Butane's Role in Enhancing the Technological Development of Plasticizers

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Plasticizers

Butane plays a crucial role in enhancing the technological development of plasticizers, serving as both a raw material and a processing aid. This versatile hydrocarbon has significantly contributed to the advancement of plasticizer production and performance, leading to improved product quality and expanded applications across various industries.

As a key component in the synthesis of certain plasticizers, butane serves as a precursor for the production of various chemical intermediates. These intermediates are essential in the manufacturing process of plasticizers, particularly for those used in flexible PVC and other polymer applications. The use of butane-derived compounds allows for the creation of plasticizers with tailored properties, such as enhanced flexibility, durability, and thermal stability.

In addition to its role as a raw material, butane is utilized as a processing aid in plasticizer production. Its low boiling point and high vapor pressure make it an excellent solvent and extraction medium. This property is leveraged in the purification and separation processes of plasticizers, enabling manufacturers to achieve higher levels of product purity and consistency. The improved quality control facilitated by butane-based processes has led to the development of plasticizers with superior performance characteristics.

The incorporation of butane in plasticizer technology has also contributed to the development of more environmentally friendly products. As regulatory pressures increase to reduce the use of phthalate-based plasticizers, butane-derived alternatives have emerged as viable substitutes. These new formulations often exhibit lower toxicity profiles and improved biodegradability, aligning with the growing demand for sustainable materials in various applications.

Furthermore, butane's role extends to the enhancement of plasticizer efficiency. By optimizing the molecular structure of plasticizers through butane-based modifications, researchers have developed products that require lower dosages to achieve the desired plasticizing effect. This advancement not only improves the cost-effectiveness of plasticizers but also reduces the overall environmental impact of plastic products by minimizing the amount of additives required.

The technological advancements facilitated by butane have expanded the application range of plasticizers. Industries such as automotive, construction, and medical devices have benefited from plasticizers with improved performance characteristics, including better low-temperature flexibility, enhanced resistance to extraction, and increased longevity. These improvements have enabled the development of more durable and versatile plastic products, meeting the evolving demands of various sectors.

As a key component in the synthesis of certain plasticizers, butane serves as a precursor for the production of various chemical intermediates. These intermediates are essential in the manufacturing process of plasticizers, particularly for those used in flexible PVC and other polymer applications. The use of butane-derived compounds allows for the creation of plasticizers with tailored properties, such as enhanced flexibility, durability, and thermal stability.

In addition to its role as a raw material, butane is utilized as a processing aid in plasticizer production. Its low boiling point and high vapor pressure make it an excellent solvent and extraction medium. This property is leveraged in the purification and separation processes of plasticizers, enabling manufacturers to achieve higher levels of product purity and consistency. The improved quality control facilitated by butane-based processes has led to the development of plasticizers with superior performance characteristics.

The incorporation of butane in plasticizer technology has also contributed to the development of more environmentally friendly products. As regulatory pressures increase to reduce the use of phthalate-based plasticizers, butane-derived alternatives have emerged as viable substitutes. These new formulations often exhibit lower toxicity profiles and improved biodegradability, aligning with the growing demand for sustainable materials in various applications.

Furthermore, butane's role extends to the enhancement of plasticizer efficiency. By optimizing the molecular structure of plasticizers through butane-based modifications, researchers have developed products that require lower dosages to achieve the desired plasticizing effect. This advancement not only improves the cost-effectiveness of plasticizers but also reduces the overall environmental impact of plastic products by minimizing the amount of additives required.

The technological advancements facilitated by butane have expanded the application range of plasticizers. Industries such as automotive, construction, and medical devices have benefited from plasticizers with improved performance characteristics, including better low-temperature flexibility, enhanced resistance to extraction, and increased longevity. These improvements have enabled the development of more durable and versatile plastic products, meeting the evolving demands of various sectors.

Market Demand Analysis

The global plasticizer market has been experiencing steady growth, driven by increasing demand across various industries such as construction, automotive, and consumer goods. Butane, as a key component in the production of certain plasticizers, plays a significant role in shaping market dynamics and technological advancements in this sector.

The construction industry remains the largest consumer of plasticizers, particularly in the production of PVC products for flooring, roofing, and wall coverings. The growing urbanization and infrastructure development in emerging economies have fueled the demand for these materials, consequently boosting the market for butane-based plasticizers.

In the automotive sector, the shift towards lightweight materials to improve fuel efficiency has led to an increased use of plastics and, by extension, plasticizers. Butane-enhanced plasticizers offer improved flexibility and durability to automotive components, making them an attractive option for manufacturers seeking to meet stringent performance and environmental standards.

The consumer goods industry, including packaging, toys, and personal care products, has also contributed to the rising demand for plasticizers. Butane's role in enhancing the properties of plasticizers has made it particularly valuable in applications requiring improved flexibility, transparency, and resistance to temperature variations.

Environmental concerns and regulatory pressures have been significant drivers in shaping the plasticizer market. There is a growing demand for eco-friendly and non-phthalate plasticizers, which has led to increased research and development efforts in butane-based alternatives. This trend is expected to continue as consumers and regulators push for safer and more sustainable products.

The Asia-Pacific region, particularly China and India, has emerged as the largest and fastest-growing market for plasticizers. The rapid industrialization, booming construction sector, and expanding automotive industry in these countries have created a substantial demand for butane-enhanced plasticizers. North America and Europe, while mature markets, continue to show steady growth, driven by technological innovations and the replacement of older plasticizer formulations with newer, butane-based alternatives.

Market analysts project that the global plasticizer market will continue to expand in the coming years, with butane-based formulations playing a crucial role in this growth. The development of novel applications and the ongoing efforts to improve the performance and sustainability of plasticizers are expected to create new opportunities for butane in this sector.

The construction industry remains the largest consumer of plasticizers, particularly in the production of PVC products for flooring, roofing, and wall coverings. The growing urbanization and infrastructure development in emerging economies have fueled the demand for these materials, consequently boosting the market for butane-based plasticizers.

In the automotive sector, the shift towards lightweight materials to improve fuel efficiency has led to an increased use of plastics and, by extension, plasticizers. Butane-enhanced plasticizers offer improved flexibility and durability to automotive components, making them an attractive option for manufacturers seeking to meet stringent performance and environmental standards.

The consumer goods industry, including packaging, toys, and personal care products, has also contributed to the rising demand for plasticizers. Butane's role in enhancing the properties of plasticizers has made it particularly valuable in applications requiring improved flexibility, transparency, and resistance to temperature variations.

Environmental concerns and regulatory pressures have been significant drivers in shaping the plasticizer market. There is a growing demand for eco-friendly and non-phthalate plasticizers, which has led to increased research and development efforts in butane-based alternatives. This trend is expected to continue as consumers and regulators push for safer and more sustainable products.

The Asia-Pacific region, particularly China and India, has emerged as the largest and fastest-growing market for plasticizers. The rapid industrialization, booming construction sector, and expanding automotive industry in these countries have created a substantial demand for butane-enhanced plasticizers. North America and Europe, while mature markets, continue to show steady growth, driven by technological innovations and the replacement of older plasticizer formulations with newer, butane-based alternatives.

Market analysts project that the global plasticizer market will continue to expand in the coming years, with butane-based formulations playing a crucial role in this growth. The development of novel applications and the ongoing efforts to improve the performance and sustainability of plasticizers are expected to create new opportunities for butane in this sector.

Technical Challenges

The development of butane-based plasticizers faces several technical challenges that require innovative solutions. One of the primary obstacles is achieving optimal compatibility between butane-derived plasticizers and various polymer matrices. The molecular structure and polarity of butane-based compounds often result in limited miscibility with certain polymers, potentially leading to phase separation and reduced plasticizing efficiency.

Another significant challenge lies in enhancing the thermal stability of butane-based plasticizers. As plasticizers are frequently exposed to elevated temperatures during processing and end-use applications, ensuring their resistance to thermal degradation is crucial. The relatively low boiling point of butane and its derivatives necessitates the development of advanced stabilization techniques to prevent volatilization and maintain long-term performance.

The environmental impact of butane-derived plasticizers presents a complex technical hurdle. While butane itself is a naturally occurring compound, the synthesis and use of its derivatives in plasticizers may contribute to volatile organic compound (VOC) emissions. Addressing this issue requires the development of low-VOC formulations and improved manufacturing processes to minimize environmental footprint without compromising plasticizer effectiveness.

Achieving a balance between plasticizing efficiency and migration resistance poses another technical challenge. Butane-based plasticizers must effectively reduce the glass transition temperature of polymers while simultaneously resisting migration out of the material matrix. This dual requirement demands careful molecular design and the potential incorporation of anchoring groups or cross-linking mechanisms.

The scalability of butane-based plasticizer production presents technical difficulties in maintaining consistent quality and performance across large-scale manufacturing. Optimizing reaction conditions, purification processes, and quality control measures for industrial-scale production requires significant engineering efforts and process innovations.

Furthermore, the regulatory landscape surrounding plasticizers continues to evolve, with increasing scrutiny on health and safety aspects. Developing butane-based plasticizers that meet stringent regulatory requirements while maintaining desired performance characteristics necessitates extensive toxicological studies and the potential redesign of molecular structures to ensure compliance.

Lastly, the challenge of cost-effectiveness in comparison to established plasticizer technologies cannot be overlooked. While butane offers potential advantages in terms of availability and sustainability, the economic viability of butane-based plasticizers depends on optimizing production processes, improving yield, and demonstrating superior performance to justify any cost premiums.

Another significant challenge lies in enhancing the thermal stability of butane-based plasticizers. As plasticizers are frequently exposed to elevated temperatures during processing and end-use applications, ensuring their resistance to thermal degradation is crucial. The relatively low boiling point of butane and its derivatives necessitates the development of advanced stabilization techniques to prevent volatilization and maintain long-term performance.

The environmental impact of butane-derived plasticizers presents a complex technical hurdle. While butane itself is a naturally occurring compound, the synthesis and use of its derivatives in plasticizers may contribute to volatile organic compound (VOC) emissions. Addressing this issue requires the development of low-VOC formulations and improved manufacturing processes to minimize environmental footprint without compromising plasticizer effectiveness.

Achieving a balance between plasticizing efficiency and migration resistance poses another technical challenge. Butane-based plasticizers must effectively reduce the glass transition temperature of polymers while simultaneously resisting migration out of the material matrix. This dual requirement demands careful molecular design and the potential incorporation of anchoring groups or cross-linking mechanisms.

The scalability of butane-based plasticizer production presents technical difficulties in maintaining consistent quality and performance across large-scale manufacturing. Optimizing reaction conditions, purification processes, and quality control measures for industrial-scale production requires significant engineering efforts and process innovations.

Furthermore, the regulatory landscape surrounding plasticizers continues to evolve, with increasing scrutiny on health and safety aspects. Developing butane-based plasticizers that meet stringent regulatory requirements while maintaining desired performance characteristics necessitates extensive toxicological studies and the potential redesign of molecular structures to ensure compliance.

Lastly, the challenge of cost-effectiveness in comparison to established plasticizer technologies cannot be overlooked. While butane offers potential advantages in terms of availability and sustainability, the economic viability of butane-based plasticizers depends on optimizing production processes, improving yield, and demonstrating superior performance to justify any cost premiums.

Current Solutions

01 Butane fuel system improvements

Advancements in butane fuel systems focus on enhancing efficiency, safety, and performance. These improvements include optimized combustion processes, better fuel delivery mechanisms, and innovative storage solutions. Such developments aim to increase the reliability and effectiveness of butane-powered devices while reducing environmental impact.- Butane purification and separation technologies: Advancements in butane purification and separation processes have been developed to improve the quality and efficiency of butane production. These technologies focus on removing impurities and separating butane from other hydrocarbons, resulting in higher-grade butane for various applications.

- Butane storage and transportation systems: Innovative storage and transportation systems have been designed to enhance the safety and efficiency of handling butane. These developments include improved tank designs, pressure regulation mechanisms, and leak detection systems to ensure secure storage and transport of butane.

- Butane-powered devices and appliances: Technological advancements have led to the development of various butane-powered devices and appliances. These innovations include portable stoves, heaters, and torches that utilize butane as a fuel source, offering improved efficiency and convenience for users.

- Butane production and processing optimization: Improvements in butane production and processing techniques have been made to enhance yield, reduce energy consumption, and minimize environmental impact. These advancements include catalytic processes, heat integration systems, and automated control systems for more efficient butane production.

- Butane blending and formulation technologies: New technologies have been developed for blending butane with other substances to create specialized fuel mixtures or chemical products. These advancements focus on precise formulation techniques, quality control measures, and optimized blending processes to meet specific industry requirements.

02 Butane purification and processing

Technological developments in butane purification and processing involve novel methods for removing impurities, separating isomers, and enhancing the quality of butane products. These advancements contribute to producing higher-grade butane for various industrial and consumer applications, improving overall product performance and reducing potential contaminants.Expand Specific Solutions03 Butane-based refrigeration systems

Innovations in butane-based refrigeration systems focus on improving energy efficiency, reducing environmental impact, and enhancing cooling performance. These developments include advanced compressor designs, optimized heat exchange mechanisms, and smart control systems that maximize the cooling potential of butane while minimizing energy consumption.Expand Specific Solutions04 Butane detection and safety technologies

Advancements in butane detection and safety technologies aim to prevent accidents and improve handling procedures. These developments include high-sensitivity sensors, real-time monitoring systems, and automated safety mechanisms that can quickly detect leaks, shut off gas flow, and alert users to potential hazards, enhancing overall safety in butane-related applications.Expand Specific Solutions05 Butane in alternative energy applications

Emerging technologies explore the use of butane in alternative energy applications, such as fuel cells and hybrid energy systems. These innovations focus on harnessing butane's energy potential in more efficient and environmentally friendly ways, potentially opening new avenues for sustainable energy production and storage solutions.Expand Specific Solutions

Key Industry Players

The development of butane-based plasticizers is in a growth phase, with increasing market size driven by demand for eco-friendly alternatives in various industries. The technology is maturing, but still offers room for innovation. Key players like BASF Corp., DuPont de Nemours, Inc., and LG Chem Ltd. are leading the charge with advanced research and development efforts. Smaller companies such as Gevo, Inc. and Butamax Advanced Biofuels LLC are also making significant contributions, particularly in bio-based solutions. The competitive landscape is characterized by a mix of established chemical giants and innovative startups, each striving to enhance the technological capabilities and applications of butane in plasticizers.

BASF Corp.

Technical Solution: BASF has developed innovative butane-based plasticizers that offer improved performance and sustainability. Their technology utilizes butane as a key feedstock to produce non-phthalate plasticizers with enhanced flexibility and durability. BASF's process involves the oxidation of butane to maleic anhydride, which is then further processed to create plasticizers like Hexamoll DINCH[1]. This method reduces the reliance on traditional phthalate-based plasticizers, addressing environmental and health concerns. The company has also invested in bio-based alternatives, combining butane-derived components with renewable resources to create hybrid plasticizers that offer a balance of performance and sustainability[2].

Strengths: Advanced chemical expertise, global reach, and commitment to sustainability. Weaknesses: Higher production costs compared to traditional plasticizers, potential regulatory challenges in some markets.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in utilizing butane for plasticizer production. Their approach involves the dehydrogenation of butane to produce butene, which is then used as a precursor for various plasticizers[3]. Sinopec has developed a proprietary catalyst system that enhances the efficiency of this process, resulting in higher yields and reduced energy consumption. The company has also implemented a closed-loop system that recycles unreacted butane, minimizing waste and improving overall process economics[4]. Additionally, Sinopec is exploring the use of butane-derived plasticizers in biodegradable polymers, aiming to create more environmentally friendly plastic products.

Strengths: Large-scale production capabilities, strong domestic market presence. Weaknesses: Potential environmental concerns, dependence on fossil fuel-based feedstocks.

Core Innovations

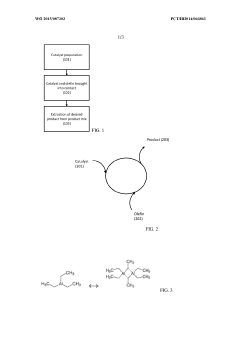

Catalyst compositions for selective dimerization of ethylene

PatentWO2015087303A2

Innovation

- A catalyst composition comprising a titanate, a catalyst additive such as dibutyl ether or silicate, and an organic aluminum compound, pre-treated with an inert solvent, is used to enhance catalytic activity and reduce polymer formation, with a specific molar ratio of aluminum to titanium optimizing the reaction conditions.

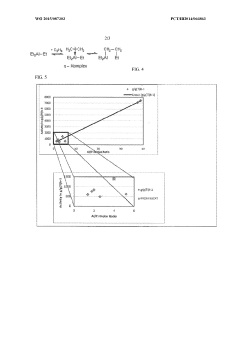

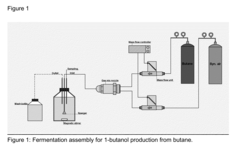

Process for the Bioconversion of Butane to 1-Butanol

PatentInactiveUS20160168597A1

Innovation

- A bioconversion process involving a host organism with a functional P153 enzyme, such as Escherichia coli, is used to convert butane to 1-butanol under elevated pressure in the presence of oxygen, utilizing a three-component system of P450 monooxygenases and redox proteins to enhance enzymatic oxidation and increase product yield.

Environmental Impact

The environmental impact of butane's role in enhancing the technological development of plasticizers is a critical aspect that requires thorough examination. Butane, as a key component in plasticizer production, contributes to both positive and negative environmental outcomes.

One of the primary environmental concerns associated with butane-based plasticizers is their potential for volatile organic compound (VOC) emissions. When released into the atmosphere, these compounds can contribute to the formation of ground-level ozone and smog, which have detrimental effects on air quality and human health. However, advancements in butane-based plasticizer technology have led to the development of low-VOC formulations, significantly reducing these emissions and mitigating their environmental impact.

The production process of butane-based plasticizers also raises environmental considerations. The extraction and refining of butane from natural gas or petroleum sources can lead to greenhouse gas emissions and potential soil and water contamination if not properly managed. Nevertheless, the industry has made substantial progress in implementing cleaner production methods and more efficient resource utilization, thereby reducing the overall environmental footprint of butane-based plasticizer manufacturing.

On the positive side, butane's role in plasticizer development has contributed to the creation of more durable and long-lasting plastic products. This increased longevity can lead to reduced waste generation and lower demand for raw materials, ultimately conserving natural resources and minimizing the environmental impact associated with frequent product replacement.

Furthermore, the enhanced performance characteristics of butane-based plasticizers have enabled the development of more environmentally friendly plastic formulations. These include biodegradable plastics and those with improved recyclability, which can significantly reduce the accumulation of plastic waste in landfills and oceans.

The use of butane-based plasticizers in energy-efficient applications, such as in the production of lightweight materials for automotive and aerospace industries, indirectly contributes to reduced fuel consumption and lower carbon emissions. This aligns with global efforts to combat climate change and promote sustainable development.

However, the end-of-life management of products containing butane-based plasticizers remains a challenge. Improper disposal or incineration of these materials can release harmful substances into the environment. To address this issue, ongoing research focuses on developing more environmentally benign alternatives and improving recycling technologies for plasticizer-containing products.

In conclusion, while butane's role in plasticizer technology has historically posed environmental challenges, continuous innovation and stringent regulations have led to significant improvements in its environmental profile. The industry's commitment to sustainable practices and the development of eco-friendly alternatives demonstrates a positive trajectory towards minimizing the environmental impact of butane-based plasticizers.

One of the primary environmental concerns associated with butane-based plasticizers is their potential for volatile organic compound (VOC) emissions. When released into the atmosphere, these compounds can contribute to the formation of ground-level ozone and smog, which have detrimental effects on air quality and human health. However, advancements in butane-based plasticizer technology have led to the development of low-VOC formulations, significantly reducing these emissions and mitigating their environmental impact.

The production process of butane-based plasticizers also raises environmental considerations. The extraction and refining of butane from natural gas or petroleum sources can lead to greenhouse gas emissions and potential soil and water contamination if not properly managed. Nevertheless, the industry has made substantial progress in implementing cleaner production methods and more efficient resource utilization, thereby reducing the overall environmental footprint of butane-based plasticizer manufacturing.

On the positive side, butane's role in plasticizer development has contributed to the creation of more durable and long-lasting plastic products. This increased longevity can lead to reduced waste generation and lower demand for raw materials, ultimately conserving natural resources and minimizing the environmental impact associated with frequent product replacement.

Furthermore, the enhanced performance characteristics of butane-based plasticizers have enabled the development of more environmentally friendly plastic formulations. These include biodegradable plastics and those with improved recyclability, which can significantly reduce the accumulation of plastic waste in landfills and oceans.

The use of butane-based plasticizers in energy-efficient applications, such as in the production of lightweight materials for automotive and aerospace industries, indirectly contributes to reduced fuel consumption and lower carbon emissions. This aligns with global efforts to combat climate change and promote sustainable development.

However, the end-of-life management of products containing butane-based plasticizers remains a challenge. Improper disposal or incineration of these materials can release harmful substances into the environment. To address this issue, ongoing research focuses on developing more environmentally benign alternatives and improving recycling technologies for plasticizer-containing products.

In conclusion, while butane's role in plasticizer technology has historically posed environmental challenges, continuous innovation and stringent regulations have led to significant improvements in its environmental profile. The industry's commitment to sustainable practices and the development of eco-friendly alternatives demonstrates a positive trajectory towards minimizing the environmental impact of butane-based plasticizers.

Regulatory Framework

The regulatory framework surrounding the use of butane in plasticizer development is complex and multifaceted, reflecting the need to balance technological innovation with safety and environmental concerns. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines on the use of chemical substances in consumer products, including plasticizers. These guidelines often serve as a basis for national and regional regulations.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of butane and other chemicals in plasticizer production. Under the Toxic Substances Control Act (TSCA), the EPA has the authority to require reporting, record-keeping, and testing of chemical substances. The agency also maintains the TSCA Inventory, which lists all existing chemical substances manufactured or processed in the United States, including those used in plasticizer production.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register chemicals, including those used in plasticizers, and provide safety data. The European Chemicals Agency (ECHA) oversees this process and maintains a database of registered substances. Butane and its derivatives used in plasticizer production must comply with REACH requirements.

In Asia, countries like China and Japan have their own regulatory systems. China's Ministry of Ecology and Environment oversees the Measures for Environmental Management of New Chemical Substances, which requires registration and risk assessment of new chemicals, including those used in plasticizer development. Japan's Chemical Substances Control Law (CSCL) similarly regulates the manufacture, import, and use of chemical substances.

Industry-specific regulations also impact the use of butane in plasticizer development. For instance, in the food packaging industry, the U.S. Food and Drug Administration (FDA) regulates food contact substances, including plasticizers, under the Federal Food, Drug, and Cosmetic Act. The European Food Safety Authority (EFSA) performs a similar function in the EU, evaluating the safety of substances used in food contact materials.

As environmental concerns grow, many jurisdictions are implementing regulations to promote the use of more sustainable plasticizers. This has led to increased scrutiny of traditional phthalate-based plasticizers and a push towards alternatives, including those derived from butane. Regulatory bodies are increasingly focusing on lifecycle assessments and the long-term environmental impact of plasticizers, which may influence future regulations on butane-based plasticizer technologies.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of butane and other chemicals in plasticizer production. Under the Toxic Substances Control Act (TSCA), the EPA has the authority to require reporting, record-keeping, and testing of chemical substances. The agency also maintains the TSCA Inventory, which lists all existing chemical substances manufactured or processed in the United States, including those used in plasticizer production.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. REACH requires manufacturers and importers to register chemicals, including those used in plasticizers, and provide safety data. The European Chemicals Agency (ECHA) oversees this process and maintains a database of registered substances. Butane and its derivatives used in plasticizer production must comply with REACH requirements.

In Asia, countries like China and Japan have their own regulatory systems. China's Ministry of Ecology and Environment oversees the Measures for Environmental Management of New Chemical Substances, which requires registration and risk assessment of new chemicals, including those used in plasticizer development. Japan's Chemical Substances Control Law (CSCL) similarly regulates the manufacture, import, and use of chemical substances.

Industry-specific regulations also impact the use of butane in plasticizer development. For instance, in the food packaging industry, the U.S. Food and Drug Administration (FDA) regulates food contact substances, including plasticizers, under the Federal Food, Drug, and Cosmetic Act. The European Food Safety Authority (EFSA) performs a similar function in the EU, evaluating the safety of substances used in food contact materials.

As environmental concerns grow, many jurisdictions are implementing regulations to promote the use of more sustainable plasticizers. This has led to increased scrutiny of traditional phthalate-based plasticizers and a push towards alternatives, including those derived from butane. Regulatory bodies are increasingly focusing on lifecycle assessments and the long-term environmental impact of plasticizers, which may influence future regulations on butane-based plasticizer technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!