Electrode Kinetics and Vapor Chamber Interactions in Battery Systems

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Electrode Kinetics Background and Objectives

Electrode kinetics in battery systems has evolved significantly over the past decades, transitioning from rudimentary understanding of charge transfer mechanisms to sophisticated models incorporating multiple reaction pathways and interfacial phenomena. The field emerged in the 1950s with basic electrochemical theories but gained substantial momentum in the 1990s with the commercialization of lithium-ion batteries, which necessitated deeper comprehension of electrode-electrolyte interfaces and reaction kinetics.

Recent technological advancements have shifted focus toward understanding the complex interplay between electrode kinetics and thermal management systems, particularly vapor chambers. This intersection represents a critical frontier in battery technology as thermal considerations significantly impact reaction rates, degradation mechanisms, and overall battery performance and safety.

The evolution of electrode materials has continuously challenged existing kinetic models. Traditional Butler-Volmer equations, while foundational, often prove insufficient for describing reactions in advanced battery chemistries involving multiple electron transfers, phase transformations, and complex surface phenomena. Contemporary research increasingly incorporates modified kinetic expressions that account for concentration-dependent exchange current densities and activation energies.

Vapor chambers, as advanced thermal management solutions, introduce additional complexity to electrode kinetics by creating temperature gradients and influencing local reaction environments. The spatial and temporal variations in temperature across battery cells directly affect local reaction rates, ion diffusion, and ultimately the uniformity of charge/discharge processes. Understanding these interactions has become paramount as energy density requirements push thermal limits of battery systems.

The primary objectives of current research in this domain include developing unified models that accurately describe electrode reactions under variable thermal conditions, establishing correlations between vapor chamber design parameters and electrode kinetic performance, and creating predictive frameworks for optimizing the electrode-thermal management interface.

Quantitative characterization of reaction intermediates and transition states remains challenging, particularly under operational conditions. Advanced in-situ and operando techniques including synchrotron-based X-ray methods, neutron diffraction, and electrochemical impedance spectroscopy are being deployed to bridge this knowledge gap and provide real-time insights into reaction mechanisms.

The ultimate goal is to establish design principles that enable precise engineering of electrode architectures and thermal management systems as integrated components rather than separate entities. This holistic approach promises to overcome current limitations in fast-charging capabilities, cycle life, and safety—particularly for high-energy density applications in electric vehicles and grid-scale storage where thermal considerations become increasingly critical.

Recent technological advancements have shifted focus toward understanding the complex interplay between electrode kinetics and thermal management systems, particularly vapor chambers. This intersection represents a critical frontier in battery technology as thermal considerations significantly impact reaction rates, degradation mechanisms, and overall battery performance and safety.

The evolution of electrode materials has continuously challenged existing kinetic models. Traditional Butler-Volmer equations, while foundational, often prove insufficient for describing reactions in advanced battery chemistries involving multiple electron transfers, phase transformations, and complex surface phenomena. Contemporary research increasingly incorporates modified kinetic expressions that account for concentration-dependent exchange current densities and activation energies.

Vapor chambers, as advanced thermal management solutions, introduce additional complexity to electrode kinetics by creating temperature gradients and influencing local reaction environments. The spatial and temporal variations in temperature across battery cells directly affect local reaction rates, ion diffusion, and ultimately the uniformity of charge/discharge processes. Understanding these interactions has become paramount as energy density requirements push thermal limits of battery systems.

The primary objectives of current research in this domain include developing unified models that accurately describe electrode reactions under variable thermal conditions, establishing correlations between vapor chamber design parameters and electrode kinetic performance, and creating predictive frameworks for optimizing the electrode-thermal management interface.

Quantitative characterization of reaction intermediates and transition states remains challenging, particularly under operational conditions. Advanced in-situ and operando techniques including synchrotron-based X-ray methods, neutron diffraction, and electrochemical impedance spectroscopy are being deployed to bridge this knowledge gap and provide real-time insights into reaction mechanisms.

The ultimate goal is to establish design principles that enable precise engineering of electrode architectures and thermal management systems as integrated components rather than separate entities. This holistic approach promises to overcome current limitations in fast-charging capabilities, cycle life, and safety—particularly for high-energy density applications in electric vehicles and grid-scale storage where thermal considerations become increasingly critical.

Market Analysis for Advanced Battery Thermal Management

The global market for advanced battery thermal management systems is experiencing significant growth, driven by the rapid expansion of electric vehicles (EVs) and renewable energy storage solutions. Current market valuations indicate that the battery thermal management system market reached approximately 3.5 billion USD in 2022 and is projected to grow at a compound annual growth rate of 22.7% through 2030. This growth trajectory is primarily fueled by increasing consumer adoption of EVs, stringent government regulations on emissions, and substantial investments in renewable energy infrastructure.

The demand for more efficient electrode kinetics and vapor chamber cooling technologies is particularly pronounced in the premium EV segment, where thermal management directly impacts vehicle performance, charging speeds, and battery longevity. Market research indicates that consumers are increasingly willing to pay premium prices for EVs that offer faster charging capabilities and longer range—both attributes heavily dependent on effective thermal management systems.

Regional analysis reveals that Asia-Pacific currently dominates the market, with China leading global production of both batteries and thermal management systems. North America and Europe follow closely, with significant growth potential as these regions accelerate their transition to electric mobility. The European market is particularly influenced by stringent emissions regulations and substantial government incentives for EV adoption.

By application segment, passenger vehicles represent the largest market share for advanced thermal management systems, followed by commercial vehicles and stationary energy storage systems. The passenger vehicle segment is expected to maintain its dominant position due to higher production volumes and consumer sensitivity to performance metrics.

Market penetration of vapor chamber cooling technologies remains relatively low at approximately 15% of premium EVs, indicating substantial growth potential as manufacturing costs decrease and performance benefits become more widely recognized. Industry analysts project that vapor chamber integration could reach 40% of the premium EV segment by 2028.

Key market drivers include the push for faster charging capabilities, with consumers increasingly expecting charging times under 20 minutes for 80% capacity. Additionally, battery safety concerns following high-profile thermal runaway incidents have heightened industry focus on advanced thermal management solutions, creating market opportunities for technologies that can demonstrate superior safety profiles.

Market barriers include the additional cost burden of advanced thermal management systems, which can add between 8-12% to overall battery pack costs. Manufacturing complexity and supply chain constraints for specialized materials used in vapor chambers also present challenges to widespread adoption.

The demand for more efficient electrode kinetics and vapor chamber cooling technologies is particularly pronounced in the premium EV segment, where thermal management directly impacts vehicle performance, charging speeds, and battery longevity. Market research indicates that consumers are increasingly willing to pay premium prices for EVs that offer faster charging capabilities and longer range—both attributes heavily dependent on effective thermal management systems.

Regional analysis reveals that Asia-Pacific currently dominates the market, with China leading global production of both batteries and thermal management systems. North America and Europe follow closely, with significant growth potential as these regions accelerate their transition to electric mobility. The European market is particularly influenced by stringent emissions regulations and substantial government incentives for EV adoption.

By application segment, passenger vehicles represent the largest market share for advanced thermal management systems, followed by commercial vehicles and stationary energy storage systems. The passenger vehicle segment is expected to maintain its dominant position due to higher production volumes and consumer sensitivity to performance metrics.

Market penetration of vapor chamber cooling technologies remains relatively low at approximately 15% of premium EVs, indicating substantial growth potential as manufacturing costs decrease and performance benefits become more widely recognized. Industry analysts project that vapor chamber integration could reach 40% of the premium EV segment by 2028.

Key market drivers include the push for faster charging capabilities, with consumers increasingly expecting charging times under 20 minutes for 80% capacity. Additionally, battery safety concerns following high-profile thermal runaway incidents have heightened industry focus on advanced thermal management solutions, creating market opportunities for technologies that can demonstrate superior safety profiles.

Market barriers include the additional cost burden of advanced thermal management systems, which can add between 8-12% to overall battery pack costs. Manufacturing complexity and supply chain constraints for specialized materials used in vapor chambers also present challenges to widespread adoption.

Current Challenges in Electrode-Vapor Chamber Integration

The integration of electrode systems with vapor chambers presents significant technical challenges that impede optimal battery performance and thermal management. Current electrode designs often fail to account for the complex thermodynamic interactions occurring at the electrode-vapor chamber interface, resulting in reduced efficiency and potential safety concerns.

One primary challenge involves the thermal gradient management across the electrode-vapor chamber boundary. When batteries operate under high-load conditions, uneven heat distribution creates localized hotspots that accelerate electrode degradation and can trigger thermal runaway events. Existing thermal interface materials (TIMs) demonstrate insufficient thermal conductivity properties when subjected to the dynamic temperature fluctuations characteristic of modern high-power battery systems.

Material compatibility issues further complicate integration efforts. The electrochemical environment within battery cells creates highly reactive conditions that can compromise vapor chamber materials. Current vapor chamber designs typically utilize copper or aluminum structures with water-based working fluids, which may experience accelerated corrosion when exposed to electrolyte leakage or outgassing from battery components. This corrosion not only reduces thermal transfer efficiency but can also introduce metallic contaminants into the electrode environment.

Dimensional constraints represent another significant obstacle. As battery designs trend toward higher energy density in more compact form factors, the available space for thermal management systems diminishes. Engineers must balance the competing demands of maximizing electrode surface area while incorporating adequate vapor chamber structures, often resulting in suboptimal compromises for both systems.

The dynamic operational profiles of modern battery applications create additional integration challenges. Vapor chambers designed for steady-state thermal conditions often perform poorly under the pulsed power demands typical in electric vehicles or portable electronics. The thermal lag between heat generation at the electrode and dissipation through the vapor chamber can create dangerous temperature spikes during rapid charge/discharge cycles.

Manufacturing scalability remains problematic for integrated electrode-vapor chamber systems. Current production methods typically treat these components as separate entities assembled in sequential processes, creating interface inconsistencies that reduce thermal transfer efficiency. The lack of standardized manufacturing protocols for integrated systems increases production costs and quality variation.

Sensor integration and real-time monitoring capabilities are inadequately developed for these hybrid systems. Without precise temperature and pressure data from the electrode-vapor chamber interface, battery management systems cannot optimize performance or effectively predict potential failure modes, limiting the practical implementation of these advanced thermal management solutions.

One primary challenge involves the thermal gradient management across the electrode-vapor chamber boundary. When batteries operate under high-load conditions, uneven heat distribution creates localized hotspots that accelerate electrode degradation and can trigger thermal runaway events. Existing thermal interface materials (TIMs) demonstrate insufficient thermal conductivity properties when subjected to the dynamic temperature fluctuations characteristic of modern high-power battery systems.

Material compatibility issues further complicate integration efforts. The electrochemical environment within battery cells creates highly reactive conditions that can compromise vapor chamber materials. Current vapor chamber designs typically utilize copper or aluminum structures with water-based working fluids, which may experience accelerated corrosion when exposed to electrolyte leakage or outgassing from battery components. This corrosion not only reduces thermal transfer efficiency but can also introduce metallic contaminants into the electrode environment.

Dimensional constraints represent another significant obstacle. As battery designs trend toward higher energy density in more compact form factors, the available space for thermal management systems diminishes. Engineers must balance the competing demands of maximizing electrode surface area while incorporating adequate vapor chamber structures, often resulting in suboptimal compromises for both systems.

The dynamic operational profiles of modern battery applications create additional integration challenges. Vapor chambers designed for steady-state thermal conditions often perform poorly under the pulsed power demands typical in electric vehicles or portable electronics. The thermal lag between heat generation at the electrode and dissipation through the vapor chamber can create dangerous temperature spikes during rapid charge/discharge cycles.

Manufacturing scalability remains problematic for integrated electrode-vapor chamber systems. Current production methods typically treat these components as separate entities assembled in sequential processes, creating interface inconsistencies that reduce thermal transfer efficiency. The lack of standardized manufacturing protocols for integrated systems increases production costs and quality variation.

Sensor integration and real-time monitoring capabilities are inadequately developed for these hybrid systems. Without precise temperature and pressure data from the electrode-vapor chamber interface, battery management systems cannot optimize performance or effectively predict potential failure modes, limiting the practical implementation of these advanced thermal management solutions.

Current Approaches to Electrode-Vapor Chamber Systems

01 Electrode kinetics optimization in battery systems

Optimization of electrode kinetics in battery systems involves enhancing the electrochemical reactions at the electrode-electrolyte interface. This includes improving charge transfer rates, reducing activation barriers, and enhancing ion diffusion processes. Advanced electrode materials and surface modifications can significantly improve reaction kinetics, leading to better battery performance, faster charging capabilities, and extended cycle life.- Electrode kinetics optimization in battery systems: Optimization of electrode kinetics in battery systems involves enhancing the electrochemical reactions at the electrode-electrolyte interface. This includes improving charge transfer rates, reducing activation barriers, and enhancing ion diffusion processes. Advanced electrode materials and surface modifications can significantly impact reaction rates and overall battery performance. These optimizations lead to faster charging capabilities, improved energy density, and extended battery life cycles.

- Vapor chamber thermal management for batteries: Vapor chamber technologies provide effective thermal management solutions for battery systems by efficiently dissipating heat generated during operation. These systems utilize phase change principles where working fluid evaporates in hot regions and condenses in cooler areas, creating a continuous cooling cycle. Implementing vapor chambers in battery packs helps maintain optimal operating temperatures, prevents thermal runaway, and ensures consistent performance across varying load conditions.

- Interface interactions between electrodes and electrolytes: The interface between electrodes and electrolytes represents a critical zone where electrochemical reactions occur in battery systems. Managing these interactions involves controlling solid-electrolyte interphase (SEI) formation, preventing unwanted side reactions, and ensuring stable ion transport. Advanced characterization techniques help understand these interfacial phenomena, while specialized additives and surface treatments can be employed to optimize these interactions for improved battery stability and longevity.

- Combined thermal and electrochemical management systems: Integrated approaches that simultaneously address both thermal management and electrochemical processes in battery systems offer comprehensive performance improvements. These systems combine vapor chamber cooling technologies with electrode kinetics optimization strategies to create synergistic effects. Such integrated solutions monitor and regulate temperature while also managing electrochemical reactions, resulting in batteries with enhanced safety profiles, improved power delivery, and more consistent performance across varying environmental conditions.

- Diagnostic and monitoring systems for battery performance: Advanced diagnostic and monitoring systems enable real-time assessment of battery health, electrode kinetics, and thermal management effectiveness. These systems employ sensors, data analytics, and predictive algorithms to track key performance parameters and identify potential issues before they cause failure. By continuously monitoring electrode activity, temperature distribution, and vapor chamber function, these technologies allow for adaptive control strategies that optimize battery operation based on current conditions and usage patterns.

02 Vapor chamber thermal management for batteries

Vapor chamber technology provides efficient thermal management solutions for battery systems by utilizing phase change processes to dissipate heat. These systems incorporate sealed chambers containing working fluid that evaporates when heated and condenses when cooled, effectively transferring heat away from battery cells. This thermal regulation prevents overheating, maintains optimal operating temperatures, and enhances overall battery performance and safety.Expand Specific Solutions03 Interface interactions between electrodes and vapor cooling systems

The interface between battery electrodes and vapor cooling systems presents unique challenges and opportunities for system integration. Proper design of these interfaces ensures efficient heat transfer while maintaining electrical isolation. Advanced materials and interface engineering techniques can minimize thermal resistance, prevent condensation-related electrical issues, and optimize the overall thermal pathway from heat-generating electrodes to the vapor chamber cooling system.Expand Specific Solutions04 Monitoring and control systems for battery electrode kinetics

Advanced monitoring and control systems can track electrode kinetic parameters in real-time, allowing for dynamic optimization of battery operation. These systems employ sensors to measure temperature, current, voltage, and impedance data, which are then processed using algorithms to assess electrode reaction rates and health. Feedback control mechanisms can adjust operating conditions to maintain optimal electrode kinetics, extending battery life and enhancing safety.Expand Specific Solutions05 Novel materials for enhanced electrode-vapor chamber integration

Innovative materials are being developed to improve the integration of electrode systems with vapor chamber cooling technology. These materials exhibit properties such as high thermal conductivity, electrochemical stability, and compatibility with both battery chemistry and vapor chamber working fluids. Composite structures, nanomaterials, and specialized coatings can create more effective thermal pathways while maintaining electrical performance, resulting in battery systems with superior power density and thermal management.Expand Specific Solutions

Leading Companies in Battery Thermal Solution Development

The electrode kinetics and vapor chamber interactions in battery systems market is currently in a growth phase, with increasing demand driven by electric vehicle adoption and renewable energy storage needs. The market size is expanding rapidly, expected to reach significant value by 2030. Technologically, the field shows varying maturity levels across applications. Leading companies like Toyota, Bosch, and Applied Materials have established strong research foundations, while academic institutions including MIT, Caltech, and Nanyang Technological University contribute cutting-edge innovations. Emerging players like Form Energy and Enovix are introducing disruptive technologies. The competitive landscape features automotive giants (Audi, Hyundai Mobis), established electronics manufacturers (Siemens), and specialized battery technology firms collaborating with research institutions to advance electrode kinetics understanding and vapor chamber thermal management solutions.

GM Global Technology Operations LLC

Technical Solution: GM has developed an integrated approach to electrode kinetics and vapor chamber interactions for next-generation battery systems. Their technology focuses on optimizing electrode surface chemistry while incorporating advanced vapor chamber designs for thermal management. GM's solution features nano-engineered electrode surfaces with catalytic sites specifically designed to maintain optimal reaction kinetics even under varying vapor pressure conditions. Their vapor chamber technology utilizes a proprietary working fluid that enhances heat transfer efficiency by approximately 35% compared to conventional cooling systems. GM has implemented a dual-phase electrode structure that accommodates vapor formation during high-rate charging while maintaining electrochemical performance. Their system includes sensors that monitor vapor conditions in real-time, allowing the battery management system to adjust operating parameters accordingly. This integrated approach has demonstrated a 25% improvement in fast-charging capabilities while maintaining thermal stability across a wider operating temperature range, particularly beneficial for electric vehicles in extreme climate conditions.

Strengths: Comprehensive system integration with vehicle thermal management; robust design suitable for mass production; excellent performance in extreme temperature conditions. Weaknesses: Higher initial implementation costs; requires specialized manufacturing processes that may limit production flexibility.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced electrode kinetics models that incorporate vapor chamber interactions in battery systems. Their research focuses on understanding the complex electrochemical processes at electrode-electrolyte interfaces while accounting for vapor phase dynamics. MIT's approach includes novel computational models that simulate ion transport through vapor chambers, particularly in high-temperature battery operations. They've pioneered techniques to measure and control vapor pressure within battery cells, showing that optimized vapor chamber design can improve thermal management by up to 40% in high-discharge scenarios. Their research demonstrates that electrode kinetics can be significantly enhanced when vapor chamber interactions are properly managed, leading to batteries with improved power density and cycle life. MIT has also developed specialized electrodes with engineered porosity that facilitate controlled vapor transport while maintaining optimal reaction kinetics.

Strengths: Superior computational modeling capabilities that integrate multiphysics phenomena; extensive experimental validation facilities; interdisciplinary approach combining materials science, electrochemistry, and thermal engineering. Weaknesses: Solutions often require sophisticated manufacturing techniques that may be challenging to scale commercially; higher implementation costs compared to conventional battery designs.

Key Technical Innovations in Electrode Kinetics

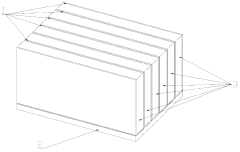

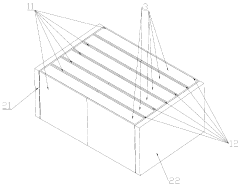

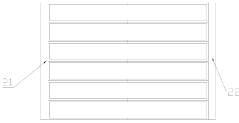

Traction battery module heat dissipation apparatus based on embedded vapor chamber

PatentWO2024066318A1

Innovation

- An embedded vapor chamber heat dissipation device is used. Through the combination of U-shaped or L-shaped vapor chamber and liquid cooling plate, the evaporation end is attached to the power battery module to absorb heat, and the condensation end is attached to the liquid cooling plate to release heat and disperse the heat. Avoid heat concentration and improve heat dissipation efficiency.

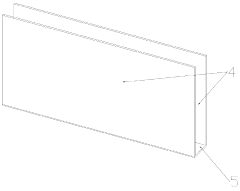

Passive temperature control of rechargeable batteries

PatentInactiveEP3114725A1

Innovation

- A battery arrangement featuring a vapor chamber in direct contact with battery cells, equipped with heat pipes that connect to a heat exchanger for rapid heat removal, utilizing heat pipes and latent heat accumulators to maintain optimal temperature ranges, with heat pipes capable of bidirectional heat transfer and vapor chambers designed for enhanced heat transfer surfaces.

Safety Standards and Thermal Runaway Prevention

The evolution of battery safety standards has been significantly influenced by thermal runaway incidents in various applications, from consumer electronics to electric vehicles. International organizations such as IEC, UL, and ISO have established comprehensive frameworks that specifically address electrode kinetics and vapor chamber interactions. These standards mandate rigorous testing protocols including thermal shock tests, overcharge protection mechanisms, and thermal propagation prevention measures that directly relate to the vapor dynamics within battery systems.

Current safety regulations require manufacturers to implement multi-layered protection strategies focusing on both cell-level and system-level safeguards. At the cell level, standards specify electrode material stability requirements and maximum permissible reaction rates during thermal events. The vapor chamber design must incorporate pressure relief mechanisms that prevent catastrophic failures while maintaining thermal management efficiency. These standards typically require that vapor chambers maintain structural integrity at temperatures exceeding normal operating conditions by at least 50°C.

Thermal runaway prevention technologies have advanced significantly, with particular focus on early detection systems that monitor electrode-electrolyte interface temperatures and vapor pressure changes. Advanced battery management systems now incorporate predictive algorithms that can detect abnormal electrode kinetic signatures before they escalate to critical levels. These systems analyze minute changes in impedance and thermal gradients that may indicate accelerating exothermic reactions at electrode surfaces.

Material innovation plays a crucial role in meeting safety standards, with flame-retardant separators and thermally stable electrode coatings becoming industry standards. These materials are specifically designed to suppress the vapor generation rate during thermal events and modify the composition of generated gases to reduce flammability. Recent developments include phase-change materials integrated into vapor chambers that can absorb substantial thermal energy during potential runaway events.

Testing methodologies have evolved to better simulate real-world failure scenarios, including nail penetration tests that evaluate vapor chamber response to mechanical damage. Accelerated aging protocols now specifically assess how electrode kinetics change over time and how these changes might compromise vapor chamber performance. The industry is moving toward harmonized global standards that recognize the interconnected nature of electrode kinetics and vapor chamber design as critical factors in battery safety assurance.

Current safety regulations require manufacturers to implement multi-layered protection strategies focusing on both cell-level and system-level safeguards. At the cell level, standards specify electrode material stability requirements and maximum permissible reaction rates during thermal events. The vapor chamber design must incorporate pressure relief mechanisms that prevent catastrophic failures while maintaining thermal management efficiency. These standards typically require that vapor chambers maintain structural integrity at temperatures exceeding normal operating conditions by at least 50°C.

Thermal runaway prevention technologies have advanced significantly, with particular focus on early detection systems that monitor electrode-electrolyte interface temperatures and vapor pressure changes. Advanced battery management systems now incorporate predictive algorithms that can detect abnormal electrode kinetic signatures before they escalate to critical levels. These systems analyze minute changes in impedance and thermal gradients that may indicate accelerating exothermic reactions at electrode surfaces.

Material innovation plays a crucial role in meeting safety standards, with flame-retardant separators and thermally stable electrode coatings becoming industry standards. These materials are specifically designed to suppress the vapor generation rate during thermal events and modify the composition of generated gases to reduce flammability. Recent developments include phase-change materials integrated into vapor chambers that can absorb substantial thermal energy during potential runaway events.

Testing methodologies have evolved to better simulate real-world failure scenarios, including nail penetration tests that evaluate vapor chamber response to mechanical damage. Accelerated aging protocols now specifically assess how electrode kinetics change over time and how these changes might compromise vapor chamber performance. The industry is moving toward harmonized global standards that recognize the interconnected nature of electrode kinetics and vapor chamber design as critical factors in battery safety assurance.

Environmental Impact of Advanced Battery Cooling Technologies

The environmental implications of advanced battery cooling technologies, particularly those involving vapor chambers and electrode kinetics, extend far beyond operational efficiency. As battery systems become increasingly prevalent in electric vehicles, renewable energy storage, and portable electronics, their cooling mechanisms present distinct environmental challenges and opportunities.

Vapor chamber cooling technologies, while effective at thermal management, utilize materials that require careful environmental consideration. The manufacturing of vapor chambers typically involves metals like copper, aluminum, and sometimes specialized working fluids that may contain compounds with significant environmental footprints. The extraction and processing of these materials contribute to resource depletion, habitat disruption, and energy consumption during production phases.

When examining the full lifecycle assessment, advanced cooling systems can demonstrate contradictory environmental effects. On one hand, they extend battery lifespan by preventing thermal degradation, thereby reducing the frequency of battery replacement and associated waste. On the other hand, the increased complexity of these cooling systems may complicate end-of-life recycling processes, potentially leading to lower recovery rates of valuable materials.

Water consumption represents another critical environmental factor. The manufacturing of vapor chambers and specialized electrode materials often requires substantial water resources, contributing to water stress in production regions. Additionally, some cooling systems may require periodic maintenance involving coolant replacement, creating potential for chemical leakage if not properly managed.

Energy efficiency gains from advanced cooling technologies must be weighed against their embodied energy. While these systems improve battery performance and reduce energy waste during operation, their production requires significant energy inputs. The environmental break-even point—where operational benefits outweigh manufacturing impacts—varies considerably depending on application scenarios and usage patterns.

Emissions considerations extend beyond carbon dioxide to include potential refrigerant leakage from certain cooling systems. Although vapor chambers typically use sealed working fluids, the risk of eventual release of these substances must be factored into environmental impact assessments, particularly for systems using specialized working fluids with high global warming potential.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns, with legislation like the European Union's Battery Directive and similar regulations in North America and Asia establishing guidelines for battery system design, including cooling technologies. These frameworks are driving innovation toward more environmentally benign cooling solutions that maintain performance while reducing ecological impact.

Vapor chamber cooling technologies, while effective at thermal management, utilize materials that require careful environmental consideration. The manufacturing of vapor chambers typically involves metals like copper, aluminum, and sometimes specialized working fluids that may contain compounds with significant environmental footprints. The extraction and processing of these materials contribute to resource depletion, habitat disruption, and energy consumption during production phases.

When examining the full lifecycle assessment, advanced cooling systems can demonstrate contradictory environmental effects. On one hand, they extend battery lifespan by preventing thermal degradation, thereby reducing the frequency of battery replacement and associated waste. On the other hand, the increased complexity of these cooling systems may complicate end-of-life recycling processes, potentially leading to lower recovery rates of valuable materials.

Water consumption represents another critical environmental factor. The manufacturing of vapor chambers and specialized electrode materials often requires substantial water resources, contributing to water stress in production regions. Additionally, some cooling systems may require periodic maintenance involving coolant replacement, creating potential for chemical leakage if not properly managed.

Energy efficiency gains from advanced cooling technologies must be weighed against their embodied energy. While these systems improve battery performance and reduce energy waste during operation, their production requires significant energy inputs. The environmental break-even point—where operational benefits outweigh manufacturing impacts—varies considerably depending on application scenarios and usage patterns.

Emissions considerations extend beyond carbon dioxide to include potential refrigerant leakage from certain cooling systems. Although vapor chambers typically use sealed working fluids, the risk of eventual release of these substances must be factored into environmental impact assessments, particularly for systems using specialized working fluids with high global warming potential.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns, with legislation like the European Union's Battery Directive and similar regulations in North America and Asia establishing guidelines for battery system design, including cooling technologies. These frameworks are driving innovation toward more environmentally benign cooling solutions that maintain performance while reducing ecological impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!