Comparative Study of Microfluidics and Nanofluidics for Control

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidics and Nanofluidics Control Background and Objectives

Microfluidics and nanofluidics represent revolutionary approaches to fluid manipulation at microscale and nanoscale dimensions, respectively. The evolution of these technologies traces back to the early 1990s when microfluidics emerged as a distinct field, followed by nanofluidics in the early 2000s as fabrication techniques advanced to accommodate nanometer-scale channels. These technologies have progressively transformed from academic curiosities to practical tools with applications spanning healthcare, environmental monitoring, and advanced manufacturing.

The technological trajectory has been characterized by significant milestones, including the development of lab-on-a-chip devices, organ-on-chip platforms, and increasingly sophisticated flow control mechanisms. Recent advancements have focused on integrating multiple functionalities into single platforms, enhancing precision control, and developing novel materials compatible with biological samples and harsh chemical environments.

Current research trends indicate a convergence of microfluidics and nanofluidics with complementary technologies such as artificial intelligence, advanced sensing, and novel fabrication methods. This integration is driving innovation in areas such as point-of-care diagnostics, personalized medicine, and high-throughput screening applications.

The fundamental physical principles governing fluid behavior change dramatically when transitioning from micro to nano scales. While microfluidic systems primarily operate in laminar flow regimes where viscous forces dominate, nanofluidic systems encounter additional phenomena including surface charge effects, electrokinetic transport, and molecular interactions that significantly influence fluid behavior.

This comparative study aims to systematically analyze control mechanisms across both microfluidic and nanofluidic domains, identifying their respective advantages, limitations, and optimal application scenarios. The technical objectives include establishing quantitative performance metrics for various control strategies, developing predictive models for fluid behavior across different scales, and formulating design principles for hybrid micro-nano systems.

Additionally, this research seeks to address critical challenges including precise flow control at nanoscale dimensions, minimizing surface interaction effects, reducing fabrication complexity, and enhancing system reliability for commercial applications. By comprehensively examining both domains, we aim to identify synergistic approaches that leverage the strengths of each technology while mitigating their individual limitations.

The ultimate goal is to establish a unified framework for understanding and implementing control strategies across the micro-to-nano continuum, enabling next-generation fluidic systems with unprecedented precision, functionality, and applicability across diverse scientific and industrial domains.

The technological trajectory has been characterized by significant milestones, including the development of lab-on-a-chip devices, organ-on-chip platforms, and increasingly sophisticated flow control mechanisms. Recent advancements have focused on integrating multiple functionalities into single platforms, enhancing precision control, and developing novel materials compatible with biological samples and harsh chemical environments.

Current research trends indicate a convergence of microfluidics and nanofluidics with complementary technologies such as artificial intelligence, advanced sensing, and novel fabrication methods. This integration is driving innovation in areas such as point-of-care diagnostics, personalized medicine, and high-throughput screening applications.

The fundamental physical principles governing fluid behavior change dramatically when transitioning from micro to nano scales. While microfluidic systems primarily operate in laminar flow regimes where viscous forces dominate, nanofluidic systems encounter additional phenomena including surface charge effects, electrokinetic transport, and molecular interactions that significantly influence fluid behavior.

This comparative study aims to systematically analyze control mechanisms across both microfluidic and nanofluidic domains, identifying their respective advantages, limitations, and optimal application scenarios. The technical objectives include establishing quantitative performance metrics for various control strategies, developing predictive models for fluid behavior across different scales, and formulating design principles for hybrid micro-nano systems.

Additionally, this research seeks to address critical challenges including precise flow control at nanoscale dimensions, minimizing surface interaction effects, reducing fabrication complexity, and enhancing system reliability for commercial applications. By comprehensively examining both domains, we aim to identify synergistic approaches that leverage the strengths of each technology while mitigating their individual limitations.

The ultimate goal is to establish a unified framework for understanding and implementing control strategies across the micro-to-nano continuum, enabling next-generation fluidic systems with unprecedented precision, functionality, and applicability across diverse scientific and industrial domains.

Market Applications and Demand Analysis for Micro/Nanofluidic Systems

The global market for micro and nanofluidic systems has witnessed substantial growth in recent years, driven primarily by increasing applications in healthcare, pharmaceuticals, and biotechnology sectors. The market size for microfluidic devices reached approximately $13.5 billion in 2022 and is projected to grow at a compound annual growth rate of 11.2% through 2028, while nanofluidics, though smaller in market share, is experiencing even faster growth rates.

Healthcare applications represent the largest market segment, accounting for nearly 40% of the total demand. Within this sector, point-of-care diagnostics has emerged as a particularly promising application area, with the COVID-19 pandemic accelerating adoption of rapid testing platforms based on microfluidic technologies. The ability to perform complex assays with minimal sample volumes and reduced reagent consumption has made these systems increasingly attractive for resource-limited settings.

Pharmaceutical research and drug discovery constitute another significant market driver, where high-throughput screening platforms utilizing microfluidic technologies enable more efficient drug development processes. The demand for organ-on-a-chip and lab-on-a-chip systems has grown substantially, with major pharmaceutical companies investing heavily in these technologies to reduce development costs and accelerate time-to-market for new therapeutics.

In the biotechnology sector, applications in genomics and proteomics have created substantial demand for micro/nanofluidic systems capable of single-cell analysis and molecular manipulation. The precision control offered by these technologies enables researchers to study cellular behavior at unprecedented resolution, driving innovation in personalized medicine and biomarker discovery.

Environmental monitoring represents an emerging application area with significant growth potential. Portable microfluidic systems for water quality testing and environmental contaminant detection are gaining traction in both developed and developing markets, supported by increasing regulatory requirements for environmental protection.

Regional analysis reveals North America as the dominant market for micro/nanofluidic systems, accounting for approximately 35% of global demand, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by increasing healthcare expenditure, expanding research infrastructure, and government initiatives supporting biotechnology development in countries like China, Japan, and South Korea.

Customer requirements are evolving toward more integrated, automated systems with improved user interfaces and data analysis capabilities. End-users increasingly demand solutions that combine the precision control of micro/nanofluidic technologies with simplified workflows suitable for non-specialist operators, particularly in clinical and industrial settings.

Healthcare applications represent the largest market segment, accounting for nearly 40% of the total demand. Within this sector, point-of-care diagnostics has emerged as a particularly promising application area, with the COVID-19 pandemic accelerating adoption of rapid testing platforms based on microfluidic technologies. The ability to perform complex assays with minimal sample volumes and reduced reagent consumption has made these systems increasingly attractive for resource-limited settings.

Pharmaceutical research and drug discovery constitute another significant market driver, where high-throughput screening platforms utilizing microfluidic technologies enable more efficient drug development processes. The demand for organ-on-a-chip and lab-on-a-chip systems has grown substantially, with major pharmaceutical companies investing heavily in these technologies to reduce development costs and accelerate time-to-market for new therapeutics.

In the biotechnology sector, applications in genomics and proteomics have created substantial demand for micro/nanofluidic systems capable of single-cell analysis and molecular manipulation. The precision control offered by these technologies enables researchers to study cellular behavior at unprecedented resolution, driving innovation in personalized medicine and biomarker discovery.

Environmental monitoring represents an emerging application area with significant growth potential. Portable microfluidic systems for water quality testing and environmental contaminant detection are gaining traction in both developed and developing markets, supported by increasing regulatory requirements for environmental protection.

Regional analysis reveals North America as the dominant market for micro/nanofluidic systems, accounting for approximately 35% of global demand, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by increasing healthcare expenditure, expanding research infrastructure, and government initiatives supporting biotechnology development in countries like China, Japan, and South Korea.

Customer requirements are evolving toward more integrated, automated systems with improved user interfaces and data analysis capabilities. End-users increasingly demand solutions that combine the precision control of micro/nanofluidic technologies with simplified workflows suitable for non-specialist operators, particularly in clinical and industrial settings.

Current Technological Status and Challenges in Fluidic Control

The field of fluidic control has witnessed significant advancements in recent years, with microfluidics and nanofluidics emerging as pivotal technologies. Globally, microfluidic technologies have reached a relatively mature state, with established fabrication methods including soft lithography, hot embossing, and injection molding. These techniques have enabled the development of lab-on-a-chip devices, point-of-care diagnostics, and organ-on-chip platforms that are increasingly being commercialized.

In contrast, nanofluidics remains predominantly in the research phase, with fewer commercial applications due to fabrication challenges at the nanoscale. Current nanofabrication techniques include electron beam lithography, focused ion beam milling, and nanoimprint lithography, which require sophisticated equipment and controlled environments, limiting widespread adoption.

The geographical distribution of fluidic control technology development shows concentration in North America, Europe, and East Asia. The United States leads in research output and patent filings, particularly through institutions like MIT, Stanford, and Harvard. European contributions are significant, especially from Germany, Switzerland, and the Netherlands, while Japan, South Korea, and China are rapidly advancing their capabilities in this domain.

A major technical challenge in microfluidic control is achieving precise manipulation of fluids at microscale without external pumping mechanisms. Current solutions often rely on bulky external equipment, contradicting the miniaturization goals of microfluidic devices. Integration of control systems directly onto chips remains difficult, particularly for complex multi-step processes.

For nanofluidics, the fundamental challenge lies in understanding and controlling fluid behavior at the nanoscale, where surface forces dominate and continuum fluid mechanics breaks down. Fabrication precision at this scale presents significant hurdles, with channel dimensions approaching molecular sizes requiring atomic-level precision.

Both fields face challenges in standardization and reproducibility. The lack of universal design standards and fabrication protocols hampers cross-laboratory validation and commercial scaling. Additionally, interfacing these miniaturized systems with macroscale equipment for practical applications remains problematic.

Material limitations also constrain advancement, particularly for nanofluidics where traditional materials like PDMS exhibit limitations at extreme scales. Novel materials with appropriate surface properties, biocompatibility, and manufacturing feasibility are needed to overcome current barriers.

The integration of sensing and actuation components within fluidic systems presents another significant challenge, especially for real-time monitoring and feedback control in dynamic applications. Current solutions often involve compromises between sensitivity, response time, and system complexity.

In contrast, nanofluidics remains predominantly in the research phase, with fewer commercial applications due to fabrication challenges at the nanoscale. Current nanofabrication techniques include electron beam lithography, focused ion beam milling, and nanoimprint lithography, which require sophisticated equipment and controlled environments, limiting widespread adoption.

The geographical distribution of fluidic control technology development shows concentration in North America, Europe, and East Asia. The United States leads in research output and patent filings, particularly through institutions like MIT, Stanford, and Harvard. European contributions are significant, especially from Germany, Switzerland, and the Netherlands, while Japan, South Korea, and China are rapidly advancing their capabilities in this domain.

A major technical challenge in microfluidic control is achieving precise manipulation of fluids at microscale without external pumping mechanisms. Current solutions often rely on bulky external equipment, contradicting the miniaturization goals of microfluidic devices. Integration of control systems directly onto chips remains difficult, particularly for complex multi-step processes.

For nanofluidics, the fundamental challenge lies in understanding and controlling fluid behavior at the nanoscale, where surface forces dominate and continuum fluid mechanics breaks down. Fabrication precision at this scale presents significant hurdles, with channel dimensions approaching molecular sizes requiring atomic-level precision.

Both fields face challenges in standardization and reproducibility. The lack of universal design standards and fabrication protocols hampers cross-laboratory validation and commercial scaling. Additionally, interfacing these miniaturized systems with macroscale equipment for practical applications remains problematic.

Material limitations also constrain advancement, particularly for nanofluidics where traditional materials like PDMS exhibit limitations at extreme scales. Novel materials with appropriate surface properties, biocompatibility, and manufacturing feasibility are needed to overcome current barriers.

The integration of sensing and actuation components within fluidic systems presents another significant challenge, especially for real-time monitoring and feedback control in dynamic applications. Current solutions often involve compromises between sensitivity, response time, and system complexity.

Comparative Analysis of Current Control Methodologies

01 Microfluidic flow control systems

Advanced systems for precise control of fluid flow in microfluidic devices, including pressure-driven mechanisms, electrokinetic methods, and automated control systems. These technologies enable accurate manipulation of small fluid volumes, critical for applications in diagnostics, drug delivery, and chemical analysis. The systems incorporate sensors, actuators, and feedback mechanisms to maintain stable flow conditions and respond to changes in operational parameters.- Microfluidic flow control mechanisms: Various mechanisms are employed to control fluid flow in microfluidic devices, including pressure-driven systems, electrokinetic methods, and valve-based approaches. These control mechanisms enable precise manipulation of small fluid volumes within microchannels, allowing for accurate dosing, mixing, and separation processes. Advanced flow control systems can dynamically adjust flow rates and directions in response to external signals or programmed sequences.

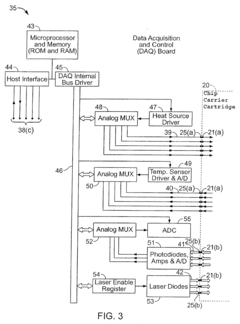

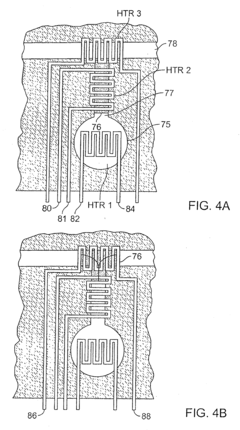

- Integrated sensing and feedback systems: Microfluidic and nanofluidic devices incorporate integrated sensors that monitor parameters such as flow rate, pressure, temperature, and chemical composition in real-time. These sensing capabilities, when coupled with feedback control systems, enable autonomous operation and self-regulation of fluid behavior. The integration of sensors with control algorithms allows for adaptive responses to changing conditions, enhancing the reliability and precision of microfluidic operations.

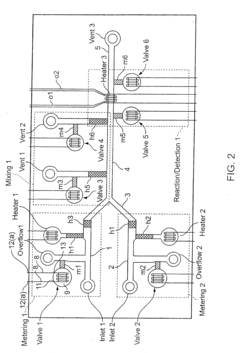

- Lab-on-a-chip automation technologies: Advanced automation technologies are implemented in lab-on-a-chip devices to control complex sequences of microfluidic operations. These systems integrate multiple functional components including pumps, mixers, separators, and detectors on a single platform. Automation enables the execution of sophisticated analytical protocols with minimal human intervention, improving reproducibility and throughput while reducing sample and reagent consumption.

- Droplet-based microfluidic control: Droplet-based microfluidics involves the generation, manipulation, and analysis of discrete fluid droplets within immiscible carrier fluids. Control systems for droplet microfluidics enable precise formation, sorting, merging, and splitting of droplets at high throughput. These technologies facilitate digital assays, single-cell analysis, and high-throughput screening applications by creating isolated microreactors that can be individually controlled and monitored.

- Nanofluidic transport and manipulation: Nanofluidic control systems address the unique challenges of fluid behavior at the nanoscale, where surface forces and molecular interactions dominate. These systems employ specialized techniques to manipulate fluids in nanochannels, including electrokinetic methods, surface modification approaches, and novel channel geometries. Nanofluidic control enables applications such as single-molecule analysis, nanopore sensing, and biomolecular separation with unprecedented precision.

02 Nanofluidic channel fabrication and control

Techniques for fabricating and controlling fluid flow in nanoscale channels, where dimensions approach molecular scales. These methods include nanolithography, etching processes, and surface modification to create channels with precise dimensions and properties. Control mechanisms address unique challenges at the nanoscale, including surface tension effects, electroosmotic phenomena, and molecular interactions that dominate at these dimensions. These technologies enable applications in single-molecule analysis, DNA sequencing, and nanoparticle manipulation.Expand Specific Solutions03 Integrated microfluidic valve technologies

Innovative valve designs specifically developed for microfluidic applications, including pneumatic valves, hydraulic valves, and electrically actuated systems. These valves enable precise control of fluid routing, mixing, and compartmentalization within microfluidic chips. The technologies incorporate materials and actuation mechanisms that function reliably at the microscale, with minimal dead volume and rapid response times. Advanced designs include multiplexed valve arrays for complex fluid handling operations and programmable flow control.Expand Specific Solutions04 Droplet-based microfluidic control systems

Systems designed for generating, manipulating, and analyzing discrete droplets within microfluidic environments. These technologies enable the creation of uniform droplets that serve as microreactors or carriers for biological samples, cells, or reagents. Control mechanisms include electrowetting, acoustic actuation, and surface tension-based techniques that allow for droplet generation, splitting, merging, and sorting. Applications include digital PCR, single-cell analysis, and high-throughput screening where compartmentalization of reactions is advantageous.Expand Specific Solutions05 Sensor integration for microfluidic feedback control

Integration of sensing elements within microfluidic and nanofluidic systems to enable real-time monitoring and feedback control. These sensors measure parameters such as flow rate, pressure, temperature, pH, and analyte concentration, providing data for automated control systems. The technologies include optical sensors, electrochemical detectors, and MEMS-based sensing elements that are compatible with microfluidic fabrication processes. Feedback control algorithms use sensor data to adjust flow conditions, reaction parameters, or sample processing steps, enhancing reproducibility and automation in microfluidic applications.Expand Specific Solutions

Leading Research Groups and Commercial Entities in Fluidic Control

The microfluidics and nanofluidics control technology landscape is currently in a growth phase, with the market expanding rapidly due to increasing applications in diagnostics, pharmaceuticals, and research. The global market size is projected to reach significant value as both established companies and research institutions invest heavily in this field. Technology maturity varies across applications, with microfluidics being more commercially established than nanofluidics. Key industry players include HandyLab (acquired by BD) with their patented microfluidic PCR technology, IBM with advanced research capabilities, HP Development focusing on printing applications, and Applied Biosystems (Thermo Fisher) offering integrated genetic analysis systems. Academic institutions like Tsinghua University, Nanjing University, and UNC Chapel Hill are driving fundamental research, while companies like Boao Biology and Shenzhen Huanuo are commercializing applications in the Asian market.

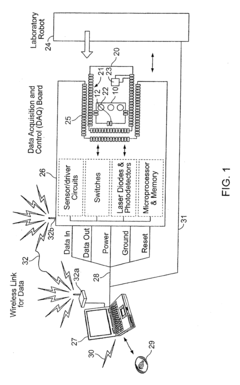

HandyLab, Inc.

Technical Solution: HandyLab has developed advanced microfluidic control systems for point-of-care diagnostics, featuring integrated pneumatic valves and pumps that enable precise fluid manipulation at microscale. Their technology incorporates a network of microchannels with electronically controlled pressure differentials to achieve accurate sample preparation, reagent mixing, and analysis. The company's proprietary "Lab-on-a-Chip" platform utilizes electrokinetic forces for fluid transport, eliminating the need for mechanical pumps in some applications. HandyLab's microfluidic cartridges incorporate multiple functional elements including sample preparation chambers, mixing zones, and detection regions within a single integrated device, allowing for automated processing of complex biological assays with minimal user intervention[1].

Strengths: Highly integrated systems with automated sample processing capabilities; excellent reproducibility in clinical diagnostic applications; compact form factor suitable for point-of-care use. Weaknesses: Limited throughput compared to larger laboratory systems; relatively high manufacturing costs for disposable cartridges; less suitable for applications requiring nanoscale precision.

International Business Machines Corp.

Technical Solution: IBM has pioneered advanced nanofluidic control systems leveraging their semiconductor manufacturing expertise. Their technology utilizes nanochannels with dimensions comparable to the size of biomolecules (10-100nm), enabling precise manipulation of individual molecules. IBM's nanofluidic platforms incorporate electronic field control for electrophoretic separation and concentration of biomolecules with unprecedented resolution. The company has developed silicon-based nanofluidic chips with integrated sensors that can detect and analyze single molecules as they pass through nanochannels. Their approach combines nanolithography techniques with surface chemistry modifications to create functional nanofluidic devices with controlled surface properties. IBM has demonstrated DNA sequencing applications where DNA molecules are threaded through nanopores while measuring electrical signals to identify nucleotide sequences[2][3]. Their systems also incorporate machine learning algorithms to interpret complex signals from nanofluidic sensors.

Strengths: Exceptional precision at the molecular level; ability to manipulate and analyze individual molecules; leverages established semiconductor manufacturing infrastructure. Weaknesses: Extremely high fabrication costs; requires specialized equipment and clean room facilities; limited scalability for mass production; complex integration with macroscale systems.

Key Patents and Scientific Breakthroughs in Fluidic Control

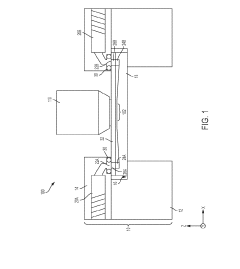

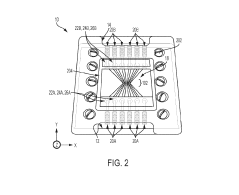

Fluidic cell designs for interfacing microfluidic chips and nanofluidic chips

PatentActiveUS20190299208A1

Innovation

- A fluidic cell design with a two-plate configuration, where one plate holds the nanofluidic chip and the other has angled ports that intersect to form a junction, allowing for direct access to air bubbles at the chip interface, enabling effective air removal and fluid input/output management through a modular and scalable architecture.

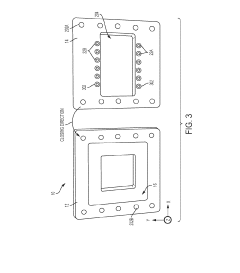

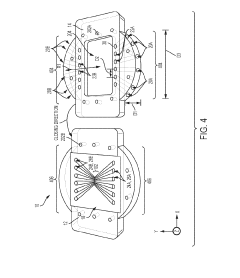

Microfluidic devices having a reduced number of input and output connections

PatentInactiveUS20100158754A1

Innovation

- The arrangement of leads in microfluidic substrates allows for the sharing of I/O contacts among multiple components, reducing the total number of contacts required while ensuring independent control of each component through unique combinations of contacts, thereby minimizing the number of I/O pins needed for communication with external controllers.

Fabrication Techniques and Materials Science Considerations

The fabrication of microfluidic and nanofluidic devices represents a critical aspect in their development and application. Traditional microfluidic fabrication techniques include photolithography, soft lithography, and micromachining. Photolithography, borrowed from semiconductor manufacturing, enables precise pattern transfer onto substrates with micrometer resolution. Soft lithography, particularly using polydimethylsiloxane (PDMS), offers rapid prototyping capabilities and has become the workhorse for microfluidic research due to its flexibility, optical transparency, and biocompatibility.

As we transition to nanofluidics, conventional techniques reach their limitations. Electron beam lithography (EBL) emerges as a key fabrication method, capable of achieving feature sizes below 10 nm. Focused ion beam (FIB) milling provides another approach for creating nanochannels with precise dimensions. These advanced techniques, however, come with significant cost implications and throughput limitations compared to microfluidic fabrication methods.

Materials selection critically influences device performance across both domains. Silicon and glass dominated early microfluidic devices, offering excellent chemical resistance and well-established processing protocols. Polymeric materials like PDMS, PMMA, and COC have gained popularity due to their lower cost and easier processing. For nanofluidics, material considerations become more complex as surface properties dominate fluid behavior at the nanoscale.

Surface chemistry modifications represent another crucial aspect of fabrication. In microfluidics, surface treatments primarily address issues like protein adsorption or cell adhesion. In nanofluidics, surface modifications directly impact fluid transport phenomena as the surface-to-volume ratio increases dramatically. Techniques such as plasma treatment, chemical vapor deposition, and self-assembled monolayers enable precise control over surface properties.

Scaling challenges present significant hurdles when transitioning from micro to nanoscale fabrication. As channel dimensions approach the size of fluid molecules, continuum assumptions break down, requiring new fabrication approaches that account for molecular-level interactions. Additionally, nanofabrication faces challenges in maintaining consistent channel dimensions and surface properties across the device.

Recent innovations include 3D printing technologies for microfluidics, offering rapid prototyping capabilities, though resolution limitations currently restrict their application in nanofluidics. Roll-to-roll manufacturing shows promise for high-throughput production of polymer-based devices. Hybrid fabrication approaches combining top-down lithographic techniques with bottom-up self-assembly methods represent an emerging frontier, potentially enabling more efficient production of nanofluidic structures with precise dimensional control.

As we transition to nanofluidics, conventional techniques reach their limitations. Electron beam lithography (EBL) emerges as a key fabrication method, capable of achieving feature sizes below 10 nm. Focused ion beam (FIB) milling provides another approach for creating nanochannels with precise dimensions. These advanced techniques, however, come with significant cost implications and throughput limitations compared to microfluidic fabrication methods.

Materials selection critically influences device performance across both domains. Silicon and glass dominated early microfluidic devices, offering excellent chemical resistance and well-established processing protocols. Polymeric materials like PDMS, PMMA, and COC have gained popularity due to their lower cost and easier processing. For nanofluidics, material considerations become more complex as surface properties dominate fluid behavior at the nanoscale.

Surface chemistry modifications represent another crucial aspect of fabrication. In microfluidics, surface treatments primarily address issues like protein adsorption or cell adhesion. In nanofluidics, surface modifications directly impact fluid transport phenomena as the surface-to-volume ratio increases dramatically. Techniques such as plasma treatment, chemical vapor deposition, and self-assembled monolayers enable precise control over surface properties.

Scaling challenges present significant hurdles when transitioning from micro to nanoscale fabrication. As channel dimensions approach the size of fluid molecules, continuum assumptions break down, requiring new fabrication approaches that account for molecular-level interactions. Additionally, nanofabrication faces challenges in maintaining consistent channel dimensions and surface properties across the device.

Recent innovations include 3D printing technologies for microfluidics, offering rapid prototyping capabilities, though resolution limitations currently restrict their application in nanofluidics. Roll-to-roll manufacturing shows promise for high-throughput production of polymer-based devices. Hybrid fabrication approaches combining top-down lithographic techniques with bottom-up self-assembly methods represent an emerging frontier, potentially enabling more efficient production of nanofluidic structures with precise dimensional control.

Scaling Effects and Physical Phenomena at Micro/Nano Scales

The transition from microfluidics to nanofluidics introduces significant changes in physical phenomena due to scaling effects. At the microscale (typically 1-100 μm), fluid behavior still largely follows conventional continuum mechanics, with Reynolds numbers typically below 100 indicating laminar flow dominance. However, as dimensions decrease to the nanoscale (1-100 nm), several physical phenomena become increasingly prominent and can dramatically alter fluid behavior and control mechanisms.

Surface-to-volume ratio increases exponentially at smaller scales, making surface forces such as van der Waals interactions and electrostatic forces increasingly dominant compared to body forces like gravity. This shift fundamentally changes fluid-structure interactions and necessitates different control approaches between micro and nanofluidic systems.

Electrokinetic phenomena become particularly significant at the nanoscale. The electric double layer (EDL) that forms at solid-liquid interfaces can occupy a substantial portion of nanochannels, leading to unique charge distribution patterns and ion transport mechanisms not observed in microfluidics. When the channel dimensions approach the Debye length, overlapping EDLs create distinctive flow profiles and ion selectivity properties.

Viscous effects dominate at both scales but manifest differently. In microfluidics, viscosity primarily affects flow resistance and mixing efficiency. In nanofluidics, the no-slip boundary condition may break down, leading to apparent slip lengths that significantly impact flow behavior and require different mathematical models for accurate prediction.

Thermal fluctuations and Brownian motion become increasingly relevant at nanoscales. While negligible in microfluidic systems, these stochastic effects can substantially influence nanoparticle transport and molecular interactions in nanofluidic devices, introducing inherent randomness that must be accounted for in control strategies.

Quantum effects begin to emerge at the smallest nanoscales, particularly when channel dimensions approach molecular sizes. Phenomena such as quantum confinement and tunneling have no counterpart in microfluidics but can affect electron transport and molecular behavior in extreme nanoconfinement.

These scaling-dependent phenomena necessitate fundamentally different approaches to flow control. Microfluidic control typically relies on pressure gradients, capillary forces, and external fields acting on bulk fluid properties. Nanofluidic control, conversely, often leverages electrokinetic phenomena, molecular interactions, and surface chemistry modifications to achieve precise manipulation of extremely small fluid volumes and individual molecules.

Surface-to-volume ratio increases exponentially at smaller scales, making surface forces such as van der Waals interactions and electrostatic forces increasingly dominant compared to body forces like gravity. This shift fundamentally changes fluid-structure interactions and necessitates different control approaches between micro and nanofluidic systems.

Electrokinetic phenomena become particularly significant at the nanoscale. The electric double layer (EDL) that forms at solid-liquid interfaces can occupy a substantial portion of nanochannels, leading to unique charge distribution patterns and ion transport mechanisms not observed in microfluidics. When the channel dimensions approach the Debye length, overlapping EDLs create distinctive flow profiles and ion selectivity properties.

Viscous effects dominate at both scales but manifest differently. In microfluidics, viscosity primarily affects flow resistance and mixing efficiency. In nanofluidics, the no-slip boundary condition may break down, leading to apparent slip lengths that significantly impact flow behavior and require different mathematical models for accurate prediction.

Thermal fluctuations and Brownian motion become increasingly relevant at nanoscales. While negligible in microfluidic systems, these stochastic effects can substantially influence nanoparticle transport and molecular interactions in nanofluidic devices, introducing inherent randomness that must be accounted for in control strategies.

Quantum effects begin to emerge at the smallest nanoscales, particularly when channel dimensions approach molecular sizes. Phenomena such as quantum confinement and tunneling have no counterpart in microfluidics but can affect electron transport and molecular behavior in extreme nanoconfinement.

These scaling-dependent phenomena necessitate fundamentally different approaches to flow control. Microfluidic control typically relies on pressure gradients, capillary forces, and external fields acting on bulk fluid properties. Nanofluidic control, conversely, often leverages electrokinetic phenomena, molecular interactions, and surface chemistry modifications to achieve precise manipulation of extremely small fluid volumes and individual molecules.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!