Cyclone Separator Vs Cartridge Filters: Cost-Benefit Analysis

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone vs Cartridge Background and Objectives

Cyclone separators and cartridge filters have been integral components in industrial air filtration systems for decades. The evolution of these technologies has been driven by the increasing demand for efficient and cost-effective particulate removal in various industries, including manufacturing, mining, and pharmaceuticals. Cyclone separators, first patented in the late 19th century, utilize centrifugal force to separate particles from gas streams. Their simple design and low maintenance requirements have made them a popular choice for many applications.

Cartridge filters, on the other hand, emerged in the mid-20th century as a more versatile solution for capturing finer particles. These filters use pleated media to trap contaminants, offering higher efficiency in removing smaller particulates compared to cyclone separators. The development of advanced filter media and designs has further enhanced their performance and longevity.

The primary objective of this cost-benefit analysis is to compare cyclone separators and cartridge filters in terms of their operational efficiency, initial investment, maintenance costs, and overall long-term value. This comparison aims to provide insights into the most suitable filtration solution for different industrial applications, considering factors such as particle size distribution, gas flow rates, and specific industry requirements.

Another key goal is to evaluate the environmental impact of both technologies. As environmental regulations become increasingly stringent, industries are under pressure to adopt more efficient and sustainable filtration methods. This analysis will assess the ability of cyclone separators and cartridge filters to meet current and future environmental standards, as well as their potential for reducing energy consumption and waste generation.

Furthermore, this study seeks to explore the technological advancements in both cyclone separators and cartridge filters. Recent innovations, such as high-efficiency cyclones and nanofiber filter media, have expanded the capabilities of these systems. Understanding these developments is crucial for predicting future trends and identifying potential areas for improvement in air filtration technology.

Lastly, this analysis aims to provide a comprehensive understanding of the market dynamics surrounding cyclone separators and cartridge filters. By examining current market trends, customer preferences, and industry-specific requirements, we can better assess the future prospects of these technologies and their potential impact on various sectors.

Cartridge filters, on the other hand, emerged in the mid-20th century as a more versatile solution for capturing finer particles. These filters use pleated media to trap contaminants, offering higher efficiency in removing smaller particulates compared to cyclone separators. The development of advanced filter media and designs has further enhanced their performance and longevity.

The primary objective of this cost-benefit analysis is to compare cyclone separators and cartridge filters in terms of their operational efficiency, initial investment, maintenance costs, and overall long-term value. This comparison aims to provide insights into the most suitable filtration solution for different industrial applications, considering factors such as particle size distribution, gas flow rates, and specific industry requirements.

Another key goal is to evaluate the environmental impact of both technologies. As environmental regulations become increasingly stringent, industries are under pressure to adopt more efficient and sustainable filtration methods. This analysis will assess the ability of cyclone separators and cartridge filters to meet current and future environmental standards, as well as their potential for reducing energy consumption and waste generation.

Furthermore, this study seeks to explore the technological advancements in both cyclone separators and cartridge filters. Recent innovations, such as high-efficiency cyclones and nanofiber filter media, have expanded the capabilities of these systems. Understanding these developments is crucial for predicting future trends and identifying potential areas for improvement in air filtration technology.

Lastly, this analysis aims to provide a comprehensive understanding of the market dynamics surrounding cyclone separators and cartridge filters. By examining current market trends, customer preferences, and industry-specific requirements, we can better assess the future prospects of these technologies and their potential impact on various sectors.

Industrial Filtration Market Analysis

The industrial filtration market has experienced significant growth in recent years, driven by increasing environmental regulations, growing awareness of air and water quality, and the need for efficient filtration solutions across various industries. This market encompasses a wide range of filtration technologies, including cyclone separators and cartridge filters, which are widely used in industrial applications for removing particulate matter from air and gas streams.

The global industrial filtration market was valued at approximately $29 billion in 2020 and is projected to reach $41 billion by 2025, growing at a compound annual growth rate (CAGR) of 7.1%. This growth is attributed to the rising demand for filtration systems in manufacturing, power generation, oil and gas, and pharmaceutical industries, among others.

Within this market, the demand for cyclone separators and cartridge filters has been particularly strong. Cyclone separators, known for their simplicity and low maintenance requirements, have found widespread use in industries dealing with large volumes of particulate matter. On the other hand, cartridge filters have gained popularity due to their high efficiency in capturing fine particles and their versatility across various applications.

The market for cyclone separators is expected to grow steadily, with a CAGR of around 5% from 2021 to 2026. This growth is driven by their cost-effectiveness and suitability for heavy-duty industrial applications. Cartridge filters, however, are experiencing more rapid growth, with a projected CAGR of 6.5% during the same period, due to their higher filtration efficiency and increasing adoption in industries requiring stringent air quality standards.

Key factors influencing the market dynamics include stringent environmental regulations, particularly in developed countries, which are pushing industries to adopt more efficient filtration technologies. The implementation of workplace safety standards and the need to improve indoor air quality in industrial settings are also driving the demand for advanced filtration solutions.

Geographically, Asia-Pacific is emerging as the fastest-growing market for industrial filtration, driven by rapid industrialization in countries like China and India. North America and Europe continue to be significant markets, with a focus on upgrading existing filtration systems to meet stricter environmental standards.

The competitive landscape of the industrial filtration market is characterized by the presence of several large multinational corporations and numerous smaller, specialized players. Leading companies in this space are investing heavily in research and development to improve filtration efficiency, reduce energy consumption, and develop smart filtration systems integrated with IoT technologies.

The global industrial filtration market was valued at approximately $29 billion in 2020 and is projected to reach $41 billion by 2025, growing at a compound annual growth rate (CAGR) of 7.1%. This growth is attributed to the rising demand for filtration systems in manufacturing, power generation, oil and gas, and pharmaceutical industries, among others.

Within this market, the demand for cyclone separators and cartridge filters has been particularly strong. Cyclone separators, known for their simplicity and low maintenance requirements, have found widespread use in industries dealing with large volumes of particulate matter. On the other hand, cartridge filters have gained popularity due to their high efficiency in capturing fine particles and their versatility across various applications.

The market for cyclone separators is expected to grow steadily, with a CAGR of around 5% from 2021 to 2026. This growth is driven by their cost-effectiveness and suitability for heavy-duty industrial applications. Cartridge filters, however, are experiencing more rapid growth, with a projected CAGR of 6.5% during the same period, due to their higher filtration efficiency and increasing adoption in industries requiring stringent air quality standards.

Key factors influencing the market dynamics include stringent environmental regulations, particularly in developed countries, which are pushing industries to adopt more efficient filtration technologies. The implementation of workplace safety standards and the need to improve indoor air quality in industrial settings are also driving the demand for advanced filtration solutions.

Geographically, Asia-Pacific is emerging as the fastest-growing market for industrial filtration, driven by rapid industrialization in countries like China and India. North America and Europe continue to be significant markets, with a focus on upgrading existing filtration systems to meet stricter environmental standards.

The competitive landscape of the industrial filtration market is characterized by the presence of several large multinational corporations and numerous smaller, specialized players. Leading companies in this space are investing heavily in research and development to improve filtration efficiency, reduce energy consumption, and develop smart filtration systems integrated with IoT technologies.

Current Challenges in Dust Collection Systems

Dust collection systems face several significant challenges in today's industrial landscape. One of the primary issues is the increasing demand for higher efficiency in particle removal, particularly for fine and ultrafine particles. As environmental regulations become more stringent, industries are under pressure to improve their dust collection performance to meet these standards.

Another challenge is the need for more energy-efficient systems. Traditional dust collection methods often consume substantial amounts of energy, contributing to high operational costs and environmental impact. This has led to a growing interest in developing more sustainable solutions that can maintain or improve collection efficiency while reducing energy consumption.

The variability of dust characteristics across different industries poses another significant challenge. Dust particles can vary greatly in size, shape, and composition depending on the industrial process. This diversity makes it difficult to design a one-size-fits-all solution, necessitating customized approaches for different applications.

Maintenance and operational costs present ongoing challenges for dust collection systems. Regular filter replacement, system cleaning, and potential downtime for maintenance can significantly impact productivity and profitability. There is a constant need for solutions that can extend filter life, reduce maintenance frequency, and minimize operational disruptions.

Space constraints in industrial settings often complicate the implementation of dust collection systems. Many facilities, especially older ones, may not have been designed with modern dust collection requirements in mind. This limitation can make it challenging to install or upgrade systems without significant modifications to existing infrastructure.

The handling and disposal of collected dust also present challenges. Depending on the nature of the dust, it may be hazardous, requiring special handling and disposal procedures. This not only adds to operational complexity but also increases costs associated with dust management.

Lastly, there is an ongoing challenge in balancing performance with cost-effectiveness. While high-efficiency systems like cartridge filters offer excellent particle removal, they often come with higher initial and operational costs. On the other hand, more economical options like cyclone separators may not always meet the required efficiency standards for all applications. Finding the optimal balance between performance and cost remains a key challenge in the industry.

Another challenge is the need for more energy-efficient systems. Traditional dust collection methods often consume substantial amounts of energy, contributing to high operational costs and environmental impact. This has led to a growing interest in developing more sustainable solutions that can maintain or improve collection efficiency while reducing energy consumption.

The variability of dust characteristics across different industries poses another significant challenge. Dust particles can vary greatly in size, shape, and composition depending on the industrial process. This diversity makes it difficult to design a one-size-fits-all solution, necessitating customized approaches for different applications.

Maintenance and operational costs present ongoing challenges for dust collection systems. Regular filter replacement, system cleaning, and potential downtime for maintenance can significantly impact productivity and profitability. There is a constant need for solutions that can extend filter life, reduce maintenance frequency, and minimize operational disruptions.

Space constraints in industrial settings often complicate the implementation of dust collection systems. Many facilities, especially older ones, may not have been designed with modern dust collection requirements in mind. This limitation can make it challenging to install or upgrade systems without significant modifications to existing infrastructure.

The handling and disposal of collected dust also present challenges. Depending on the nature of the dust, it may be hazardous, requiring special handling and disposal procedures. This not only adds to operational complexity but also increases costs associated with dust management.

Lastly, there is an ongoing challenge in balancing performance with cost-effectiveness. While high-efficiency systems like cartridge filters offer excellent particle removal, they often come with higher initial and operational costs. On the other hand, more economical options like cyclone separators may not always meet the required efficiency standards for all applications. Finding the optimal balance between performance and cost remains a key challenge in the industry.

Cyclone and Cartridge Filter Solutions

01 Cyclone separator design and efficiency

Cyclone separators are designed to remove particles from gas streams using centrifugal force. The efficiency of these separators depends on factors such as inlet velocity, particle size, and separator geometry. Improvements in design can lead to better separation performance and reduced energy consumption.- Cyclone separator design and efficiency: Cyclone separators are designed to remove particles from gas streams using centrifugal force. Their efficiency depends on factors such as inlet velocity, particle size, and separator geometry. Improvements in design can enhance separation efficiency and reduce pressure drop, leading to better overall performance and cost-effectiveness.

- Cartridge filter materials and construction: Cartridge filters use various materials and construction techniques to improve filtration efficiency and durability. Advanced filter media, pleating designs, and support structures can enhance particle capture, extend filter life, and reduce maintenance costs. Innovations in this area focus on balancing filtration performance with pressure drop and energy consumption.

- Cost-benefit analysis of filtration systems: Evaluating the cost-benefit ratio of cyclone separators and cartridge filters involves considering initial investment, operating costs, maintenance requirements, and performance metrics. Factors such as energy consumption, filter replacement frequency, and downtime for maintenance play crucial roles in determining the overall economic viability of different filtration solutions.

- Hybrid filtration systems: Combining cyclone separators with cartridge filters in hybrid systems can offer advantages in terms of efficiency and cost-effectiveness. The cyclone separator removes larger particles, reducing the load on the cartridge filter and extending its life. This approach can optimize overall system performance and reduce long-term operational costs.

- Automated monitoring and maintenance: Implementing automated monitoring systems for cyclone separators and cartridge filters can improve performance and reduce costs. These systems can track pressure drop, flow rates, and other key parameters to optimize maintenance schedules, predict filter life, and ensure efficient operation. This proactive approach can minimize downtime and extend equipment lifespan.

02 Cartridge filter cost-effectiveness

Cartridge filters offer a balance between filtration efficiency and cost. They are relatively inexpensive to replace and can be designed for specific applications. The cost-effectiveness of cartridge filters depends on factors such as filter media, housing design, and maintenance requirements.Expand Specific Solutions03 Hybrid filtration systems

Combining cyclone separators with cartridge filters can create hybrid systems that leverage the strengths of both technologies. These systems can offer improved particle removal efficiency across a wider range of particle sizes while potentially reducing overall operating costs.Expand Specific Solutions04 Maintenance and operational benefits

Both cyclone separators and cartridge filters offer unique maintenance and operational benefits. Cyclones have no moving parts and require minimal maintenance, while cartridge filters can be easily replaced without shutting down the entire system. Proper maintenance schedules and procedures can significantly extend the life of both types of equipment.Expand Specific Solutions05 Environmental and regulatory considerations

The choice between cyclone separators and cartridge filters may be influenced by environmental regulations and emission standards. Both technologies can be designed to meet specific air quality requirements, but their effectiveness in capturing different types of pollutants varies. Compliance with local and international standards is an important factor in system selection and design.Expand Specific Solutions

Key Players in Filtration Industry

The cost-benefit analysis of Cyclone Separator vs Cartridge Filters is situated in a mature industry with established players and growing market demand. The global air filtration market is expanding, driven by increasing awareness of air quality and stringent environmental regulations. Technologically, both cyclone separators and cartridge filters are well-developed, with ongoing innovations focused on efficiency and sustainability. Key players like MANN+HUMMEL, Donaldson, and 3M are investing in R&D to enhance performance and reduce operational costs. Emerging companies from China, such as Midea and Haier, are also making significant strides in this field, intensifying competition and driving further technological advancements.

MANN+HUMMEL GmbH

Technical Solution: MANN+HUMMEL's approach to the cost-benefit analysis of Cyclone Separators vs Cartridge Filters involves a comprehensive evaluation of both technologies. Their cyclone separators utilize centrifugal force to separate particles from air or liquid streams, achieving up to 98% efficiency for particles larger than 5 microns[1]. The company's cartridge filters, on the other hand, employ advanced filter media to capture particles as small as 0.3 microns with efficiencies up to 99.97%[2]. MANN+HUMMEL conducts extensive life cycle cost analyses, considering factors such as initial investment, energy consumption, maintenance requirements, and replacement frequency. Their studies show that while cyclone separators have lower initial costs and minimal maintenance needs, cartridge filters often provide superior filtration efficiency and longer service life in certain applications[3].

Strengths: Expertise in both technologies allows for unbiased comparison. Comprehensive life cycle cost analysis provides accurate long-term cost projections. Weaknesses: May be biased towards promoting their own product lines, potentially overlooking emerging technologies from competitors.

Donaldson Filtration Deutschland GmbH

Technical Solution: Donaldson's approach to comparing cyclone separators and cartridge filters focuses on application-specific performance and total cost of ownership. Their cyclone technology, PowerCore, combines cyclonic action with high-efficiency filter media, achieving up to 99.99% efficiency for particles as small as 0.5 microns[1]. For cartridge filters, Donaldson employs Ultra-Web nanofiber technology, offering superior dust holding capacity and extended filter life[2]. The company utilizes advanced computational fluid dynamics (CFD) modeling to optimize both cyclone and cartridge filter designs for specific industrial applications. Donaldson's cost-benefit analysis considers factors such as initial equipment cost, energy consumption, maintenance frequency, and filter replacement costs over the system's lifetime. Their studies indicate that while cyclones often have lower initial costs and pressure drops, cartridge filters can provide better filtration efficiency and longer service intervals in many applications[3].

Strengths: Innovative hybrid technologies combining cyclone and media filtration. Extensive CFD modeling capabilities for optimized designs. Weaknesses: Potential bias towards their proprietary technologies, which may not always be the most cost-effective solution for all applications.

Core Innovations in Separation Efficiency

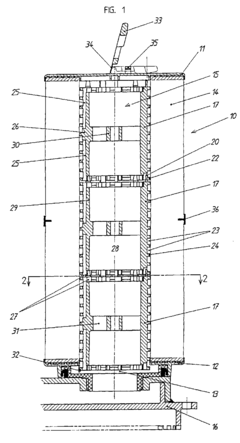

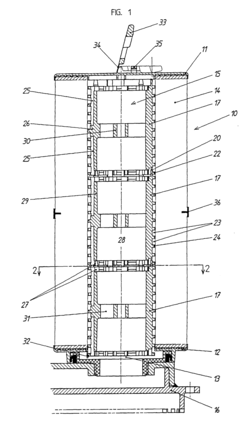

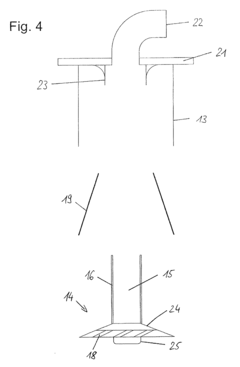

Cartridge filter with a rigid tubular core

PatentInactiveEP0769317A1

Innovation

- A cylindrical filter cartridge design featuring a rigid molded plastic core that is separable from a one-piece assembly with a filter medium and bases, allowing for axial sliding and reuse of the core while the flexible parts can be compacted for disposal or recycling, reducing waste and maintaining fluid flow efficiency.

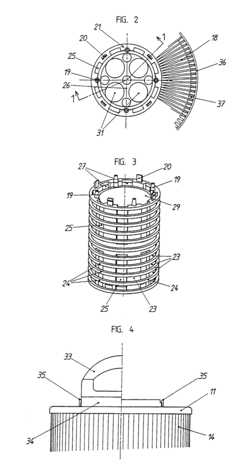

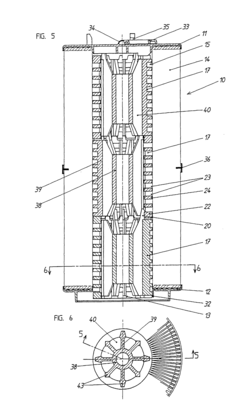

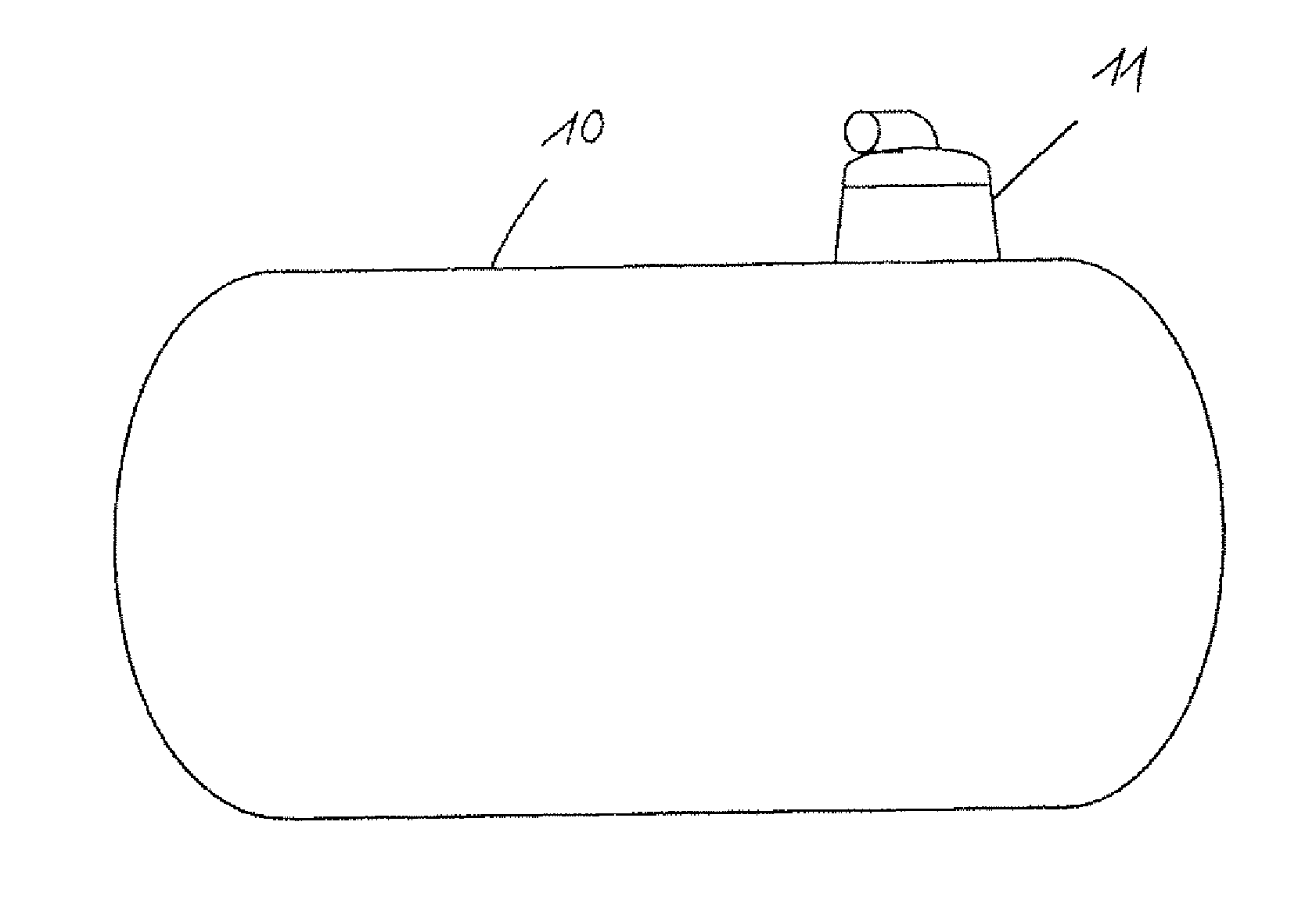

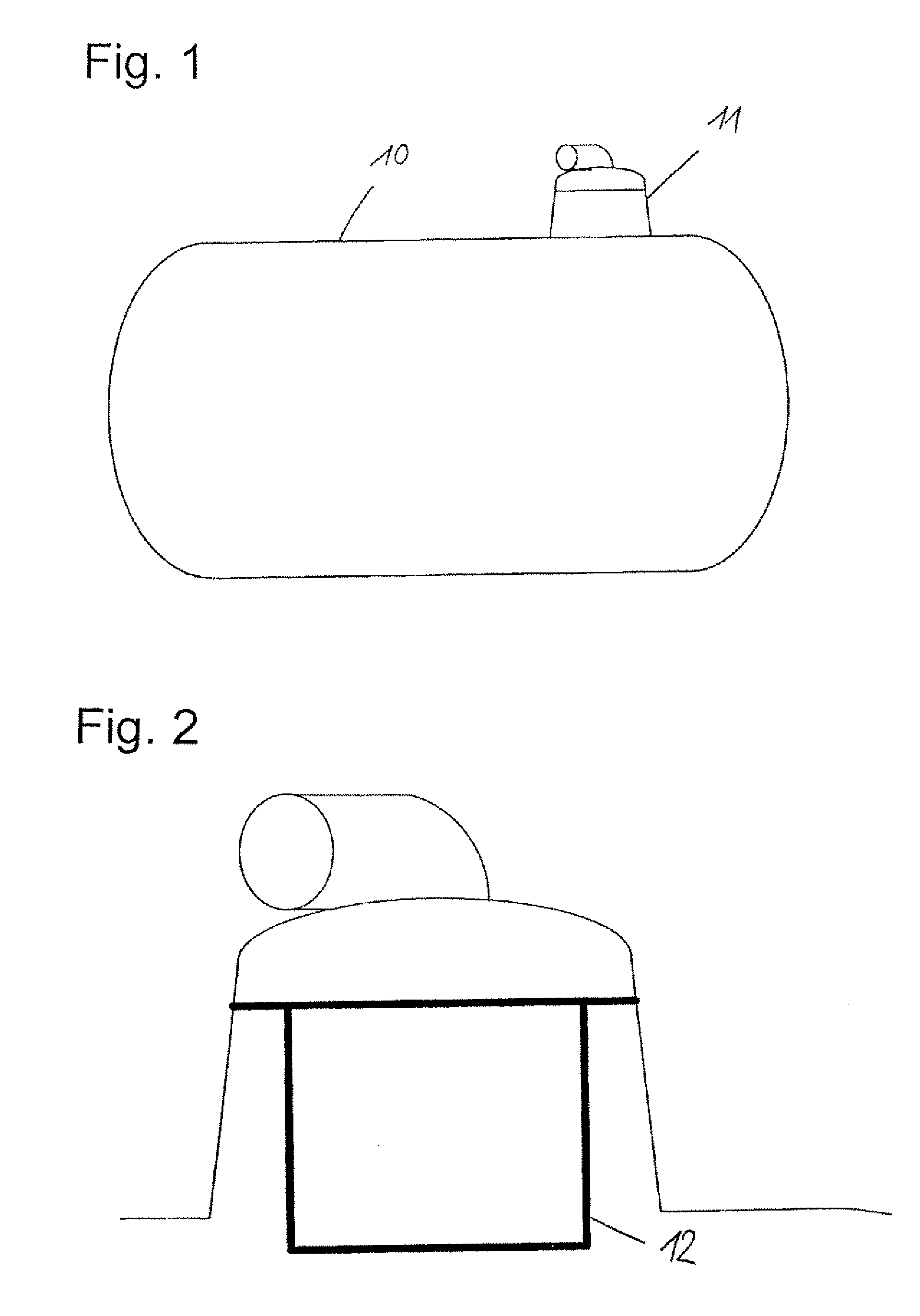

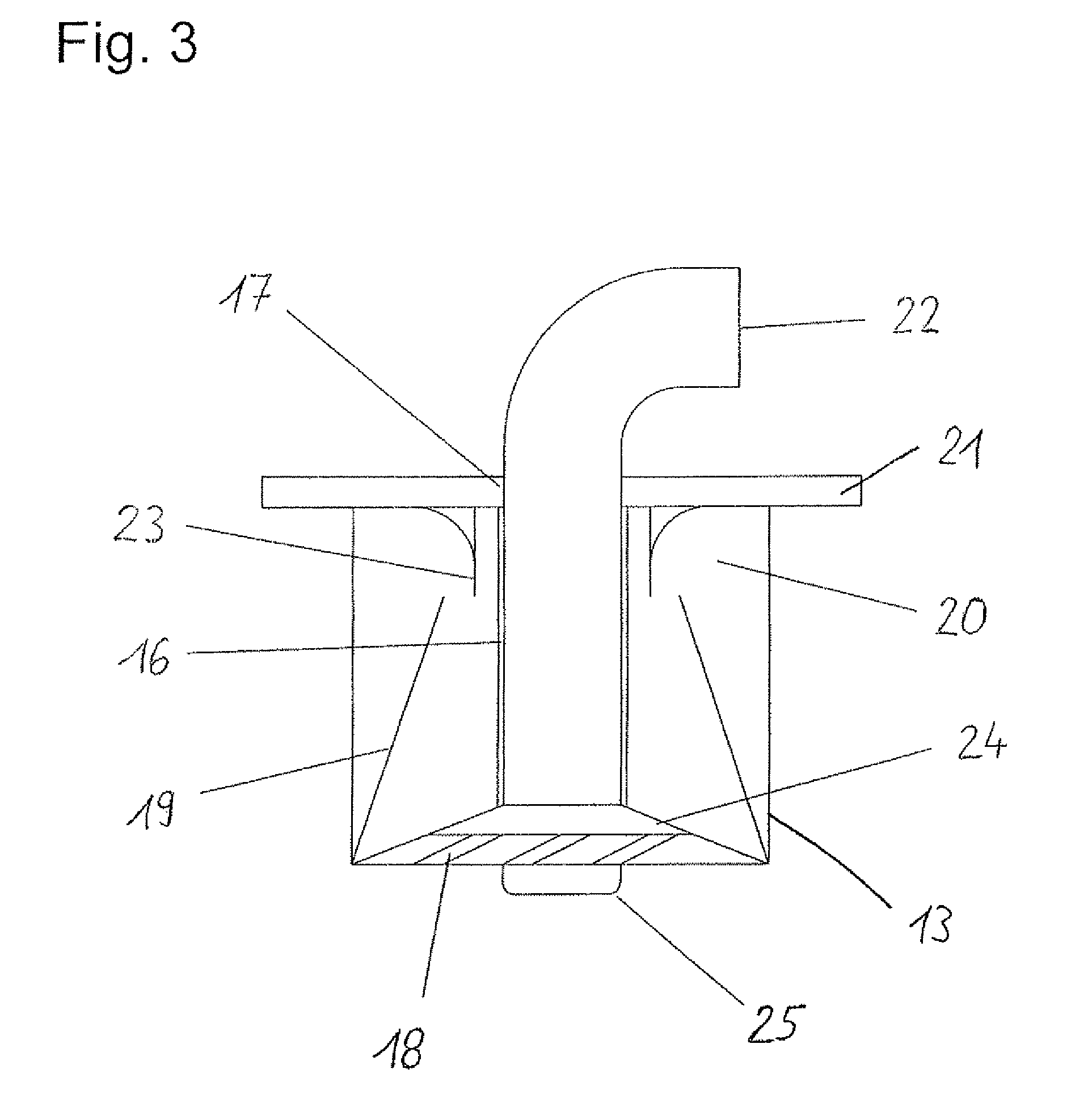

Cyclone separator

PatentActiveUS20100125939A1

Innovation

- A cyclone separator with a casing, input-side swirl generator, a tapering separating wall, and a collection tank is introduced, allowing for the separation and accumulation of liquid constituents, which delays or prevents clogging and facilitates easier cleaning, while accommodating the pressure constraints by utilizing intermittent operation to manage the flow of separated material.

Environmental Impact Assessment

The environmental impact assessment of cyclone separators and cartridge filters is a crucial aspect of their cost-benefit analysis. Cyclone separators, which rely on centrifugal force to separate particles from gas streams, generally have a lower environmental footprint compared to cartridge filters. They require no filter media, reducing waste generation and the need for frequent replacements. This results in fewer disposable materials entering landfills and less energy consumption associated with manufacturing replacement parts.

However, cyclone separators may be less efficient in capturing very fine particles, potentially leading to higher emissions of particulate matter. This could have implications for air quality and compliance with environmental regulations, especially in industries where ultra-fine particle control is critical. In contrast, cartridge filters can achieve higher filtration efficiencies, particularly for smaller particles, contributing to better air quality outcomes.

Cartridge filters, while more effective at particle removal, generate more waste due to the need for periodic replacement of filter elements. This waste, often contaminated with captured pollutants, requires proper disposal, which can have environmental implications. The production and transportation of replacement cartridges also contribute to the overall carbon footprint of this technology.

Energy consumption is another important factor. Cyclone separators typically have lower pressure drops, resulting in reduced energy requirements for air movement. This can lead to lower operational energy costs and associated greenhouse gas emissions. Cartridge filters, especially as they become loaded with particles, may require more energy to maintain airflow, potentially increasing the overall energy consumption and carbon footprint of the filtration system.

Water usage is generally minimal for both technologies, but cartridge filters may require occasional cleaning, which can consume water and potentially generate contaminated wastewater. Cyclone separators, being primarily dry separation devices, typically do not require water for operation or maintenance.

The choice between these technologies also impacts resource utilization. Cyclone separators are often made of durable materials with long lifespans, reducing the need for frequent replacements and conserving resources. Cartridge filters, while requiring more frequent replacements, can be designed with recyclable or biodegradable materials to mitigate their environmental impact.

In conclusion, the environmental impact assessment favors cyclone separators in terms of waste generation, energy consumption, and resource utilization. However, cartridge filters may have an edge in scenarios where stringent air quality standards must be met. The final environmental impact depends on specific application requirements, local regulations, and the overall system design.

However, cyclone separators may be less efficient in capturing very fine particles, potentially leading to higher emissions of particulate matter. This could have implications for air quality and compliance with environmental regulations, especially in industries where ultra-fine particle control is critical. In contrast, cartridge filters can achieve higher filtration efficiencies, particularly for smaller particles, contributing to better air quality outcomes.

Cartridge filters, while more effective at particle removal, generate more waste due to the need for periodic replacement of filter elements. This waste, often contaminated with captured pollutants, requires proper disposal, which can have environmental implications. The production and transportation of replacement cartridges also contribute to the overall carbon footprint of this technology.

Energy consumption is another important factor. Cyclone separators typically have lower pressure drops, resulting in reduced energy requirements for air movement. This can lead to lower operational energy costs and associated greenhouse gas emissions. Cartridge filters, especially as they become loaded with particles, may require more energy to maintain airflow, potentially increasing the overall energy consumption and carbon footprint of the filtration system.

Water usage is generally minimal for both technologies, but cartridge filters may require occasional cleaning, which can consume water and potentially generate contaminated wastewater. Cyclone separators, being primarily dry separation devices, typically do not require water for operation or maintenance.

The choice between these technologies also impacts resource utilization. Cyclone separators are often made of durable materials with long lifespans, reducing the need for frequent replacements and conserving resources. Cartridge filters, while requiring more frequent replacements, can be designed with recyclable or biodegradable materials to mitigate their environmental impact.

In conclusion, the environmental impact assessment favors cyclone separators in terms of waste generation, energy consumption, and resource utilization. However, cartridge filters may have an edge in scenarios where stringent air quality standards must be met. The final environmental impact depends on specific application requirements, local regulations, and the overall system design.

Total Cost of Ownership Analysis

When evaluating the cost-effectiveness of cyclone separators versus cartridge filters, a comprehensive Total Cost of Ownership (TCO) analysis is essential. This analysis encompasses not only the initial purchase and installation costs but also the long-term operational expenses and performance factors.

The upfront costs for cyclone separators are generally lower than those for cartridge filters. Cyclone separators have a simpler design with fewer components, resulting in lower manufacturing and installation costs. However, cartridge filters often require more complex housing and support systems, leading to higher initial investments.

Operational costs play a significant role in the TCO analysis. Cyclone separators typically have lower energy consumption due to their passive separation mechanism, which relies on centrifugal force. In contrast, cartridge filters may require more energy to maintain the necessary pressure drop for effective filtration. This difference in energy requirements can lead to substantial cost savings over time, especially in large-scale industrial applications.

Maintenance expenses are another crucial factor. Cyclone separators have fewer moving parts and no replaceable filter elements, resulting in lower maintenance costs and reduced downtime. Cartridge filters, however, require regular replacement of filter elements, which incurs ongoing material costs and labor expenses for maintenance activities.

The efficiency and effectiveness of the filtration process also impact the TCO. While cyclone separators are generally less efficient at removing very fine particles, they excel at separating larger particulates. Cartridge filters offer higher filtration efficiency, especially for smaller particles, but this comes at the cost of more frequent replacements and potentially higher pressure drops.

Longevity and durability contribute to the overall cost picture. Cyclone separators, with their robust construction and lack of consumable parts, often have longer operational lifespans. Cartridge filters may require more frequent system upgrades or replacements, particularly in harsh industrial environments.

Environmental factors and disposal costs should also be considered. Cyclone separators produce less waste as they do not have disposable filter elements. Cartridge filters generate a steady stream of used filter elements that require proper disposal, which can incur additional costs and environmental considerations.

In conclusion, the TCO analysis reveals that while cyclone separators often have lower upfront and operational costs, cartridge filters may offer superior filtration performance for certain applications. The choice between the two technologies ultimately depends on the specific requirements of the application, including particle size distribution, desired filtration efficiency, and long-term operational considerations.

The upfront costs for cyclone separators are generally lower than those for cartridge filters. Cyclone separators have a simpler design with fewer components, resulting in lower manufacturing and installation costs. However, cartridge filters often require more complex housing and support systems, leading to higher initial investments.

Operational costs play a significant role in the TCO analysis. Cyclone separators typically have lower energy consumption due to their passive separation mechanism, which relies on centrifugal force. In contrast, cartridge filters may require more energy to maintain the necessary pressure drop for effective filtration. This difference in energy requirements can lead to substantial cost savings over time, especially in large-scale industrial applications.

Maintenance expenses are another crucial factor. Cyclone separators have fewer moving parts and no replaceable filter elements, resulting in lower maintenance costs and reduced downtime. Cartridge filters, however, require regular replacement of filter elements, which incurs ongoing material costs and labor expenses for maintenance activities.

The efficiency and effectiveness of the filtration process also impact the TCO. While cyclone separators are generally less efficient at removing very fine particles, they excel at separating larger particulates. Cartridge filters offer higher filtration efficiency, especially for smaller particles, but this comes at the cost of more frequent replacements and potentially higher pressure drops.

Longevity and durability contribute to the overall cost picture. Cyclone separators, with their robust construction and lack of consumable parts, often have longer operational lifespans. Cartridge filters may require more frequent system upgrades or replacements, particularly in harsh industrial environments.

Environmental factors and disposal costs should also be considered. Cyclone separators produce less waste as they do not have disposable filter elements. Cartridge filters generate a steady stream of used filter elements that require proper disposal, which can incur additional costs and environmental considerations.

In conclusion, the TCO analysis reveals that while cyclone separators often have lower upfront and operational costs, cartridge filters may offer superior filtration performance for certain applications. The choice between the two technologies ultimately depends on the specific requirements of the application, including particle size distribution, desired filtration efficiency, and long-term operational considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!