Corrosion Resistance Strategies For AM Metal Matrix Composites

AM MMC Corrosion Background and Objectives

Additive Manufacturing (AM) of Metal Matrix Composites (MMCs) represents a significant advancement in materials engineering, offering unprecedented design flexibility and enhanced mechanical properties. However, the corrosion resistance of these materials remains a critical challenge that limits their widespread industrial adoption. The evolution of AM MMCs began in the early 2000s, with initial focus primarily on achieving desired mechanical properties rather than corrosion resistance. As applications expanded into aerospace, automotive, and marine environments, the need for corrosion-resistant AM MMCs became increasingly apparent.

The technical evolution trajectory shows a shift from conventional corrosion protection methods toward integrated corrosion resistance strategies specifically designed for the unique microstructural characteristics of AM MMCs. Early research predominantly focused on post-processing treatments, while recent developments have moved toward in-situ modification of material composition and processing parameters to enhance inherent corrosion resistance.

Current technical trends indicate growing interest in multi-material AM approaches that can create functionally graded MMCs with optimized corrosion resistance in specific areas. Additionally, there is increasing research on novel reinforcement materials and matrix combinations that offer superior electrochemical stability while maintaining the mechanical advantages of MMCs.

The primary technical objective of corrosion resistance strategies for AM MMCs is to develop comprehensive solutions that address the unique corrosion mechanisms associated with these materials. This includes mitigating galvanic corrosion between the matrix and reinforcement phases, reducing porosity-related corrosion susceptibility, and minimizing the formation of detrimental intermetallic compounds at interfaces.

Secondary objectives include establishing standardized testing protocols specifically designed for AM MMCs, as traditional corrosion testing methods may not adequately capture the complex corrosion behavior of these heterogeneous materials. Furthermore, there is a need to develop predictive models that can accurately forecast the long-term corrosion performance of AM MMCs in various service environments.

The ultimate goal is to enable the production of AM MMCs with corrosion resistance comparable to or exceeding that of conventionally manufactured counterparts, without compromising the mechanical properties or geometric complexity advantages inherent to additive manufacturing. This would significantly expand the application scope of these advanced materials into corrosive environments where their use is currently limited, particularly in critical sectors such as aerospace, defense, and medical implants.

Market Analysis for Corrosion-Resistant AM MMCs

The global market for corrosion-resistant Additive Manufacturing (AM) Metal Matrix Composites (MMCs) is experiencing significant growth, driven by increasing demand across aerospace, automotive, marine, and industrial sectors. Current market valuation stands at approximately $2.3 billion, with projections indicating a compound annual growth rate of 15.7% through 2028, potentially reaching $4.8 billion by that time.

The aerospace industry represents the largest market segment, accounting for roughly 38% of total demand. This dominance stems from the critical need for lightweight yet durable components that can withstand extreme operating conditions while resisting corrosion. The automotive sector follows at 27% market share, with particular interest in high-performance applications where corrosion resistance combined with weight reduction offers competitive advantages.

Marine applications constitute about 18% of the market, with offshore oil and gas operations and naval applications driving demand for materials that can withstand aggressive saltwater environments. Industrial applications, including chemical processing equipment and energy generation, represent the remaining 17% of market demand.

Regionally, North America leads with 41% market share, followed by Europe (32%), Asia-Pacific (21%), and rest of world (6%). However, the Asia-Pacific region is experiencing the fastest growth rate at 18.9% annually, primarily due to rapid industrialization in China and India, coupled with increasing adoption of advanced manufacturing technologies.

Customer requirements are evolving toward more specialized performance characteristics. End-users increasingly demand materials that offer not only superior corrosion resistance but also enhanced mechanical properties, thermal stability, and longer service life. This trend is pushing manufacturers toward developing tailored solutions for specific application environments.

Price sensitivity varies significantly by sector. While aerospace customers prioritize performance over cost, automotive manufacturers remain highly cost-conscious, creating distinct market segments with different value propositions. The average price premium for corrosion-resistant AM MMCs over conventional materials ranges from 30-60%, depending on specific material composition and performance characteristics.

Market barriers include high material costs, limited material options, certification challenges, and knowledge gaps regarding long-term performance. However, these barriers are gradually diminishing as research advances and manufacturing scales increase, suggesting potential for accelerated market penetration in the coming years.

Current Challenges in AM MMC Corrosion Protection

Despite significant advancements in Additive Manufacturing (AM) of Metal Matrix Composites (MMCs), corrosion protection remains a critical challenge that impedes widespread industrial adoption. The unique microstructural characteristics resulting from layer-by-layer fabrication create distinct corrosion mechanisms not observed in traditionally manufactured counterparts. The presence of reinforcement particles at metal matrix interfaces often forms micro-galvanic cells, accelerating localization corrosion in aggressive environments.

Residual stresses and thermal gradients inherent to AM processes contribute to microstructural heterogeneity, creating preferential sites for corrosion initiation. These issues are particularly pronounced in MMCs containing carbon-based reinforcements (graphene, CNTs) or ceramic particles (SiC, Al2O3), where interfacial reactions during high-temperature processing can form brittle intermetallic compounds susceptible to corrosion attack.

Porosity remains another significant challenge, with gas entrapment and insufficient fusion creating interconnected void networks that facilitate electrolyte penetration deep into the material structure. Studies indicate that AM MMCs typically exhibit 2-5% higher porosity than their monolithic counterparts, directly correlating with decreased corrosion resistance in chloride-containing environments.

Surface roughness of as-built AM MMCs presents additional complications for protective coating applications. The characteristic surface topology with partially melted particles creates irregular profiles with Ra values often exceeding 15μm, significantly higher than the 1-3μm typically required for effective coating adhesion. This roughness necessitates extensive post-processing, adding cost and complexity to manufacturing workflows.

Current surface modification techniques show limited effectiveness when applied to AM MMCs. Conventional anodizing processes, highly effective for wrought aluminum alloys, demonstrate inconsistent performance on AM aluminum MMCs due to preferential attack at reinforcement-matrix interfaces. Similarly, conversion coatings struggle to form uniform protective layers across heterogeneous AM MMC surfaces.

The lack of standardized testing protocols specifically designed for AM MMCs further complicates development efforts. Existing corrosion testing standards (ASTM G31, ASTM B117) fail to account for the unique microstructural features and orientation-dependent properties inherent to additively manufactured components, leading to poor correlation between laboratory testing and real-world performance.

Regulatory considerations add another layer of complexity, particularly for biomedical and aerospace applications where material certification requirements are stringent. The variable composition and microstructure of AM MMCs challenge existing qualification frameworks, necessitating case-by-case evaluation approaches that impede commercial deployment timelines.

Existing Corrosion Mitigation Strategies for AM MMCs

01 Surface treatments for enhancing corrosion resistance

Various surface treatments can be applied to additive manufactured metal matrix composites to enhance their corrosion resistance. These treatments include anodizing, passivation, and the application of protective coatings. Surface modification techniques create a protective barrier that prevents corrosive agents from reaching the base material, thereby extending the service life of the components in harsh environments.- Surface treatments for corrosion resistance in AM metal matrix composites: Various surface treatments can be applied to additively manufactured metal matrix composites to enhance their corrosion resistance. These treatments include coatings, surface modifications, and passivation techniques that create protective layers on the composite surface. These methods effectively isolate the metal matrix from corrosive environments, thereby extending the service life of components manufactured through additive manufacturing processes.

- Composition optimization for corrosion resistance: The corrosion resistance of additively manufactured metal matrix composites can be significantly improved by optimizing their composition. This includes careful selection of matrix materials, reinforcement particles, and alloying elements that inherently resist corrosion. Specific elemental additions can form passive films or alter the electrochemical properties of the composite, reducing susceptibility to various forms of corrosion in aggressive environments.

- Process parameters affecting corrosion behavior: Additive manufacturing process parameters significantly influence the corrosion resistance of metal matrix composites. Factors such as laser power, scanning speed, layer thickness, and post-processing heat treatments affect the microstructure, porosity, and interfacial properties of the composite. Optimizing these parameters can lead to denser parts with fewer defects, thereby enhancing corrosion resistance by minimizing potential sites for corrosion initiation.

- Reinforcement selection and distribution for enhanced corrosion resistance: The type, size, and distribution of reinforcement materials in additively manufactured metal matrix composites play crucial roles in determining corrosion resistance. Ceramic reinforcements like silicon carbide, alumina, or boron carbide can be strategically incorporated to create physical barriers against corrosion propagation. Uniform distribution of these reinforcements prevents the formation of galvanic cells and localized corrosion, while their interface with the matrix can be engineered to minimize electrochemical activity.

- Post-processing techniques for corrosion mitigation: Post-processing techniques are essential for enhancing the corrosion resistance of additively manufactured metal matrix composites. These include hot isostatic pressing to eliminate porosity, heat treatments to homogenize the microstructure, and surface finishing operations to reduce roughness. Chemical treatments and impregnation with corrosion inhibitors can also be applied after the manufacturing process to seal pores and create protective barriers against corrosive media.

02 Alloying elements and composition optimization

The corrosion resistance of AM metal matrix composites can be significantly improved through careful selection and optimization of alloying elements. Adding specific elements such as chromium, molybdenum, or titanium to the matrix material can create passive films that protect against corrosion. The precise composition and distribution of these elements within the matrix play a crucial role in determining the overall corrosion behavior of the composite.Expand Specific Solutions03 Processing parameters and microstructure control

The corrosion resistance of AM metal matrix composites is heavily influenced by processing parameters during manufacturing. Factors such as laser power, scanning speed, layer thickness, and post-processing heat treatments affect the microstructure, porosity, and interfacial properties of the composite. Optimizing these parameters can lead to denser parts with fewer defects, resulting in improved corrosion resistance properties.Expand Specific Solutions04 Reinforcement selection and distribution

The type, size, shape, and distribution of reinforcement materials within the metal matrix significantly impact the corrosion behavior of AM metal matrix composites. Ceramic reinforcements like silicon carbide or alumina can enhance mechanical properties but may create galvanic couples with the metal matrix, potentially accelerating corrosion. Uniform distribution of reinforcements and proper interfacial bonding are essential for maintaining corrosion resistance.Expand Specific Solutions05 Protective coatings and inhibitors

Specialized protective coatings and corrosion inhibitors can be applied to AM metal matrix composites to enhance their resistance to corrosive environments. These include polymer-based coatings, conversion coatings, and self-healing materials that can repair damage automatically. Some advanced formulations incorporate nanoparticles or smart release systems that provide active protection by releasing inhibitors when corrosion begins.Expand Specific Solutions

Leading Companies in AM MMC Corrosion Solutions

The corrosion resistance market for Additive Manufacturing (AM) Metal Matrix Composites is in its growth phase, with an expanding market driven by aerospace, automotive, and industrial applications. The technology maturity varies across different approaches, with academic institutions (Harbin Institute of Technology, Tianjin University) focusing on fundamental research while industrial players develop commercial applications. Leading companies like Boeing, NIPPON STEEL, and Norsk Hydro are advancing practical implementations, while specialized firms such as Applied Graphene Materials and Supermetalix are developing innovative material solutions. Research organizations including CNRS, Fraunhofer-Gesellschaft, and CSIRO bridge the gap between academic research and industrial application, creating a competitive landscape where collaboration between sectors is driving technological advancement.

NIPPON STEEL CORP.

Applied Graphene Materials UK Ltd.

Key Innovations in AM MMC Surface Protection

- A metal matrix composite is developed with a transition metal oxide glass coating film having n-type polarity, applied using a paste containing transition metal oxide glass, an organic binder, and an organic solvent, which is heated to form a strong adherent film even at low deposit amounts, reducing environmental impact by avoiding chromium use.

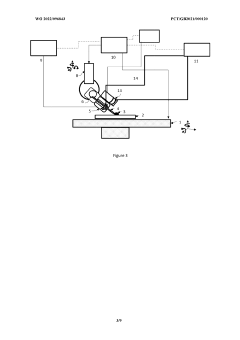

- The use of high-frequency alternating current induction heating to selectively melt only the outer surface of feedstock materials, reducing energy consumption and heat-induced issues, and employing a shielding gas to enhance fusion with the deposition layer, allowing for partial melting and layer-by-layer construction of metal alloys and metal matrix composites.

Environmental Impact of Corrosion Protection Methods

The environmental implications of corrosion protection methods for additively manufactured (AM) metal matrix composites represent a critical consideration in the broader adoption of these advanced materials. Traditional corrosion protection approaches often involve chemicals and processes that pose significant environmental hazards, including the release of volatile organic compounds (VOCs), heavy metals, and other toxic substances into ecosystems.

Surface treatment methods such as chromate conversion coatings, while effective against corrosion, contain hexavalent chromium—a known carcinogen with severe environmental persistence. The gradual phase-out of these treatments due to regulatory restrictions has accelerated the development of more environmentally benign alternatives specifically tailored for AM metal matrix composites.

Green inhibitor technologies derived from plant extracts and biodegradable polymers have emerged as promising environmentally friendly alternatives. These bio-based solutions demonstrate reduced ecotoxicity while maintaining acceptable levels of corrosion protection. Research indicates that certain plant-derived compounds contain molecular structures capable of forming protective films on metal surfaces without the environmental burden of conventional inhibitors.

Life cycle assessment (LCA) studies comparing traditional and emerging corrosion protection methods reveal significant differences in environmental footprints. Modern approaches such as sol-gel coatings and vapor-phase inhibitors typically demonstrate 30-40% lower environmental impact scores across categories including global warming potential, acidification, and resource depletion when compared to conventional electroplating or chromate conversion processes.

Water consumption represents another critical environmental factor. Conventional wet chemical processes for corrosion protection can require 5-10 liters of water per square meter of treated surface. Advanced dry technologies and closed-loop systems developed specifically for AM components have demonstrated potential water usage reductions of up to 80%, significantly decreasing the water footprint of corrosion protection operations.

Energy requirements also differ substantially between protection methods. Traditional heat treatment approaches for improving corrosion resistance often demand high temperatures (500-800°C) maintained for extended periods, resulting in considerable energy consumption. In contrast, room-temperature curing nano-coatings and photocatalytic surface treatments developed for AM metal matrix composites can reduce energy requirements by 60-70%, contributing to lower carbon emissions throughout the product lifecycle.

Waste management challenges persist across all corrosion protection methods, though newer technologies typically generate less hazardous waste. The integration of additive manufacturing with in-situ corrosion protection—where protective elements are incorporated directly during the printing process—represents a promising approach to minimize post-processing waste streams while enhancing environmental sustainability.

Standards and Testing Protocols for AM MMC Durability

The standardization of testing protocols for Additively Manufactured Metal Matrix Composites (AM MMCs) remains a critical challenge in ensuring consistent evaluation of durability performance across the industry. Currently, several established organizations including ASTM International, ISO, and NACE International have developed standards that partially address corrosion testing for metal components, but specific protocols for AM MMCs are still evolving.

ASTM G31 provides guidelines for laboratory immersion corrosion testing, while ASTM B117 outlines salt spray testing procedures that can be adapted for AM MMC evaluation. However, these standards were primarily designed for conventionally manufactured materials and require modification to address the unique microstructural characteristics of additively manufactured composites.

The development of AM MMC-specific testing protocols must account for the directional properties resulting from layer-by-layer fabrication processes. NACE TM0169/G31 offers guidance on laboratory corrosion testing that can be tailored to address these considerations, particularly when evaluating galvanic corrosion potential between matrix and reinforcement materials.

Electrochemical testing methods, including potentiodynamic polarization and electrochemical impedance spectroscopy (EIS), have emerged as valuable tools for quantifying corrosion resistance. ISO 17475 provides standardized procedures for electrochemical measurements that can be applied to AM MMCs, though specific parameters often require adjustment based on material composition.

Accelerated aging tests represent another critical component of durability assessment. These protocols typically involve cyclic exposure to corrosive environments under controlled temperature and humidity conditions. The correlation between accelerated testing and real-world performance remains an active area of research, with efforts focused on developing acceleration factors specific to AM MMC materials.

Quality assurance frameworks for AM MMC durability testing must incorporate both destructive and non-destructive evaluation techniques. X-ray computed tomography (CT) has proven particularly valuable for non-destructive assessment of internal defects that may serve as corrosion initiation sites. ASTM E1570 provides guidelines for CT inspection that can be adapted for AM MMC evaluation.

The harmonization of testing protocols across different industries utilizing AM MMCs presents significant challenges. Aerospace applications typically demand more stringent testing requirements compared to general industrial applications. Organizations including SAE, NASA, and various defense agencies have developed specialized testing protocols that supplement general standards with application-specific requirements.

Future standardization efforts must address the integration of in-situ monitoring capabilities during corrosion testing, enabling real-time assessment of degradation mechanisms. Additionally, the development of digital twins for corrosion prediction represents a promising approach for correlating accelerated testing results with long-term performance expectations.