Discovering Kevlar's Potential in Space Exploration Missions

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Space: Background and Objectives

Kevlar, a synthetic fiber developed by DuPont in the 1960s, has long been recognized for its exceptional strength-to-weight ratio and heat-resistant properties. Initially designed for use in automotive tires, Kevlar's potential has expanded far beyond its original purpose, finding applications in various industries, including aerospace and defense. As space exploration continues to push the boundaries of human achievement, the need for advanced materials capable of withstanding extreme conditions has become increasingly critical.

The evolution of Kevlar's role in space exploration can be traced back to the early days of the Space Shuttle program, where it was used in the thermal protection system. Since then, its applications have diversified, encompassing everything from spacecraft components to spacesuit materials. The unique combination of Kevlar's lightweight nature and robust mechanical properties makes it an ideal candidate for addressing many of the challenges faced in space missions.

In recent years, the space industry has experienced a renaissance, with both government agencies and private companies investing heavily in new technologies and missions. This resurgence has reignited interest in innovative materials that can enhance the safety, efficiency, and capabilities of space vehicles and equipment. Kevlar, with its proven track record and ongoing advancements, stands at the forefront of this materials revolution.

The primary objective of exploring Kevlar's potential in space exploration missions is to identify and develop novel applications that can significantly improve the performance and durability of space-related technologies. This includes investigating its use in structural components, impact shielding, thermal management systems, and even in the development of next-generation spacesuits. By leveraging Kevlar's unique properties, researchers aim to create lighter, stronger, and more resilient space systems that can withstand the harsh conditions of extraterrestrial environments.

Furthermore, the exploration of Kevlar's potential extends beyond immediate applications to long-term space exploration goals. As humanity sets its sights on extended missions to the Moon, Mars, and beyond, the demand for materials that can provide reliable protection and performance over extended periods becomes paramount. Kevlar's resistance to degradation and its ability to maintain its properties under extreme conditions position it as a promising candidate for these future endeavors.

The technological trajectory of Kevlar in space applications is closely aligned with broader trends in materials science and engineering. Ongoing research into nanocomposites and hybrid materials incorporating Kevlar fibers promises to unlock even greater potential, potentially revolutionizing spacecraft design and construction. As such, the investigation into Kevlar's role in space exploration represents not just an enhancement of existing technologies, but a pathway to entirely new possibilities in space travel and habitation.

The evolution of Kevlar's role in space exploration can be traced back to the early days of the Space Shuttle program, where it was used in the thermal protection system. Since then, its applications have diversified, encompassing everything from spacecraft components to spacesuit materials. The unique combination of Kevlar's lightweight nature and robust mechanical properties makes it an ideal candidate for addressing many of the challenges faced in space missions.

In recent years, the space industry has experienced a renaissance, with both government agencies and private companies investing heavily in new technologies and missions. This resurgence has reignited interest in innovative materials that can enhance the safety, efficiency, and capabilities of space vehicles and equipment. Kevlar, with its proven track record and ongoing advancements, stands at the forefront of this materials revolution.

The primary objective of exploring Kevlar's potential in space exploration missions is to identify and develop novel applications that can significantly improve the performance and durability of space-related technologies. This includes investigating its use in structural components, impact shielding, thermal management systems, and even in the development of next-generation spacesuits. By leveraging Kevlar's unique properties, researchers aim to create lighter, stronger, and more resilient space systems that can withstand the harsh conditions of extraterrestrial environments.

Furthermore, the exploration of Kevlar's potential extends beyond immediate applications to long-term space exploration goals. As humanity sets its sights on extended missions to the Moon, Mars, and beyond, the demand for materials that can provide reliable protection and performance over extended periods becomes paramount. Kevlar's resistance to degradation and its ability to maintain its properties under extreme conditions position it as a promising candidate for these future endeavors.

The technological trajectory of Kevlar in space applications is closely aligned with broader trends in materials science and engineering. Ongoing research into nanocomposites and hybrid materials incorporating Kevlar fibers promises to unlock even greater potential, potentially revolutionizing spacecraft design and construction. As such, the investigation into Kevlar's role in space exploration represents not just an enhancement of existing technologies, but a pathway to entirely new possibilities in space travel and habitation.

Space Industry Demand Analysis

The space industry has been experiencing significant growth and transformation in recent years, driven by both government initiatives and private sector investments. This surge in space exploration activities has created a substantial demand for advanced materials that can withstand the extreme conditions of space environments. Kevlar, a high-strength synthetic fiber known for its exceptional durability and heat resistance, has emerged as a potential game-changer in space exploration missions.

The market demand for Kevlar in space applications is primarily fueled by the need for lightweight, yet robust materials that can protect spacecraft, satellites, and astronauts from the harsh conditions of space. As space agencies and private companies plan more ambitious missions, including long-duration space travel and potential colonization of other planets, the demand for materials like Kevlar is expected to grow exponentially.

One of the key drivers of this demand is the increasing number of satellite launches. With the rise of mega-constellations for global internet coverage and Earth observation, the satellite market is projected to expand significantly in the coming years. Kevlar's potential applications in satellite structures and protective layers could lead to a substantial increase in its usage within this sector.

Moreover, the growing interest in human spaceflight, both for scientific research and space tourism, is creating new opportunities for Kevlar. Its potential use in space suits, habitats, and other life support systems could revolutionize the safety and efficiency of manned space missions. The material's ability to provide superior protection against micrometeoroids and space debris is particularly valuable in this context.

The space industry's focus on reusability and cost reduction also aligns well with Kevlar's properties. Its high strength-to-weight ratio makes it an attractive option for developing more efficient and durable spacecraft components, potentially reducing launch costs and increasing payload capacity.

Furthermore, the expansion of space exploration to include missions to the Moon, Mars, and beyond is opening up new avenues for Kevlar's application. These missions require materials that can withstand extreme temperature variations, radiation, and other challenging conditions, areas where Kevlar's unique properties could prove invaluable.

As the space industry continues to evolve, the demand for innovative materials like Kevlar is likely to increase. The material's potential to enhance the safety, durability, and efficiency of space exploration missions positions it as a critical component in the future of space technology. This growing demand is expected to drive further research and development into Kevlar's space applications, potentially leading to new breakthroughs and expanded use cases in the coming years.

The market demand for Kevlar in space applications is primarily fueled by the need for lightweight, yet robust materials that can protect spacecraft, satellites, and astronauts from the harsh conditions of space. As space agencies and private companies plan more ambitious missions, including long-duration space travel and potential colonization of other planets, the demand for materials like Kevlar is expected to grow exponentially.

One of the key drivers of this demand is the increasing number of satellite launches. With the rise of mega-constellations for global internet coverage and Earth observation, the satellite market is projected to expand significantly in the coming years. Kevlar's potential applications in satellite structures and protective layers could lead to a substantial increase in its usage within this sector.

Moreover, the growing interest in human spaceflight, both for scientific research and space tourism, is creating new opportunities for Kevlar. Its potential use in space suits, habitats, and other life support systems could revolutionize the safety and efficiency of manned space missions. The material's ability to provide superior protection against micrometeoroids and space debris is particularly valuable in this context.

The space industry's focus on reusability and cost reduction also aligns well with Kevlar's properties. Its high strength-to-weight ratio makes it an attractive option for developing more efficient and durable spacecraft components, potentially reducing launch costs and increasing payload capacity.

Furthermore, the expansion of space exploration to include missions to the Moon, Mars, and beyond is opening up new avenues for Kevlar's application. These missions require materials that can withstand extreme temperature variations, radiation, and other challenging conditions, areas where Kevlar's unique properties could prove invaluable.

As the space industry continues to evolve, the demand for innovative materials like Kevlar is likely to increase. The material's potential to enhance the safety, durability, and efficiency of space exploration missions positions it as a critical component in the future of space technology. This growing demand is expected to drive further research and development into Kevlar's space applications, potentially leading to new breakthroughs and expanded use cases in the coming years.

Current Kevlar Applications and Limitations in Space

Kevlar, a high-strength synthetic fiber developed by DuPont, has found numerous applications in space exploration missions due to its exceptional properties. In spacecraft and satellites, Kevlar is widely used for thermal insulation and micrometeoroid protection. Its lightweight nature and high tensile strength make it an ideal material for constructing components of space suits, tethers, and inflatable habitats.

One of the primary applications of Kevlar in space is in the construction of spacecraft heat shields. The material's ability to withstand extreme temperatures and its low thermal conductivity make it an excellent choice for protecting spacecraft during atmospheric re-entry. Kevlar is also utilized in the fabrication of fuel tanks and pressure vessels for spacecraft, offering a combination of strength and weight reduction crucial for space missions.

In satellite technology, Kevlar finds applications in antenna structures and solar panel substrates. Its resistance to UV radiation and thermal cycling in the space environment contributes to the longevity and reliability of these components. Additionally, Kevlar fibers are incorporated into composite materials used in the construction of spacecraft structural elements, providing enhanced strength-to-weight ratios.

Despite its numerous advantages, Kevlar does face certain limitations in space applications. One significant challenge is its susceptibility to atomic oxygen erosion in low Earth orbit. This can lead to degradation of Kevlar-based materials over time, potentially compromising their structural integrity. To mitigate this issue, protective coatings or alternative materials may be required for long-duration missions.

Another limitation is Kevlar's relatively high cost compared to some alternative materials. This factor can impact the overall budget of space missions, particularly for large-scale applications. Furthermore, while Kevlar exhibits excellent tensile strength, its compressive strength is comparatively lower, which may limit its use in certain structural applications where compressive loads are significant.

The processing and manufacturing of Kevlar for space applications also present challenges. The material's high melting point and resistance to solvents make it difficult to form into complex shapes or integrate with other materials. This can restrict design flexibility and increase production complexity for space components.

Lastly, while Kevlar performs well in many aspects of the space environment, it may not be the optimal choice for all applications. For instance, in scenarios requiring extreme radiation resistance or specific electromagnetic properties, alternative materials might be preferred. This necessitates careful consideration and material selection based on the specific requirements of each space mission component.

One of the primary applications of Kevlar in space is in the construction of spacecraft heat shields. The material's ability to withstand extreme temperatures and its low thermal conductivity make it an excellent choice for protecting spacecraft during atmospheric re-entry. Kevlar is also utilized in the fabrication of fuel tanks and pressure vessels for spacecraft, offering a combination of strength and weight reduction crucial for space missions.

In satellite technology, Kevlar finds applications in antenna structures and solar panel substrates. Its resistance to UV radiation and thermal cycling in the space environment contributes to the longevity and reliability of these components. Additionally, Kevlar fibers are incorporated into composite materials used in the construction of spacecraft structural elements, providing enhanced strength-to-weight ratios.

Despite its numerous advantages, Kevlar does face certain limitations in space applications. One significant challenge is its susceptibility to atomic oxygen erosion in low Earth orbit. This can lead to degradation of Kevlar-based materials over time, potentially compromising their structural integrity. To mitigate this issue, protective coatings or alternative materials may be required for long-duration missions.

Another limitation is Kevlar's relatively high cost compared to some alternative materials. This factor can impact the overall budget of space missions, particularly for large-scale applications. Furthermore, while Kevlar exhibits excellent tensile strength, its compressive strength is comparatively lower, which may limit its use in certain structural applications where compressive loads are significant.

The processing and manufacturing of Kevlar for space applications also present challenges. The material's high melting point and resistance to solvents make it difficult to form into complex shapes or integrate with other materials. This can restrict design flexibility and increase production complexity for space components.

Lastly, while Kevlar performs well in many aspects of the space environment, it may not be the optimal choice for all applications. For instance, in scenarios requiring extreme radiation resistance or specific electromagnetic properties, alternative materials might be preferred. This necessitates careful consideration and material selection based on the specific requirements of each space mission component.

Existing Kevlar Solutions for Space Missions

01 Kevlar-reinforced composite materials

Kevlar fibers are incorporated into various composite materials to enhance their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The combination of Kevlar with other materials like carbon fiber or polymers creates lightweight yet robust structures.- Kevlar-reinforced composite materials: Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The incorporation of Kevlar improves the overall performance and lightweight properties of the resulting materials.

- Kevlar-based protective gear: Kevlar is extensively used in the development of protective gear, including bulletproof vests, helmets, and other personal protective equipment. Its high tensile strength and heat-resistant properties make it ideal for applications requiring impact and ballistic protection. Innovations in this area focus on improving comfort, flexibility, and overall protective capabilities.

- Kevlar in textile and fabric applications: Kevlar fibers are incorporated into various textile and fabric applications to enhance their strength, durability, and heat resistance. This includes the development of cut-resistant gloves, fire-resistant clothing, and high-performance sportswear. Innovations in this area focus on improving the integration of Kevlar with other materials and enhancing its properties for specific end-use requirements.

- Kevlar-enhanced structural components: Kevlar is used to reinforce structural components in various industries, including construction, marine, and aerospace. Its high strength-to-weight ratio and resistance to environmental factors make it suitable for improving the performance of beams, panels, and other load-bearing elements. Innovations in this area focus on optimizing the integration of Kevlar with traditional construction materials.

- Kevlar in advanced manufacturing processes: Kevlar is being incorporated into advanced manufacturing processes, such as 3D printing and additive manufacturing. This allows for the creation of complex, lightweight structures with enhanced mechanical properties. Innovations in this area focus on developing new manufacturing techniques and optimizing the use of Kevlar in various printing and molding processes.

02 Kevlar-based protective gear

Kevlar is extensively used in the development of personal protective equipment, including bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and heat-resistant properties make it ideal for creating lightweight yet effective protective gear for military, law enforcement, and industrial applications.Expand Specific Solutions03 Kevlar in textile and clothing applications

Kevlar fibers are incorporated into various textile products to improve their strength, abrasion resistance, and heat resistance. This includes applications in high-performance sportswear, fire-resistant clothing, and industrial workwear. The integration of Kevlar enhances the durability and protective properties of these textiles.Expand Specific Solutions04 Kevlar-enhanced construction materials

Kevlar is used to reinforce construction materials such as concrete, asphalt, and building panels. The addition of Kevlar fibers improves the tensile strength, crack resistance, and overall durability of these materials. This results in stronger and more resilient structures in civil engineering and architectural applications.Expand Specific Solutions05 Kevlar in automotive and transportation

Kevlar is utilized in various automotive and transportation applications to reduce weight while maintaining strength and safety. It is used in tire reinforcement, brake pads, and body panels. The lightweight nature of Kevlar contributes to improved fuel efficiency and performance in vehicles and aircraft.Expand Specific Solutions

Key Players in Space-Grade Kevlar Development

The exploration of Kevlar's potential in space missions is currently in an early development stage, with a growing market driven by the increasing demand for lightweight, high-strength materials in spacecraft design. The global space industry, valued at over $400 billion, presents significant opportunities for Kevlar applications. While the technology is mature in terrestrial uses, its space-specific applications are still evolving. Key players like China Academy of Space Technology, United Launch Alliance, and Lockheed Martin are likely at the forefront of integrating Kevlar into space systems. Universities such as Harbin Institute of Technology and Northwestern Polytechnical University are contributing to research and development efforts, potentially accelerating the technology's adaptation for space environments.

China Academy of Space Technology

Technical Solution: China Academy of Space Technology (CAST) has been exploring the potential of Kevlar in space exploration missions. They have developed a Kevlar-reinforced composite material for spacecraft structures, which offers superior strength-to-weight ratio compared to traditional materials. This composite integrates Kevlar fibers with advanced resin systems, resulting in a material that is both lightweight and highly resistant to impact and thermal stresses encountered in space environments[1]. CAST has also implemented Kevlar in the design of inflatable habitats for potential lunar or Martian missions, leveraging its flexibility and durability[2]. Additionally, they are researching Kevlar-based micrometeoroid and orbital debris (MMOD) shields to enhance spacecraft protection during long-duration missions[3].

Strengths: Lightweight, high strength-to-weight ratio, excellent impact resistance, and thermal stability. Weaknesses: Higher cost compared to traditional materials, potential for moisture absorption in certain environments.

Southwest Research Institute

Technical Solution: The Southwest Research Institute (SwRI) has been actively researching Kevlar's applications in space exploration missions. They have developed a Kevlar-based micrometeoroid capture system for sample return missions, which allows for the collection of space debris and micrometeoroids without damaging the particles[13]. This technology has potential applications in studying the composition of asteroids and other celestial bodies. SwRI has also been working on Kevlar-reinforced inflatable structures for space habitats, focusing on improving the radiation shielding and impact resistance of these structures[14]. Additionally, they are exploring the use of Kevlar in advanced propulsion systems, particularly in the development of lightweight pressure vessels for storing propellants in spacecraft[15]. SwRI's research also extends to using Kevlar in space-based scientific instruments, where its properties can help protect sensitive equipment from the harsh space environment.

Strengths: Innovative applications in sample return missions, expertise in inflatable space structures, advancements in propulsion system components. Weaknesses: Some technologies still in early development stages, potential challenges in long-term durability testing for novel applications.

Innovative Kevlar Technologies for Space Applications

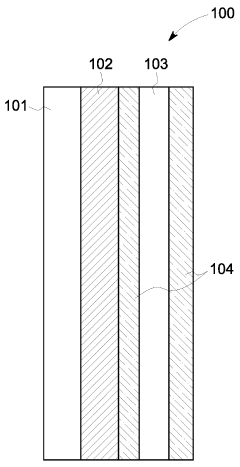

Reinforced composite material with high impact strength

PatentUndeterminedIN201931044509A

Innovation

- A multi-layered reinforced laminated structure comprising an outer Kevlar layer for heat and penetration resistance, a middle graphene layer for resilience, and an inner carbyne layer stabilized by double-walled carbon nanotubes for rigidity, providing lightweight, high impact strength, and enhanced tensile strength and elasticity.

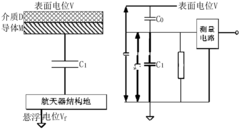

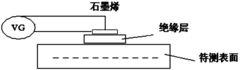

Graphene purpose in spacecraft surface potential measurement

PatentActiveCN108872725A

Innovation

- A graphene array is set on the surface of the spacecraft through an insulator layer, and the electric field effect change of graphene is used to measure the resistance value to achieve high-precision, interference-free multi-dimensional vector potential monitoring, including single-point and all-round detection.

Space Debris Mitigation Strategies Using Kevlar

Space debris mitigation strategies using Kevlar have gained significant attention in recent years due to the material's exceptional strength-to-weight ratio and impact resistance properties. Kevlar, a synthetic fiber developed by DuPont, has demonstrated remarkable potential in addressing the growing concern of space debris in Earth's orbit.

One of the primary strategies employing Kevlar involves the development of advanced shielding systems for spacecraft and satellites. These shields, often consisting of multiple layers of Kevlar fabric combined with other materials, provide enhanced protection against micrometeoroid and orbital debris impacts. The layered structure allows for the dissipation of impact energy, reducing the risk of catastrophic damage to space assets.

Another innovative approach utilizes Kevlar in the design of debris removal systems. Tethers made from Kevlar fibers have been proposed for capturing and de-orbiting defunct satellites and large debris pieces. The high tensile strength and low weight of Kevlar make it an ideal material for such applications, as it can withstand the extreme forces encountered during debris removal operations while minimizing additional mass added to the system.

Kevlar-based nets and harpoons have also been explored as potential tools for active debris removal missions. These devices can be deployed from dedicated spacecraft to capture and control larger debris objects, facilitating their controlled re-entry into Earth's atmosphere. The flexibility and durability of Kevlar allow for the creation of lightweight yet robust capture mechanisms capable of withstanding the harsh space environment.

In addition to active debris removal, Kevlar has shown promise in passive debris mitigation strategies. Researchers have investigated the use of Kevlar-reinforced inflatable structures that can be deployed at the end of a satellite's operational life. These structures increase the surface area of the satellite, accelerating its orbital decay and reducing the time it remains in orbit as potential debris.

Furthermore, Kevlar composites are being explored for the development of self-healing materials for spacecraft exteriors. These advanced materials could potentially repair minor damage caused by small debris impacts, extending the operational life of space assets and reducing the generation of new debris from degraded spacecraft components.

As space activities continue to increase, the implementation of effective debris mitigation strategies becomes increasingly critical. Kevlar's unique properties position it as a key material in addressing this challenge, offering innovative solutions for both protecting space assets and actively reducing the existing debris population in Earth's orbit.

One of the primary strategies employing Kevlar involves the development of advanced shielding systems for spacecraft and satellites. These shields, often consisting of multiple layers of Kevlar fabric combined with other materials, provide enhanced protection against micrometeoroid and orbital debris impacts. The layered structure allows for the dissipation of impact energy, reducing the risk of catastrophic damage to space assets.

Another innovative approach utilizes Kevlar in the design of debris removal systems. Tethers made from Kevlar fibers have been proposed for capturing and de-orbiting defunct satellites and large debris pieces. The high tensile strength and low weight of Kevlar make it an ideal material for such applications, as it can withstand the extreme forces encountered during debris removal operations while minimizing additional mass added to the system.

Kevlar-based nets and harpoons have also been explored as potential tools for active debris removal missions. These devices can be deployed from dedicated spacecraft to capture and control larger debris objects, facilitating their controlled re-entry into Earth's atmosphere. The flexibility and durability of Kevlar allow for the creation of lightweight yet robust capture mechanisms capable of withstanding the harsh space environment.

In addition to active debris removal, Kevlar has shown promise in passive debris mitigation strategies. Researchers have investigated the use of Kevlar-reinforced inflatable structures that can be deployed at the end of a satellite's operational life. These structures increase the surface area of the satellite, accelerating its orbital decay and reducing the time it remains in orbit as potential debris.

Furthermore, Kevlar composites are being explored for the development of self-healing materials for spacecraft exteriors. These advanced materials could potentially repair minor damage caused by small debris impacts, extending the operational life of space assets and reducing the generation of new debris from degraded spacecraft components.

As space activities continue to increase, the implementation of effective debris mitigation strategies becomes increasingly critical. Kevlar's unique properties position it as a key material in addressing this challenge, offering innovative solutions for both protecting space assets and actively reducing the existing debris population in Earth's orbit.

Environmental Impact of Kevlar in Space Missions

The environmental impact of Kevlar in space missions is a critical consideration as space exploration continues to advance. Kevlar, a high-strength synthetic fiber, has found numerous applications in space technology due to its exceptional properties. However, its use in space missions also raises important environmental concerns that must be carefully evaluated.

In the context of space exploration, Kevlar is primarily used in protective gear, spacecraft components, and tethers. Its durability and resistance to extreme temperatures make it an ideal material for these applications. However, the production of Kevlar involves energy-intensive processes and the use of potentially harmful chemicals, which can have significant environmental implications on Earth.

The manufacturing of Kevlar requires substantial energy consumption, contributing to greenhouse gas emissions and climate change. Additionally, the production process generates hazardous waste, including sulfuric acid and organic solvents, which must be carefully managed to prevent environmental contamination. These factors necessitate a comprehensive life cycle assessment of Kevlar's environmental impact, from raw material extraction to end-of-life disposal.

In space, the environmental impact of Kevlar is primarily related to space debris. As Kevlar-containing components degrade or become obsolete, they contribute to the growing problem of space junk orbiting the Earth. This debris poses risks to active satellites and future space missions, potentially leading to collisions and further fragmentation of objects in orbit.

However, Kevlar's durability may also offer environmental benefits in space applications. Its long lifespan and resistance to degradation can reduce the frequency of replacements and repairs, potentially decreasing the overall material consumption and launch frequency. This could indirectly contribute to reducing the carbon footprint associated with space missions.

The use of Kevlar in space tethers presents both opportunities and challenges from an environmental perspective. While tethers can be used for debris removal and satellite de-orbiting, potentially mitigating the space debris problem, the introduction of long tethers into orbit also carries risks of entanglement and creation of new debris if not properly managed.

As space agencies and private companies continue to explore Kevlar's potential in space exploration, it is crucial to develop sustainable practices for its use. This includes optimizing production processes to reduce environmental impact, implementing effective space debris mitigation strategies, and exploring recycling and reuse options for Kevlar components both on Earth and in space.

In conclusion, while Kevlar offers significant advantages for space exploration missions, its environmental impact must be carefully considered and managed. Balancing the material's benefits with its potential environmental drawbacks is essential for ensuring the long-term sustainability of space exploration activities.

In the context of space exploration, Kevlar is primarily used in protective gear, spacecraft components, and tethers. Its durability and resistance to extreme temperatures make it an ideal material for these applications. However, the production of Kevlar involves energy-intensive processes and the use of potentially harmful chemicals, which can have significant environmental implications on Earth.

The manufacturing of Kevlar requires substantial energy consumption, contributing to greenhouse gas emissions and climate change. Additionally, the production process generates hazardous waste, including sulfuric acid and organic solvents, which must be carefully managed to prevent environmental contamination. These factors necessitate a comprehensive life cycle assessment of Kevlar's environmental impact, from raw material extraction to end-of-life disposal.

In space, the environmental impact of Kevlar is primarily related to space debris. As Kevlar-containing components degrade or become obsolete, they contribute to the growing problem of space junk orbiting the Earth. This debris poses risks to active satellites and future space missions, potentially leading to collisions and further fragmentation of objects in orbit.

However, Kevlar's durability may also offer environmental benefits in space applications. Its long lifespan and resistance to degradation can reduce the frequency of replacements and repairs, potentially decreasing the overall material consumption and launch frequency. This could indirectly contribute to reducing the carbon footprint associated with space missions.

The use of Kevlar in space tethers presents both opportunities and challenges from an environmental perspective. While tethers can be used for debris removal and satellite de-orbiting, potentially mitigating the space debris problem, the introduction of long tethers into orbit also carries risks of entanglement and creation of new debris if not properly managed.

As space agencies and private companies continue to explore Kevlar's potential in space exploration, it is crucial to develop sustainable practices for its use. This includes optimizing production processes to reduce environmental impact, implementing effective space debris mitigation strategies, and exploring recycling and reuse options for Kevlar components both on Earth and in space.

In conclusion, while Kevlar offers significant advantages for space exploration missions, its environmental impact must be carefully considered and managed. Balancing the material's benefits with its potential environmental drawbacks is essential for ensuring the long-term sustainability of space exploration activities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!