Comparative Analysis of Vapor Chamber and Microchannel Heat Sinks

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Management Evolution and Objectives

Thermal management technologies have evolved significantly over the past decades, driven by the continuous miniaturization and increasing power density of electronic devices. The journey began with simple heat sinks and fans in the 1960s, progressing through heat pipes in the 1970s, and eventually leading to advanced solutions like vapor chambers and microchannel heat sinks that we see today. This evolution reflects the industry's response to the escalating thermal challenges posed by modern computing and power electronics.

The thermal management landscape has witnessed several paradigm shifts, from passive cooling to active cooling, and from air cooling to liquid cooling systems. Each transition has been necessitated by the limitations of previous technologies to handle the increasing heat flux densities. The thermal design power (TDP) of processors has increased from a few watts to hundreds of watts, while simultaneously shrinking in physical dimensions, creating unprecedented cooling challenges.

Vapor chambers emerged as an extension of heat pipe technology in the 1990s, offering enhanced thermal spreading capabilities through their planar geometry. These devices utilize the phase change of a working fluid to efficiently transport heat from localized sources to larger dissipation areas. Concurrently, microchannel heat sinks developed as a response to the need for more efficient convective heat transfer, particularly in high-performance computing and power electronics applications.

The primary objective of modern thermal management solutions is to maintain electronic components within their operational temperature limits while minimizing the thermal resistance path from the heat source to the ambient environment. For vapor chambers and microchannel heat sinks specifically, the goals include maximizing heat flux handling capability, minimizing thermal resistance, reducing form factor, ensuring reliability over product lifetime, and achieving these while maintaining cost-effectiveness.

Current research aims to push the boundaries of these technologies to address the thermal challenges of next-generation electronics. For vapor chambers, this includes developing ultra-thin profiles, enhancing wick structures, and exploring alternative working fluids. For microchannel heat sinks, efforts focus on optimizing channel geometries, implementing two-phase flow regimes, and integrating advanced manufacturing techniques to create complex microstructures.

The comparative analysis of vapor chambers and microchannel heat sinks represents a critical area of study as industries seek optimal thermal solutions for diverse applications ranging from mobile devices to data centers and from automotive electronics to aerospace systems. Understanding their respective strengths, limitations, and potential synergies is essential for developing integrated thermal management strategies that can meet the demands of future electronic systems.

The thermal management landscape has witnessed several paradigm shifts, from passive cooling to active cooling, and from air cooling to liquid cooling systems. Each transition has been necessitated by the limitations of previous technologies to handle the increasing heat flux densities. The thermal design power (TDP) of processors has increased from a few watts to hundreds of watts, while simultaneously shrinking in physical dimensions, creating unprecedented cooling challenges.

Vapor chambers emerged as an extension of heat pipe technology in the 1990s, offering enhanced thermal spreading capabilities through their planar geometry. These devices utilize the phase change of a working fluid to efficiently transport heat from localized sources to larger dissipation areas. Concurrently, microchannel heat sinks developed as a response to the need for more efficient convective heat transfer, particularly in high-performance computing and power electronics applications.

The primary objective of modern thermal management solutions is to maintain electronic components within their operational temperature limits while minimizing the thermal resistance path from the heat source to the ambient environment. For vapor chambers and microchannel heat sinks specifically, the goals include maximizing heat flux handling capability, minimizing thermal resistance, reducing form factor, ensuring reliability over product lifetime, and achieving these while maintaining cost-effectiveness.

Current research aims to push the boundaries of these technologies to address the thermal challenges of next-generation electronics. For vapor chambers, this includes developing ultra-thin profiles, enhancing wick structures, and exploring alternative working fluids. For microchannel heat sinks, efforts focus on optimizing channel geometries, implementing two-phase flow regimes, and integrating advanced manufacturing techniques to create complex microstructures.

The comparative analysis of vapor chambers and microchannel heat sinks represents a critical area of study as industries seek optimal thermal solutions for diverse applications ranging from mobile devices to data centers and from automotive electronics to aerospace systems. Understanding their respective strengths, limitations, and potential synergies is essential for developing integrated thermal management strategies that can meet the demands of future electronic systems.

Market Demand for Advanced Cooling Solutions

The global market for advanced thermal management solutions is experiencing unprecedented growth, driven primarily by the rapid evolution of high-performance computing systems, data centers, and consumer electronics. Current market research indicates that the thermal management market is projected to reach $22.6 billion by 2027, with cooling solutions for electronics representing the largest segment. This growth trajectory is particularly relevant for vapor chamber and microchannel heat sink technologies, which are increasingly becoming critical components in managing thermal challenges.

Consumer electronics, particularly smartphones and gaming laptops, represent a significant demand driver for advanced cooling solutions. As devices become thinner while processing capabilities increase, manufacturers are facing critical thermal constraints that traditional cooling methods cannot adequately address. Vapor chambers, with their ultra-thin profile and superior heat spreading capabilities, have seen adoption rates increase by approximately 35% annually in premium smartphone models since 2019.

The data center sector presents perhaps the most compelling market opportunity for advanced cooling technologies. With global data center power consumption expected to reach 8% of total worldwide electricity by 2030, cooling efficiency has become both an economic and environmental imperative. Microchannel heat sinks, with their ability to handle high heat flux densities, are increasingly being integrated into server cooling solutions, with implementation growing at 28% annually.

Automotive electronics, particularly in electric vehicles (EVs) and autonomous driving systems, represent an emerging but rapidly expanding market segment. Battery thermal management systems in EVs require sophisticated cooling solutions to maintain optimal operating temperatures, with the market for these systems growing at 24% annually. Both vapor chambers and microchannel technologies are being evaluated for next-generation vehicle thermal management systems.

Industrial applications, including power electronics, telecommunications infrastructure, and medical devices, collectively account for approximately 18% of the current advanced cooling solutions market. These sectors value reliability and longevity alongside thermal performance, creating distinct requirements compared to consumer electronics applications.

Geographically, Asia-Pacific represents the largest market for advanced cooling technologies, accounting for 42% of global demand, followed by North America (28%) and Europe (22%). This distribution closely follows manufacturing centers for electronics and data center deployments. Notably, China has emerged as both the largest consumer and producer of vapor chamber technology, while North America leads in microchannel cooling research and implementation for high-performance computing applications.

Consumer electronics, particularly smartphones and gaming laptops, represent a significant demand driver for advanced cooling solutions. As devices become thinner while processing capabilities increase, manufacturers are facing critical thermal constraints that traditional cooling methods cannot adequately address. Vapor chambers, with their ultra-thin profile and superior heat spreading capabilities, have seen adoption rates increase by approximately 35% annually in premium smartphone models since 2019.

The data center sector presents perhaps the most compelling market opportunity for advanced cooling technologies. With global data center power consumption expected to reach 8% of total worldwide electricity by 2030, cooling efficiency has become both an economic and environmental imperative. Microchannel heat sinks, with their ability to handle high heat flux densities, are increasingly being integrated into server cooling solutions, with implementation growing at 28% annually.

Automotive electronics, particularly in electric vehicles (EVs) and autonomous driving systems, represent an emerging but rapidly expanding market segment. Battery thermal management systems in EVs require sophisticated cooling solutions to maintain optimal operating temperatures, with the market for these systems growing at 24% annually. Both vapor chambers and microchannel technologies are being evaluated for next-generation vehicle thermal management systems.

Industrial applications, including power electronics, telecommunications infrastructure, and medical devices, collectively account for approximately 18% of the current advanced cooling solutions market. These sectors value reliability and longevity alongside thermal performance, creating distinct requirements compared to consumer electronics applications.

Geographically, Asia-Pacific represents the largest market for advanced cooling technologies, accounting for 42% of global demand, followed by North America (28%) and Europe (22%). This distribution closely follows manufacturing centers for electronics and data center deployments. Notably, China has emerged as both the largest consumer and producer of vapor chamber technology, while North America leads in microchannel cooling research and implementation for high-performance computing applications.

Current State and Challenges in Heat Dissipation Technologies

Heat dissipation technologies have evolved significantly over the past decades, with vapor chambers and microchannel heat sinks emerging as two prominent solutions for thermal management in high-performance electronic devices. Currently, the global thermal management market is valued at approximately $12.8 billion and is projected to reach $22.1 billion by 2026, driven by increasing power densities in electronic components and the miniaturization trend across industries.

Vapor chamber technology has matured considerably, with widespread adoption in consumer electronics, particularly in ultra-thin laptops and smartphones. These devices utilize a flattened heat pipe design that spreads heat horizontally across a larger surface area before transferring it to heat sinks. The current generation of vapor chambers can achieve thermal conductivities of 1,000-5,000 W/m·K, significantly outperforming solid copper (400 W/m·K) in lateral heat spreading applications.

Microchannel heat sinks, conversely, have gained traction in high-performance computing and data center applications. These structures feature small channels (typically 10-1000 μm) through which coolant flows, enabling direct heat removal from hotspots. Recent advancements have pushed cooling capacities to exceed 500 W/cm², making them suitable for next-generation semiconductor devices with extreme heat fluxes.

Despite these advancements, both technologies face significant challenges. For vapor chambers, the primary limitations include thickness constraints (minimum practical thickness of approximately 0.3mm), manufacturing complexity for complex geometries, and performance degradation over time due to working fluid loss. Additionally, vapor chambers exhibit diminishing returns at extreme heat fluxes exceeding 300 W/cm², where the internal wick structure can experience dry-out phenomena.

Microchannel heat sinks confront challenges related to pressure drop requirements, flow distribution uniformity, and manufacturing precision. The narrow channels necessitate high pumping power, with pressure drops often exceeding 50 kPa for high-performance applications. Furthermore, clogging risks and corrosion concerns limit the long-term reliability of these systems, particularly in industrial environments.

Geographically, thermal management technology development shows distinct patterns. North America and Europe lead in research and intellectual property for advanced cooling solutions, while Asia-Pacific dominates manufacturing capacity, particularly for vapor chambers. Japan maintains leadership in high-precision microchannel fabrication techniques, while China has rapidly expanded production capabilities for conventional heat dissipation technologies.

The integration of these cooling technologies with emerging materials presents another frontier. Graphene-enhanced vapor chambers and diamond-copper composite microchannel heat sinks have demonstrated promising results in laboratory settings but face commercialization hurdles related to cost and scalable manufacturing processes. Similarly, the application of nanofluids in microchannel systems shows potential for enhanced heat transfer but requires further development to address stability and reliability concerns.

Vapor chamber technology has matured considerably, with widespread adoption in consumer electronics, particularly in ultra-thin laptops and smartphones. These devices utilize a flattened heat pipe design that spreads heat horizontally across a larger surface area before transferring it to heat sinks. The current generation of vapor chambers can achieve thermal conductivities of 1,000-5,000 W/m·K, significantly outperforming solid copper (400 W/m·K) in lateral heat spreading applications.

Microchannel heat sinks, conversely, have gained traction in high-performance computing and data center applications. These structures feature small channels (typically 10-1000 μm) through which coolant flows, enabling direct heat removal from hotspots. Recent advancements have pushed cooling capacities to exceed 500 W/cm², making them suitable for next-generation semiconductor devices with extreme heat fluxes.

Despite these advancements, both technologies face significant challenges. For vapor chambers, the primary limitations include thickness constraints (minimum practical thickness of approximately 0.3mm), manufacturing complexity for complex geometries, and performance degradation over time due to working fluid loss. Additionally, vapor chambers exhibit diminishing returns at extreme heat fluxes exceeding 300 W/cm², where the internal wick structure can experience dry-out phenomena.

Microchannel heat sinks confront challenges related to pressure drop requirements, flow distribution uniformity, and manufacturing precision. The narrow channels necessitate high pumping power, with pressure drops often exceeding 50 kPa for high-performance applications. Furthermore, clogging risks and corrosion concerns limit the long-term reliability of these systems, particularly in industrial environments.

Geographically, thermal management technology development shows distinct patterns. North America and Europe lead in research and intellectual property for advanced cooling solutions, while Asia-Pacific dominates manufacturing capacity, particularly for vapor chambers. Japan maintains leadership in high-precision microchannel fabrication techniques, while China has rapidly expanded production capabilities for conventional heat dissipation technologies.

The integration of these cooling technologies with emerging materials presents another frontier. Graphene-enhanced vapor chambers and diamond-copper composite microchannel heat sinks have demonstrated promising results in laboratory settings but face commercialization hurdles related to cost and scalable manufacturing processes. Similarly, the application of nanofluids in microchannel systems shows potential for enhanced heat transfer but requires further development to address stability and reliability concerns.

Technical Comparison of Vapor Chamber and Microchannel Designs

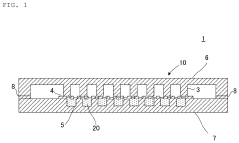

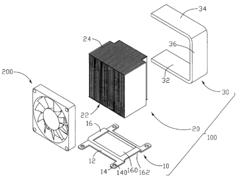

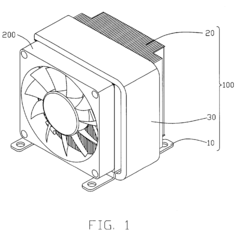

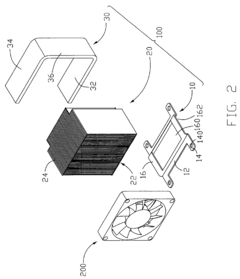

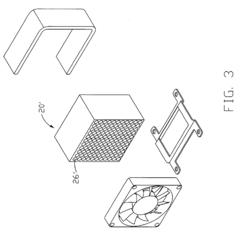

01 Vapor chamber design and structure for enhanced thermal performance

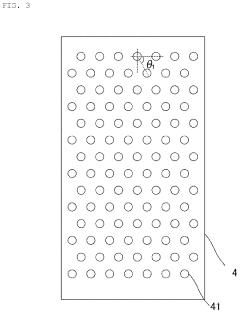

Vapor chambers are designed with specific internal structures to optimize thermal performance. These designs include specialized wick structures, vapor flow channels, and condensation surfaces that facilitate efficient heat transfer. The chambers can be configured with varying thicknesses, materials, and internal geometries to maximize heat spreading capabilities and minimize thermal resistance, making them effective for high-heat-flux applications in electronic devices.- Vapor chamber design and structure for enhanced thermal performance: Vapor chambers are designed with specific internal structures to optimize heat transfer. These designs include specialized wick structures, vapor flow channels, and condensation surfaces that facilitate efficient phase change heat transfer. The chambers can be configured in various shapes and thicknesses to accommodate different application requirements, with some designs incorporating multiple chambers or hybrid structures to maximize thermal performance.

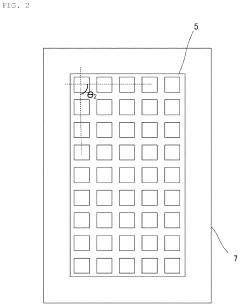

- Microchannel heat sink configurations for improved cooling: Microchannel heat sinks utilize small channels to increase surface area for heat dissipation. These channels can be designed with varying geometries, dimensions, and patterns to optimize fluid flow and heat transfer. Advanced configurations include tapered channels, bifurcating structures, and variable cross-sections that reduce pressure drop while maximizing thermal performance. The channel design significantly impacts cooling efficiency in high heat flux applications.

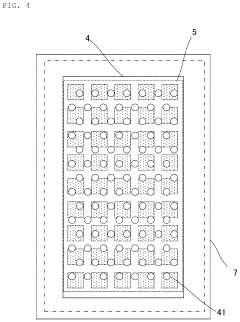

- Integration of vapor chambers with microchannel heat sinks: Combining vapor chambers with microchannel heat sinks creates hybrid cooling solutions that leverage the advantages of both technologies. The vapor chamber spreads heat across a larger area, while the microchannels provide efficient heat dissipation to the cooling medium. This integration enables more uniform temperature distribution and reduces thermal resistance in high-power electronic devices. Various attachment methods and interface materials are used to minimize contact resistance between components.

- Working fluid selection and optimization for two-phase cooling systems: The selection of appropriate working fluids is critical for vapor chamber and microchannel heat sink performance. Factors considered include thermophysical properties, operating temperature range, compatibility with chamber materials, and environmental impact. Advanced systems may use engineered fluids, nanofluids, or fluid mixtures to enhance heat transfer coefficients and phase change efficiency. The fluid charging process and volume are also optimized to ensure proper operation across varying thermal loads.

- Manufacturing techniques and materials for thermal management devices: Advanced manufacturing methods are employed to produce high-performance vapor chambers and microchannel heat sinks. These include precision machining, additive manufacturing, chemical etching, and bonding technologies that enable complex internal structures. Material selection focuses on high thermal conductivity metals like copper and aluminum, with some designs incorporating composite materials or surface treatments to enhance wettability and heat transfer. Manufacturing considerations also address cost-effectiveness, reliability, and scalability for mass production.

02 Microchannel heat sink configurations for improved cooling

Microchannel heat sinks utilize small channels to increase surface area for heat dissipation. Various configurations of microchannels, including different cross-sectional shapes, dimensions, and arrangements, can significantly impact cooling efficiency. Advanced designs incorporate optimized channel width-to-height ratios, variable channel geometries, and strategic flow distributions to reduce thermal resistance and pressure drop, thereby enhancing overall thermal performance in compact cooling systems.Expand Specific Solutions03 Integration of vapor chambers with microchannel heat sinks

Combining vapor chambers with microchannel heat sinks creates hybrid thermal management systems with superior performance. The vapor chamber efficiently spreads heat across a larger area, while the microchannel structure provides enhanced convective heat transfer. This integration allows for more uniform temperature distribution, reduced hotspots, and improved overall thermal efficiency, particularly beneficial for high-power density applications like processors, power electronics, and LED lighting systems.Expand Specific Solutions04 Advanced materials and manufacturing techniques for thermal solutions

Novel materials and manufacturing processes significantly enhance the performance of vapor chambers and microchannel heat sinks. Advanced materials with high thermal conductivity, such as copper alloys, aluminum composites, and sintered metal powders, improve heat transfer efficiency. Innovative manufacturing techniques, including additive manufacturing, selective laser sintering, and precision machining, enable the creation of complex internal structures and optimized surface features that were previously impossible to produce, resulting in superior thermal performance.Expand Specific Solutions05 Working fluid selection and two-phase heat transfer optimization

The selection of appropriate working fluids and optimization of two-phase heat transfer mechanisms are crucial for vapor chamber and microchannel heat sink performance. Different working fluids, including water, refrigerants, and engineered nanofluids, offer varying thermal properties that can be matched to specific application requirements. Optimizing phase change processes, flow rates, and pressure conditions enhances heat absorption, transport, and dissipation capabilities, resulting in more efficient thermal management systems for electronic cooling applications.Expand Specific Solutions

Key Manufacturers and Research Institutions in Cooling Industry

The vapor chamber and microchannel heat sink technology market is currently in a growth phase, with an estimated global thermal management market size exceeding $10 billion. Samsung Electronics, Delta Electronics, and Murata Manufacturing lead the commercial sector with advanced thermal solutions for electronics cooling applications. Academic institutions like Tsinghua University, Purdue Research Foundation, and University of Maryland are driving fundamental research innovations. The technology maturity varies by application: vapor chambers are well-established in consumer electronics, while microchannel solutions are advancing rapidly for high-performance computing and automotive applications. Companies like Gree Electric, Haier Smart Home, and Carrier are expanding implementation in HVAC systems, while Ciena and II-VI Delaware focus on telecommunications thermal management solutions, indicating cross-industry adoption potential.

Purdue Research Foundation

Technical Solution: Purdue Research Foundation, through its Cooling Technologies Research Center, has developed sophisticated comparative analysis frameworks for vapor chamber and microchannel heat sink technologies. Their approach combines high-fidelity experimental characterization with advanced multi-physics modeling to evaluate performance across diverse operating conditions. Purdue's research has quantified the thermal performance boundaries of both technologies, demonstrating that vapor chambers provide optimal performance for heat loads below 200 W with spreading requirements, while microchannels excel at dissipating concentrated heat fluxes exceeding 500 W/cm². Their comparative analysis includes transient response characterization, showing that microchannels can respond to thermal load changes up to 40% faster than vapor chambers due to lower thermal mass. Purdue has also pioneered novel visualization techniques to directly observe the internal working mechanisms of vapor chambers, correlating wick structure parameters with thermal performance. Their research extends to reliability considerations, with accelerated life testing protocols that evaluate performance degradation under thermal cycling and various orientations, providing valuable insights for technology selection in applications with varying reliability requirements.

Strengths: World-class research facilities specifically focused on thermal management; strong industry partnerships for practical validation. Weaknesses: Academic research focus may sometimes prioritize novel concepts over immediate commercial applicability; research outcomes may require further development for direct industrial implementation.

Tsinghua University

Technical Solution: Tsinghua University has conducted extensive comparative research on vapor chamber and microchannel heat sink technologies through their State Key Laboratory of Thermal Science. Their methodological approach combines multi-scale modeling with advanced visualization techniques to understand the fundamental heat transfer mechanisms in both technologies. Their research has revealed that vapor chambers achieve 25-30% better thermal spreading for large area cooling but suffer from performance limitations at heat fluxes exceeding 500 W/cm². In contrast, their optimized microchannel designs demonstrate superior performance at high heat fluxes, achieving thermal resistances below 0.1 K/W for concentrated heat sources. Tsinghua's comparative analysis framework incorporates manufacturing precision requirements, showing that microchannel performance is more sensitive to fabrication tolerances, with channel width variations of ±10μm potentially causing up to 15% performance degradation. They've also pioneered novel performance metrics that account for pumping power requirements in microchannels versus the passive operation of vapor chambers, providing a more comprehensive comparison basis for system designers.

Strengths: Cutting-edge fundamental research capabilities; access to advanced fabrication and characterization facilities. Weaknesses: Some research may prioritize theoretical advancements over practical implementation considerations; geographic distance from Western markets may limit collaboration opportunities.

Critical Patents and Research in Advanced Heat Sink Technologies

Vapor chamber

PatentActiveUS11473850B2

Innovation

- The vapor chamber incorporates a microchannel with a concavo-convex shape and a wick with specific area ratios and dimensions, ensuring a 5% to 40% contact area between the wick and microchannel, and optimized dimensions for the wick thickness and microchannel opening width to prevent wick sinking and enhance heat conduction.

Vapor chamber heat sink

PatentInactiveUS7699094B2

Innovation

- A vapor chamber heat sink with a U-shaped, flat-type heat pipe that enhances contact area and thermal conductive speed by having a plate-type lower portion contacting the base and fins, and a plate-type upper portion contacting the electronic component, along with a connecting portion to interconnect these, ensuring a wide contact surface for improved heat transfer.

Material Science Advancements for Thermal Solutions

Recent advancements in material science have significantly transformed thermal management solutions, particularly for high-performance electronic devices. The development of novel materials with enhanced thermal conductivity properties has revolutionized both vapor chamber and microchannel heat sink technologies. These innovations address the growing thermal challenges posed by increasingly powerful and compact electronic components.

Copper has traditionally dominated thermal solution materials due to its excellent thermal conductivity (approximately 400 W/m·K). However, newer composite materials incorporating graphene, carbon nanotubes, and diamond particles have demonstrated thermal conductivity values exceeding 1500 W/m·K in laboratory settings. These materials, when applied to vapor chamber wick structures, have shown up to 35% improvement in heat dissipation capacity compared to conventional copper wicks.

For microchannel heat sinks, the introduction of aluminum-graphene composites has enabled the creation of more intricate channel geometries while maintaining structural integrity under high-pressure coolant flow. These composites offer 25-40% weight reduction compared to copper alternatives while providing comparable thermal performance, making them particularly valuable for mobile and aerospace applications where weight considerations are paramount.

Surface coating technologies have also evolved significantly, with hydrophilic and hydrophobic coatings strategically applied to enhance fluid dynamics within both thermal solutions. In vapor chambers, specialized nano-coatings have improved capillary action and reduced the risk of dry-out conditions at high heat loads. For microchannels, anti-fouling coatings have extended operational lifespans by minimizing mineral deposits and biological growth that typically impede thermal performance over time.

Additive manufacturing techniques have enabled previously impossible material structures, including gradient-density wicks for vapor chambers and complex three-dimensional microchannel geometries that optimize fluid flow patterns. These manufacturing advances allow for application-specific customization of thermal solutions rather than relying on one-size-fits-all approaches.

Phase change materials (PCMs) integrated into thermal solution designs represent another frontier in material science advancement. These materials absorb and release thermal energy during phase transitions, effectively buffering temperature spikes in high-performance computing applications. When combined with traditional vapor chamber or microchannel technologies, PCMs can reduce thermal cycling and improve component reliability under variable load conditions.

Copper has traditionally dominated thermal solution materials due to its excellent thermal conductivity (approximately 400 W/m·K). However, newer composite materials incorporating graphene, carbon nanotubes, and diamond particles have demonstrated thermal conductivity values exceeding 1500 W/m·K in laboratory settings. These materials, when applied to vapor chamber wick structures, have shown up to 35% improvement in heat dissipation capacity compared to conventional copper wicks.

For microchannel heat sinks, the introduction of aluminum-graphene composites has enabled the creation of more intricate channel geometries while maintaining structural integrity under high-pressure coolant flow. These composites offer 25-40% weight reduction compared to copper alternatives while providing comparable thermal performance, making them particularly valuable for mobile and aerospace applications where weight considerations are paramount.

Surface coating technologies have also evolved significantly, with hydrophilic and hydrophobic coatings strategically applied to enhance fluid dynamics within both thermal solutions. In vapor chambers, specialized nano-coatings have improved capillary action and reduced the risk of dry-out conditions at high heat loads. For microchannels, anti-fouling coatings have extended operational lifespans by minimizing mineral deposits and biological growth that typically impede thermal performance over time.

Additive manufacturing techniques have enabled previously impossible material structures, including gradient-density wicks for vapor chambers and complex three-dimensional microchannel geometries that optimize fluid flow patterns. These manufacturing advances allow for application-specific customization of thermal solutions rather than relying on one-size-fits-all approaches.

Phase change materials (PCMs) integrated into thermal solution designs represent another frontier in material science advancement. These materials absorb and release thermal energy during phase transitions, effectively buffering temperature spikes in high-performance computing applications. When combined with traditional vapor chamber or microchannel technologies, PCMs can reduce thermal cycling and improve component reliability under variable load conditions.

Environmental Impact and Sustainability Considerations

The environmental impact of thermal management solutions has become increasingly important as industries strive for sustainability. Vapor chambers and microchannel heat sinks present different environmental profiles throughout their lifecycle, from manufacturing to disposal.

Manufacturing vapor chambers typically involves copper or aluminum materials, with internal working fluids that may include water, methanol, or other refrigerants. Some of these working fluids can have significant global warming potential (GWP) if released into the atmosphere. The production process also requires precision manufacturing techniques that consume considerable energy. Conversely, microchannel heat sinks generally utilize simpler manufacturing processes with potentially lower energy requirements, though the precision machining of microchannels can still be resource-intensive.

Operational efficiency represents a critical environmental consideration. Microchannel heat sinks often demonstrate superior thermal performance per unit volume, potentially reducing the overall material footprint in electronic devices. However, they typically require pumping mechanisms that consume additional energy during operation. Vapor chambers operate passively without external power requirements for fluid circulation, potentially offering lower operational carbon footprints in certain applications.

Longevity and reliability factors significantly impact sustainability. Vapor chambers may experience performance degradation over time due to non-condensable gas generation or working fluid depletion. Microchannels, while less prone to these specific issues, can suffer from clogging or corrosion depending on the cooling fluid used. Longer-lasting solutions reduce replacement frequency and associated environmental impacts.

End-of-life considerations reveal that vapor chambers present recycling challenges due to their sealed construction and mixed materials, including working fluids that may require special handling. Microchannel heat sinks, particularly those made from single materials like aluminum or copper, potentially offer more straightforward recycling pathways.

Water usage represents another important environmental metric. Liquid-cooled microchannel systems may require periodic fluid replacement and can pose water consumption concerns in large-scale deployments such as data centers. Vapor chambers, once charged, typically do not require fluid replenishment during their operational lifetime.

Recent sustainability innovations include the development of bio-based working fluids for vapor chambers and more energy-efficient manufacturing processes for both technologies. Additionally, design approaches focusing on material reduction and improved recyclability are emerging as manufacturers respond to growing environmental regulations and corporate sustainability goals.

Manufacturing vapor chambers typically involves copper or aluminum materials, with internal working fluids that may include water, methanol, or other refrigerants. Some of these working fluids can have significant global warming potential (GWP) if released into the atmosphere. The production process also requires precision manufacturing techniques that consume considerable energy. Conversely, microchannel heat sinks generally utilize simpler manufacturing processes with potentially lower energy requirements, though the precision machining of microchannels can still be resource-intensive.

Operational efficiency represents a critical environmental consideration. Microchannel heat sinks often demonstrate superior thermal performance per unit volume, potentially reducing the overall material footprint in electronic devices. However, they typically require pumping mechanisms that consume additional energy during operation. Vapor chambers operate passively without external power requirements for fluid circulation, potentially offering lower operational carbon footprints in certain applications.

Longevity and reliability factors significantly impact sustainability. Vapor chambers may experience performance degradation over time due to non-condensable gas generation or working fluid depletion. Microchannels, while less prone to these specific issues, can suffer from clogging or corrosion depending on the cooling fluid used. Longer-lasting solutions reduce replacement frequency and associated environmental impacts.

End-of-life considerations reveal that vapor chambers present recycling challenges due to their sealed construction and mixed materials, including working fluids that may require special handling. Microchannel heat sinks, particularly those made from single materials like aluminum or copper, potentially offer more straightforward recycling pathways.

Water usage represents another important environmental metric. Liquid-cooled microchannel systems may require periodic fluid replacement and can pose water consumption concerns in large-scale deployments such as data centers. Vapor chambers, once charged, typically do not require fluid replenishment during their operational lifetime.

Recent sustainability innovations include the development of bio-based working fluids for vapor chambers and more energy-efficient manufacturing processes for both technologies. Additionally, design approaches focusing on material reduction and improved recyclability are emerging as manufacturers respond to growing environmental regulations and corporate sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!