Developing user-friendly interfaces for controlling submersible pumps.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump UI Evolution and Objectives

Submersible pumps have undergone significant evolution in their user interfaces over the past decades, driven by technological advancements and changing user expectations. Initially, these pumps were controlled through basic mechanical switches and analog dials, requiring operators to be physically present at the pump location. This approach, while functional, was limited in terms of precision and remote accessibility.

The advent of digital technology in the 1980s and 1990s marked a turning point in submersible pump interfaces. Digital control panels with LCD displays began to replace analog systems, offering more accurate readings and programmable functions. This shift allowed for better monitoring of pump performance and simplified troubleshooting processes. However, these early digital interfaces were often complex and required specialized training to operate effectively.

As we entered the 21st century, the focus shifted towards developing more intuitive and user-friendly interfaces. Touch screen panels emerged, providing a more interactive and visually appealing way to control pump operations. These interfaces incorporated graphical representations of pump systems, making it easier for operators to understand and manage complex pump configurations.

The rise of mobile technology and the Internet of Things (IoT) has further transformed submersible pump interfaces. Modern systems now offer remote monitoring and control capabilities through smartphone apps and web-based platforms. This advancement allows operators to manage pumps from anywhere, receive real-time alerts, and access historical performance data, significantly improving operational efficiency and response times.

Looking ahead, the objectives for submersible pump interfaces are centered around enhancing user experience, improving operational efficiency, and integrating advanced technologies. Key goals include:

1. Developing more intuitive and customizable user interfaces that can adapt to different user skill levels and preferences.

2. Implementing advanced data analytics and machine learning algorithms to provide predictive maintenance recommendations and optimize pump performance.

3. Enhancing remote control capabilities with augmented reality (AR) and virtual reality (VR) technologies, allowing for immersive troubleshooting and training experiences.

4. Improving integration with broader industrial control systems and enterprise resource planning (ERP) software to streamline overall operations.

5. Incorporating voice-activated controls and natural language processing to enable hands-free operation in challenging environments.

6. Ensuring robust cybersecurity measures to protect pump systems from potential cyber threats as they become more connected.

By focusing on these objectives, the industry aims to create submersible pump interfaces that are not only user-friendly but also highly efficient, secure, and capable of leveraging cutting-edge technologies to meet the evolving needs of operators and businesses.

The advent of digital technology in the 1980s and 1990s marked a turning point in submersible pump interfaces. Digital control panels with LCD displays began to replace analog systems, offering more accurate readings and programmable functions. This shift allowed for better monitoring of pump performance and simplified troubleshooting processes. However, these early digital interfaces were often complex and required specialized training to operate effectively.

As we entered the 21st century, the focus shifted towards developing more intuitive and user-friendly interfaces. Touch screen panels emerged, providing a more interactive and visually appealing way to control pump operations. These interfaces incorporated graphical representations of pump systems, making it easier for operators to understand and manage complex pump configurations.

The rise of mobile technology and the Internet of Things (IoT) has further transformed submersible pump interfaces. Modern systems now offer remote monitoring and control capabilities through smartphone apps and web-based platforms. This advancement allows operators to manage pumps from anywhere, receive real-time alerts, and access historical performance data, significantly improving operational efficiency and response times.

Looking ahead, the objectives for submersible pump interfaces are centered around enhancing user experience, improving operational efficiency, and integrating advanced technologies. Key goals include:

1. Developing more intuitive and customizable user interfaces that can adapt to different user skill levels and preferences.

2. Implementing advanced data analytics and machine learning algorithms to provide predictive maintenance recommendations and optimize pump performance.

3. Enhancing remote control capabilities with augmented reality (AR) and virtual reality (VR) technologies, allowing for immersive troubleshooting and training experiences.

4. Improving integration with broader industrial control systems and enterprise resource planning (ERP) software to streamline overall operations.

5. Incorporating voice-activated controls and natural language processing to enable hands-free operation in challenging environments.

6. Ensuring robust cybersecurity measures to protect pump systems from potential cyber threats as they become more connected.

By focusing on these objectives, the industry aims to create submersible pump interfaces that are not only user-friendly but also highly efficient, secure, and capable of leveraging cutting-edge technologies to meet the evolving needs of operators and businesses.

Market Analysis for Smart Pump Control Systems

The market for smart pump control systems, particularly those designed for submersible pumps, is experiencing significant growth driven by increasing demand for efficient water management solutions across various industries. The global smart pump market is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026, with the submersible pump segment showing particularly strong potential.

Key factors contributing to this market growth include the rising need for water and wastewater management in urban areas, the expansion of agricultural irrigation systems, and the increasing adoption of smart technologies in industrial processes. The oil and gas industry, in particular, has been a major driver of demand for advanced submersible pump control systems, as companies seek to optimize their extraction processes and reduce operational costs.

In terms of regional distribution, North America and Europe currently dominate the smart pump control system market, owing to their well-established industrial sectors and early adoption of IoT technologies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, urbanization, and government initiatives promoting smart water management solutions.

The market is characterized by a growing emphasis on user-friendly interfaces, as end-users across various sectors demand more intuitive and accessible control systems. This trend is particularly evident in the agricultural sector, where farmers are increasingly adopting smart irrigation systems that can be easily monitored and controlled through mobile applications or web-based interfaces.

Challenges in the market include the high initial investment costs associated with smart pump control systems and the need for specialized technical expertise for installation and maintenance. However, these barriers are gradually being overcome as manufacturers focus on developing more cost-effective solutions and providing comprehensive training and support services.

The competitive landscape of the smart pump control system market is characterized by a mix of established industrial automation companies and innovative startups. Key players are investing heavily in research and development to enhance their product offerings, with a particular focus on improving user interfaces and integrating advanced analytics capabilities.

Looking ahead, the market for user-friendly interfaces in submersible pump control systems is expected to continue its upward trajectory, driven by the increasing digitalization of industrial processes and the growing awareness of the benefits of smart water management solutions. As technology continues to evolve, we can anticipate the emergence of more sophisticated, AI-driven control systems that offer even greater levels of automation and optimization.

Key factors contributing to this market growth include the rising need for water and wastewater management in urban areas, the expansion of agricultural irrigation systems, and the increasing adoption of smart technologies in industrial processes. The oil and gas industry, in particular, has been a major driver of demand for advanced submersible pump control systems, as companies seek to optimize their extraction processes and reduce operational costs.

In terms of regional distribution, North America and Europe currently dominate the smart pump control system market, owing to their well-established industrial sectors and early adoption of IoT technologies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, urbanization, and government initiatives promoting smart water management solutions.

The market is characterized by a growing emphasis on user-friendly interfaces, as end-users across various sectors demand more intuitive and accessible control systems. This trend is particularly evident in the agricultural sector, where farmers are increasingly adopting smart irrigation systems that can be easily monitored and controlled through mobile applications or web-based interfaces.

Challenges in the market include the high initial investment costs associated with smart pump control systems and the need for specialized technical expertise for installation and maintenance. However, these barriers are gradually being overcome as manufacturers focus on developing more cost-effective solutions and providing comprehensive training and support services.

The competitive landscape of the smart pump control system market is characterized by a mix of established industrial automation companies and innovative startups. Key players are investing heavily in research and development to enhance their product offerings, with a particular focus on improving user interfaces and integrating advanced analytics capabilities.

Looking ahead, the market for user-friendly interfaces in submersible pump control systems is expected to continue its upward trajectory, driven by the increasing digitalization of industrial processes and the growing awareness of the benefits of smart water management solutions. As technology continues to evolve, we can anticipate the emergence of more sophisticated, AI-driven control systems that offer even greater levels of automation and optimization.

Current Challenges in Pump Interface Design

The design of user-friendly interfaces for controlling submersible pumps faces several significant challenges in the current technological landscape. One of the primary obstacles is the complexity of pump operations, which often involve multiple parameters such as flow rate, pressure, and depth. Translating these complex operations into an intuitive interface that can be easily understood and operated by users with varying levels of technical expertise remains a formidable task.

Another challenge lies in the harsh environments where submersible pumps are typically deployed. These pumps are often used in underwater or subterranean settings, which can be difficult to access and monitor. Designing interfaces that can withstand these challenging conditions while maintaining functionality and user-friendliness is a significant engineering hurdle. This includes developing robust hardware that can resist water, pressure, and corrosion, as well as creating software interfaces that remain responsive and accurate under extreme conditions.

The need for remote monitoring and control adds another layer of complexity to interface design. As submersible pumps are frequently installed in locations that are not easily accessible, there is a growing demand for remote operation capabilities. This necessitates the development of reliable wireless communication systems and user interfaces that can provide real-time data and control options from a distance. Ensuring the security and integrity of these remote connections is also a critical concern, particularly in industrial or sensitive applications.

Standardization across different pump models and manufacturers presents yet another challenge. The lack of a unified interface standard in the industry leads to a proliferation of proprietary systems, each with its own unique control mechanisms. This diversity can lead to confusion and inefficiency for users who need to operate multiple pump systems, highlighting the need for more standardized interface designs that can be applied across different pump types and brands.

Energy efficiency and sustainability considerations also play a crucial role in modern pump interface design. There is an increasing demand for interfaces that not only control pump operations but also provide detailed energy consumption data and optimization suggestions. Integrating these advanced features while maintaining simplicity and ease of use is a delicate balance that interface designers must strike.

Lastly, the integration of emerging technologies such as artificial intelligence and machine learning into pump control systems presents both opportunities and challenges. While these technologies offer the potential for more intelligent and autonomous pump operations, they also introduce new complexities in interface design. Creating interfaces that can effectively communicate AI-driven decisions and allow for human oversight without overwhelming the user is an ongoing challenge in the field.

Another challenge lies in the harsh environments where submersible pumps are typically deployed. These pumps are often used in underwater or subterranean settings, which can be difficult to access and monitor. Designing interfaces that can withstand these challenging conditions while maintaining functionality and user-friendliness is a significant engineering hurdle. This includes developing robust hardware that can resist water, pressure, and corrosion, as well as creating software interfaces that remain responsive and accurate under extreme conditions.

The need for remote monitoring and control adds another layer of complexity to interface design. As submersible pumps are frequently installed in locations that are not easily accessible, there is a growing demand for remote operation capabilities. This necessitates the development of reliable wireless communication systems and user interfaces that can provide real-time data and control options from a distance. Ensuring the security and integrity of these remote connections is also a critical concern, particularly in industrial or sensitive applications.

Standardization across different pump models and manufacturers presents yet another challenge. The lack of a unified interface standard in the industry leads to a proliferation of proprietary systems, each with its own unique control mechanisms. This diversity can lead to confusion and inefficiency for users who need to operate multiple pump systems, highlighting the need for more standardized interface designs that can be applied across different pump types and brands.

Energy efficiency and sustainability considerations also play a crucial role in modern pump interface design. There is an increasing demand for interfaces that not only control pump operations but also provide detailed energy consumption data and optimization suggestions. Integrating these advanced features while maintaining simplicity and ease of use is a delicate balance that interface designers must strike.

Lastly, the integration of emerging technologies such as artificial intelligence and machine learning into pump control systems presents both opportunities and challenges. While these technologies offer the potential for more intelligent and autonomous pump operations, they also introduce new complexities in interface design. Creating interfaces that can effectively communicate AI-driven decisions and allow for human oversight without overwhelming the user is an ongoing challenge in the field.

Existing User-Friendly Pump Control Solutions

01 Intuitive graphical user interfaces

Designing user-friendly interfaces with intuitive graphical elements to enhance user experience. This includes the use of visual cues, icons, and layouts that are easily understandable and navigable for users of all skill levels.- Intuitive graphical user interfaces: Designing user-friendly interfaces with intuitive graphical elements to enhance user experience. This includes creating visually appealing layouts, easy-to-understand icons, and interactive elements that guide users through the interface effortlessly.

- Customizable user interfaces: Implementing customizable interfaces that allow users to personalize their experience. This feature enables users to adjust layouts, color schemes, and functionality according to their preferences, improving overall user satisfaction and efficiency.

- Adaptive interfaces for multiple devices: Developing adaptive interfaces that seamlessly adjust to various device types and screen sizes. This approach ensures a consistent user experience across desktop computers, tablets, and smartphones, enhancing accessibility and usability.

- User-centric design principles: Applying user-centric design principles to create interfaces that prioritize user needs and preferences. This involves conducting user research, usability testing, and iterative design processes to develop interfaces that are intuitive, efficient, and satisfying for the target audience.

- Accessibility features for diverse users: Incorporating accessibility features to ensure interfaces are usable by people with diverse abilities. This includes implementing screen reader compatibility, adjustable font sizes, color contrast options, and alternative input methods to accommodate users with various disabilities.

02 Customizable user interfaces

Implementing customizable interfaces that allow users to personalize their experience. This feature enables users to adjust layouts, themes, and functionalities according to their preferences, improving overall user-friendliness.Expand Specific Solutions03 Adaptive interfaces for different devices

Developing adaptive interfaces that can adjust to various screen sizes and device types. This approach ensures a consistent and user-friendly experience across desktop computers, tablets, and smartphones.Expand Specific Solutions04 Simplified navigation and interaction

Implementing simplified navigation structures and interaction methods to reduce complexity. This includes streamlined menus, clear call-to-action buttons, and intuitive gestures for touch-based interfaces.Expand Specific Solutions05 User feedback and error handling

Incorporating effective user feedback mechanisms and error handling processes. This includes providing clear error messages, helpful tooltips, and guided assistance to enhance the overall user experience and reduce frustration.Expand Specific Solutions

Key Players in Submersible Pump Interface Industry

The development of user-friendly interfaces for controlling submersible pumps is in a growth phase, with increasing market demand driven by automation trends in various industries. The global submersible pump market is expanding, expected to reach significant value in the coming years. Technologically, the field is advancing rapidly, with companies like Hayward Industries, Zodiac Pool Systems, and KSB SE & Co. KGaA leading innovation in pump control interfaces. These firms are integrating smart technologies, IoT connectivity, and intuitive user experiences to enhance pump management. The competition is intensifying as both established players and new entrants focus on developing more sophisticated, efficient, and user-centric control systems for submersible pumps.

Zodiac Pool Care Europe SAS

Technical Solution: Zodiac Pool Care Europe has developed a user-friendly interface for submersible pump control, focusing on simplicity and efficiency. Their system features a modular design that allows for easy customization based on specific user needs[4]. The interface incorporates a color-coded display system for quick status identification and a simplified menu structure for easy navigation. Zodiac has also implemented a multi-language support feature, making the interface accessible to a diverse user base[5]. The system includes automated scheduling capabilities, allowing users to set pump operation times in advance, optimizing energy usage and maintenance schedules[6].

Strengths: Modular design for customization, multi-language support, automated scheduling. Weaknesses: May lack advanced features compared to some competitors, potential limitations in remote access capabilities.

Hayward Industries, Inc.

Technical Solution: Hayward Industries has developed an advanced user interface for controlling submersible pumps, focusing on intuitive operation and remote accessibility. Their system incorporates a touchscreen display with a graphical user interface (GUI) that simplifies pump control and monitoring. The interface features real-time data visualization, allowing users to easily track pump performance, energy consumption, and maintenance needs[1]. Additionally, Hayward has integrated mobile app connectivity, enabling users to control and monitor their submersible pumps remotely via smartphones or tablets[2]. The system also includes voice control capabilities, enhancing user convenience and accessibility[3].

Strengths: Intuitive GUI, remote access via mobile app, voice control integration. Weaknesses: Potential complexity for less tech-savvy users, reliance on stable internet connection for remote features.

Innovative HMI Technologies for Submersible Pumps

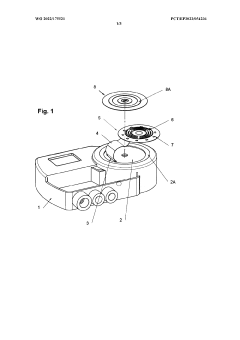

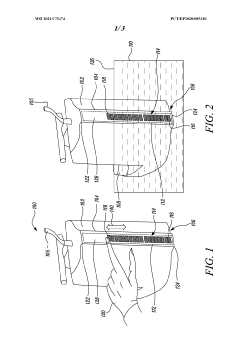

Pump having a control panel

PatentWO2022175521A1

Innovation

- A touch-sensitive surface with capacitive technology, sealed with a splash-proof film and integrated light sources for visual feedback, simulating the operation of a mechanical setting wheel, allowing for finger or stylus inputs without mechanical movement, and optionally combined with mechanical elements for enhanced usability.

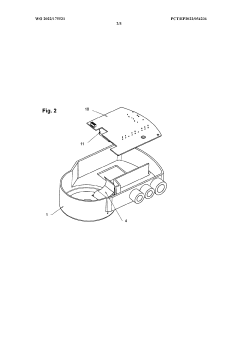

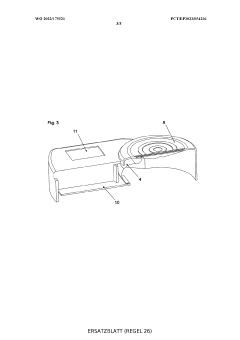

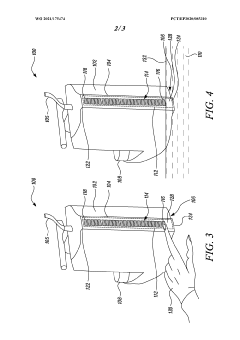

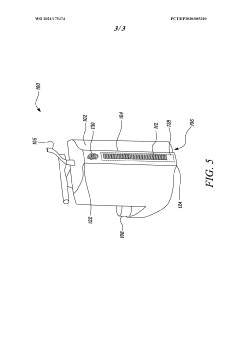

Submersible pump with touch sensitive sensors

PatentWO2021175474A1

Innovation

- Integration of stationary capacitive touch sensors on the pump body that allow users to set and adjust the liquid level through intuitive gestures such as swiping or pressing, eliminating the need for movable components and providing an indicator for confirmation.

Regulatory Framework for Industrial Control Systems

The regulatory framework for industrial control systems plays a crucial role in ensuring the safety, reliability, and security of submersible pump control interfaces. In the context of developing user-friendly interfaces for controlling submersible pumps, adherence to relevant regulations and standards is paramount.

Industrial control systems, including those used for submersible pumps, are subject to various national and international regulations. These regulations often focus on safety, environmental protection, and cybersecurity aspects. For instance, in the United States, the Occupational Safety and Health Administration (OSHA) sets standards for industrial equipment operation, which includes control interfaces for submersible pumps.

The International Electrotechnical Commission (IEC) provides global standards for industrial control systems. IEC 61131-3, for example, standardizes programming languages for programmable logic controllers (PLCs), which are commonly used in submersible pump control systems. This standard ensures consistency and interoperability across different control systems.

Cybersecurity regulations have become increasingly important in recent years. The National Institute of Standards and Technology (NIST) in the U.S. has developed guidelines for industrial control system security, which are applicable to submersible pump control interfaces. These guidelines emphasize the importance of secure user authentication, data encryption, and protection against unauthorized access.

Environmental regulations also impact the design of control interfaces for submersible pumps. For instance, the European Union's Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous materials in electrical and electronic equipment, including control interfaces.

When developing user-friendly interfaces for submersible pump control, designers must consider ergonomic standards. ISO 9241, which covers ergonomics of human-system interaction, provides guidelines for designing user interfaces that are both efficient and comfortable to use. This standard is particularly relevant for creating intuitive and easy-to-use control interfaces for submersible pumps.

Compliance with these regulatory frameworks not only ensures legal adherence but also contributes to the overall quality and reliability of the control interface. It helps in creating standardized, safe, and user-friendly interfaces that can be easily adopted across different industries and geographical regions.

As technology evolves, regulatory frameworks are continuously updated to address new challenges and opportunities. Developers of submersible pump control interfaces must stay informed about these changes and adapt their designs accordingly to maintain compliance and ensure optimal user experience.

Industrial control systems, including those used for submersible pumps, are subject to various national and international regulations. These regulations often focus on safety, environmental protection, and cybersecurity aspects. For instance, in the United States, the Occupational Safety and Health Administration (OSHA) sets standards for industrial equipment operation, which includes control interfaces for submersible pumps.

The International Electrotechnical Commission (IEC) provides global standards for industrial control systems. IEC 61131-3, for example, standardizes programming languages for programmable logic controllers (PLCs), which are commonly used in submersible pump control systems. This standard ensures consistency and interoperability across different control systems.

Cybersecurity regulations have become increasingly important in recent years. The National Institute of Standards and Technology (NIST) in the U.S. has developed guidelines for industrial control system security, which are applicable to submersible pump control interfaces. These guidelines emphasize the importance of secure user authentication, data encryption, and protection against unauthorized access.

Environmental regulations also impact the design of control interfaces for submersible pumps. For instance, the European Union's Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous materials in electrical and electronic equipment, including control interfaces.

When developing user-friendly interfaces for submersible pump control, designers must consider ergonomic standards. ISO 9241, which covers ergonomics of human-system interaction, provides guidelines for designing user interfaces that are both efficient and comfortable to use. This standard is particularly relevant for creating intuitive and easy-to-use control interfaces for submersible pumps.

Compliance with these regulatory frameworks not only ensures legal adherence but also contributes to the overall quality and reliability of the control interface. It helps in creating standardized, safe, and user-friendly interfaces that can be easily adopted across different industries and geographical regions.

As technology evolves, regulatory frameworks are continuously updated to address new challenges and opportunities. Developers of submersible pump control interfaces must stay informed about these changes and adapt their designs accordingly to maintain compliance and ensure optimal user experience.

Human Factors in Submersible Pump UI Design

Human factors play a crucial role in the design of user-friendly interfaces for controlling submersible pumps. The interface serves as the primary point of interaction between operators and the complex machinery beneath the surface, making it essential to prioritize usability, safety, and efficiency in its design.

One of the key considerations in submersible pump UI design is the cognitive load placed on operators. The interface must present information in a clear, concise manner that allows for quick decision-making without overwhelming the user. This involves careful selection and organization of data, utilizing visual hierarchies and color coding to highlight critical information and system status.

Ergonomics also play a significant role in the design process. The physical layout of controls and displays must accommodate a wide range of users, considering factors such as reach distances, button sizes, and screen visibility under various lighting conditions. This is particularly important in industrial environments where operators may be wearing protective equipment or working in challenging conditions.

The incorporation of intuitive navigation and control schemes is another vital aspect of human-centered design for submersible pump interfaces. Designers must consider the mental models of operators and align the system's functionality with their expectations. This may involve the use of familiar metaphors, consistent layout patterns, and clear labeling to reduce the learning curve and minimize errors.

Feedback mechanisms are essential for maintaining operator awareness and confidence in the system. Visual, auditory, and tactile feedback should be employed to confirm user actions, alert operators to changes in pump status, and provide warnings in case of potential issues. The timing and intensity of these feedback elements must be carefully calibrated to ensure they are noticeable without being disruptive.

Adaptability is another key factor in UI design for submersible pumps. The interface should be flexible enough to accommodate different user preferences and skill levels, potentially offering customizable displays or multiple modes of operation. This adaptability extends to the ability to function effectively across various devices and screen sizes, from control room monitors to mobile tablets used for on-site inspections.

Safety considerations are paramount in the design of submersible pump interfaces. The UI must incorporate fail-safe mechanisms, clear emergency procedures, and redundant controls for critical functions. Visual cues and confirmation dialogs for potentially dangerous operations can help prevent accidental activation and ensure that operators are fully aware of the consequences of their actions.

By focusing on these human factors in the design process, developers can create interfaces for submersible pumps that not only enhance operational efficiency but also improve safety and user satisfaction. The result is a more robust and user-friendly control system that can be operated effectively even in challenging industrial environments.

One of the key considerations in submersible pump UI design is the cognitive load placed on operators. The interface must present information in a clear, concise manner that allows for quick decision-making without overwhelming the user. This involves careful selection and organization of data, utilizing visual hierarchies and color coding to highlight critical information and system status.

Ergonomics also play a significant role in the design process. The physical layout of controls and displays must accommodate a wide range of users, considering factors such as reach distances, button sizes, and screen visibility under various lighting conditions. This is particularly important in industrial environments where operators may be wearing protective equipment or working in challenging conditions.

The incorporation of intuitive navigation and control schemes is another vital aspect of human-centered design for submersible pump interfaces. Designers must consider the mental models of operators and align the system's functionality with their expectations. This may involve the use of familiar metaphors, consistent layout patterns, and clear labeling to reduce the learning curve and minimize errors.

Feedback mechanisms are essential for maintaining operator awareness and confidence in the system. Visual, auditory, and tactile feedback should be employed to confirm user actions, alert operators to changes in pump status, and provide warnings in case of potential issues. The timing and intensity of these feedback elements must be carefully calibrated to ensure they are noticeable without being disruptive.

Adaptability is another key factor in UI design for submersible pumps. The interface should be flexible enough to accommodate different user preferences and skill levels, potentially offering customizable displays or multiple modes of operation. This adaptability extends to the ability to function effectively across various devices and screen sizes, from control room monitors to mobile tablets used for on-site inspections.

Safety considerations are paramount in the design of submersible pump interfaces. The UI must incorporate fail-safe mechanisms, clear emergency procedures, and redundant controls for critical functions. Visual cues and confirmation dialogs for potentially dangerous operations can help prevent accidental activation and ensure that operators are fully aware of the consequences of their actions.

By focusing on these human factors in the design process, developers can create interfaces for submersible pumps that not only enhance operational efficiency but also improve safety and user satisfaction. The result is a more robust and user-friendly control system that can be operated effectively even in challenging industrial environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!