds applications in medical devices and pharmaceutical packaging, manufacturers must adhere to strict quality control standards and regulatory requirements set by agencies such as the FDA and the European Medicines Agency (EMA). These regulations often necessitate rigorous testing, documentation, and validation processes to ensure product safety and efficacy.

To navigate this complex regulatory landscape, companies working with EVA must invest in robust compliance management systems, stay informed about evolving regulations across different markets, and engage in proactive dialogue with regulatory bodies. Collaboration with industry associations and participation in standards development processes can also help companies anticipate and adapt to changing regulatory requirements, ensuring the continued growth and innovation in advanced EVA applications.

In the United States, the Food and Drug Administration (FDA) regulates the use of EVA in food contact applications. Manufacturers must comply with specific requirements outlined in the Code of Federal Regulations (CFR) Title 21, particularly in sections 175.105 and 177.1350. These regulations stipulate the permissible composition of EVA copolymers and their conditions of use in food packaging and processing equipment.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the production and import of EVA materials. Companies dealing with EVA must register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the EU's Restriction of Hazardous Substances (RoHS) directive impacts the use of EVA in electrical and electronic equipment, requiring manufacturers to ensure their products are free from restricted substances.

In the automotive industry, EVA materials used in vehicle components must comply with various safety standards set by organizations such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the United Nations Economic Commission for Europe (UNECE). These regulations often focus on flammability, emissions, and durability requirements for materials used in vehicle interiors and exteriors.

The construction sector faces stringent regulations regarding the use of EVA in building materials. In many countries, fire safety codes dictate the flame-retardant properties required for EVA-based products used in insulation, flooring, and roofing applications. Compliance with these standards often involves extensive testing and certification processes.

Environmental regulations also significantly impact EVA production and disposal. Many jurisdictions have implemented restrictions on volatile organic compound (VOC) emissions, affecting the manufacturing processes and formulations of EVA-based products. Furthermore, end-of-life considerations for EVA materials are becoming increasingly important, with regulations promoting recycling and proper disposal to minimize environmental impact.

As EVA finds applications in medical devices and pharmaceutical packaging, manufacturers must adhere to strict quality control standards and regulatory requirements set by agencies such as the FDA and the European Medicines Agency (EMA). These regulations often necessitate rigorous testing, documentation, and validation processes to ensure product safety and efficacy.

To navigate this complex regulatory landscape, companies working with EVA must invest in robust compliance management systems, stay informed about evolving regulations across different markets, and engage in proactive dialogue with regulatory bodies. Collaboration with industry associations and participation in standards development processes can also help companies anticipate and adapt to changing regulatory requirements, ensuring the continued growth and innovation in advanced EVA applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!