Electrolyte Design And Solvation For Room-Temperature Sodium-Sulfur Batteries

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Na-S Battery Electrolyte Evolution and Objectives

Sodium-sulfur (Na-S) batteries have emerged as promising candidates for large-scale energy storage systems due to their high theoretical energy density, abundant raw materials, and cost-effectiveness. The evolution of Na-S battery technology can be traced back to the 1960s when Ford Motor Company first developed high-temperature Na-S batteries operating at 300-350°C. These early systems utilized molten sodium and sulfur electrodes separated by a solid beta-alumina ceramic electrolyte.

The high operating temperatures of conventional Na-S batteries presented significant safety concerns and practical limitations for widespread application. This led to a paradigm shift in research focus towards room-temperature Na-S batteries in the early 2000s. The transition to ambient temperature operation required fundamental redesign of the electrolyte systems to accommodate the complex electrochemistry occurring at lower temperatures.

A critical challenge in room-temperature Na-S batteries has been the shuttle effect, where soluble polysulfide intermediates dissolve in the electrolyte and shuttle between electrodes, causing capacity fading and poor cycling stability. This phenomenon has driven extensive research into electrolyte design to mitigate these issues while maintaining adequate ionic conductivity and electrochemical stability.

The evolution of electrolytes for room-temperature Na-S batteries has progressed through several generations. Initial efforts focused on conventional carbonate-based electrolytes, which were later found inadequate due to their reactivity with polysulfides. This led to exploration of ether-based electrolytes, which demonstrated improved compatibility with sulfur cathodes but suffered from limited oxidative stability.

Recent advances have introduced functional additives, ionic liquids, and solid-state electrolytes as promising solutions. Fluorinated electrolytes have shown enhanced stability against the sodium metal anode, while concentrated electrolyte formulations have demonstrated reduced polysulfide solubility and improved cycling performance.

The primary objectives of current electrolyte design for room-temperature Na-S batteries include: (1) suppressing the polysulfide shuttle effect through reduced solubility or enhanced interfacial stability; (2) forming stable solid electrolyte interphase (SEI) layers on the sodium anode to prevent dendrite formation; (3) achieving wide electrochemical stability windows compatible with both sulfur cathodes and sodium anodes; and (4) maintaining high ionic conductivity at ambient temperatures to support practical discharge rates.

Future electrolyte development aims to integrate multifunctional components that simultaneously address multiple challenges. This includes the development of novel solvation chemistry to control the coordination environment of sodium ions and polysulfides, as well as the incorporation of advanced additives that can selectively interact with specific reaction intermediates to guide the electrochemical processes toward desired pathways.

The high operating temperatures of conventional Na-S batteries presented significant safety concerns and practical limitations for widespread application. This led to a paradigm shift in research focus towards room-temperature Na-S batteries in the early 2000s. The transition to ambient temperature operation required fundamental redesign of the electrolyte systems to accommodate the complex electrochemistry occurring at lower temperatures.

A critical challenge in room-temperature Na-S batteries has been the shuttle effect, where soluble polysulfide intermediates dissolve in the electrolyte and shuttle between electrodes, causing capacity fading and poor cycling stability. This phenomenon has driven extensive research into electrolyte design to mitigate these issues while maintaining adequate ionic conductivity and electrochemical stability.

The evolution of electrolytes for room-temperature Na-S batteries has progressed through several generations. Initial efforts focused on conventional carbonate-based electrolytes, which were later found inadequate due to their reactivity with polysulfides. This led to exploration of ether-based electrolytes, which demonstrated improved compatibility with sulfur cathodes but suffered from limited oxidative stability.

Recent advances have introduced functional additives, ionic liquids, and solid-state electrolytes as promising solutions. Fluorinated electrolytes have shown enhanced stability against the sodium metal anode, while concentrated electrolyte formulations have demonstrated reduced polysulfide solubility and improved cycling performance.

The primary objectives of current electrolyte design for room-temperature Na-S batteries include: (1) suppressing the polysulfide shuttle effect through reduced solubility or enhanced interfacial stability; (2) forming stable solid electrolyte interphase (SEI) layers on the sodium anode to prevent dendrite formation; (3) achieving wide electrochemical stability windows compatible with both sulfur cathodes and sodium anodes; and (4) maintaining high ionic conductivity at ambient temperatures to support practical discharge rates.

Future electrolyte development aims to integrate multifunctional components that simultaneously address multiple challenges. This includes the development of novel solvation chemistry to control the coordination environment of sodium ions and polysulfides, as well as the incorporation of advanced additives that can selectively interact with specific reaction intermediates to guide the electrochemical processes toward desired pathways.

Market Analysis for Room-Temperature Na-S Battery Applications

The global energy storage market is witnessing significant growth, with projections indicating a compound annual growth rate (CAGR) of 20-25% through 2030. Within this expanding landscape, room-temperature sodium-sulfur (RT Na-S) batteries are emerging as a promising technology that addresses several critical market needs.

The primary market driver for RT Na-S batteries is the increasing demand for cost-effective energy storage solutions. With sodium resources approximately 1,000 times more abundant than lithium and sulfur being an industrial byproduct, RT Na-S batteries offer potential cost advantages of 30-40% compared to lithium-ion technologies. This positions them favorably in price-sensitive market segments.

Grid-scale energy storage represents the most substantial immediate opportunity for RT Na-S technology. The global grid storage market is expanding rapidly as renewable energy integration accelerates, creating demand for long-duration storage solutions. RT Na-S batteries, with their potential for high energy density and lower material costs, could capture a significant portion of this market, particularly in regions prioritizing cost over energy density or cycle life.

The electric vehicle (EV) sector presents a secondary but growing market opportunity. While current RT Na-S batteries face challenges in meeting the high energy density and fast charging requirements of premium EVs, they show promise for applications in commercial vehicles, public transportation, and entry-level consumer EVs where cost considerations outweigh performance parameters.

Stationary storage for residential and commercial applications constitutes another viable market segment. As distributed energy resources proliferate, demand for safe, low-cost storage solutions increases. RT Na-S batteries could address this market need once safety concerns related to sodium reactivity and sulfur shuttling are adequately resolved through advanced electrolyte designs.

Geographically, emerging economies in Asia and Africa represent particularly attractive markets for RT Na-S technology. These regions often prioritize affordability over cutting-edge performance and have less established lithium-ion supply chains, creating openings for alternative technologies.

Market adoption faces several barriers, including competition from established lithium-ion technologies and emerging alternatives like flow batteries and sodium-ion systems. The success of RT Na-S batteries will largely depend on achieving breakthroughs in electrolyte design that address current limitations in cycle life, energy density, and safety while maintaining their inherent cost advantages.

The primary market driver for RT Na-S batteries is the increasing demand for cost-effective energy storage solutions. With sodium resources approximately 1,000 times more abundant than lithium and sulfur being an industrial byproduct, RT Na-S batteries offer potential cost advantages of 30-40% compared to lithium-ion technologies. This positions them favorably in price-sensitive market segments.

Grid-scale energy storage represents the most substantial immediate opportunity for RT Na-S technology. The global grid storage market is expanding rapidly as renewable energy integration accelerates, creating demand for long-duration storage solutions. RT Na-S batteries, with their potential for high energy density and lower material costs, could capture a significant portion of this market, particularly in regions prioritizing cost over energy density or cycle life.

The electric vehicle (EV) sector presents a secondary but growing market opportunity. While current RT Na-S batteries face challenges in meeting the high energy density and fast charging requirements of premium EVs, they show promise for applications in commercial vehicles, public transportation, and entry-level consumer EVs where cost considerations outweigh performance parameters.

Stationary storage for residential and commercial applications constitutes another viable market segment. As distributed energy resources proliferate, demand for safe, low-cost storage solutions increases. RT Na-S batteries could address this market need once safety concerns related to sodium reactivity and sulfur shuttling are adequately resolved through advanced electrolyte designs.

Geographically, emerging economies in Asia and Africa represent particularly attractive markets for RT Na-S technology. These regions often prioritize affordability over cutting-edge performance and have less established lithium-ion supply chains, creating openings for alternative technologies.

Market adoption faces several barriers, including competition from established lithium-ion technologies and emerging alternatives like flow batteries and sodium-ion systems. The success of RT Na-S batteries will largely depend on achieving breakthroughs in electrolyte design that address current limitations in cycle life, energy density, and safety while maintaining their inherent cost advantages.

Current Electrolyte Challenges in Na-S Battery Systems

Room-temperature sodium-sulfur (RT Na-S) batteries face significant electrolyte challenges that hinder their commercial viability despite their theoretical advantages. The primary issue stems from the highly reactive nature of polysulfide intermediates, which readily dissolve in conventional electrolytes. This dissolution triggers the notorious "shuttle effect," where polysulfides migrate between electrodes, causing rapid capacity fading, self-discharge, and poor cycling stability.

Conventional carbonate-based electrolytes, while offering good ionic conductivity, react irreversibly with polysulfide species, forming inactive byproducts that diminish active material utilization. Ether-based electrolytes, though more compatible with sulfur chemistry, still struggle with polysulfide solubility and provide insufficient protection for the sodium metal anode against dendrite formation.

The solid-electrolyte interphase (SEI) formation on sodium anodes presents another critical challenge. Unlike lithium batteries, sodium systems form less stable and more permeable SEI layers, leading to continuous electrolyte decomposition and sodium corrosion. This instability is exacerbated by the larger ionic radius of sodium compared to lithium, affecting solvation structures and transport properties.

Electrolyte viscosity and wettability issues further complicate RT Na-S battery performance. High-concentration electrolytes, while potentially suppressing polysulfide dissolution, often exhibit excessive viscosity that impedes ion transport and increases internal resistance. Conversely, low-viscosity formulations may not adequately wet sulfur-carbon composite cathodes, resulting in poor active material utilization.

Temperature sensitivity represents another significant hurdle. Many promising electrolyte formulations display dramatic performance variations across the operating temperature range of room-temperature applications (0-40°C). This instability manifests as fluctuating ionic conductivity, changing solvation environments, and varying degrees of side reactions.

The cost and safety profiles of current electrolyte solutions also remain problematic. Fluorinated salts like NaClO₄ and NaPF₆ raise concerns regarding thermal stability and moisture sensitivity, while more stable alternatives often come with prohibitive costs for large-scale applications.

Addressing these multifaceted challenges requires innovative approaches beyond incremental improvements to existing formulations. Researchers are exploring functional additives, novel salt-solvent combinations, and hybrid electrolyte systems that can simultaneously address polysulfide shuttling, sodium dendrite formation, and SEI stability while maintaining adequate ionic conductivity and electrochemical windows.

Conventional carbonate-based electrolytes, while offering good ionic conductivity, react irreversibly with polysulfide species, forming inactive byproducts that diminish active material utilization. Ether-based electrolytes, though more compatible with sulfur chemistry, still struggle with polysulfide solubility and provide insufficient protection for the sodium metal anode against dendrite formation.

The solid-electrolyte interphase (SEI) formation on sodium anodes presents another critical challenge. Unlike lithium batteries, sodium systems form less stable and more permeable SEI layers, leading to continuous electrolyte decomposition and sodium corrosion. This instability is exacerbated by the larger ionic radius of sodium compared to lithium, affecting solvation structures and transport properties.

Electrolyte viscosity and wettability issues further complicate RT Na-S battery performance. High-concentration electrolytes, while potentially suppressing polysulfide dissolution, often exhibit excessive viscosity that impedes ion transport and increases internal resistance. Conversely, low-viscosity formulations may not adequately wet sulfur-carbon composite cathodes, resulting in poor active material utilization.

Temperature sensitivity represents another significant hurdle. Many promising electrolyte formulations display dramatic performance variations across the operating temperature range of room-temperature applications (0-40°C). This instability manifests as fluctuating ionic conductivity, changing solvation environments, and varying degrees of side reactions.

The cost and safety profiles of current electrolyte solutions also remain problematic. Fluorinated salts like NaClO₄ and NaPF₆ raise concerns regarding thermal stability and moisture sensitivity, while more stable alternatives often come with prohibitive costs for large-scale applications.

Addressing these multifaceted challenges requires innovative approaches beyond incremental improvements to existing formulations. Researchers are exploring functional additives, novel salt-solvent combinations, and hybrid electrolyte systems that can simultaneously address polysulfide shuttling, sodium dendrite formation, and SEI stability while maintaining adequate ionic conductivity and electrochemical windows.

State-of-Art Electrolyte Solutions for Room-Temperature Na-S Batteries

01 Solid electrolyte materials for sodium-sulfur batteries

Solid electrolyte materials, particularly beta-alumina ceramics, are widely used in sodium-sulfur batteries due to their high sodium ion conductivity at operating temperatures. These materials provide a physical barrier between the sodium and sulfur electrodes while allowing sodium ions to pass through. Innovations in solid electrolyte composition and manufacturing techniques have led to improved ionic conductivity, mechanical strength, and thermal stability, which are crucial for long-term battery performance and safety.- Solid electrolyte materials for sodium-sulfur batteries: Solid electrolyte materials, particularly beta-alumina ceramics, are crucial components in sodium-sulfur batteries. These materials facilitate sodium ion transport while preventing direct contact between sodium and sulfur electrodes. Advanced manufacturing techniques and compositional modifications can enhance the ionic conductivity and mechanical stability of these solid electrolytes, leading to improved battery performance and safety. Recent developments include doping strategies and novel synthesis methods to optimize the crystal structure for efficient sodium ion conduction.

- Polymer-based electrolyte systems: Polymer-based electrolytes offer advantages for sodium-sulfur batteries including flexibility, improved safety, and better interface compatibility. These systems typically incorporate sodium salts into polymer matrices such as polyethylene oxide (PEO), polyvinylidene fluoride (PVDF), or their derivatives. The addition of plasticizers and ceramic fillers can enhance ionic conductivity while maintaining mechanical integrity. Recent innovations focus on cross-linked polymer networks and composite structures to achieve optimal balance between conductivity and stability at various operating temperatures.

- Ionic liquid electrolytes for enhanced performance: Ionic liquids serve as promising electrolyte components for sodium-sulfur batteries due to their negligible vapor pressure, wide electrochemical window, and thermal stability. These molten salts, typically containing imidazolium, pyrrolidinium, or quaternary ammonium cations paired with various anions, can dissolve sodium salts effectively. The solvation environment they provide helps control the sodium polysulfide shuttle effect, a common issue in sodium-sulfur systems. Customized ionic liquids with specific functional groups can further enhance sodium ion transport and electrode interface stability.

- Room temperature sodium-sulfur battery electrolytes: Developing electrolytes for room temperature sodium-sulfur batteries represents a significant advancement over traditional high-temperature systems. These electrolytes typically combine organic solvents like ethers, carbonates, or glymes with sodium salts to achieve sufficient ionic conductivity at ambient temperatures. Additives such as fluoroethylene carbonate (FEC) help form stable solid electrolyte interphase layers on electrode surfaces. The solvation structure of sodium ions in these electrolytes critically affects battery cycling performance, with recent research focusing on optimizing solvent mixtures for ideal coordination environments.

- Electrolyte additives and interface engineering: Strategic use of electrolyte additives and interface engineering techniques can significantly improve sodium-sulfur battery performance. Additives such as metal fluorides, nitrates, and polysulfide mediators help control the electrode-electrolyte interface reactions and suppress unwanted side reactions. Surface-active agents can modify the solvation structure of sodium ions near electrode surfaces, facilitating more efficient charge transfer. Advanced interface engineering approaches include artificial protective layers, functional separators, and gradient electrolyte structures that collectively enhance battery cycle life, rate capability, and safety characteristics.

02 Polymer-based electrolyte systems

Polymer-based electrolytes offer advantages for sodium-sulfur batteries operating at lower temperatures. These systems typically incorporate sodium salts into polymer matrices to create flexible, processable electrolytes with good ionic conductivity. Various polymers such as polyethylene oxide (PEO), polyvinylidene fluoride (PVDF), and their derivatives are being explored. The addition of plasticizers and ceramic fillers can enhance the ionic conductivity and mechanical properties of these polymer electrolytes, making them suitable for room-temperature sodium-sulfur battery applications.Expand Specific Solutions03 Ionic liquid electrolytes for enhanced performance

Ionic liquids are being investigated as electrolytes or electrolyte components for sodium-sulfur batteries due to their negligible vapor pressure, wide electrochemical window, and good thermal stability. These properties help address the polysulfide shuttle effect and improve battery cycling performance. Ionic liquids can be tailored by selecting appropriate cation and anion combinations to optimize properties such as viscosity, conductivity, and compatibility with electrode materials. Some formulations incorporate additives to further enhance the electrolyte-electrode interface stability.Expand Specific Solutions04 Electrolyte additives for interface stabilization

Various additives are incorporated into sodium-sulfur battery electrolytes to stabilize the electrode-electrolyte interfaces and suppress unwanted side reactions. These additives can form protective films on electrode surfaces, trap polysulfide intermediates, or modify the solvation environment of sodium ions. Common additives include fluorinated compounds, metal salts, and organic molecules that can enhance the coulombic efficiency and cycling stability of the batteries. The selection of appropriate additives depends on the specific electrolyte system and operating conditions of the battery.Expand Specific Solutions05 Solvation structure engineering for sodium ion transport

The solvation structure of sodium ions in the electrolyte significantly affects their transport properties and electrochemical behavior. Research focuses on understanding and optimizing the coordination environment of sodium ions through solvent selection and mixing strategies. Ether-based solvents, glymes, and carbonates with appropriate donor numbers are commonly used to create favorable solvation structures. Controlling the solvation shell structure can reduce the desolvation energy barrier at electrodes, leading to improved rate capability and reduced dendrite formation in sodium-sulfur batteries.Expand Specific Solutions

Leading Companies and Research Institutions in Na-S Battery Field

The room-temperature sodium-sulfur (RT Na-S) battery market is currently in an early growth phase, characterized by intensive R&D efforts to overcome electrolyte design and solvation challenges. The global market size remains relatively modest but is projected to expand significantly as this technology offers a cost-effective alternative to lithium-ion batteries. From a technical maturity perspective, companies like CATL, LG Energy Solution, and NGK Insulators are leading commercial development, while research institutions such as Central South University and KAIST are advancing fundamental electrolyte innovations. Toyota Motor and Idemitsu Kosan are focusing on specialized electrolyte formulations, while startups like GODI India and Wildcat Discovery Technologies are employing high-throughput screening methods to accelerate electrolyte optimization. The competitive landscape reflects a blend of established battery manufacturers and specialized materials science companies working to address stability, conductivity, and safety challenges.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed advanced electrolyte systems for room-temperature sodium-sulfur (RT Na-S) batteries focusing on ether-based solutions with sodium salt additives. Their approach utilizes glyme-based solvents (particularly diglyme and tetraglyme) combined with sodium trifluoromethanesulfonimide (NaTFSI) and sodium nitrate (NaNO3) additives to form stable solid electrolyte interphases (SEI) on both sodium anode and sulfur cathode. The laboratory has demonstrated that these electrolyte formulations effectively suppress the shuttle effect of soluble sodium polysulfides while enabling high ionic conductivity at room temperature. Their research has achieved cells with initial discharge capacities exceeding 1000 mAh/g-sulfur and coulombic efficiencies above 95% for over 100 cycles, representing significant improvements over conventional carbonate-based electrolytes.

Strengths: Superior suppression of polysulfide shuttle effect, excellent room temperature ionic conductivity, and demonstrated long-term cycling stability. Weaknesses: Potential safety concerns with ether-based solvents due to their flammability, and relatively high cost of specialized sodium salts for commercial applications.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has pioneered a novel electrolyte design for room-temperature sodium-sulfur batteries based on ionic liquid technology. Their approach incorporates sodium bis(fluorosulfonyl)imide (NaFSI) salt in pyrrolidinium-based ionic liquids, supplemented with small amounts of fluoroethylene carbonate (FEC) as a critical SEI-forming additive. This electrolyte system demonstrates exceptional thermal stability up to 150°C while maintaining conductivity at room temperature (>1 mS/cm). The research team has implemented a dual-salt strategy, incorporating both NaFSI and NaTFSI to optimize the solvation structure around sodium ions, effectively preventing aluminum current collector corrosion and enhancing sodium plating/stripping efficiency. Their electrolyte formulation has enabled RT Na-S cells with capacity retention of approximately 600 mAh/g after 200 cycles and dramatically reduced self-discharge rates compared to conventional electrolytes.

Strengths: Exceptional thermal stability, non-flammability, and excellent electrochemical stability window (>4.5V vs. Na/Na+). Weaknesses: Higher viscosity than conventional liquid electrolytes leading to somewhat lower rate capability, and higher production costs associated with ionic liquid components.

Key Patents and Research on Na-S Battery Electrolyte Design

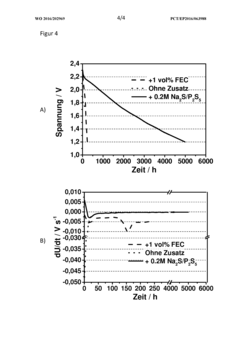

Sodium-sulfur battery, method for operating same, and use of phosphorus polysulfide as electrolyte additive in sodium-sulfur batteries

PatentActiveEP3311440A1

Innovation

- A sodium-sulfur battery design incorporating a cathode of carbon-sulfur composite, an anode with sodium metal and alloying agents, a ceramic or hydrophobic plastic separator, and an electrolyte with phosphorus polysulfide as an additive to complex sodium polysulfide, forming a solid electrolyte interface that suppresses the polysulfide shuttle and enhances energy efficiency and discharge capacity.

Sodium-sulfur battery, method for operating same, and use of phosphorus polysulfide as electrolyte additive in sodium-sulfur batteries

PatentWO2016202969A1

Innovation

- A sodium-sulfur battery design using a carbon-sulfur composite cathode, an organic solvent-based electrolyte with a conductive salt and phosphorus polysulfide as an additive to suppress the polysulfide shuttle, allowing operation at room temperature with enhanced energy efficiency and discharge capacity.

Safety and Stability Considerations for Na-S Electrolytes

Safety considerations for room-temperature sodium-sulfur (RT Na-S) battery electrolytes are paramount due to the highly reactive nature of both sodium metal and sulfur species. Traditional high-temperature Na-S batteries operate at 300-350°C, where safety risks are managed through robust engineering controls. However, RT Na-S systems present unique challenges that require specialized electrolyte design approaches.

The primary safety concern with Na-S electrolytes is their potential reactivity with sodium polysulfides, which can lead to shuttle effects and capacity fading. More critically, the formation of sodium dendrites during cycling poses significant safety risks, potentially causing internal short circuits and thermal runaway events. Electrolytes must therefore incorporate dendrite suppression capabilities through either mechanical strength or chemical modification strategies.

Thermal stability represents another crucial consideration, as electrolyte decomposition at elevated temperatures can release flammable gases and accelerate exothermic reactions. Recent research has focused on developing flame-retardant additives and thermally stable ionic liquids to mitigate these risks. For instance, phosphate-based additives have demonstrated promising flame-retardant properties while maintaining acceptable electrochemical performance.

Chemical stability of electrolytes against both sodium metal and sulfur species requires careful molecular design. The electrolyte must form a stable solid electrolyte interphase (SEI) on the sodium anode while resisting degradation from increasingly reactive sodium polysulfides. Studies have shown that fluorinated solvents and certain salt combinations can enhance this stability, though often at the cost of ionic conductivity.

Long-term stability testing reveals that many conventional carbonate-based electrolytes undergo gradual decomposition when exposed to sodium polysulfides, generating gas and increasing internal pressure. This necessitates the development of ether-based or hybrid electrolyte systems with enhanced chemical resistance. Recent work with glyme-based electrolytes has shown improved compatibility with the Na-S chemistry.

Environmental and health considerations must also factor into electrolyte design. Many high-performance electrolyte components contain toxic or environmentally persistent materials. The industry trend is moving toward "greener" alternatives, including bio-derived solvents and less toxic salt formulations that maintain performance while reducing environmental impact.

Standardized safety testing protocols for RT Na-S electrolytes remain underdeveloped compared to lithium-ion systems. Establishing comprehensive testing frameworks that address the unique reactivity profiles of sodium and sulfur species is essential for commercial development. These should include accelerated aging tests, thermal abuse protocols, and compatibility assessments with common battery materials.

The primary safety concern with Na-S electrolytes is their potential reactivity with sodium polysulfides, which can lead to shuttle effects and capacity fading. More critically, the formation of sodium dendrites during cycling poses significant safety risks, potentially causing internal short circuits and thermal runaway events. Electrolytes must therefore incorporate dendrite suppression capabilities through either mechanical strength or chemical modification strategies.

Thermal stability represents another crucial consideration, as electrolyte decomposition at elevated temperatures can release flammable gases and accelerate exothermic reactions. Recent research has focused on developing flame-retardant additives and thermally stable ionic liquids to mitigate these risks. For instance, phosphate-based additives have demonstrated promising flame-retardant properties while maintaining acceptable electrochemical performance.

Chemical stability of electrolytes against both sodium metal and sulfur species requires careful molecular design. The electrolyte must form a stable solid electrolyte interphase (SEI) on the sodium anode while resisting degradation from increasingly reactive sodium polysulfides. Studies have shown that fluorinated solvents and certain salt combinations can enhance this stability, though often at the cost of ionic conductivity.

Long-term stability testing reveals that many conventional carbonate-based electrolytes undergo gradual decomposition when exposed to sodium polysulfides, generating gas and increasing internal pressure. This necessitates the development of ether-based or hybrid electrolyte systems with enhanced chemical resistance. Recent work with glyme-based electrolytes has shown improved compatibility with the Na-S chemistry.

Environmental and health considerations must also factor into electrolyte design. Many high-performance electrolyte components contain toxic or environmentally persistent materials. The industry trend is moving toward "greener" alternatives, including bio-derived solvents and less toxic salt formulations that maintain performance while reducing environmental impact.

Standardized safety testing protocols for RT Na-S electrolytes remain underdeveloped compared to lithium-ion systems. Establishing comprehensive testing frameworks that address the unique reactivity profiles of sodium and sulfur species is essential for commercial development. These should include accelerated aging tests, thermal abuse protocols, and compatibility assessments with common battery materials.

Environmental Impact and Sustainability of Electrolyte Materials

The environmental impact of electrolyte materials in room-temperature sodium-sulfur (RT Na-S) batteries represents a critical consideration in the broader context of sustainable energy storage solutions. Traditional lithium-ion battery electrolytes often contain fluorinated salts and carbonate-based solvents that pose significant environmental concerns due to their toxicity, flammability, and poor biodegradability. In contrast, many electrolyte designs for RT Na-S batteries offer opportunities for improved environmental performance.

Aqueous electrolytes for Na-S systems demonstrate particular promise from a sustainability perspective, as they eliminate volatile organic compounds and reduce fire hazards. However, their limited electrochemical stability window presents challenges for practical implementation. Recent research has focused on water-in-salt electrolytes that maintain safety advantages while expanding the stability window, representing a promising direction for environmentally conscious design.

The carbon footprint associated with electrolyte production warrants careful examination. Conventional electrolyte manufacturing processes often involve energy-intensive synthesis and purification steps. Life cycle assessments indicate that electrolytes can contribute 10-15% of a battery's total environmental impact. For RT Na-S batteries to fulfill their potential as sustainable energy storage solutions, electrolyte production methods must be optimized to reduce energy consumption and minimize waste generation.

Recycling and end-of-life considerations present another dimension of environmental impact. Current electrolyte recovery technologies remain underdeveloped compared to electrode material recycling. The development of electrolyte systems designed with recyclability in mind could significantly enhance the sustainability profile of RT Na-S batteries. This includes exploring bio-derived solvents and designing separation processes that facilitate electrolyte recovery and reuse.

Regulatory frameworks increasingly emphasize reduced environmental impact of battery components. The European Union's Battery Directive and similar regulations worldwide are driving manufacturers toward greener electrolyte formulations. This regulatory landscape creates both challenges and opportunities for RT Na-S battery development, as novel electrolyte designs must balance performance requirements with environmental compliance.

The transition from laboratory-scale to industrial-scale production introduces additional sustainability considerations. Scalable green synthesis routes for electrolyte components represent a critical research need. Recent advances in continuous flow chemistry and solvent-free synthesis methods offer promising approaches to reduce the environmental footprint of electrolyte manufacturing while maintaining economic viability.

Aqueous electrolytes for Na-S systems demonstrate particular promise from a sustainability perspective, as they eliminate volatile organic compounds and reduce fire hazards. However, their limited electrochemical stability window presents challenges for practical implementation. Recent research has focused on water-in-salt electrolytes that maintain safety advantages while expanding the stability window, representing a promising direction for environmentally conscious design.

The carbon footprint associated with electrolyte production warrants careful examination. Conventional electrolyte manufacturing processes often involve energy-intensive synthesis and purification steps. Life cycle assessments indicate that electrolytes can contribute 10-15% of a battery's total environmental impact. For RT Na-S batteries to fulfill their potential as sustainable energy storage solutions, electrolyte production methods must be optimized to reduce energy consumption and minimize waste generation.

Recycling and end-of-life considerations present another dimension of environmental impact. Current electrolyte recovery technologies remain underdeveloped compared to electrode material recycling. The development of electrolyte systems designed with recyclability in mind could significantly enhance the sustainability profile of RT Na-S batteries. This includes exploring bio-derived solvents and designing separation processes that facilitate electrolyte recovery and reuse.

Regulatory frameworks increasingly emphasize reduced environmental impact of battery components. The European Union's Battery Directive and similar regulations worldwide are driving manufacturers toward greener electrolyte formulations. This regulatory landscape creates both challenges and opportunities for RT Na-S battery development, as novel electrolyte designs must balance performance requirements with environmental compliance.

The transition from laboratory-scale to industrial-scale production introduces additional sustainability considerations. Scalable green synthesis routes for electrolyte components represent a critical research need. Recent advances in continuous flow chemistry and solvent-free synthesis methods offer promising approaches to reduce the environmental footprint of electrolyte manufacturing while maintaining economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!