Ceramic Reinforcements For AM MMCs: Selection And Dispersion Techniques

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Reinforcement Background and Objectives

Ceramic reinforcements have emerged as critical components in the evolution of metal matrix composites (MMCs), particularly in the context of additive manufacturing (AM). The integration of ceramic particles into metal matrices dates back to the 1960s, with significant advancements occurring in the 1980s and 1990s through conventional manufacturing methods. However, the adaptation of these reinforcements for AM processes represents a relatively recent technological frontier that has gained momentum over the past decade.

The evolution of ceramic reinforcements in AM-MMCs has progressed from simple oxide particles (Al₂O₃, SiO₂) to more advanced carbides (SiC, TiC, B₄C), nitrides (Si₃N₄, TiN), and borides (TiB₂). This progression reflects the industry's pursuit of enhanced mechanical properties, thermal stability, and wear resistance in metal components manufactured through additive processes.

Current technological trends indicate a growing interest in nano-sized ceramic reinforcements, which offer superior strengthening mechanisms compared to their micro-sized counterparts. Additionally, there is an increasing focus on developing hybrid reinforcement systems that combine multiple ceramic types to achieve synergistic property enhancements. The AM-MMC field is also witnessing exploration of novel reinforcement geometries beyond spherical particles, including whiskers, platelets, and engineered structures.

The primary technical objective in this domain is to develop systematic selection methodologies for ceramic reinforcements that optimize compatibility with specific metal matrices and AM processes. This includes considerations of thermal expansion coefficients, wettability, interfacial reactions, and particle size distributions. A parallel objective involves establishing reliable dispersion techniques that ensure homogeneous distribution of ceramic reinforcements throughout the metal matrix during AM processes.

Additional goals include mitigating common challenges such as agglomeration, poor wettability, and undesired interfacial reactions that can compromise the mechanical integrity of the final components. The field aims to develop predictive models that can accurately forecast the behavior of ceramic-reinforced MMCs during AM processes, thereby reducing the empirical nature of current development approaches.

From a broader perspective, the technological trajectory is moving toward establishing standardized protocols for ceramic reinforcement selection and dispersion that can be readily implemented across various AM platforms, including powder bed fusion, directed energy deposition, and binder jetting. This standardization would significantly accelerate the industrial adoption of AM-MMCs across aerospace, automotive, and biomedical sectors.

The ultimate objective remains the creation of AM-MMCs with tailored property profiles that outperform conventional materials while maintaining processability through additive manufacturing routes. This includes achieving unprecedented combinations of strength, ductility, wear resistance, and thermal stability through strategic selection and dispersion of ceramic reinforcements.

The evolution of ceramic reinforcements in AM-MMCs has progressed from simple oxide particles (Al₂O₃, SiO₂) to more advanced carbides (SiC, TiC, B₄C), nitrides (Si₃N₄, TiN), and borides (TiB₂). This progression reflects the industry's pursuit of enhanced mechanical properties, thermal stability, and wear resistance in metal components manufactured through additive processes.

Current technological trends indicate a growing interest in nano-sized ceramic reinforcements, which offer superior strengthening mechanisms compared to their micro-sized counterparts. Additionally, there is an increasing focus on developing hybrid reinforcement systems that combine multiple ceramic types to achieve synergistic property enhancements. The AM-MMC field is also witnessing exploration of novel reinforcement geometries beyond spherical particles, including whiskers, platelets, and engineered structures.

The primary technical objective in this domain is to develop systematic selection methodologies for ceramic reinforcements that optimize compatibility with specific metal matrices and AM processes. This includes considerations of thermal expansion coefficients, wettability, interfacial reactions, and particle size distributions. A parallel objective involves establishing reliable dispersion techniques that ensure homogeneous distribution of ceramic reinforcements throughout the metal matrix during AM processes.

Additional goals include mitigating common challenges such as agglomeration, poor wettability, and undesired interfacial reactions that can compromise the mechanical integrity of the final components. The field aims to develop predictive models that can accurately forecast the behavior of ceramic-reinforced MMCs during AM processes, thereby reducing the empirical nature of current development approaches.

From a broader perspective, the technological trajectory is moving toward establishing standardized protocols for ceramic reinforcement selection and dispersion that can be readily implemented across various AM platforms, including powder bed fusion, directed energy deposition, and binder jetting. This standardization would significantly accelerate the industrial adoption of AM-MMCs across aerospace, automotive, and biomedical sectors.

The ultimate objective remains the creation of AM-MMCs with tailored property profiles that outperform conventional materials while maintaining processability through additive manufacturing routes. This includes achieving unprecedented combinations of strength, ductility, wear resistance, and thermal stability through strategic selection and dispersion of ceramic reinforcements.

Market Analysis for MMC Additive Manufacturing

The global market for Metal Matrix Composites (MMCs) in additive manufacturing is experiencing significant growth, driven by increasing demand for high-performance materials in aerospace, automotive, and defense sectors. The market was valued at approximately $125 million in 2022 and is projected to reach $350 million by 2028, representing a compound annual growth rate of 18.7% during the forecast period.

Aerospace remains the dominant application segment, accounting for nearly 40% of the MMC additive manufacturing market. This dominance stems from the industry's stringent requirements for lightweight yet strong materials capable of withstanding extreme operating conditions. The automotive sector follows closely, with growing adoption for high-performance components such as engine parts, brake systems, and structural elements where weight reduction and thermal management are critical.

Regional analysis reveals North America as the leading market for MMC additive manufacturing, holding approximately 35% market share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and Japan, is expected to witness the fastest growth due to increasing industrialization, government initiatives supporting advanced manufacturing, and rising investments in aerospace and defense sectors.

Key market drivers include the growing demand for lightweight materials with superior mechanical properties, increasing adoption of additive manufacturing across industries, and continuous advancements in ceramic reinforcement technologies. The ability of ceramic-reinforced MMCs to offer enhanced wear resistance, thermal stability, and specific strength compared to conventional alloys positions them favorably in high-value applications.

Market challenges include high material costs, technical complexities in achieving uniform ceramic particle dispersion, and limited standardization across the industry. The average cost of ceramic-reinforced MMC powders remains 3-5 times higher than conventional metal powders, creating a significant barrier to widespread adoption in cost-sensitive applications.

Customer demand patterns indicate growing interest in customized MMC formulations tailored to specific application requirements. End-users are increasingly seeking materials that offer optimized combinations of properties such as high-temperature performance, wear resistance, and specific strength-to-weight ratios. This trend is driving material suppliers and additive manufacturing service providers to develop more specialized ceramic reinforcement solutions and dispersion techniques.

Aerospace remains the dominant application segment, accounting for nearly 40% of the MMC additive manufacturing market. This dominance stems from the industry's stringent requirements for lightweight yet strong materials capable of withstanding extreme operating conditions. The automotive sector follows closely, with growing adoption for high-performance components such as engine parts, brake systems, and structural elements where weight reduction and thermal management are critical.

Regional analysis reveals North America as the leading market for MMC additive manufacturing, holding approximately 35% market share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and Japan, is expected to witness the fastest growth due to increasing industrialization, government initiatives supporting advanced manufacturing, and rising investments in aerospace and defense sectors.

Key market drivers include the growing demand for lightweight materials with superior mechanical properties, increasing adoption of additive manufacturing across industries, and continuous advancements in ceramic reinforcement technologies. The ability of ceramic-reinforced MMCs to offer enhanced wear resistance, thermal stability, and specific strength compared to conventional alloys positions them favorably in high-value applications.

Market challenges include high material costs, technical complexities in achieving uniform ceramic particle dispersion, and limited standardization across the industry. The average cost of ceramic-reinforced MMC powders remains 3-5 times higher than conventional metal powders, creating a significant barrier to widespread adoption in cost-sensitive applications.

Customer demand patterns indicate growing interest in customized MMC formulations tailored to specific application requirements. End-users are increasingly seeking materials that offer optimized combinations of properties such as high-temperature performance, wear resistance, and specific strength-to-weight ratios. This trend is driving material suppliers and additive manufacturing service providers to develop more specialized ceramic reinforcement solutions and dispersion techniques.

Technical Challenges in Ceramic-Metal Integration

The integration of ceramic reinforcements into metal matrices presents significant technical challenges that must be addressed to achieve successful additive manufacturing of metal matrix composites (MMCs). One of the primary difficulties lies in the inherent incompatibility between ceramics and metals at their interfaces. The substantial differences in physical properties, including thermal expansion coefficients, wetting behavior, and chemical reactivity, often lead to weak interfacial bonding and subsequent mechanical failure under stress.

Thermal mismatch between ceramic reinforcements and metal matrices creates residual stresses during cooling from processing temperatures, potentially causing microcracking and degradation of mechanical properties. This issue becomes particularly pronounced in additive manufacturing processes where rapid heating and cooling cycles are common, creating steep thermal gradients that exacerbate these stresses.

Wettability presents another significant challenge, as many ceramic materials exhibit poor wetting by molten metals. This poor wettability hinders uniform distribution of reinforcements and creates voids at interfaces, compromising the structural integrity of the composite. Various surface treatments and coatings have been developed to enhance wettability, but their effectiveness varies widely depending on the specific ceramic-metal combination.

Chemical reactions at ceramic-metal interfaces can form brittle intermetallic compounds that compromise mechanical properties. While controlled interfacial reactions can sometimes enhance bonding, excessive reactions typically lead to degradation of both the reinforcement and the matrix. The high-energy conditions present during additive manufacturing processes often accelerate these reactions, making them difficult to control.

The processing parameters for ceramic-metal integration must be precisely controlled. Laser power, scanning speed, and layer thickness in additive manufacturing processes significantly affect the quality of ceramic-metal interfaces. Insufficient energy input may result in incomplete melting and poor bonding, while excessive energy can cause reinforcement degradation or undesired phase transformations.

Porosity formation at interfaces represents another critical challenge. The difference in densification behavior between ceramics and metals during sintering or consolidation processes can lead to residual porosity, which acts as stress concentrators and crack initiation sites. Advanced processing techniques, including hot isostatic pressing post-processing, are often required to minimize this porosity.

Scale-up challenges also exist when transitioning from laboratory-scale demonstrations to industrial production. Maintaining consistent ceramic-metal interfaces across large components with complex geometries requires sophisticated process control and monitoring systems that can adapt to changing conditions during the build process.

Thermal mismatch between ceramic reinforcements and metal matrices creates residual stresses during cooling from processing temperatures, potentially causing microcracking and degradation of mechanical properties. This issue becomes particularly pronounced in additive manufacturing processes where rapid heating and cooling cycles are common, creating steep thermal gradients that exacerbate these stresses.

Wettability presents another significant challenge, as many ceramic materials exhibit poor wetting by molten metals. This poor wettability hinders uniform distribution of reinforcements and creates voids at interfaces, compromising the structural integrity of the composite. Various surface treatments and coatings have been developed to enhance wettability, but their effectiveness varies widely depending on the specific ceramic-metal combination.

Chemical reactions at ceramic-metal interfaces can form brittle intermetallic compounds that compromise mechanical properties. While controlled interfacial reactions can sometimes enhance bonding, excessive reactions typically lead to degradation of both the reinforcement and the matrix. The high-energy conditions present during additive manufacturing processes often accelerate these reactions, making them difficult to control.

The processing parameters for ceramic-metal integration must be precisely controlled. Laser power, scanning speed, and layer thickness in additive manufacturing processes significantly affect the quality of ceramic-metal interfaces. Insufficient energy input may result in incomplete melting and poor bonding, while excessive energy can cause reinforcement degradation or undesired phase transformations.

Porosity formation at interfaces represents another critical challenge. The difference in densification behavior between ceramics and metals during sintering or consolidation processes can lead to residual porosity, which acts as stress concentrators and crack initiation sites. Advanced processing techniques, including hot isostatic pressing post-processing, are often required to minimize this porosity.

Scale-up challenges also exist when transitioning from laboratory-scale demonstrations to industrial production. Maintaining consistent ceramic-metal interfaces across large components with complex geometries requires sophisticated process control and monitoring systems that can adapt to changing conditions during the build process.

Current Ceramic Dispersion Methodologies

01 Types of ceramic reinforcements for MMCs

Various ceramic materials can be used as reinforcements in metal matrix composites to enhance mechanical properties. Common ceramic reinforcements include silicon carbide (SiC), aluminum oxide (Al2O3), boron carbide (B4C), and titanium diboride (TiB2). These materials are selected based on their compatibility with the metal matrix, thermal stability, and ability to provide desired mechanical properties such as strength, stiffness, and wear resistance.- Types of ceramic reinforcements for MMCs: Various ceramic materials can be used as reinforcements in metal matrix composites to enhance mechanical properties. Common ceramic reinforcements include silicon carbide (SiC), alumina (Al2O3), boron carbide (B4C), and titanium diboride (TiB2). These ceramics provide high strength, stiffness, and wear resistance to the metal matrix. The selection of ceramic reinforcement depends on the desired properties of the final composite and compatibility with the metal matrix.

- Dispersion techniques for ceramic particles in metal matrices: Effective dispersion of ceramic reinforcements in metal matrices is crucial for achieving optimal composite properties. Various techniques are employed including mechanical stirring, ultrasonic dispersion, powder metallurgy, and in-situ synthesis. These methods aim to achieve uniform distribution of reinforcement particles throughout the metal matrix while minimizing agglomeration and clustering. Proper dispersion ensures consistent mechanical properties and prevents weak spots in the composite material.

- Size and morphology control of ceramic reinforcements: The size, shape, and morphology of ceramic reinforcements significantly impact the properties of metal matrix composites. Nano-sized ceramic particles provide enhanced mechanical properties compared to micro-sized particles due to their higher surface area and better interfacial bonding. Controlling particle size distribution and morphology (spherical, whisker, fiber, or platelet) allows tailoring of specific composite properties such as strength, ductility, and thermal conductivity. Advanced processing techniques enable precise control over these parameters.

- Interface engineering between ceramic reinforcements and metal matrix: The interface between ceramic reinforcements and the metal matrix plays a critical role in determining composite properties. Surface treatments of ceramic particles, such as coating with reactive metals or applying coupling agents, can improve wettability and bonding with the metal matrix. Controlling interfacial reactions during processing prevents formation of brittle phases while promoting strong adhesion. Proper interface engineering enhances load transfer between matrix and reinforcement, improving overall mechanical performance.

- Advanced manufacturing methods for ceramic-reinforced MMCs: Advanced manufacturing techniques have been developed to produce ceramic-reinforced metal matrix composites with superior properties. These include stir casting, squeeze casting, spray deposition, additive manufacturing, and pressure infiltration. Each method offers specific advantages in terms of reinforcement distribution, porosity control, and scalability. Selection of the appropriate manufacturing process depends on the specific ceramic-metal combination, desired component geometry, and required performance characteristics of the final composite.

02 Dispersion techniques for ceramic particles

Effective dispersion of ceramic reinforcements in metal matrices is crucial for achieving optimal composite properties. Various techniques are employed including mechanical stirring, ultrasonic dispersion, high-energy ball milling, and powder metallurgy processes. These methods help to break up agglomerates, ensure uniform distribution of reinforcement particles, and promote good interfacial bonding between the ceramic reinforcements and metal matrix, which is essential for load transfer and overall composite performance.Expand Specific Solutions03 Surface treatment of ceramic reinforcements

Surface modification of ceramic reinforcements improves their wettability and bonding with the metal matrix. Treatments include coating with metallic layers, chemical functionalization, and thermal treatments. These modifications help overcome the natural incompatibility between ceramic and metal phases, reduce interfacial reactions that could form brittle phases, and enhance the mechanical properties of the resulting composite by improving load transfer across the ceramic-metal interface.Expand Specific Solutions04 Size and morphology control of ceramic reinforcements

The size, shape, and aspect ratio of ceramic reinforcements significantly impact the properties of metal matrix composites. Nano-sized particles provide enhanced strengthening mechanisms but are more challenging to disperse uniformly. Whiskers and fibers offer directional reinforcement and superior load-bearing capabilities compared to particulates. Controlling these parameters allows for tailoring of specific mechanical properties such as strength, ductility, and wear resistance according to application requirements.Expand Specific Solutions05 Hybrid and multi-scale reinforcement systems

Combining different types, sizes, or morphologies of ceramic reinforcements creates hybrid systems with enhanced performance. Multi-scale approaches incorporate both micro and nano-sized reinforcements to simultaneously address different strengthening mechanisms. These hybrid systems can overcome the limitations of single reinforcement types, providing improved combinations of strength, ductility, wear resistance, and thermal properties. The synergistic effects between different reinforcements often result in properties superior to those achievable with single reinforcement systems.Expand Specific Solutions

Leading Companies in MMC Additive Manufacturing

The ceramic reinforcement market for additive manufacturing metal matrix composites is currently in a growth phase, with increasing adoption across aerospace, automotive, and industrial sectors. The global market size is estimated to reach $2.5 billion by 2027, driven by demand for lightweight, high-performance components. Technologically, the field is transitioning from early development to commercial application, with varying maturity levels across dispersion techniques. Leading players include Boeing and GE, who are pioneering aerospace applications; 3M and HRL Laboratories focusing on advanced material development; and academic institutions like Huazhong University of Science & Technology contributing fundamental research. Companies like Nissan, Honda, and Siemens Energy are exploring automotive and energy applications, while specialized firms such as M4 Sciences and Southwest Research Institute are developing proprietary dispersion technologies to overcome agglomeration challenges.

The Boeing Co.

Technical Solution: Boeing has pioneered a specialized approach for ceramic reinforcement in aerospace-grade metal matrix composites using additive manufacturing. Their technology centers on a multi-phase dispersion technique for incorporating ceramic reinforcements into titanium and nickel-based superalloys. Boeing's method employs functionalized ceramic nanoparticles (primarily SiC, TiC, and B4C) that undergo surface modification with titanium-organic compounds to enhance compatibility with the metal matrix. Their proprietary "gradient dispersion" technique creates controlled concentration variations of ceramic reinforcements throughout the printed part, allowing for optimized mechanical properties in specific high-stress regions while maintaining ductility elsewhere. Boeing has developed a specialized powder handling system that uses electrostatic charging to prevent agglomeration of ceramic particles during the powder spreading process in selective laser melting. This system has demonstrated the ability to incorporate up to 15 vol% ceramic reinforcement while maintaining powder flowability suitable for AM processes.

Strengths: Aerospace-specific optimization for high-temperature and high-stress applications; gradient reinforcement capability allows tailored mechanical properties; excellent high-temperature stability of reinforced components. Weaknesses: Highly specialized equipment requirements limit broader adoption; process is optimized primarily for aerospace alloys; higher production costs compared to conventional methods.

General Electric Company

Technical Solution: General Electric has developed a comprehensive approach for ceramic reinforcement in metal matrix composites (MMCs) for additive manufacturing. Their technology focuses on uniform dispersion of ceramic particles in metal powders using a proprietary mechanical alloying process combined with ultrasonic treatment. GE's method involves pre-coating ceramic nanoparticles (typically SiC, Al2O3, or TiB2) with metallic elements compatible with the matrix to improve wettability and interfacial bonding. For laser-based AM processes, they've engineered ceramic particles with specific size distributions (0.1-5μm) to optimize laser absorption and minimize agglomeration issues. GE has also developed a hybrid approach combining in-situ and ex-situ reinforcement methods, where some ceramic phases are added directly while others are formed during the printing process through controlled chemical reactions between precursors. This approach has demonstrated up to 40% improvement in tensile strength while maintaining good ductility in aluminum-based composites.

Strengths: Superior dispersion uniformity through multi-stage processing; excellent interfacial bonding between ceramics and metal matrix; scalable production capability for industrial applications. Weaknesses: Complex pre-processing requirements increase production costs; process parameters require precise control for consistent results; limited to certain ceramic-metal combinations.

Key Patents in Ceramic Reinforcement Selection

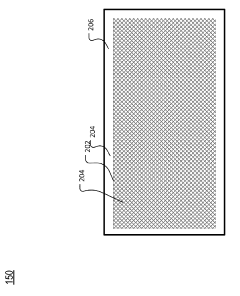

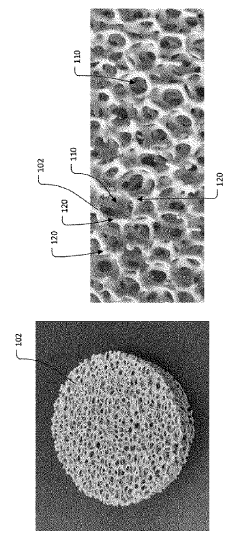

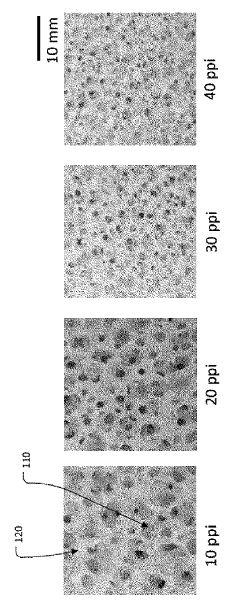

Reinforced metal matrix composite material and methods of making the same

PatentPendingJP2024035147A

Innovation

- A reinforced metal matrix composite is developed, comprising a porous and interconnected ceramic reinforcement within a metal matrix, with a porosity of 10-20% and pore sizes of 10-50 PPI, using aluminum oxide or other ceramics, and a metal matrix of aluminum or its alloys, enhancing both stiffness and ductility through a three-dimensional lattice structure.

Metal matrix composite articles with thread

PatentInactiveEP1694456A1

Innovation

- The use of a soluble core wrapped with substantially continuous fibers to create net-shaped or near net-shaped MMC articles, where the fibers are aligned with features like threads, allowing for the reduction of ceramic material usage and minimizing post-formation machining, such as grinding, by infiltrating the fibers with molten metal and removing the core, thus forming threads with reduced material waste.

Material Compatibility Assessment Framework

The Material Compatibility Assessment Framework for ceramic reinforcements in metal matrix composites (MMCs) requires systematic evaluation of the interfacial interactions between ceramic particles and metal matrices during additive manufacturing processes. This framework establishes critical parameters for determining optimal ceramic-metal combinations that ensure structural integrity and enhanced mechanical properties.

The assessment begins with thermodynamic compatibility analysis, examining the wettability characteristics between ceramics and molten metals. Ceramics with contact angles below 90° with the selected metal matrix typically demonstrate superior interfacial bonding. Thermal expansion coefficient (CTE) matching represents another crucial parameter, as significant CTE mismatches between ceramic reinforcements and metal matrices can induce residual stresses during cooling, potentially leading to microcracking and premature failure.

Chemical reactivity evaluation constitutes the next critical component, focusing on potential interfacial reactions during high-temperature processing. While limited interfacial reactions may enhance bonding, excessive reactions can form brittle intermetallic compounds that compromise mechanical properties. The framework incorporates reaction kinetics modeling to predict the extent of these reactions under specific additive manufacturing thermal conditions.

Processing temperature compatibility must be assessed to ensure ceramic reinforcements maintain stability throughout the manufacturing process. This includes evaluating potential phase transformations, decomposition temperatures, and thermal degradation mechanisms of ceramic candidates. For laser-based additive manufacturing processes, the framework also evaluates optical absorption characteristics of ceramics, as these influence energy transfer efficiency and thermal gradients during processing.

Mechanical property matching between reinforcements and matrices requires careful consideration of elastic modulus ratios, hardness differentials, and fracture toughness compatibility. These factors directly influence load transfer efficiency and crack propagation behavior in the resulting composite.

The framework incorporates quantitative scoring metrics for each compatibility parameter, enabling systematic comparison across potential material combinations. This includes weighted evaluation criteria that prioritize application-specific requirements, whether focused on wear resistance, thermal stability, or mechanical strength. Additionally, the framework integrates processing-specific considerations unique to various additive manufacturing techniques, recognizing that material compatibility can vary significantly between powder bed fusion, directed energy deposition, and binder jetting processes.

The assessment begins with thermodynamic compatibility analysis, examining the wettability characteristics between ceramics and molten metals. Ceramics with contact angles below 90° with the selected metal matrix typically demonstrate superior interfacial bonding. Thermal expansion coefficient (CTE) matching represents another crucial parameter, as significant CTE mismatches between ceramic reinforcements and metal matrices can induce residual stresses during cooling, potentially leading to microcracking and premature failure.

Chemical reactivity evaluation constitutes the next critical component, focusing on potential interfacial reactions during high-temperature processing. While limited interfacial reactions may enhance bonding, excessive reactions can form brittle intermetallic compounds that compromise mechanical properties. The framework incorporates reaction kinetics modeling to predict the extent of these reactions under specific additive manufacturing thermal conditions.

Processing temperature compatibility must be assessed to ensure ceramic reinforcements maintain stability throughout the manufacturing process. This includes evaluating potential phase transformations, decomposition temperatures, and thermal degradation mechanisms of ceramic candidates. For laser-based additive manufacturing processes, the framework also evaluates optical absorption characteristics of ceramics, as these influence energy transfer efficiency and thermal gradients during processing.

Mechanical property matching between reinforcements and matrices requires careful consideration of elastic modulus ratios, hardness differentials, and fracture toughness compatibility. These factors directly influence load transfer efficiency and crack propagation behavior in the resulting composite.

The framework incorporates quantitative scoring metrics for each compatibility parameter, enabling systematic comparison across potential material combinations. This includes weighted evaluation criteria that prioritize application-specific requirements, whether focused on wear resistance, thermal stability, or mechanical strength. Additionally, the framework integrates processing-specific considerations unique to various additive manufacturing techniques, recognizing that material compatibility can vary significantly between powder bed fusion, directed energy deposition, and binder jetting processes.

Sustainability Aspects of Ceramic-Metal Composites

The sustainability of ceramic-metal composites in additive manufacturing represents a critical dimension that must be evaluated comprehensively. These composite materials offer significant potential for reducing environmental impact compared to traditional manufacturing processes, primarily through material efficiency and waste reduction. Additive manufacturing inherently minimizes material waste by utilizing only the necessary amount of feedstock for part production, contrasting sharply with subtractive manufacturing techniques that can waste up to 90% of raw materials.

When specifically examining ceramic reinforcements in metal matrix composites, several sustainability advantages emerge. The enhanced mechanical properties and wear resistance provided by ceramic particles such as SiC, Al2O3, and TiC extend component lifespans significantly, reducing replacement frequency and associated resource consumption. Furthermore, the improved thermal properties of these composites can lead to energy efficiency gains in high-temperature applications, contributing to reduced operational carbon footprints.

Life cycle assessment (LCA) studies indicate that the energy intensity during the manufacturing phase of ceramic-reinforced metal matrix composites remains a challenge. However, this initial energy investment is often offset by efficiency gains during the use phase, particularly in aerospace and automotive applications where weight reduction translates directly to fuel savings and emissions reduction. Research suggests that a 10% weight reduction in transportation applications can yield approximately 6-8% improvement in fuel efficiency.

Material recyclability presents both opportunities and challenges for these composites. The heterogeneous nature of ceramic-metal composites complicates end-of-life recycling processes, as separation of the ceramic reinforcements from the metal matrix often requires energy-intensive methods. Recent developments in selective dissolution techniques show promise for more efficient material recovery, though these approaches remain at laboratory scale.

Supply chain considerations also factor into sustainability assessments. Many ceramic reinforcement materials require energy-intensive processing and may involve critical raw materials with geopolitical supply constraints. Developing alternative, locally-sourced ceramic reinforcements from industrial waste streams represents an emerging research direction with significant sustainability potential.

Water usage in ceramic slurry preparation for dispersion techniques presents another environmental consideration. Advanced dispersion methods utilizing supercritical CO2 or solvent-free mechanical alloying offer pathways to reduce water consumption and eliminate hazardous chemical dispersants, aligning with green chemistry principles and circular economy frameworks.

When specifically examining ceramic reinforcements in metal matrix composites, several sustainability advantages emerge. The enhanced mechanical properties and wear resistance provided by ceramic particles such as SiC, Al2O3, and TiC extend component lifespans significantly, reducing replacement frequency and associated resource consumption. Furthermore, the improved thermal properties of these composites can lead to energy efficiency gains in high-temperature applications, contributing to reduced operational carbon footprints.

Life cycle assessment (LCA) studies indicate that the energy intensity during the manufacturing phase of ceramic-reinforced metal matrix composites remains a challenge. However, this initial energy investment is often offset by efficiency gains during the use phase, particularly in aerospace and automotive applications where weight reduction translates directly to fuel savings and emissions reduction. Research suggests that a 10% weight reduction in transportation applications can yield approximately 6-8% improvement in fuel efficiency.

Material recyclability presents both opportunities and challenges for these composites. The heterogeneous nature of ceramic-metal composites complicates end-of-life recycling processes, as separation of the ceramic reinforcements from the metal matrix often requires energy-intensive methods. Recent developments in selective dissolution techniques show promise for more efficient material recovery, though these approaches remain at laboratory scale.

Supply chain considerations also factor into sustainability assessments. Many ceramic reinforcement materials require energy-intensive processing and may involve critical raw materials with geopolitical supply constraints. Developing alternative, locally-sourced ceramic reinforcements from industrial waste streams represents an emerging research direction with significant sustainability potential.

Water usage in ceramic slurry preparation for dispersion techniques presents another environmental consideration. Advanced dispersion methods utilizing supercritical CO2 or solvent-free mechanical alloying offer pathways to reduce water consumption and eliminate hazardous chemical dispersants, aligning with green chemistry principles and circular economy frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!