Barrier And Mechanical Tradeoffs In Nanocellulose-Based Packaging Films

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocellulose Packaging Evolution and Objectives

Nanocellulose-based packaging materials have evolved significantly over the past two decades, transitioning from laboratory curiosities to commercially viable sustainable packaging alternatives. The journey began in the early 2000s with fundamental research on nanocellulose extraction methods, primarily focused on mechanical and chemical processes to isolate cellulose nanofibrils (CNF) and cellulose nanocrystals (CNC) from various biomass sources. These early efforts were characterized by low yields and energy-intensive production methods that limited practical applications.

By 2010, breakthrough developments in production efficiency, including TEMPO-mediated oxidation and enzymatic pretreatments, dramatically reduced energy requirements and improved nanocellulose quality. This period marked the shift from purely academic interest to industrial exploration, with the first pilot-scale production facilities established in North America and Scandinavia. The packaging industry began recognizing nanocellulose's potential as a renewable barrier material with exceptional oxygen and water vapor resistance properties.

The 2015-2020 period witnessed accelerated commercialization efforts, with several companies introducing nanocellulose-enhanced packaging products. This phase highlighted the critical challenge that continues to define the field today: the fundamental tradeoff between barrier properties and mechanical performance. As nanocellulose content increases to improve oxygen barrier properties, film flexibility and elongation properties often deteriorate, creating a technical paradox that requires innovative solutions.

Current research objectives center on optimizing this barrier-mechanical performance balance through several approaches. First, developing hybrid systems that combine nanocellulose with complementary materials like biodegradable polymers or other nanomaterials to achieve synergistic effects. Second, exploring surface modifications of nanocellulose to enhance compatibility with hydrophobic matrices while maintaining barrier integrity. Third, investigating novel processing techniques that can preserve the nanoscale structure while improving film formation and flexibility.

The ultimate goal is to develop nanocellulose-based packaging films that can match or exceed the performance of conventional petroleum-based packaging materials while offering superior sustainability credentials. This includes achieving oxygen transmission rates below 1 cc/m²·day·atm, water vapor transmission rates under 10 g/m²·day, tensile strength exceeding 100 MPa, and elongation at break above 10% - all while maintaining biodegradability and food contact safety compliance.

The evolution trajectory suggests that within the next five years, nanocellulose-based packaging could reach performance parity with conventional materials in specific applications, particularly for dry and medium-moisture food products, cosmetics, and pharmaceutical packaging.

By 2010, breakthrough developments in production efficiency, including TEMPO-mediated oxidation and enzymatic pretreatments, dramatically reduced energy requirements and improved nanocellulose quality. This period marked the shift from purely academic interest to industrial exploration, with the first pilot-scale production facilities established in North America and Scandinavia. The packaging industry began recognizing nanocellulose's potential as a renewable barrier material with exceptional oxygen and water vapor resistance properties.

The 2015-2020 period witnessed accelerated commercialization efforts, with several companies introducing nanocellulose-enhanced packaging products. This phase highlighted the critical challenge that continues to define the field today: the fundamental tradeoff between barrier properties and mechanical performance. As nanocellulose content increases to improve oxygen barrier properties, film flexibility and elongation properties often deteriorate, creating a technical paradox that requires innovative solutions.

Current research objectives center on optimizing this barrier-mechanical performance balance through several approaches. First, developing hybrid systems that combine nanocellulose with complementary materials like biodegradable polymers or other nanomaterials to achieve synergistic effects. Second, exploring surface modifications of nanocellulose to enhance compatibility with hydrophobic matrices while maintaining barrier integrity. Third, investigating novel processing techniques that can preserve the nanoscale structure while improving film formation and flexibility.

The ultimate goal is to develop nanocellulose-based packaging films that can match or exceed the performance of conventional petroleum-based packaging materials while offering superior sustainability credentials. This includes achieving oxygen transmission rates below 1 cc/m²·day·atm, water vapor transmission rates under 10 g/m²·day, tensile strength exceeding 100 MPa, and elongation at break above 10% - all while maintaining biodegradability and food contact safety compliance.

The evolution trajectory suggests that within the next five years, nanocellulose-based packaging could reach performance parity with conventional materials in specific applications, particularly for dry and medium-moisture food products, cosmetics, and pharmaceutical packaging.

Market Analysis for Sustainable Packaging Solutions

The sustainable packaging market is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures. The global sustainable packaging market was valued at $274.15 billion in 2020 and is projected to reach $470.3 billion by 2027, growing at a CAGR of 7.7% during the forecast period. Nanocellulose-based packaging films represent a significant segment within this expanding market, particularly as alternatives to conventional plastic packaging materials.

Consumer demand for environmentally friendly packaging solutions has risen dramatically, with 73% of consumers expressing willingness to pay more for sustainable packaging. Major retail and consumer goods companies have responded by establishing ambitious sustainability targets, creating substantial market pull for innovations like nanocellulose-based films. The food and beverage sector constitutes the largest application segment, accounting for approximately 60% of sustainable packaging demand, followed by personal care and healthcare sectors.

Regional analysis reveals that Europe leads the sustainable packaging market with a 34% share, followed by North America at 28% and Asia-Pacific at 26%. However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India. This regional distribution significantly influences the development trajectory of nanocellulose-based packaging technologies.

Market penetration of nanocellulose-based packaging remains relatively low at 3-5% of the total sustainable packaging market, primarily due to cost factors and performance limitations. However, this segment is growing at 12.3% annually, outpacing the broader sustainable packaging market. The premium pricing of nanocellulose-based solutions (typically 30-40% higher than conventional alternatives) remains a significant market barrier, particularly in price-sensitive segments.

Competitive analysis indicates that the market is fragmented, with both established packaging giants and innovative startups competing for market share. Key players include Stora Enso, UPM-Kymmene, Sappi, and emerging specialized companies like Celluforce and American Process Inc. Strategic partnerships between material developers and packaging manufacturers have become increasingly common, accelerating commercialization timelines.

Market forecasts suggest that as production scales and technology matures, the cost-performance ratio of nanocellulose-based packaging will improve significantly. Industry experts predict that by 2025, these materials could capture 8-10% of the sustainable packaging market, particularly in high-value applications where barrier properties are critical. The market trajectory will be heavily influenced by regulatory developments, with several countries implementing plastic reduction mandates that create favorable conditions for cellulose-based alternatives.

Consumer demand for environmentally friendly packaging solutions has risen dramatically, with 73% of consumers expressing willingness to pay more for sustainable packaging. Major retail and consumer goods companies have responded by establishing ambitious sustainability targets, creating substantial market pull for innovations like nanocellulose-based films. The food and beverage sector constitutes the largest application segment, accounting for approximately 60% of sustainable packaging demand, followed by personal care and healthcare sectors.

Regional analysis reveals that Europe leads the sustainable packaging market with a 34% share, followed by North America at 28% and Asia-Pacific at 26%. However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India. This regional distribution significantly influences the development trajectory of nanocellulose-based packaging technologies.

Market penetration of nanocellulose-based packaging remains relatively low at 3-5% of the total sustainable packaging market, primarily due to cost factors and performance limitations. However, this segment is growing at 12.3% annually, outpacing the broader sustainable packaging market. The premium pricing of nanocellulose-based solutions (typically 30-40% higher than conventional alternatives) remains a significant market barrier, particularly in price-sensitive segments.

Competitive analysis indicates that the market is fragmented, with both established packaging giants and innovative startups competing for market share. Key players include Stora Enso, UPM-Kymmene, Sappi, and emerging specialized companies like Celluforce and American Process Inc. Strategic partnerships between material developers and packaging manufacturers have become increasingly common, accelerating commercialization timelines.

Market forecasts suggest that as production scales and technology matures, the cost-performance ratio of nanocellulose-based packaging will improve significantly. Industry experts predict that by 2025, these materials could capture 8-10% of the sustainable packaging market, particularly in high-value applications where barrier properties are critical. The market trajectory will be heavily influenced by regulatory developments, with several countries implementing plastic reduction mandates that create favorable conditions for cellulose-based alternatives.

Technical Barriers in Nanocellulose Film Development

The development of nanocellulose-based packaging films faces several significant technical barriers that currently limit their widespread commercial adoption. These challenges primarily revolve around the inherent tradeoff between barrier properties and mechanical performance, which represents a fundamental obstacle in the field.

One of the most persistent technical barriers is the hydrophilic nature of nanocellulose. While nanocellulose exhibits excellent oxygen barrier properties in dry conditions, its performance deteriorates dramatically in humid environments due to moisture absorption. This hygroscopicity leads to swelling, reduced mechanical strength, and compromised barrier functionality, making it difficult to maintain consistent performance across varying environmental conditions.

Manufacturing scalability presents another major challenge. Current production methods for nanocellulose films often involve energy-intensive processes such as homogenization, microfluidization, or acid hydrolysis. These processes are difficult to scale up efficiently while maintaining the nanoscale dimensions and properties that give nanocellulose its desirable characteristics. The high energy consumption and associated costs create significant barriers to industrial-scale production.

Surface compatibility issues also hinder development. Nanocellulose's highly polar surface chemistry makes it inherently incompatible with many conventional polymer processing techniques and additives. This incompatibility limits the ability to create composite materials or multi-layer structures that could potentially overcome the barrier-mechanical property tradeoff.

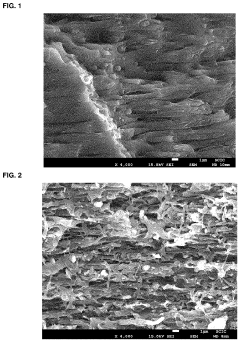

The drying process represents a critical technical barrier. As nanocellulose suspensions dry, strong hydrogen bonding between fibrils creates a dense network structure. While this enhances oxygen barrier properties, it often results in brittle films with limited flexibility and elongation capacity. This brittleness severely restricts packaging applications that require folding, stretching, or impact resistance.

Uniformity and defect control during film formation remain challenging. Inconsistencies in nanocellulose dispersion, aggregation during drying, and variations in fibril dimensions can create weak points in the film structure. These defects compromise both barrier integrity and mechanical reliability, making quality control difficult to maintain at scale.

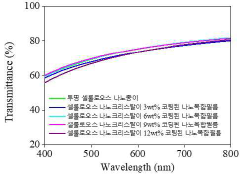

Additionally, there are significant barriers related to surface functionalization technologies. While chemical modification of nanocellulose can improve hydrophobicity and compatibility with other materials, these modifications often diminish the intrinsic properties that make nanocellulose attractive in the first place, such as its biodegradability, transparency, or mechanical strength.

The lack of standardized characterization methods for nanocellulose-based films further complicates development efforts. Without consistent testing protocols, it becomes difficult to compare results across different research groups or to establish reliable performance benchmarks for industrial applications.

One of the most persistent technical barriers is the hydrophilic nature of nanocellulose. While nanocellulose exhibits excellent oxygen barrier properties in dry conditions, its performance deteriorates dramatically in humid environments due to moisture absorption. This hygroscopicity leads to swelling, reduced mechanical strength, and compromised barrier functionality, making it difficult to maintain consistent performance across varying environmental conditions.

Manufacturing scalability presents another major challenge. Current production methods for nanocellulose films often involve energy-intensive processes such as homogenization, microfluidization, or acid hydrolysis. These processes are difficult to scale up efficiently while maintaining the nanoscale dimensions and properties that give nanocellulose its desirable characteristics. The high energy consumption and associated costs create significant barriers to industrial-scale production.

Surface compatibility issues also hinder development. Nanocellulose's highly polar surface chemistry makes it inherently incompatible with many conventional polymer processing techniques and additives. This incompatibility limits the ability to create composite materials or multi-layer structures that could potentially overcome the barrier-mechanical property tradeoff.

The drying process represents a critical technical barrier. As nanocellulose suspensions dry, strong hydrogen bonding between fibrils creates a dense network structure. While this enhances oxygen barrier properties, it often results in brittle films with limited flexibility and elongation capacity. This brittleness severely restricts packaging applications that require folding, stretching, or impact resistance.

Uniformity and defect control during film formation remain challenging. Inconsistencies in nanocellulose dispersion, aggregation during drying, and variations in fibril dimensions can create weak points in the film structure. These defects compromise both barrier integrity and mechanical reliability, making quality control difficult to maintain at scale.

Additionally, there are significant barriers related to surface functionalization technologies. While chemical modification of nanocellulose can improve hydrophobicity and compatibility with other materials, these modifications often diminish the intrinsic properties that make nanocellulose attractive in the first place, such as its biodegradability, transparency, or mechanical strength.

The lack of standardized characterization methods for nanocellulose-based films further complicates development efforts. Without consistent testing protocols, it becomes difficult to compare results across different research groups or to establish reliable performance benchmarks for industrial applications.

Current Approaches to Barrier-Strength Balance

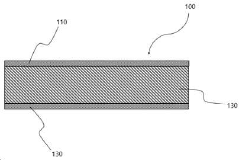

01 Nanocellulose film composition and structure

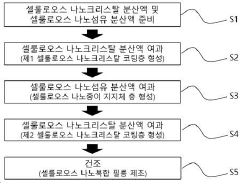

Nanocellulose-based packaging films can be formulated with various compositions and structures to enhance barrier and mechanical properties. These films typically incorporate cellulose nanofibers or nanocrystals as the primary component, which can be arranged in specific orientations or layered structures. The high aspect ratio and crystallinity of nanocellulose contribute to excellent mechanical strength and barrier properties against oxygen, water vapor, and other gases. Different processing methods can be used to control the microstructure and density of the films, further improving their performance.- Nanocellulose film composition and structure: Nanocellulose-based packaging films can be formulated with various compositions and structures to enhance barrier and mechanical properties. These films typically incorporate cellulose nanofibers or nanocrystals as the primary component, which can be arranged in specific orientations or layered structures. The high aspect ratio and crystallinity of nanocellulose contribute to excellent mechanical strength and barrier properties against gases and moisture. Different processing methods can be used to control the nanocellulose structure, affecting the final film properties.

- Composite films with polymer matrices: Combining nanocellulose with various polymer matrices creates composite films with enhanced barrier and mechanical properties. Polymers such as polyvinyl alcohol, polylactic acid, and polyethylene can serve as matrices in which nanocellulose is dispersed. These composites often exhibit synergistic effects, where the nanocellulose reinforces the polymer matrix while the polymer provides flexibility and processability. The interface between nanocellulose and the polymer matrix plays a crucial role in determining the overall performance of the composite films.

- Surface modifications and treatments: Surface modifications and treatments of nanocellulose can significantly improve the barrier and mechanical properties of packaging films. Chemical modifications such as acetylation, silylation, or grafting of hydrophobic groups can reduce the hydrophilicity of nanocellulose, enhancing moisture barrier properties. Physical treatments including plasma treatment or coating with functional materials can also improve gas barrier properties. These modifications help overcome the inherent hydrophilic nature of nanocellulose, making the resulting films more suitable for packaging applications.

- Multilayer and functional films: Multilayer structures incorporating nanocellulose layers can provide enhanced barrier and mechanical properties for packaging applications. These structures may combine nanocellulose with other materials such as biopolymers, synthetic polymers, or inorganic components in distinct layers. Each layer contributes specific properties to the overall film performance. Additionally, functional additives such as antimicrobial agents, antioxidants, or oxygen scavengers can be incorporated to create active packaging materials with extended shelf life and improved product protection.

- Sustainable and biodegradable packaging solutions: Nanocellulose-based packaging films offer sustainable and biodegradable alternatives to conventional plastic packaging. These films utilize renewable resources and can be designed to be fully biodegradable or compostable at end-of-life. The environmental benefits include reduced carbon footprint, decreased dependence on fossil fuels, and minimized plastic pollution. Research focuses on optimizing the balance between sustainability and performance, ensuring that these eco-friendly packaging solutions maintain the necessary barrier and mechanical properties required for food preservation and product protection.

02 Nanocellulose-polymer composite films

Combining nanocellulose with various polymers creates composite films with enhanced barrier and mechanical properties. These composites leverage the strength and barrier properties of nanocellulose while addressing some of its limitations through polymer addition. Common polymers used include polyvinyl alcohol, polylactic acid, polyethylene, and starch-based materials. The polymer matrix helps improve flexibility, processability, and moisture resistance while the nanocellulose reinforcement provides strength and oxygen barrier properties. The interface between nanocellulose and polymer phases is critical for achieving optimal performance in these composite systems.Expand Specific Solutions03 Surface modification and functionalization

Surface modification and functionalization of nanocellulose can significantly improve the barrier and mechanical properties of packaging films. Various chemical treatments, including silylation, acetylation, and grafting of hydrophobic groups, can reduce the hydrophilicity of nanocellulose, enhancing water vapor barrier properties. Functionalization with antimicrobial agents can provide additional protection against microbial growth. Cross-linking treatments improve mechanical stability and reduce sensitivity to moisture. These modifications can be tailored to specific packaging requirements while maintaining the biodegradability of the films.Expand Specific Solutions04 Multilayer and coating applications

Multilayer structures and coating applications of nanocellulose offer enhanced barrier and mechanical properties for packaging materials. Nanocellulose can be applied as a thin coating on conventional packaging materials or incorporated into multilayer structures to provide specific functionality. These approaches allow for combining the excellent oxygen barrier properties of nanocellulose with the water resistance of other materials. The thickness and composition of each layer can be optimized to achieve desired performance characteristics. This strategy is particularly effective for food packaging applications requiring both oxygen and moisture barriers.Expand Specific Solutions05 Additives and reinforcement materials

Various additives and reinforcement materials can be incorporated into nanocellulose-based packaging films to enhance their barrier and mechanical properties. These include nanoclays, metal oxides, graphene, carbon nanotubes, and natural extracts. Such additives can improve water resistance, mechanical strength, thermal stability, and provide additional functionalities like UV protection or antimicrobial activity. The dispersion and compatibility of these additives within the nanocellulose matrix are crucial for achieving optimal performance. Plasticizers may also be added to improve flexibility while maintaining barrier properties.Expand Specific Solutions

Leading Companies in Nanocellulose Packaging Industry

The nanocellulose-based packaging film market is currently in a growth phase, characterized by increasing adoption as sustainable alternatives to conventional plastic packaging. The global market size is projected to expand significantly, driven by growing environmental concerns and stringent regulations against single-use plastics. Technical maturity varies across applications, with companies demonstrating different levels of innovation. Leading players like Stora Enso and VTT in Finland have established commercial-scale production capabilities, while academic institutions such as South China University of Technology and University of Maine are advancing fundamental research. Companies including PulPac, Melodea, and FiberLean Technologies are developing proprietary technologies to overcome key challenges in barrier properties and mechanical strength. The competitive landscape reveals a balance between established paper industry giants (Tetra Laval, Kemira) and specialized startups, with increasing collaboration between industry and research institutions to address the critical barrier-mechanical performance tradeoff.

Stora Enso Oyj

Technical Solution: Stora Enso has developed advanced nanocellulose-based packaging films utilizing microfibrillated cellulose (MFC) technology. Their approach involves creating multi-layer structures where nanocellulose forms a dense network providing exceptional oxygen and moisture barrier properties. The company employs proprietary surface modification techniques to enhance the hydrophobicity of nanocellulose films while maintaining their biodegradability. Their MFC production process uses enzymatic pretreatment followed by mechanical fibrillation, resulting in highly uniform nanofibrils with controlled dimensions. Stora Enso has successfully integrated these films into commercial packaging solutions, particularly for food applications, where their MFC-enhanced films demonstrate oxygen transmission rates below 10 cc/m²/day and water vapor transmission rates competitive with conventional plastics. The company has also developed scalable coating technologies that allow nanocellulose to be applied as thin barrier layers on conventional packaging substrates.

Strengths: Superior oxygen barrier properties, renewable raw material source, and established industrial-scale production capabilities. Weaknesses: Higher production costs compared to conventional plastics, moisture sensitivity requiring additional treatments, and challenges in maintaining barrier properties during converting processes.

Teknologian Tutkimuskeskus VTT Oy

Technical Solution: VTT has pioneered innovative approaches to nanocellulose-based packaging films through their HefCel (High-Consistency Enzymatic Fibrillation) technology. This process enables the production of nanocellulose at high consistency (15-25%), significantly reducing water usage and energy consumption compared to conventional methods. VTT's technology addresses the mechanical-barrier tradeoff by incorporating specific enzymes that selectively modify cellulose fibrils, preserving their strength while enhancing film formation capabilities. Their research has demonstrated that controlled oxidation of nanocellulose surfaces can improve interfibril bonding, resulting in films with tensile strengths exceeding 200 MPa while maintaining oxygen permeability below 0.1 cm³·μm/m²·day·kPa. VTT has also developed hybrid materials combining nanocellulose with biodegradable polymers like PLA and PHB, creating composite films that maintain excellent barrier properties while improving moisture resistance and mechanical flexibility. Their roll-to-roll manufacturing process enables continuous production of nanocellulose films with consistent quality at semi-industrial scales.

Strengths: Energy-efficient production process, excellent oxygen barrier properties, and compatibility with existing converting equipment. Weaknesses: Challenges in scaling to full industrial production, sensitivity to humidity affecting barrier performance, and higher cost compared to conventional packaging materials.

Key Patents in Nanocellulose Film Technology

High strength Transparent Moisture Blocking Cellulose Nanocomposite Film

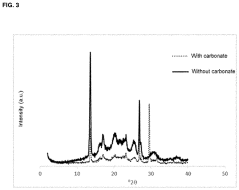

PatentActiveKR1020210119697A

Innovation

- A high-strength transparent cellulose nanocomposite film is developed, comprising a cellulose support layer and cellulose coating layers with TEMPO-oxidized cellulose nanofibers and acid-hydrolyzed, needle-shaped cellulose nanocrystals, manufactured through vacuum filtration and coating processes.

Biodegradable container, method for obtaining same and use thereof for contact, transport and/or storage of perishable products

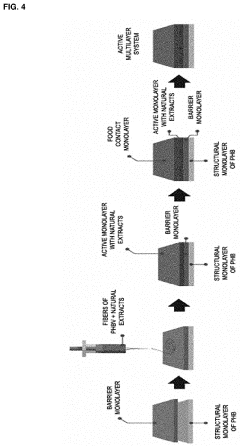

PatentInactiveUS20220195248A1

Innovation

- A biodegradable packaging system comprising a thermoformable structural layer made from polyhydroxyalkanoates (PHAs) with a second biodegradable elastomeric phase and mineral fillers, combined with self-adhesive gas and vapor barrier layers and active layers, all produced using electrodynamic or aerodynamic processes, to enhance mechanical strength, barrier properties, and tear resistance.

Environmental Impact and Biodegradability Assessment

Nanocellulose-based packaging films represent a significant advancement in sustainable packaging solutions, offering an environmentally responsible alternative to conventional petroleum-based plastics. The environmental impact assessment of these materials reveals several notable advantages. Primarily, nanocellulose is derived from renewable biomass sources, predominantly wood pulp and agricultural residues, which substantially reduces dependency on fossil fuels and minimizes carbon footprint compared to traditional plastic packaging materials.

The production process of nanocellulose-based films generally requires less energy than conventional plastic manufacturing, though this advantage can be partially offset by the energy-intensive mechanical or chemical treatments necessary to extract nanocellulose from raw materials. Recent advancements in production technologies have progressively reduced these energy requirements, enhancing the overall environmental profile of these materials.

Biodegradability represents one of the most compelling environmental benefits of nanocellulose-based packaging films. Unlike conventional plastics that persist in the environment for hundreds of years, nanocellulose materials typically decompose within months under appropriate conditions. Laboratory and field studies demonstrate that these films can be completely metabolized by soil microorganisms, leaving no toxic residues or microplastics. This characteristic significantly mitigates concerns regarding waste accumulation in landfills and marine environments.

Water consumption during nanocellulose production remains a challenge, as the process typically requires substantial amounts of water for pulping and purification stages. However, closed-loop water recycling systems implemented in modern production facilities have considerably reduced freshwater requirements, addressing this environmental concern.

The end-of-life scenarios for nanocellulose-based packaging present multiple environmentally favorable options. These materials can be composted in industrial facilities, recycled with paper streams, or even potentially used for energy recovery through incineration with significantly lower toxic emissions compared to petroleum-based plastics.

Life cycle assessment (LCA) studies comparing nanocellulose-based packaging films with conventional plastics consistently demonstrate reduced environmental impacts across multiple categories, including global warming potential, eutrophication, and ecotoxicity. However, these assessments also highlight the importance of optimizing barrier properties without compromising biodegradability, as some treatments that enhance barrier performance may simultaneously reduce biodegradation rates.

The trade-off between mechanical strength, barrier properties, and biodegradability represents a critical challenge in nanocellulose film development. Modifications that enhance water resistance and oxygen barrier properties sometimes incorporate less biodegradable components, potentially compromising the material's end-of-life environmental benefits. Research continues to focus on developing solutions that maintain optimal biodegradability while achieving the performance characteristics necessary for commercial packaging applications.

The production process of nanocellulose-based films generally requires less energy than conventional plastic manufacturing, though this advantage can be partially offset by the energy-intensive mechanical or chemical treatments necessary to extract nanocellulose from raw materials. Recent advancements in production technologies have progressively reduced these energy requirements, enhancing the overall environmental profile of these materials.

Biodegradability represents one of the most compelling environmental benefits of nanocellulose-based packaging films. Unlike conventional plastics that persist in the environment for hundreds of years, nanocellulose materials typically decompose within months under appropriate conditions. Laboratory and field studies demonstrate that these films can be completely metabolized by soil microorganisms, leaving no toxic residues or microplastics. This characteristic significantly mitigates concerns regarding waste accumulation in landfills and marine environments.

Water consumption during nanocellulose production remains a challenge, as the process typically requires substantial amounts of water for pulping and purification stages. However, closed-loop water recycling systems implemented in modern production facilities have considerably reduced freshwater requirements, addressing this environmental concern.

The end-of-life scenarios for nanocellulose-based packaging present multiple environmentally favorable options. These materials can be composted in industrial facilities, recycled with paper streams, or even potentially used for energy recovery through incineration with significantly lower toxic emissions compared to petroleum-based plastics.

Life cycle assessment (LCA) studies comparing nanocellulose-based packaging films with conventional plastics consistently demonstrate reduced environmental impacts across multiple categories, including global warming potential, eutrophication, and ecotoxicity. However, these assessments also highlight the importance of optimizing barrier properties without compromising biodegradability, as some treatments that enhance barrier performance may simultaneously reduce biodegradation rates.

The trade-off between mechanical strength, barrier properties, and biodegradability represents a critical challenge in nanocellulose film development. Modifications that enhance water resistance and oxygen barrier properties sometimes incorporate less biodegradable components, potentially compromising the material's end-of-life environmental benefits. Research continues to focus on developing solutions that maintain optimal biodegradability while achieving the performance characteristics necessary for commercial packaging applications.

Scalability and Manufacturing Challenges

The transition from laboratory-scale production to industrial manufacturing of nanocellulose-based packaging films presents significant challenges that must be addressed for commercial viability. Current production methods for nanocellulose typically involve batch processes that are difficult to scale efficiently. The energy-intensive nature of nanocellulose production, particularly in mechanical fibrillation processes, creates substantial cost barriers when scaling to industrial volumes. These energy requirements can reach 20,000-30,000 kWh/ton, making large-scale production economically prohibitive without process optimization.

Water removal represents another critical manufacturing challenge. Nanocellulose suspensions typically contain 95-99% water, necessitating extensive dewatering processes that are both energy-intensive and time-consuming. Conventional drying methods often lead to irreversible aggregation of nanofibrils (hornification), compromising the material's barrier properties and mechanical performance. This phenomenon creates a fundamental manufacturing paradox where the very properties that make nanocellulose attractive become difficult to maintain during industrial processing.

Quality control and consistency present additional manufacturing hurdles. The properties of nanocellulose can vary significantly based on source materials and processing conditions. Establishing standardized production protocols that deliver consistent film properties across large production volumes remains challenging. This variability directly impacts the barrier and mechanical performance tradeoffs that are central to packaging applications.

Equipment adaptation represents a substantial capital investment challenge. Existing paper and plastic film manufacturing infrastructure requires significant modification to accommodate nanocellulose processing. The rheological behavior of nanocellulose suspensions differs markedly from conventional materials, necessitating specialized handling equipment and modified coating technologies. The high viscosity of nanocellulose suspensions at relatively low solid content (2-3%) creates processing difficulties in conventional film-forming equipment.

Surface modification processes, essential for enhancing hydrophobicity and barrier properties, add another layer of manufacturing complexity. Achieving uniform chemical modification across large production volumes while maintaining eco-friendly credentials presents technical challenges that impact scalability. The integration of these modification steps into continuous production lines requires careful engineering to avoid compromising production efficiency.

Recent innovations addressing these challenges include continuous production systems that reduce energy consumption by up to 40% compared to batch processes, and novel drying technologies that preserve nanocellulose network structures. However, the technology readiness level for fully integrated manufacturing systems remains at TRL 5-6, indicating significant development is still required before widespread industrial implementation becomes feasible.

Water removal represents another critical manufacturing challenge. Nanocellulose suspensions typically contain 95-99% water, necessitating extensive dewatering processes that are both energy-intensive and time-consuming. Conventional drying methods often lead to irreversible aggregation of nanofibrils (hornification), compromising the material's barrier properties and mechanical performance. This phenomenon creates a fundamental manufacturing paradox where the very properties that make nanocellulose attractive become difficult to maintain during industrial processing.

Quality control and consistency present additional manufacturing hurdles. The properties of nanocellulose can vary significantly based on source materials and processing conditions. Establishing standardized production protocols that deliver consistent film properties across large production volumes remains challenging. This variability directly impacts the barrier and mechanical performance tradeoffs that are central to packaging applications.

Equipment adaptation represents a substantial capital investment challenge. Existing paper and plastic film manufacturing infrastructure requires significant modification to accommodate nanocellulose processing. The rheological behavior of nanocellulose suspensions differs markedly from conventional materials, necessitating specialized handling equipment and modified coating technologies. The high viscosity of nanocellulose suspensions at relatively low solid content (2-3%) creates processing difficulties in conventional film-forming equipment.

Surface modification processes, essential for enhancing hydrophobicity and barrier properties, add another layer of manufacturing complexity. Achieving uniform chemical modification across large production volumes while maintaining eco-friendly credentials presents technical challenges that impact scalability. The integration of these modification steps into continuous production lines requires careful engineering to avoid compromising production efficiency.

Recent innovations addressing these challenges include continuous production systems that reduce energy consumption by up to 40% compared to batch processes, and novel drying technologies that preserve nanocellulose network structures. However, the technology readiness level for fully integrated manufacturing systems remains at TRL 5-6, indicating significant development is still required before widespread industrial implementation becomes feasible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!