Comparative Analysis of Microinjection Molding and Extrusion Techniques

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection and Extrusion Technology Evolution and Objectives

Microinjection molding and extrusion technologies have evolved significantly over the past several decades, transforming manufacturing capabilities for small-scale polymer components. The evolution of these technologies can be traced back to the 1950s when conventional injection molding was first adapted for smaller components. However, it wasn't until the 1980s that true microinjection molding emerged as a distinct manufacturing process, driven by increasing demands from the electronics and medical device industries.

The technological trajectory has been characterized by continuous refinement in precision, material compatibility, and process control. Early microinjection systems faced significant challenges with material flow behavior at the micro scale, where surface tension and viscosity effects become increasingly dominant. These challenges prompted innovations in machine design, including specialized screws, barrels, and gating systems specifically engineered for micro-scale applications.

Extrusion technology has followed a parallel but distinct evolutionary path. Initially developed for large-scale continuous production, extrusion processes have been progressively miniaturized to accommodate micro-scale applications. The introduction of twin-screw micro-extruders in the 1990s represented a significant milestone, enabling better mixing capabilities and expanded material processing options at smaller scales.

A critical turning point in both technologies occurred in the early 2000s with the integration of advanced control systems and real-time monitoring capabilities. This development allowed for unprecedented precision in process parameters, reducing variability and enhancing reproducibility—essential requirements for micro-scale manufacturing where tolerances are measured in microns rather than millimeters.

Material science advancements have played a pivotal role in the evolution of both technologies. The development of specialized polymer formulations with enhanced flow properties, thermal stability, and mechanical characteristics has expanded the application scope of both microinjection molding and micro-extrusion processes. Particularly noteworthy is the introduction of biocompatible and biodegradable polymers, which has opened new frontiers in medical and environmental applications.

The primary technological objectives in this field now center around several key areas: further miniaturization capabilities, multi-material processing, enhanced surface finish quality, reduced cycle times, and improved energy efficiency. There is also growing emphasis on developing hybrid processes that combine the advantages of both microinjection molding and micro-extrusion to create novel manufacturing solutions.

Looking forward, the technological trajectory is increasingly focused on sustainability considerations, including reduced material waste, lower energy consumption, and compatibility with recycled or bio-based materials. Additionally, integration with complementary technologies such as additive manufacturing and in-line quality control systems represents an emerging frontier that promises to further expand the capabilities and applications of these micro-manufacturing techniques.

The technological trajectory has been characterized by continuous refinement in precision, material compatibility, and process control. Early microinjection systems faced significant challenges with material flow behavior at the micro scale, where surface tension and viscosity effects become increasingly dominant. These challenges prompted innovations in machine design, including specialized screws, barrels, and gating systems specifically engineered for micro-scale applications.

Extrusion technology has followed a parallel but distinct evolutionary path. Initially developed for large-scale continuous production, extrusion processes have been progressively miniaturized to accommodate micro-scale applications. The introduction of twin-screw micro-extruders in the 1990s represented a significant milestone, enabling better mixing capabilities and expanded material processing options at smaller scales.

A critical turning point in both technologies occurred in the early 2000s with the integration of advanced control systems and real-time monitoring capabilities. This development allowed for unprecedented precision in process parameters, reducing variability and enhancing reproducibility—essential requirements for micro-scale manufacturing where tolerances are measured in microns rather than millimeters.

Material science advancements have played a pivotal role in the evolution of both technologies. The development of specialized polymer formulations with enhanced flow properties, thermal stability, and mechanical characteristics has expanded the application scope of both microinjection molding and micro-extrusion processes. Particularly noteworthy is the introduction of biocompatible and biodegradable polymers, which has opened new frontiers in medical and environmental applications.

The primary technological objectives in this field now center around several key areas: further miniaturization capabilities, multi-material processing, enhanced surface finish quality, reduced cycle times, and improved energy efficiency. There is also growing emphasis on developing hybrid processes that combine the advantages of both microinjection molding and micro-extrusion to create novel manufacturing solutions.

Looking forward, the technological trajectory is increasingly focused on sustainability considerations, including reduced material waste, lower energy consumption, and compatibility with recycled or bio-based materials. Additionally, integration with complementary technologies such as additive manufacturing and in-line quality control systems represents an emerging frontier that promises to further expand the capabilities and applications of these micro-manufacturing techniques.

Market Demand Analysis for Micro-Manufacturing Processes

The global micro-manufacturing market has experienced significant growth in recent years, driven by increasing demand for miniaturized components across various industries. The market for micro-manufacturing processes, particularly microinjection molding and extrusion techniques, is projected to reach $5.7 billion by 2026, growing at a CAGR of 9.8% from 2021. This growth is primarily fueled by the expanding applications in medical devices, electronics, automotive components, and telecommunications sectors.

In the medical device industry, the demand for minimally invasive surgical tools, drug delivery systems, and diagnostic equipment has created substantial opportunities for micro-manufacturing processes. The healthcare sector alone accounts for approximately 38% of the total micro-manufacturing market, with microinjection molding being particularly valuable for producing precise, complex medical components with biocompatible materials.

The electronics industry represents another significant market segment, driven by the continuous trend toward device miniaturization and increased functionality. Microinjection molding and micro-extrusion techniques are essential for producing microconnectors, switches, and other intricate components that enable smaller, more powerful electronic devices. This sector contributes roughly 29% to the overall micro-manufacturing market demand.

Consumer preferences for smaller, lighter, and more portable products have further accelerated the adoption of micro-manufacturing processes. The automotive industry has also embraced these technologies for producing sensors, microfluidic components, and other precision parts that enhance vehicle performance and efficiency while reducing weight and size.

Regional analysis indicates that North America and Europe currently lead the market for advanced micro-manufacturing processes, with Asia-Pacific showing the fastest growth rate due to expanding manufacturing capabilities in China, Japan, and South Korea. The concentration of medical device and electronics manufacturing in these regions directly correlates with the increased adoption of microinjection molding and extrusion techniques.

Market research indicates that companies are increasingly seeking manufacturing partners with specialized capabilities in micro-manufacturing, with particular emphasis on precision, material compatibility, and production scalability. The ability to work with advanced polymers, metals, and ceramics at the micro scale has become a critical differentiator in supplier selection.

Industry surveys reveal that manufacturers are willing to invest in advanced micro-manufacturing technologies that offer improved part quality, reduced material waste, and enhanced production efficiency. This trend is expected to continue as industries push the boundaries of miniaturization and seek to incorporate more functionality into smaller spaces.

In the medical device industry, the demand for minimally invasive surgical tools, drug delivery systems, and diagnostic equipment has created substantial opportunities for micro-manufacturing processes. The healthcare sector alone accounts for approximately 38% of the total micro-manufacturing market, with microinjection molding being particularly valuable for producing precise, complex medical components with biocompatible materials.

The electronics industry represents another significant market segment, driven by the continuous trend toward device miniaturization and increased functionality. Microinjection molding and micro-extrusion techniques are essential for producing microconnectors, switches, and other intricate components that enable smaller, more powerful electronic devices. This sector contributes roughly 29% to the overall micro-manufacturing market demand.

Consumer preferences for smaller, lighter, and more portable products have further accelerated the adoption of micro-manufacturing processes. The automotive industry has also embraced these technologies for producing sensors, microfluidic components, and other precision parts that enhance vehicle performance and efficiency while reducing weight and size.

Regional analysis indicates that North America and Europe currently lead the market for advanced micro-manufacturing processes, with Asia-Pacific showing the fastest growth rate due to expanding manufacturing capabilities in China, Japan, and South Korea. The concentration of medical device and electronics manufacturing in these regions directly correlates with the increased adoption of microinjection molding and extrusion techniques.

Market research indicates that companies are increasingly seeking manufacturing partners with specialized capabilities in micro-manufacturing, with particular emphasis on precision, material compatibility, and production scalability. The ability to work with advanced polymers, metals, and ceramics at the micro scale has become a critical differentiator in supplier selection.

Industry surveys reveal that manufacturers are willing to invest in advanced micro-manufacturing technologies that offer improved part quality, reduced material waste, and enhanced production efficiency. This trend is expected to continue as industries push the boundaries of miniaturization and seek to incorporate more functionality into smaller spaces.

Current Technical Capabilities and Limitations

Microinjection molding and extrusion techniques represent two distinct manufacturing approaches with specific capabilities and limitations in the production of micro-scale components. Microinjection molding currently achieves feature sizes down to 2-5 micrometers with aspect ratios up to 20:1 under optimal conditions. The technology demonstrates excellent replication fidelity for complex geometries and can maintain dimensional tolerances of ±0.05mm for most engineering polymers. Production cycle times typically range from 5-30 seconds, making it highly efficient for high-volume manufacturing scenarios.

The current material compatibility of microinjection molding encompasses a wide range of thermoplastics, including engineering polymers like PEEK, PEI, and liquid crystal polymers. Recent advancements have enabled processing of ceramic and metal powder-filled feedstocks, though these require additional post-processing steps. Multi-material capabilities have evolved significantly, with two-component microinjection molding now commercially established, allowing for complex functional integration within single components.

Micro-extrusion technology, by comparison, excels in producing continuous profiles with consistent cross-sections. Current capabilities allow for the production of microtubes with wall thicknesses as thin as 10 micrometers and overall diameters down to 150 micrometers. The technology demonstrates superior performance in creating high-precision microchannels and hollow structures that would be challenging for injection approaches.

Material limitations represent significant constraints for both technologies. Microinjection molding struggles with high-viscosity materials and those containing abrasive fillers, which accelerate mold wear. Micro-extrusion faces challenges with materials exhibiting poor melt strength or thermal sensitivity. Both technologies encounter difficulties with biodegradable polymers due to their narrow processing windows and susceptibility to degradation.

Equipment precision constitutes another limitation, with microinjection molding requiring ultra-precise dosing systems capable of shot weights as low as 0.05 grams. Current micro-extrusion systems face challenges in maintaining consistent material flow at extremely low rates, leading to potential variations in final product dimensions. The miniaturization of tooling components also presents significant manufacturing challenges, with both technologies requiring specialized micro-machining capabilities.

Process monitoring represents a persistent limitation, as conventional sensors often lack the sensitivity required for micro-scale operations. Real-time quality control remains challenging, with most systems relying on post-production inspection rather than in-process monitoring. This gap significantly impacts process optimization and quality assurance protocols in high-precision micro-manufacturing environments.

The current material compatibility of microinjection molding encompasses a wide range of thermoplastics, including engineering polymers like PEEK, PEI, and liquid crystal polymers. Recent advancements have enabled processing of ceramic and metal powder-filled feedstocks, though these require additional post-processing steps. Multi-material capabilities have evolved significantly, with two-component microinjection molding now commercially established, allowing for complex functional integration within single components.

Micro-extrusion technology, by comparison, excels in producing continuous profiles with consistent cross-sections. Current capabilities allow for the production of microtubes with wall thicknesses as thin as 10 micrometers and overall diameters down to 150 micrometers. The technology demonstrates superior performance in creating high-precision microchannels and hollow structures that would be challenging for injection approaches.

Material limitations represent significant constraints for both technologies. Microinjection molding struggles with high-viscosity materials and those containing abrasive fillers, which accelerate mold wear. Micro-extrusion faces challenges with materials exhibiting poor melt strength or thermal sensitivity. Both technologies encounter difficulties with biodegradable polymers due to their narrow processing windows and susceptibility to degradation.

Equipment precision constitutes another limitation, with microinjection molding requiring ultra-precise dosing systems capable of shot weights as low as 0.05 grams. Current micro-extrusion systems face challenges in maintaining consistent material flow at extremely low rates, leading to potential variations in final product dimensions. The miniaturization of tooling components also presents significant manufacturing challenges, with both technologies requiring specialized micro-machining capabilities.

Process monitoring represents a persistent limitation, as conventional sensors often lack the sensitivity required for micro-scale operations. Real-time quality control remains challenging, with most systems relying on post-production inspection rather than in-process monitoring. This gap significantly impacts process optimization and quality assurance protocols in high-precision micro-manufacturing environments.

Current Implementation Methods and Process Parameters

01 Microinjection molding techniques for small-scale components

Microinjection molding is a specialized technique for producing very small plastic components with high precision. This process involves injecting polymer materials into micro-sized molds under controlled conditions of temperature and pressure. The technique allows for the production of components with intricate features at the microscale level, which is particularly valuable in industries such as medical devices, electronics, and microfluidics. Advanced microinjection molding systems incorporate precise control mechanisms to ensure dimensional accuracy and surface quality of the molded parts.- Micro-injection molding techniques for small components: Micro-injection molding is a specialized manufacturing process for producing extremely small plastic components with high precision. This technique involves injecting molten polymer material into a mold cavity under controlled conditions to create miniature parts with complex geometries. The process requires specialized equipment capable of handling small shot sizes and maintaining precise temperature and pressure control to ensure dimensional accuracy and surface quality of the final products.

- Extrusion techniques for polymer processing: Extrusion techniques involve forcing polymeric materials through a die to create products with consistent cross-sectional profiles. These techniques are widely used for continuous manufacturing of items such as tubes, pipes, films, and sheets. The process parameters including temperature, pressure, and screw speed significantly influence the quality and properties of the extruded products. Advanced extrusion methods incorporate various modifications to enhance material properties and processing efficiency.

- Innovations in mold design for micro-manufacturing: Advanced mold designs are crucial for successful micro-injection molding and micro-extrusion processes. These innovations include specialized cooling channels, precise venting systems, and optimized gate locations to ensure complete filling of microscale cavities. Mold surface treatments and coatings are employed to improve release characteristics and extend mold life. Computer-aided design and simulation tools help in predicting flow behavior and optimizing mold designs before physical implementation.

- Material considerations for micro-molding applications: The selection of appropriate materials is critical for micro-injection molding and extrusion processes. Materials must possess suitable flow properties to fill microscale features completely while maintaining dimensional stability during cooling. Specialized polymer formulations with additives can enhance processability and final product performance. Biocompatible and biodegradable polymers are increasingly being developed for medical and environmental applications in micro-manufacturing.

- Quality control and precision measurement in micro-manufacturing: Ensuring quality in micro-injection molded and extruded products requires specialized inspection and measurement techniques. Advanced optical and mechanical metrology systems are employed to verify dimensional accuracy and surface quality of microscale features. Statistical process control methods help maintain consistency in production by monitoring critical process parameters. Non-destructive testing approaches are developed to evaluate internal structures and material properties without damaging the small components.

02 Extrusion techniques for polymer processing

Extrusion techniques involve forcing polymer materials through a die to create products with a fixed cross-sectional profile. These techniques are widely used for manufacturing continuous items such as tubes, pipes, films, and sheets. The process typically involves heating the polymer to a molten state, applying pressure to force it through a shaped opening, and then cooling the extruded material to solidify it. Various modifications to the basic extrusion process, including co-extrusion and multi-layer extrusion, allow for the creation of complex products with specific properties and characteristics.Expand Specific Solutions03 Material innovations for microinjection molding and extrusion

Advanced materials play a crucial role in enhancing the performance of microinjection molding and extrusion processes. Specialized polymer blends, composites, and additives are developed to improve flow properties, mechanical strength, thermal stability, and other characteristics required for successful micro-scale manufacturing. These materials often incorporate nanoscale fillers, reinforcing agents, or processing aids to achieve specific performance attributes. Recent innovations include biodegradable polymers, high-performance thermoplastics, and materials with enhanced electrical or thermal conductivity properties specifically designed for microinjection molding and micro-extrusion applications.Expand Specific Solutions04 Equipment and tooling for micro-manufacturing processes

Specialized equipment and tooling are essential for successful microinjection molding and micro-extrusion processes. These include precision micro-molds with high-quality surface finishes, advanced injection units capable of precise dosing of small material volumes, and specialized cooling systems. The equipment often incorporates sophisticated control systems for monitoring and adjusting process parameters in real-time. Innovations in this area include the development of multi-cavity micro-molds, hybrid manufacturing platforms that combine different processes, and equipment with enhanced automation capabilities to improve productivity and consistency in micro-manufacturing operations.Expand Specific Solutions05 Process optimization and quality control in micro-manufacturing

Process optimization and quality control are critical aspects of microinjection molding and micro-extrusion techniques. This involves the development of methodologies for parameter optimization, in-process monitoring, and post-production inspection to ensure consistent product quality. Advanced simulation tools are used to predict material flow behavior and optimize process parameters before actual production. Quality control methods include optical inspection systems, dimensional measurement techniques, and material characterization approaches specifically adapted for micro-scale components. These techniques help to minimize defects, reduce cycle times, and improve the overall efficiency of micro-manufacturing processes.Expand Specific Solutions

Leading Manufacturers and Industry Competitors

The microinjection molding and extrusion techniques market is in a growth phase, with increasing demand across automotive, medical, and consumer electronics sectors. The global market size is estimated to exceed $15 billion, expanding at 6-8% CAGR. Technologically, the field shows varying maturity levels with established players like Husky Injection Molding Systems and Graham Packaging leading commercial applications, while academic institutions (Beijing University of Chemical Technology, South China University of Technology) drive innovation. Companies like BASF, Clariant, and SABIC focus on material advancements, while Flex Ltd. and LG Electronics integrate these technologies into manufacturing processes. The competitive landscape features a mix of specialized equipment manufacturers, material suppliers, and end-users developing proprietary solutions, with increasing collaboration between industry and academia to overcome technical challenges.

Husky Injection Molding Systems Ltd.

Technical Solution: Husky's Ultra SideGate technology represents a significant advancement in microinjection molding, featuring a direct side gating system that eliminates conventional cold runners. This technology utilizes a thermal-insulated nozzle design that maintains optimal melt temperature throughout the injection process, enabling the production of micro-parts with weights as low as 0.05g. The system incorporates precision valve gate technology with gate diameters down to 0.5mm, allowing for exceptional gate quality and dimensional stability. Husky's approach integrates advanced process monitoring with real-time cavity pressure sensors that adjust injection parameters within microseconds, achieving cycle times up to 40% faster than conventional systems while maintaining part quality. Their HyPET HPP5 platform specifically addresses the challenges of microinjection molding through enhanced pressure control capabilities and specialized screw designs that ensure homogeneous melt quality even at extremely low shot weights.

Strengths: Superior gate quality with minimal vestige; exceptional dimensional stability for micro-components; integrated process monitoring capabilities; significantly reduced cycle times. Weaknesses: Higher initial capital investment compared to conventional systems; requires specialized operator training; limited to thermoplastic materials; system complexity may increase maintenance requirements.

Gerresheimer Regensburg GmbH

Technical Solution: Gerresheimer has developed a specialized microinjection molding platform called MicroParts® that focuses on high-precision medical and pharmaceutical components. Their technology utilizes a modular tooling system with interchangeable micro-inserts manufactured through ultra-precision machining with tolerances as tight as ±2μm. The system incorporates a vacuum-assisted mold filling process that eliminates micro-voids and ensures complete filling of features down to 25μm. For comparative analysis with extrusion techniques, Gerresheimer employs a proprietary process simulation framework that evaluates material flow characteristics, cooling dynamics, and resultant part properties across both manufacturing methods. Their microinjection technology features specialized venting systems that allow air evacuation from micro-cavities, significantly reducing defects compared to conventional systems. Gerresheimer's approach includes in-line quality monitoring with high-resolution optical systems capable of detecting defects as small as 10μm, ensuring consistent part quality across production runs. Their comparative analysis has demonstrated that microinjection molding achieves superior dimensional accuracy for complex geometries, while micro-extrusion provides advantages for continuous profiles with consistent cross-sections.

Strengths: Exceptional precision capabilities for medical/pharmaceutical applications; comprehensive validation protocols meeting regulatory requirements; extensive experience with challenging micro-geometries; advanced in-line quality monitoring systems. Weaknesses: Higher tooling costs compared to conventional systems; longer development cycles; primarily focused on medical applications with less experience in other sectors; limited material options due to regulatory constraints in medical applications.

Key Patents and Technical Innovations

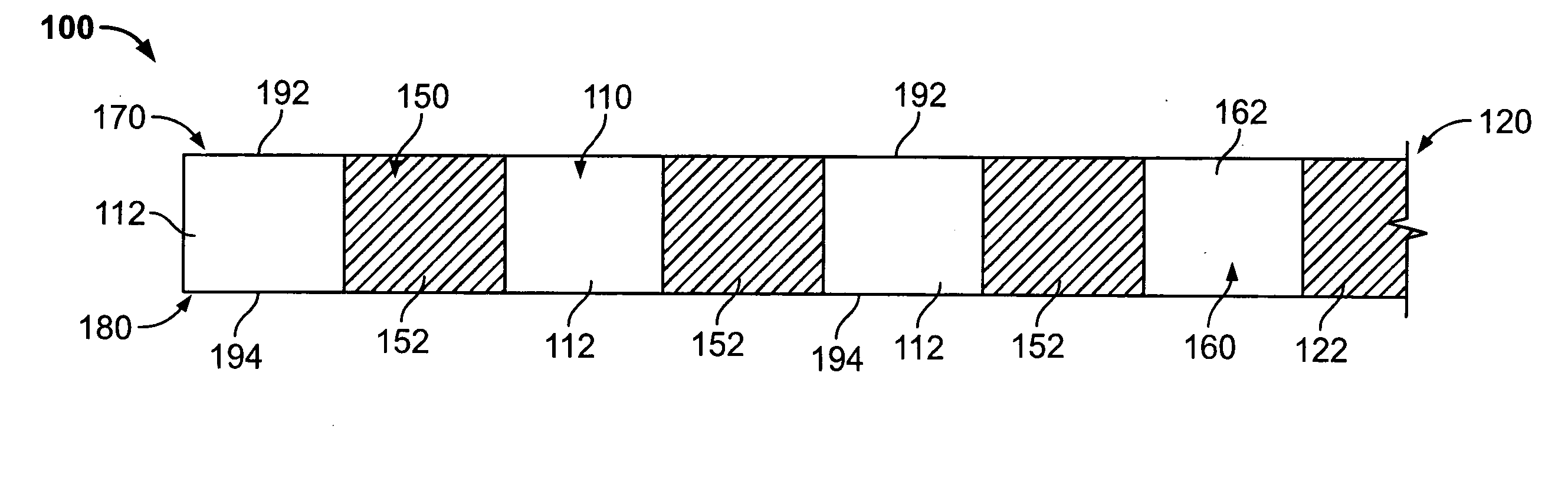

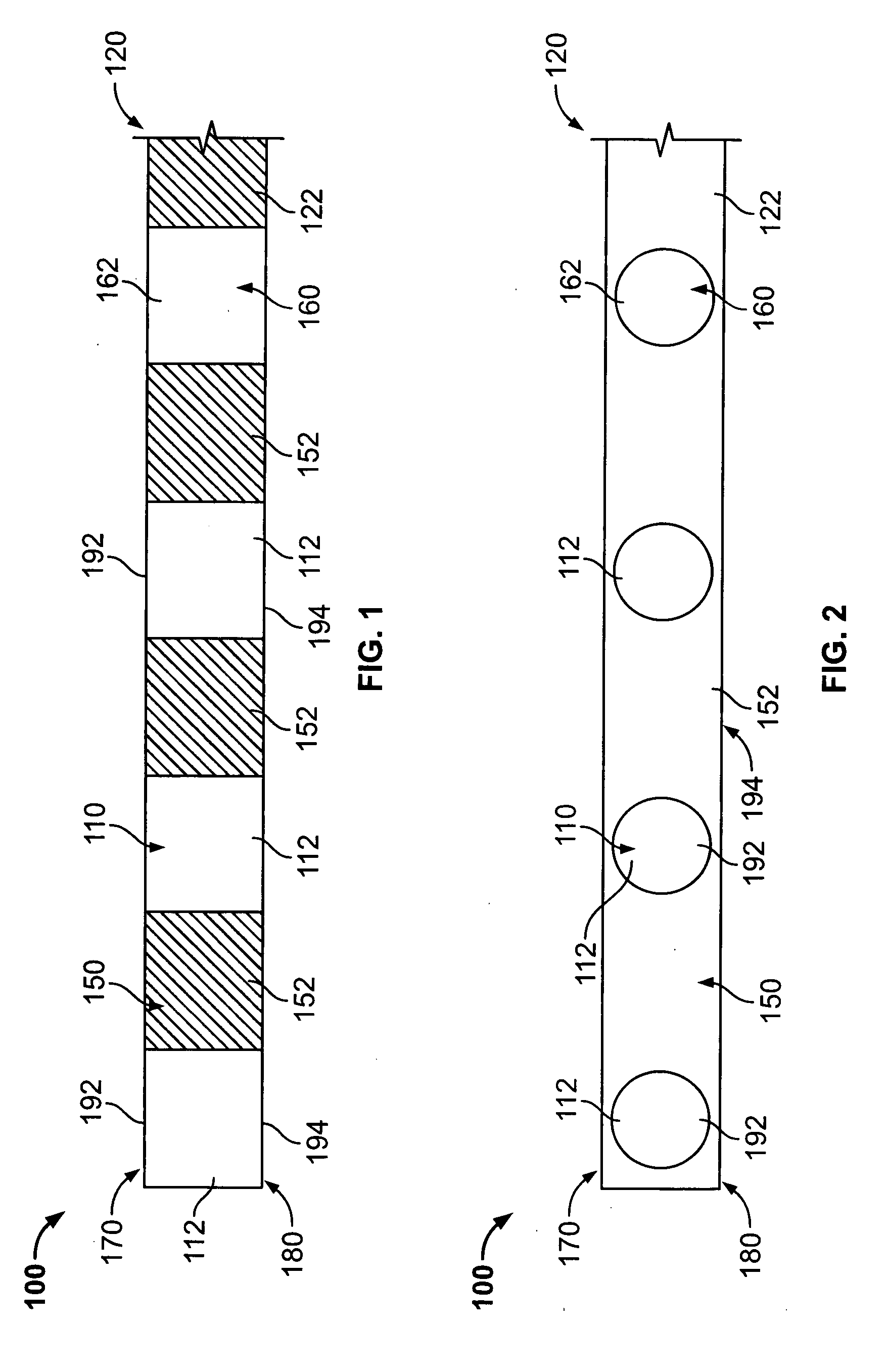

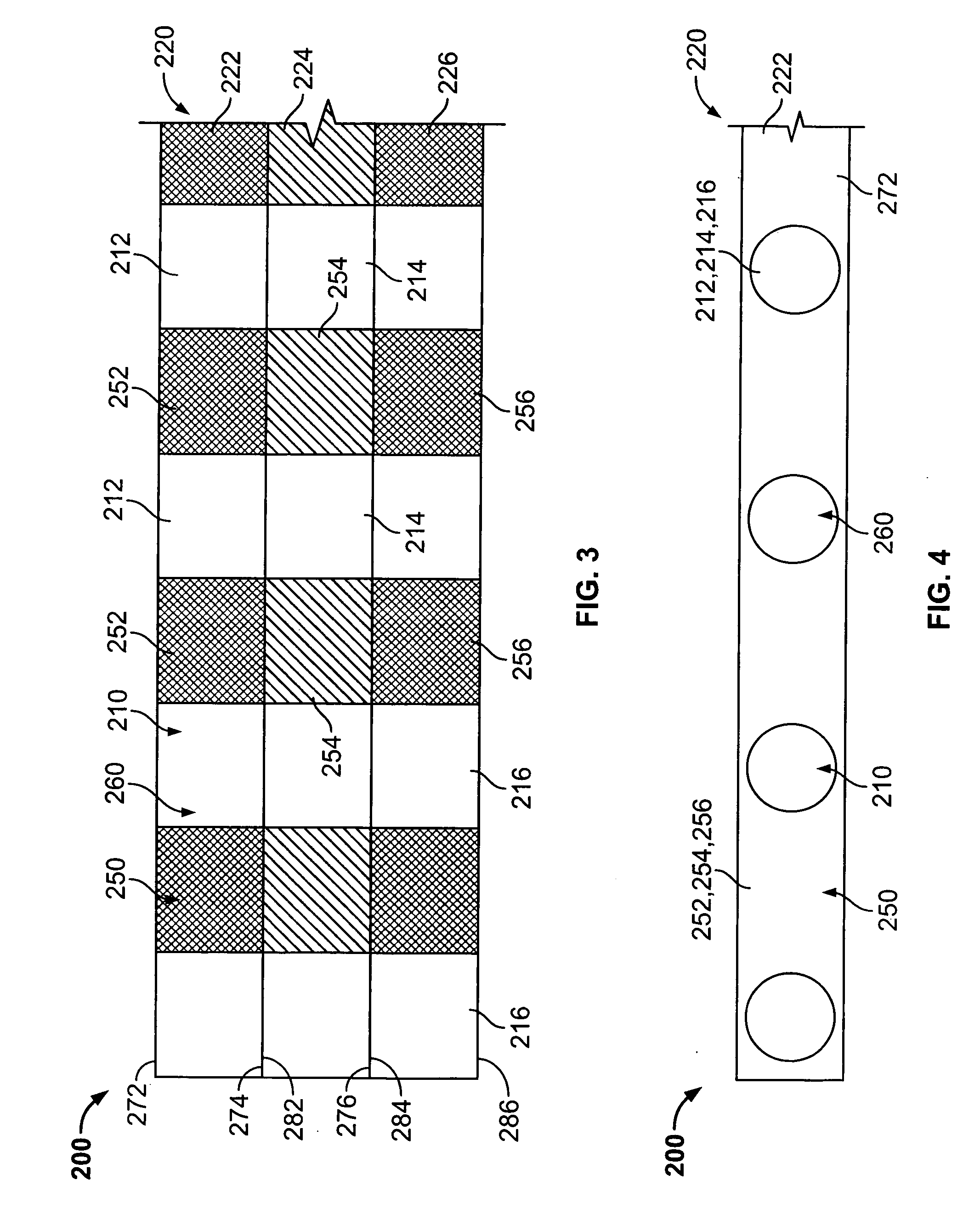

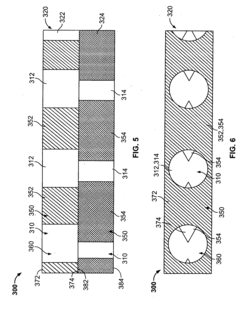

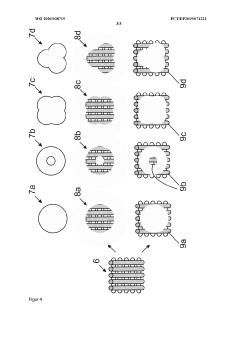

System and method of micromolded filtration microstructure and devices

PatentInactiveUS20070151920A1

Innovation

- The use of injection micromolding technology with advanced tool micro-machining techniques like EDM, MEDM, or laser beam machining to create precise filtration microstructures with a one-shot or multi-shot molding process, allowing for the production of filters with varying channel configurations and rigid structures that maintain consistency and efficiency.

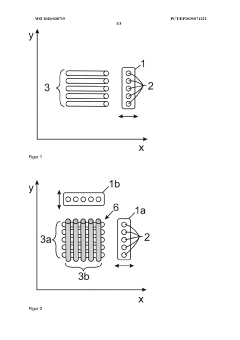

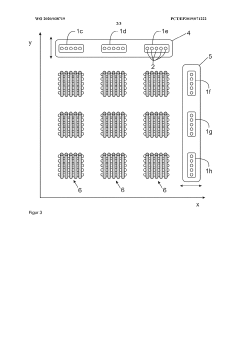

Method for microextrusion of shaped bodies through a plurality of microextrusion nozzles

PatentWO2020038719A1

Innovation

- A microextrusion process using multiple nozzles to build up shaped body precursors in layers, followed by thermal treatment, allowing for the production of macroscopically porous moldings with high geometric surface area and porosity, suitable for large-scale production of catalysts and catalyst supports.

Cost-Benefit Analysis of Production Methods

When evaluating microinjection molding versus extrusion techniques, cost-benefit analysis reveals significant economic implications for manufacturing operations. Initial capital investment differs substantially between these methods, with microinjection molding requiring specialized equipment that typically costs 30-50% more than standard extrusion setups. However, this higher initial outlay must be considered against long-term operational economics.

Material consumption represents a critical cost factor where microinjection molding demonstrates clear advantages. The process typically yields material efficiency rates of 95-98%, compared to extrusion's 85-90% efficiency. For high-value engineering polymers costing $50-200 per kilogram, this efficiency difference translates to substantial savings over production runs, particularly for miniaturized components in medical or electronics applications.

Energy consumption metrics further differentiate these technologies. Microinjection molding operates with shorter cycle times and targeted heating, consuming approximately 0.5-0.8 kWh per kilogram of processed material. Extrusion, while continuous, requires sustained heating throughout the production line, resulting in energy consumption of 0.7-1.2 kWh per kilogram. This 20-30% energy efficiency advantage for microinjection becomes increasingly significant as energy costs rise globally.

Labor requirements and associated costs vary between techniques. Microinjection molding, once properly configured, requires minimal operator intervention during production runs, supporting higher automation levels. Conversely, extrusion processes often demand continuous monitoring and adjustment, increasing labor costs by approximately 15-25% compared to microinjection operations of similar scale.

Production scale economics reveal that microinjection molding becomes increasingly cost-effective for precision components produced in medium to high volumes (50,000+ units). The amortization of tooling costs occurs more rapidly as production volumes increase. Extrusion maintains cost advantages for continuous profile production where dimensional precision requirements are less stringent.

Quality-related costs, including rejection rates and post-processing requirements, favor microinjection molding for complex geometries. Typical defect rates for microinjection molding range from 0.5-2%, versus 2-5% for extrusion of comparable components, reducing waste and rework expenses. This quality differential becomes particularly pronounced when manufacturing components with tight tolerances or complex features.

Material consumption represents a critical cost factor where microinjection molding demonstrates clear advantages. The process typically yields material efficiency rates of 95-98%, compared to extrusion's 85-90% efficiency. For high-value engineering polymers costing $50-200 per kilogram, this efficiency difference translates to substantial savings over production runs, particularly for miniaturized components in medical or electronics applications.

Energy consumption metrics further differentiate these technologies. Microinjection molding operates with shorter cycle times and targeted heating, consuming approximately 0.5-0.8 kWh per kilogram of processed material. Extrusion, while continuous, requires sustained heating throughout the production line, resulting in energy consumption of 0.7-1.2 kWh per kilogram. This 20-30% energy efficiency advantage for microinjection becomes increasingly significant as energy costs rise globally.

Labor requirements and associated costs vary between techniques. Microinjection molding, once properly configured, requires minimal operator intervention during production runs, supporting higher automation levels. Conversely, extrusion processes often demand continuous monitoring and adjustment, increasing labor costs by approximately 15-25% compared to microinjection operations of similar scale.

Production scale economics reveal that microinjection molding becomes increasingly cost-effective for precision components produced in medium to high volumes (50,000+ units). The amortization of tooling costs occurs more rapidly as production volumes increase. Extrusion maintains cost advantages for continuous profile production where dimensional precision requirements are less stringent.

Quality-related costs, including rejection rates and post-processing requirements, favor microinjection molding for complex geometries. Typical defect rates for microinjection molding range from 0.5-2%, versus 2-5% for extrusion of comparable components, reducing waste and rework expenses. This quality differential becomes particularly pronounced when manufacturing components with tight tolerances or complex features.

Sustainability and Environmental Impact Assessment

The environmental impact of manufacturing processes has become a critical consideration in today's industrial landscape. When comparing microinjection molding and extrusion techniques, sustainability metrics reveal significant differences in resource utilization and ecological footprint.

Microinjection molding demonstrates notable advantages in material efficiency, with waste rates typically ranging from 1-3% compared to extrusion's 5-10%. This efficiency stems from the precise metering of material in closed-loop systems, reducing the need for post-processing trimming operations. Additionally, microinjection molding facilities generally consume 15-25% less energy per unit produced due to shorter cycle times and more targeted heating requirements.

Water consumption patterns also differ substantially between these technologies. Extrusion processes often require continuous cooling systems that consume 30-40% more water than comparable microinjection operations. However, extrusion techniques have made significant advances in closed-loop water recycling systems, narrowing this gap in recent years.

Carbon footprint assessments indicate that microinjection molding typically generates 0.8-1.2 kg CO2 equivalent per kilogram of processed polymer, while extrusion processes average 1.1-1.5 kg CO2 equivalent. This difference becomes particularly significant in high-volume production scenarios common in medical device and consumer electronics manufacturing.

End-of-life considerations reveal another dimension of environmental impact. Products manufactured via microinjection molding often contain multiple materials in complex geometries, potentially complicating recycling efforts. Conversely, extruded products typically feature more homogeneous material compositions, facilitating easier material recovery and recycling.

Life Cycle Assessment (LCA) studies comparing these technologies have identified critical hotspots for environmental improvement. For microinjection molding, these include mold manufacturing energy intensity and specialized material formulations. For extrusion, opportunities exist in reducing thermal energy losses and implementing more efficient drive systems.

Regulatory frameworks increasingly influence technology selection, with Extended Producer Responsibility (EPR) schemes and carbon taxation mechanisms favoring processes with lower environmental impacts. Industry certification systems like ISO 14001 and emerging circular economy standards are driving manufacturers to quantify and minimize environmental impacts across production technologies.

Recent innovations in bio-based polymers and biodegradable materials have shown greater compatibility with microinjection molding processes, potentially offering a 30-45% reduction in lifecycle environmental impact compared to traditional petroleum-based polymers in conventional extrusion systems.

Microinjection molding demonstrates notable advantages in material efficiency, with waste rates typically ranging from 1-3% compared to extrusion's 5-10%. This efficiency stems from the precise metering of material in closed-loop systems, reducing the need for post-processing trimming operations. Additionally, microinjection molding facilities generally consume 15-25% less energy per unit produced due to shorter cycle times and more targeted heating requirements.

Water consumption patterns also differ substantially between these technologies. Extrusion processes often require continuous cooling systems that consume 30-40% more water than comparable microinjection operations. However, extrusion techniques have made significant advances in closed-loop water recycling systems, narrowing this gap in recent years.

Carbon footprint assessments indicate that microinjection molding typically generates 0.8-1.2 kg CO2 equivalent per kilogram of processed polymer, while extrusion processes average 1.1-1.5 kg CO2 equivalent. This difference becomes particularly significant in high-volume production scenarios common in medical device and consumer electronics manufacturing.

End-of-life considerations reveal another dimension of environmental impact. Products manufactured via microinjection molding often contain multiple materials in complex geometries, potentially complicating recycling efforts. Conversely, extruded products typically feature more homogeneous material compositions, facilitating easier material recovery and recycling.

Life Cycle Assessment (LCA) studies comparing these technologies have identified critical hotspots for environmental improvement. For microinjection molding, these include mold manufacturing energy intensity and specialized material formulations. For extrusion, opportunities exist in reducing thermal energy losses and implementing more efficient drive systems.

Regulatory frameworks increasingly influence technology selection, with Extended Producer Responsibility (EPR) schemes and carbon taxation mechanisms favoring processes with lower environmental impacts. Industry certification systems like ISO 14001 and emerging circular economy standards are driving manufacturers to quantify and minimize environmental impacts across production technologies.

Recent innovations in bio-based polymers and biodegradable materials have shown greater compatibility with microinjection molding processes, potentially offering a 30-45% reduction in lifecycle environmental impact compared to traditional petroleum-based polymers in conventional extrusion systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!